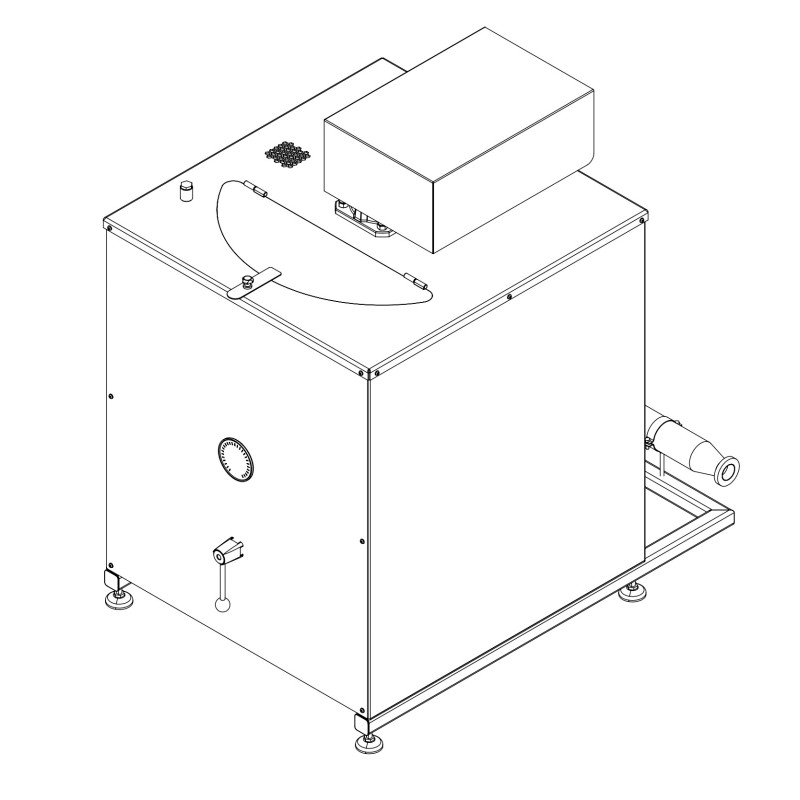

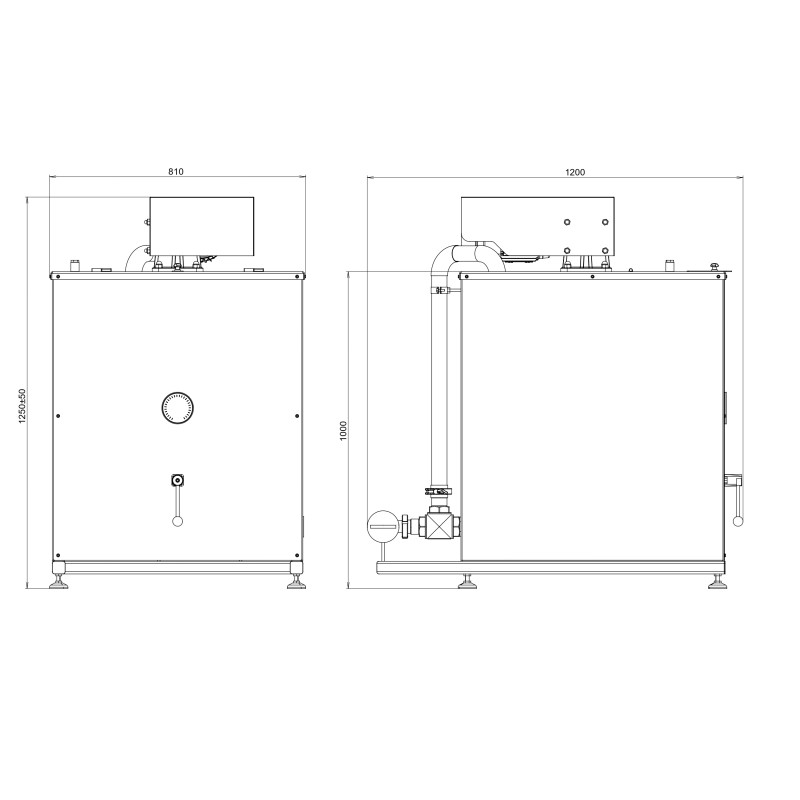

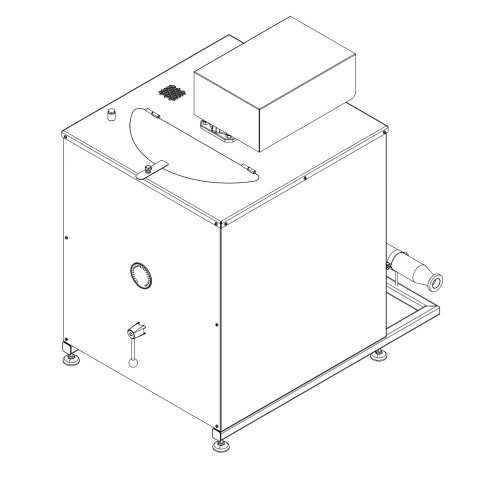

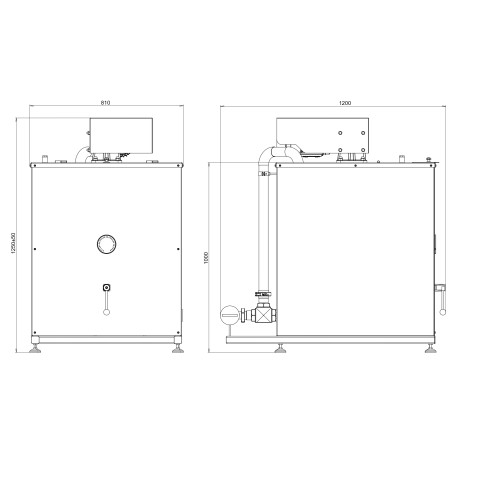

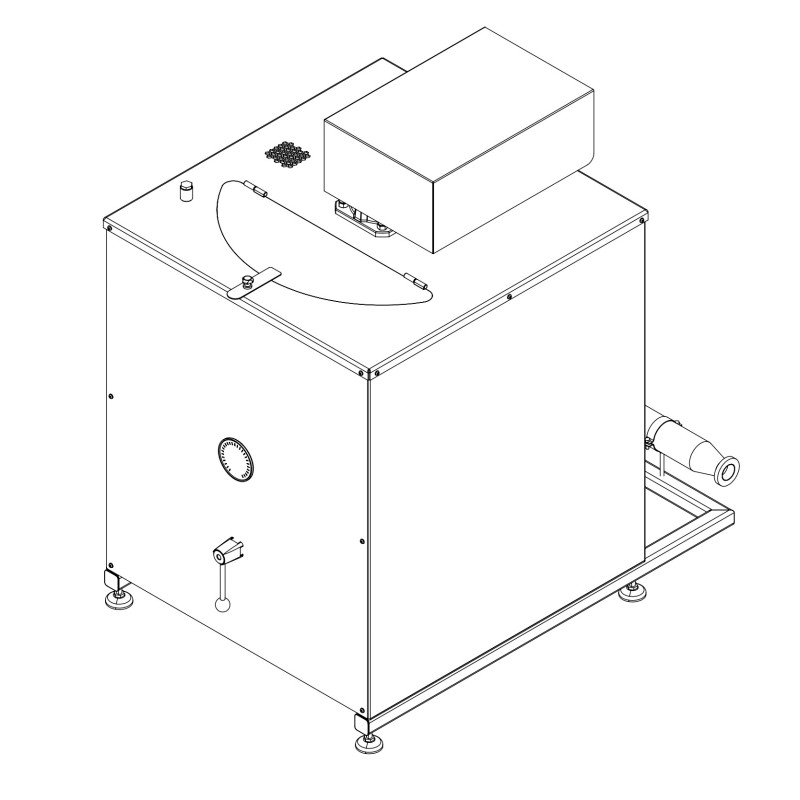

Electric thermal oil jacketed cooker STM

Cooking kettle for making syrups, caramel, sugaring paste as well as processing and producing various thick and viscous products. Often used for dissolving sugar and producing various saturated and supersaturated solutions.

