Belt blancher and cooler CB 800/2700

Price depends on the required production capacity.

Belt Blancher is a device that eliminates the risk of product damage while moving inside the blancher.

Because some specific products are sensitive to high temperatures, and direct steam injection or immersion in hot water is not suitable for processing, the ideal solution is the 800/2700 blancher, which uses a hot water system.

Conveyor-type blanching, cooking and cooling equipment CB is a high-quality professional equipment that works continuously with low energy consumption.

The processed product is harmless, preserves all beneficial substances, vitamins and nutrients. The advantage of the device is its versatility with a wide range of applications. The device can be configured to handle various products (depending on the type of processing and product type):

- Soft seafood, such as mussels without shell or shrimp┬Ā

- Different kinds of pasta

- vegetables

- mushrooms

- And many others

The device allows blanching, cooking and subsequent cooling of the product.

Belt blancher CB is designed for heat treatment of a wide range of products whose fine structure requires minimal mechanical impact in the blanching or cooking process. Unlike the drum blancher, in which the product is blanched in one direction mixing and rolling process, and the screw blancher in which the product passes through the working chamber by means of a screw, the product is not moved on the conveyor belt and it is processed without damaging its surface.

Continuous production and uniformity of cooking, blanching and cooling are achieved thanks to independent belt conveyors in each section: sections are cascaded, ie. each section is lower than the previous one, providing automatic product rotation while moving the conveyor belt from section to section.

The blanching section is followed by a cooling zone where the product is poured with ice water and cooled to 5 ┬░ C. Efficient cooling allows the process to be terminated immediately, to obtain a product of the desired degree and to prepare it for further processing or packaging. Each section is equipped with a special water pouring system for the product with continuous filtration and water circulation. Blancher consists of 5 zones: feeding, blanching (hot water), medium, cooling zone and unloading zone

On request, it is possible to add sections, eg for washing, preheating, additional cooling and so on.

Heating system: Blancher CB 800/2700 is equipped with an electric heating system.

Filtration System: Belt Blanchers CB are equipped with a highly efficient and comfortable filter system. The smallest parts of the product that are carried along with the water are captured by the filter system with interchangeable stainless steel mesh. Cleaning of the filter can be carried out while running the blancher.

Optionally, on request, the blancher can be equipped with a single or multi-turn product section for uniform heat treatment from all sides. It may also be provided with a steam / hot water delivery system from the bottom of the conveyor belt. In order to remove excess water and fine product particles, a section behind the cooling section can be installed on request. "Air knife".

Characteristics: CB blanchers have a reliable frame ensuring the stability of the entire structure even with larger equipment dimensions. The cleaning is via CIP heads connected to the CIP station system. CB Belt Blanchers are made exclusively from AISI 304 stainless steel. The conveyor belt is made of PVC or stainless steel, depending on the processing temperature and the bulk density of the product.

Versatility

- A wide range of CB blancher configurations allows you to select the optimal device for any application.

- Any heat transfer medium

- Stainless or PVC conveyor belt

- Integrated or extended water or air cooling section

- Option to install any additional equipment

- Any performance.

- The performance of the conveyor blanks determines the bulk density of the product on the belt and the processing time, depending on the product type.

- The standard model range includes blanchers with a belt width of 400 to 2000 mm.

