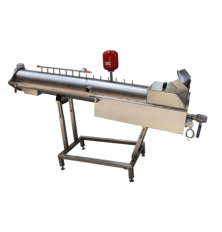

Pouring Blancher ShowerBlanch

Pouring Blancher┬ĀShowerBlanch is designed for heat treatment of a wide range of products whose fine structure requires to minimize mechanical influence in the blanching or cooking process. Unlike a drum blancher, in which the product is blanched in a process of single directional mixing and rolling and a screw blancher, in which the product passes through a working chamber by means of a screw, in the belt type blancher the product lies motionless on the conveyor belt and is processed without damaging its surface.

Blanching helps keeping the vitamins and nutritional properties of the product, as well as an outer appearance with bright and natural color

Blanching (French blanchir) is a method of cooking vegetables, fruit or meat. Meat will remain more succulent for further heat treatment. Furthermore, this heat treatment method is used to facilitate easier removal of membranes. For fruit and vegetables, blanching is used to remove the skin on fruits and vegetables that are too stiff or too thick, such as tomatoes, peaches, apricots, and the like.

Due to the short-term exposure to higher temperatures, vitamins, taste and color will be retained in the food, but micro-organisms, which may cause deterioration of food during preservation, will be destroyed. This will preserve higher quality┬Ā of food, for example, frozen vegetables will have a fresher color and more pronounced taste.

Blanchers pouring are designed for blanching:

- vegetables

- mushrooms

- frozen products

- meat and fish

- onion rings

- calamari...

Blanching preserves the taste and color of the product

Shower blanch machine is suitable for blanching meat, fish or vegetable products. Blanching is a rapid heating of fruits or vegetables that slows down or completely stops the activity of enzymes that cause loss of taste, color and structure.

Benefits of blanching

Blanching helps keeping the vitamins and nutritional properties of the product, as well as an outer appearance with bright and natural color. Blanching time is crucial and varies with the vegetable and size.

Principle of blanching

Blanching (scalding vegetables in boiling water or steam for a short time) is a must for almost all vegetables to be frozen. Blanching cleanses the surface of dirt and organisms, brightens the color and helps avoid the loss of vitamins. It also softens vegetables and makes them easier to pack.

Advantages:

- The high quality of the equipment.

- The device is fully made of stainless steel, which guarantees a long service life.

- The equipment is hygienic and easy to clean.

- The high quality of the finished product, due to the gentle processing and smart temperature regulation.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

You might also like

Heating: electric and steam - combination

- Material: Stainless steel

- Principle of operation: Continuous mode

Price depends on the required production capacity.

- Material: Stainless steel

- Heating power, kW: 90

- Dimensions, mm: 3549x1919x1490

- Blanching section, mm: 400x1800

- Cooling section, mm: 400x900

Blanching helps keeping the vitamins and nutritional properties of the product, as well as an outer appearance with bright and natural color.

- Heating: Electricity Steam

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

We offer many different types of blanchers including continuous models as well as batch blanchers.

- Material: Stainless steel

- Heating power, kW: 72

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

- Working Area Width: 420 mm

The combination of the compact 400/1100/12 fryer with the secondary upper pressure conveyor, allows you to expand the variety of products that can be fried on it. It ensures uniform, high-quality frying of fresh and semi-finished products in small to medium scale, making it suitable for small-scale production, professional kitchens and street food businesses. The fryer fully submerges the product in oil throughout the whole frying process with the help of the second pressure conveyor that forces the product beneath the oil's surface.

- The maximum height of the fried product is - up to 50 mm

- Immersion thermometer for visual monitoring of the oil temperature

- Frying time can be set from a few seconds up to an hour!

- High temperature ŌĆō up to 200┬░C

- The conveyor belt is made out of a food-grade stainless steel thin mesh

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Total power, kW: 12

- Oil volume: 60l

- Voltage: 380-400V

Blancher pouring AQ is designed for heat treatment of a wide range of products whose fine structure requires to minimize mechanical influence in the blanching or cooking process. Unlike a drum blancher, in which the product is blanched in a process of single directional mixing and rolling and a screw blancher, in which the product passes through a working chamber by means of a screw, in the belt type blancher the product lies motionless on the conveyor belt and is processed without damaging its surface.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

The Batch Blancher Cook & Chill is designed for boiling, frying, heating and cooling of a wide range of products.