- Built-in heating with thermal oil up to 150 degrees Celsius

- Anchor frame stirrer for rapid dissolution

- Conical bottom design of the working container without dead zones

The syrup cooker is used in the confectionery, dairy, fruit and vegetable processing as well as other industries. The preparation of syrup is one of the mandatory processes in the production of condensed milk. The process of preparing syrup in a syrup cooker can be fully automated. Using this kettle, you can prepare various types of sugar syrups - saturated, supersaturated or invert. A saturated sugar syrup is a syrup that contains the maximum possible amount of sugar dissolved in water at a specific temperature. Typically this syrup is used to make sweets, drinks and other food products. To produce a saturated solution, sugar is dissolved in hot water until no more sugar can dissolve in a given amount of water at a given temperature. Once the syrup is saturated, it can be used to make various products such as candies, ice cream, cakes, pies, cookies, cakes, juices, drinks. In practice, saturated sugar syrup may have different sugar concentrations depending on production and formulation needs. Typically, full syrup is about 2/3 sugar and 1/3 water, although the concentration may be higher or lower depending on the specific application. The mass of sucrose dissolved in water is measured on the Brix scale. Supersaturated sugar syrup is a syrup that contains more sugar than the maximum possible amount of sugar dissolved in a given amount of water at a given temperature. This means that a supersaturated sugar syrup is in a state where no more sugar can dissolve in a given amount of water under given conditions, and any additional sugar will not dissolve and will precipitate into crystalline form. Supersaturated sugar syrup can be produced, for example, by heating the syrup to a high temperature or by adding large amounts of sugar to the syrup. It can be used in cooking for the preparation of various sweets and confectionery products, such as caramel, candies, syrups, glazes, cookies, gingerbread as well as for glazing fruits and decorating cakes. Invert sugar syrup is a syrup that contains glucose and fructose obtained by hydrolysis (breaking down) of sucrose, the main component of regular sugar. During sucrose hydrolysis, the bond between glucose and fructose disintegrates, which forms sucrose, and results in the formation of glucose and fructose molecules. These molecules then dissolve in water, creating invert sugar syrup. Invert sugar syrup has different properties from regular sugar. It is sweeter, less prone to crystallization and has greater viscosity. This makes it an ideal ingredient for use in a variety of food products, such as creams and mousses, marshmallows and marmalades, nougat and fudge, marshmallows and meringues, breads and pastries, cake ganache, artificial honey, alcoholic and non-alcoholic drinks.

The syrup cooker is intended for the preparation of sugar syrup, invert syrup, dissolution of returnable waste and other products based on sugar, honey, syrups and other sweet ingredients:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Advantages

- Made entirely out of food grade stainless steel

- Allows you to heat the product to high temperatures - up to 150 degrees C

- Anchor frame mixing device

- Overheating safety system

- Lid opening sensor, which stops the agitator when the hatch is opened

- Visual temperature control on the front housing of the unit

- Conical working container without dead zones

- Large release valve from the working tank

Basic version

The cooking kettle comprises a food-grade atmospheric working vessel with a conical bottom, immersed in a heating jacket using thermal oil as a heating medium, inside which heating elements are installed, equipped with a frame anchor mixing device with an electric drive, a safety grill and a safety sensor installed on the hatch cover. Can be retrofitted with an external forced circulation circuit, a pump for hot, thick and viscous products and a flow-through stainless steel filter. Available models include capacities of 200, 300, or 500 liters. The working container is made entirely out of food grade stainless steel, including the external decorative casings.