- Material: Stainless steel

- Heating power, kW: 90

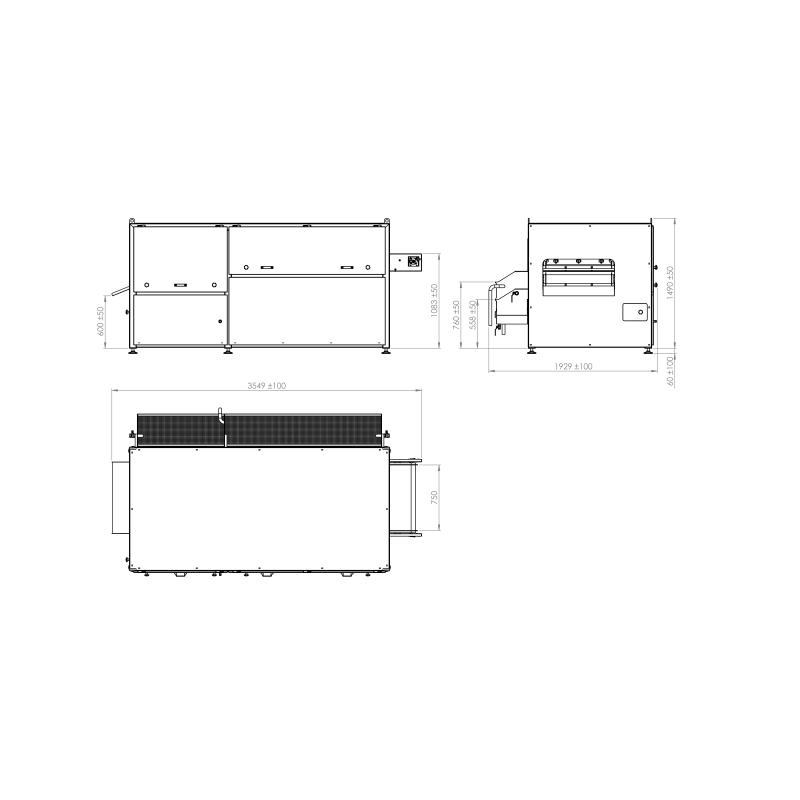

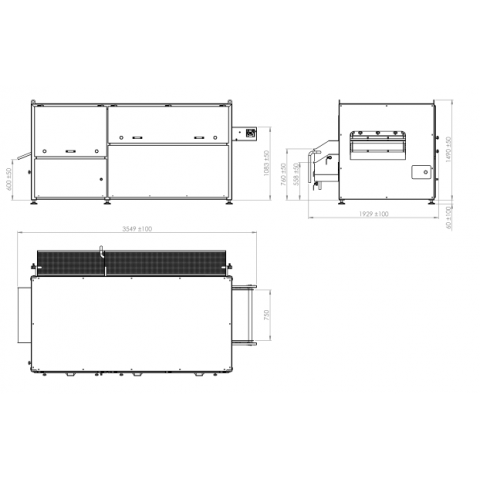

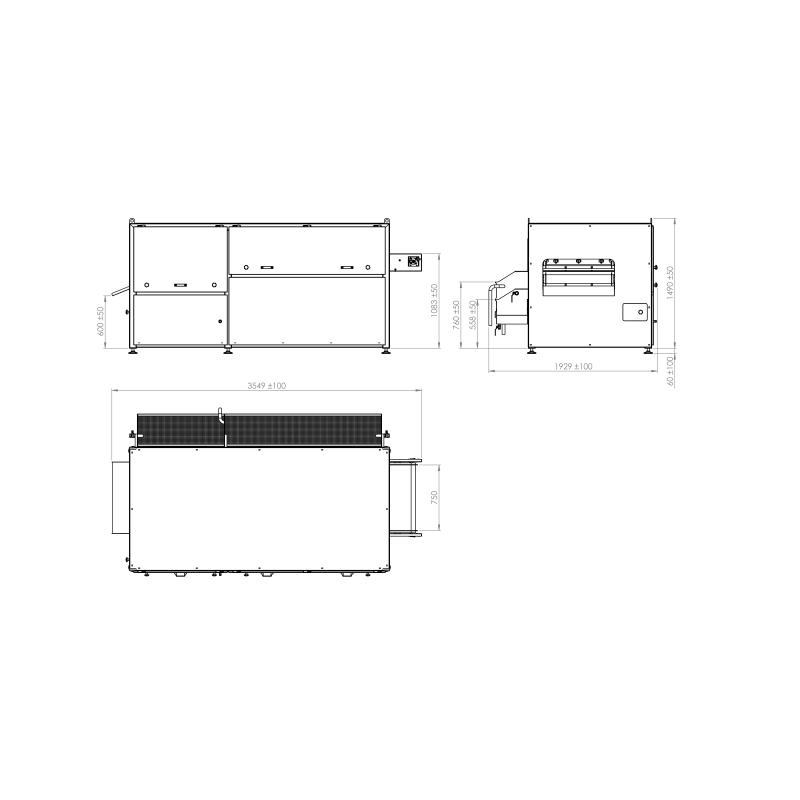

- Dimensions, mm: 3549x1919x1490

- Blanching section, mm: 400x1800

- Cooling section, mm: 400x900

You might also like

The Batch Blancher Cook & Chill is designed for boiling, frying, heating and cooling of a wide range of products.

Price depends on the chosen option.┬Ā

- Material: Stainless steel

- Country of origin: Slovakia

- Voltage: 380-400V

The blancher is designed for blanching and cooking fruits, vegetables, meat, fish, mushrooms.

The price depends on the selected options.

- Material: Stainless steel

- Working volume: 700l

- Geometric volume: 1000 l

- Dimensions, mm: 3180x1860x1080

The blancher is primarily intended for blanching lumpy products such as mushrooms and vegetables.