Price depends on the chosen option.┬Ā

- Material: Stainless steel

- Country of origin: Slovakia

- Voltage: 380-400V

Designed for blanching vegetables, fruits, legumes, pasta, seafood before preservation and freezing.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Blanching helps keeping the vitamins and nutritional properties of the product, as well as an outer appearance with bright and natural color.

- Heating: Electricity Steam

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Heating: electric and steam - combination

- Material: Stainless steel

- Principle of operation: Continuous mode

The automatic screw cooker is designed for cooking or blanching various food products in continuous mode, saving both time and energy during production.

- Heating: Mixed

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The price is set for the basic fryer version without additional modules. If purchasing the fryer together with both of the additional conveyor modules ŌĆō the double conveyor fryer and the paddle conveyor fryer ŌĆō we offer a discount of 300 EUR.

The versatile modular conveyor fryer with a single conveyor belt is used for the continuous frying of a variety of products with a low moisture content, that do not require forced immersion beneath the surface of the oil for even frying.

- Adjustable frying time from a few seconds up to an hour!

- Ability to use the unit as a continuous blancher or boiler for cooking products with a delicate structure

- Modular system, expanding functions with each new module

- Compact, desktop version

- Possibility of periodic frying of products with automatic unloading

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Oil volume: 60l

- Voltage: 380-400V

A universal cooking & cooling system for preparing large batches of food and subsequently cooling them down to preserve their structure.

Price depends on the selected options. For more information, please send us a request.┬Ā

- Heating: Steam

- Material: Stainless steel

- Working volume: 700l

- Geometric volume: 1000 l

- Dimensions, mm: 3180x1860x1080

Price depends on the required production capacity.

- Material: Stainless steel

- Heating power, kW: 90

- Dimensions, mm: 3549x1919x1490

- Blanching section, mm: 400x1800

- Cooling section, mm: 400x900

This compact batch blancher is designed for efficient and simple blanching in smaller-scale food processing. Price depends on the chosen option.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 450l/

Blancher AQ Deep is designed for heat treatment of a wide range of products whose fine structure requires to minimize mechanical influence in the blanching or cooking process. Unlike a drum blancher, in which the product is blanched in a process of single directional mixing and rolling and a screw blancher, in which the product passes through a working chamber by means of a screw, in the belt type blancher the product lies motionless on the conveyor belt and is processed without damaging its surface.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The stated price does not include the steam generator

The unique sectional cooking kettle is intended for high-performance cooking/blanching/frying of a wide range of products with subsequent cooling to avoid damaging their structure. An essential part of this technology is the efficient cooling section, necessary for halting the cooking process after unloading. This function is also necessary when processing vegetables to the "aldente" state, when vegetables retain their structure and natural color after thermal treatment. This model provides heating by direct injection of purified steam into the heating section (steam generator - option).

- Suitable for cooking small-sized products

- Fast and intense heating due to direct steam injection

- Intensive hydro-stirring

- Automatic basket lifting system

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 2x250l/ 3x250l

- Voltage: 380-400V

- Working volume: 2x175l/ 3x175l

Designed for cooking or blanching vegetables, fruits, legumes, pasta, seafood and other products in a continuous manner.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Excellent blancher and cooker for efficient handling of vegetables and other food products.

- Principle of operation: Continuous mode

- Working Area Width: 600 mm

- Voltage: 380-400V

The cost is indicated without the price of the baskets

A batch blancher with indirect electric or steam heating is used for blanching vegetables, mushrooms, meat, fish, and seafood. This type of blancher is ideal for use in catering kitchens and hospitals.

- Simple controls

- Built-in electric heating

- Large outlet valve

- Safe operation

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 18/ 24/ 30/ 36

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 200l/ 300l