Operating principle

The cooking boiler facilitates various technological operations such as: heating, dissolving, cooking, boiling, and concentrating solutions under atmospheric pressure. Ingredients can be loaded through the safety grill on the top hatch of the unit. The mixture of sugar, water, and additional components is heated, and as water evaporates, it transforms into a thick, aromatic syrup with an enticing yellow-brown color. Mixing is achieved with the help of a specialized anchor mixing device, ensuring even distribution of dry ingredients in the working fluid and promoting effective heat distribution within the product. Precise temperature and mixing speed settings are essential to produce a homogeneous syrup without lumps.

Options:

- External circulation circuit with mechanical valves and a pump for viscous products.

- Stainless steel flow filter

- Heating: Electricity

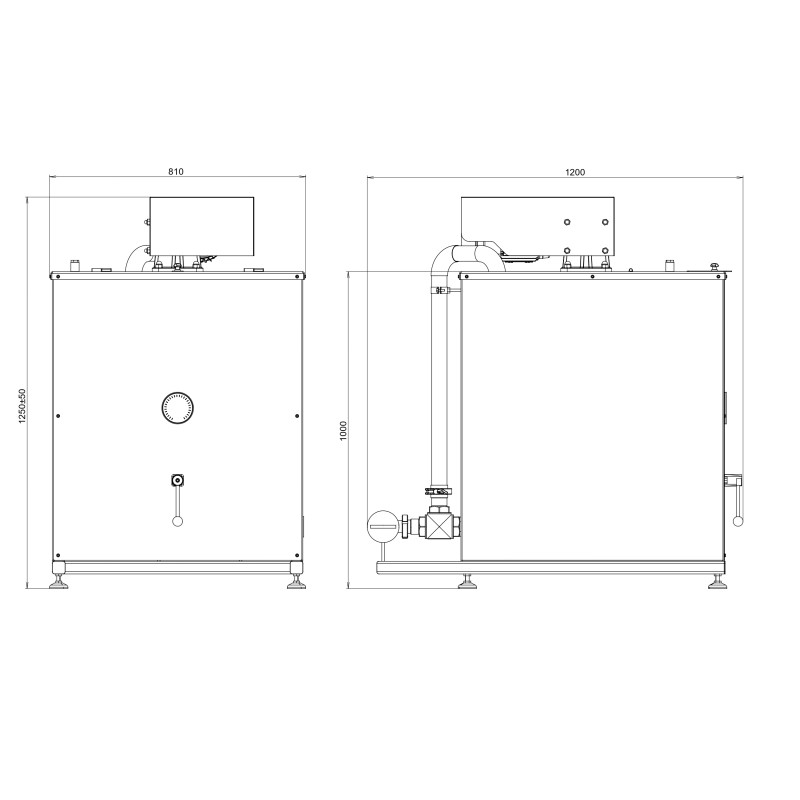

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 200l/ 300l

- Total power, kW: 19

You might also like

The 1000 L vacuum cooker is used for cooking, concentrating, and evaporating food products under reduced pressure, allowing gentle heat treatment, improved flavor retention, and precise control of moisture content.

For a price quote, send us a request.

- Heating: Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 1000l

- Dimensions, mm: 1385x1283x1892

A cooking kettle and a vacuum mixer for periodic deaeration of products such as mayonnaise, ketchup, various sauces, creams, gels and pastes. It is one of the modifications of a vacuum reactor and a vacuum evaporator. The presence of a vacuum system allows you to create a vacuum after the cooking process and perform vacuuming (deaeration) to remove air bubbles with potential contaminants and obtain a product with a denser structure. Thanks to vacuuming, the product has an extended shelf life, since pathogens and microbes contained within are removed together with the air.

- Inclined design with gravity mixing, which is 30% more efficient than usual

- 100% emptying of the product after processing due to the bottom valve

- Easy to disassemble removable mixing device

- Possibility of connecting it to a CIP station for cleaning and washing

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l

- Total power, kW: 0,12

- Max vacuum: -0,8 Bar

Heating: integrated electric. Price depends on the production capacity and product.┬Ā

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l

This electric cooking pot has a volume of 60 liters and is used to prepare a large number of dishes. It is comfortable to use and easy to clean.

- Material: Stainless steel

- Volume: 60l/

- Voltage: 380-400V

Model VMG S is an effective and reliable vacuum homogenizing unit designed to produce a wide range of liquid, pastry and viscous products with different requirements for the production conditions.

This 550 l professional tilting kettle is gas-fired and is indispensable in the professional kitchen. It allows you to easily prepare the most delicious soups, broths, sauces and creams. With this tilting version, you can make your life even easier.

- Heating: Gas

- Productivity: 500 l

- Material: Stainless steel

Vacuum homogenizer VMG M is the ideal solution for the production of pilot batches and the industrial production of a wide range of products of small and medium production. The price depends on the production capacity.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Max vacuum: -0,8 Bar

- Working volume: 50-80l

The device is designed for the pasteurization of a wide range of products in various types of packaging material such as cans and jars.

- Heating: Mixed

- Productivity: 300 l 400 l 500 l

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

The steam cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, pots, pasta, milk dishes, teaspoon cooking, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared, ready-to-cook meals, heating or steaming.

The cooking equipment is not suitable for roasting or baking.┬Ā

- Material: Stainless steel

- Volume: 100l/ 150l/ 200l/ 300l

- Steam consumption, kg/h: 50/ 60/ 70/ 90

Cooking tank with a bottom out of stainless steel AISI 316. Capacity of 150 liters.

- Heating: Steam

- Material: Stainless steel

- Volume: 150l

The tilting cooker is produced in 2 versions: with gas or electric heating. The pan is designed for use in the food, hospital, catering industry and in large kitchens for making pasta, stewing and frying meat, fish, vegetables, mushrooms, frozen or semi-prepared, ready-to-cook meals, etc.

- Principle of operation: Batch mode

- Volume: 50l/ 80l/ 120l

- Voltage: 380-400V

A versatile atmospheric kettle suitable for cooking various products, including jams, syrups, sauces, fruit and vegetable juices, and many others.

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 250l/ 300l

Wide range of catering equipment for restaurants, canteens and all kinds of food serving establishments.

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: EU

- Voltage: 380-400V

MP cooker is a reliable and extremely functional solution for cooking, pasteurizing in the same tank thus saving equipment cost, space. All material are most reliable in European market so guarantee a long and trouble free operation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

The electric cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, broths, pasta, milk dishes, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared meals, heating or steaming. The equipment is not suitable for roasting or baking.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 18/ 24/ 30/ 36

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 100l/ 150l/ 200l/ 300l

This multifunctional cooking machine with two baskets is designed for different ways of use and is suitable for a lot of variety of businesses - any enterprise or any participant of the HoReCa market. With the help of this equipment, you can cook, pasteurize, or blanch.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 135 +135 / 220+220

The VMG S 650P vacuum homogenizing unit can be used for making toothpaste as well as a variety of similar products with complex production requirements.

- The vacuum ensures effective air removal, eliminating the conditions for the development of bacteria and other pathogenic organisms.

- The special shape of the mixing device is tailored for the thickest and most viscous products.┬Ā

- The Ultra Shear submersible homogenizer creates a stable emulsion.

- The cavitation processes aid in activating hydrodynamic mixing.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 29

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 52

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

This is a 400 l capacity heating boiler, we offer different capacity commercial cooking boilers.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 25

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 400l

- Voltage: 380-400V

A universal cooking & cooling system for preparing large batches of food and subsequently cooling them down to preserve their structure.

Price depends on the selected options. For more information, please send us a request.┬Ā

- Heating: Steam

- Material: Stainless steel

- Working volume: 700l

- Geometric volume: 1000 l

- Dimensions, mm: 3180x1860x1080