Price depends on the chosen options.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 450

- Geometric volume: 550 l

- Dimensions, mm: 1770x899x997

Price depends on the chosen option.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

This multifunctional cooking machine with two baskets is designed for different ways of use and is suitable for a lot of variety of businesses - any enterprise or any participant of the HoReCa market. With the help of this equipment, you can cook, pasteurize, or blanch.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 135 +135 / 220+220

Used for blanching products in water, it is suitable for processing various vegetables, legumes, grains, mushrooms and other products. This versatile machine also functions as a water separator centrifuge which is activated after the blanching processes.

- Productivity: 30l/ 90l

- Material: Stainless steel

Price depends on the chosen option.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

Designed for blanching vegetables, fruits, legumes, pasta, seafood before preservation and freezing.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Excellent blancher and cooker for efficient handling of vegetables and other food products.

- Principle of operation: Continuous mode

- Working Area Width: 600 mm

- Voltage: 380-400V

Pouring Blancher┬ĀShowerBlanch is designed for heat treatment of a wide range of products whose fine structure requires to minimize mechanical influence in the blanching or cooking process. Unlike a drum blancher, in which the product is blanched in a process of single directional mixing and rolling and a screw blancher, in which the product passes through a working chamber by means of a screw, in the belt type blancher the product lies motionless on the conveyor belt and is processed without damaging its surface.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

This multifunctional cooking machine is designed to be used in a variety of different ways and is suitable for the majority of professional kitchens and catering businesses - any small enterprise or any participant of the HoReCa market. With the help of this equipment, you can cook, pasteurize, or blanch.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Voltage: 380-400V

Blancher AQ Deep is designed for heat treatment of a wide range of products whose fine structure requires to minimize mechanical influence in the blanching or cooking process. Unlike a drum blancher, in which the product is blanched in a process of single directional mixing and rolling and a screw blancher, in which the product passes through a working chamber by means of a screw, in the belt type blancher the product lies motionless on the conveyor belt and is processed without damaging its surface.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

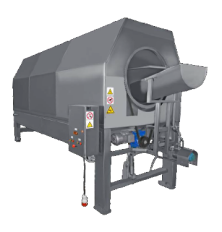

The automatic screw cooker is designed for cooking or blanching various food products in continuous mode, saving both time and energy during production.

- Heating: Mixed

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

A universal cooking & cooling system for preparing large batches of food and subsequently cooling them down to preserve their structure.

Price depends on the selected options. For more information, please send us a request.┬Ā

- Heating: Steam

- Material: Stainless steel

- Working volume: 700l

- Geometric volume: 1000 l

- Dimensions, mm: 3180x1860x1080

The Batch Blancher Cook & Chill is designed for boiling, frying, heating and cooling of a wide range of products.

Price depends on the chosen option.┬Ā

- Material: Stainless steel

- Country of origin: Slovakia

- Voltage: 380-400V

Blancher pouring AQ is designed for heat treatment of a wide range of products whose fine structure requires to minimize mechanical influence in the blanching or cooking process. Unlike a drum blancher, in which the product is blanched in a process of single directional mixing and rolling and a screw blancher, in which the product passes through a working chamber by means of a screw, in the belt type blancher the product lies motionless on the conveyor belt and is processed without damaging its surface.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

The cost is indicated without the price of the baskets

A batch blancher with indirect electric or steam heating is used for blanching vegetables, mushrooms, meat, fish, and seafood. This type of blancher is ideal for use in catering kitchens and hospitals.

- Simple controls

- Built-in electric heating

- Large outlet valve

- Safe operation

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 18/ 24/ 30/ 36

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 200l/ 300l

We offer many different types of blanchers including continuous models as well as batch blanchers.

- Material: Stainless steel

- Heating power, kW: 72

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

- Working Area Width: 420 mm

The stated price does not include the steam generator

The unique sectional cooking kettle is intended for high-performance cooking/blanching/frying of a wide range of products with subsequent cooling to avoid damaging their structure. An essential part of this technology is the efficient cooling section, necessary for halting the cooking process after unloading. This function is also necessary when processing vegetables to the "aldente" state, when vegetables retain their structure and natural color after thermal treatment. This model provides heating by direct injection of purified steam into the heating section (steam generator - option).

- Suitable for cooking small-sized products

- Fast and intense heating due to direct steam injection

- Intensive hydro-stirring

- Automatic basket lifting system

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 2x250l/ 3x250l

- Voltage: 380-400V

- Working volume: 2x175l/ 3x175l

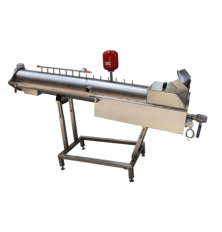

Designed for cooking or blanching vegetables, fruits, legumes, pasta, seafood and other products in a continuous manner.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia