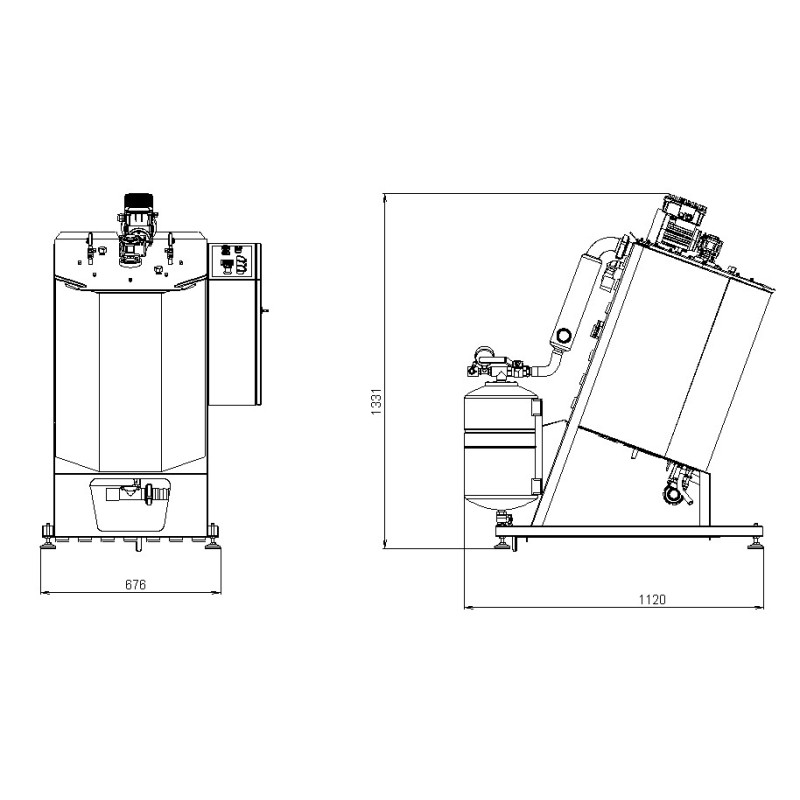

Vacuum Evaporator 110/100

The price is set for the basic version of the vacuum evaporation unit with basic controls (mixer motor switch) and without additional options. The control unit is customized based on individual customer requirements. The pump is also selected separately depending on the product.

A compact vacuum evaporation unit that allows you to concentrate solutions, mixtures, and various products by evaporating the solvent. A modular version based on the basic version of the 110/100 vacuum reactor.

- Gravity mixing - 25% more efficient

- Reinforced agitator design with no blind spots

- Bottom ball valve with no dead zones

- Condensation and secondary vapor removal system

- Easy to disassemble mixing device

- Large heat exchange area

- Ability to measure and monitor condensate volume (optional)

Vacuum evaporation units are used in the food industry for boiling milk, buttermilk, whey, producing condensed cream, condensed milk with or without added sugar. A large number of manufacturers of preserves, confiture and preserves have switched to vacuum evaporation units due to the fact that cooking at low temperatures under the conditions of a vacuum allows you to preserve the original color of fruits and berries, and most importantly, preserve most of the beneficial substances and vitamins that get destroyed at higher temperatures.

The scope of applications for vacuum evaporation units is quite wide; it can be used to produce:

|

|

|

|

|

|

|

|

For the production of various medicinal extracts from plants, herbs, juice concentrates, coffee, drinks and other liquid foods, as well as for the production of fruit syrups, biologically active additives and dietary supplements.

In the production of healthy foods, for example, baby food, fruit and vegetable purees, thermal processing and concentration are also carried out under a vacuum in order to preserve their natural taste characteristics as much as possible and to extend the shelf life of your finished products.

In the food industry, concentration is also used as a preliminary stage of production, for example, to reduce the volume of raw materials during storage and transportation, to stimulate crystallization, or as an intermediate step for the subsequent drying of various products.

A widely developing area where vacuum evaporators are used is the processing of industrial waste, where minor, in other words, micro by-products are extracted from them through evaporation.

In addition to the food industry, small evaporation units have also found their application in the cosmetics industry; they are often used, for example, to produce thick sugar paste for sugaring.

Advantages:

- A powerful heat exchanger for steam condensation (for connecting cold water with a temperature of 7-12 degrees), which is also responsible for increasing the vacuum depth during evaporation; the higher the vacuum depth, the lower the boiling point of the solvent!

- The ability to select a vacuum generator depending on the available working media and the required vacuum setting; in the basic version, an ejector is installed for compressed air from an external source with a maximum vacuum depth of up to 0.8 Bar. A "quiet" compressed air compressor is an additional option.

- Bottom DN40 valve ensures product processing without blind spots, preventing clumps and meeting high-accuracy pharmaceutical production standards.

- A mixing device with scrapers is included in the basic version of the vacuum evaporation unit!

- A 3-layer working container with thermal insulation and a top decorative stainless steel casing reduces heat loss and creates safe conditions for the operator.

- Double-layer cover with an air gap to reduce heat loss and parasitic condensation.

- The lid with vacuum thermal insulation minimize heat loss, increasing energy efficiency by up to 40%

Basic version

The basic version of the vacuum evaporator comprises a single-case installation, the design of which is based on a universal vacuum reactor (cooking kettle), the obligatory modification of which adds a system for the removal and condensation of secondary vapors, an external stainless casing with low-temperature insulation. The vacuum generation source can be selected based on the customer's preference for the working medium (water, compressed air). Just like a universal vacuum device, the basic version of the evaporation unit includes a bottom valve with a DN40 outlet!

Operating principle

The operational principle is based on the evaporation of liquid substances at a pressure below atmospheric pressure by introducing a heat transfer medium into the "jacket" of the installation. During the evaporation process, substances are concentrated as the solvent evaporates during the boiling of the liquid. The resulting vapor, passing through a condenser, is cooled and discharged from the installation in the form of water.

Technical conditions

- The working vacuum depth is -0.8 bar (0.2 bar residual), the evaporation temperature at this vacuum value is 57-59 degrees C

- The minimum loading volume varies depending on the model and volume, it is recommended that the product covers the bottom of the stirrer.

- Maximum loading volume ranges from 50% to 75% of the total volume (depending on the foaming properties of the product)

- Availability of a source of compressed air with a pressure of 6-10 Bar, 275-300 l / min

Options:

In addition to the large number of additional options that we offer both for the universal vacuum reactor and for the vacuum evaporator, we can also offer additional equipment that applies exclusively to the evaporator:

- Vacuum tank for collecting condensate, made entirely out of AISI304 stainless steel, equipped with a release valve and a three-way valve at the ‚Äúinput‚ÄĚ, which allows condensate to be released from the vacuum tank during the operation of the unit! This function allows you to control the evaporation process and evaporate the amount of moisture that is necessary, by measuring the volume of secondary steam condensate.

- Compressed air source for vacuum generation (ejector) - quiet compressor 6-10 bar, 275-300 l/min

- Vacuum generator - liquid ring pump or rotary pump to choose from

- A set for -0.9 bar (40 degrees water evaporation temperature)

Additional equipment/systems:

- Forced external circulation circuit for increased evaporation intensity

- Forced circulation circuit with a remote heat exchanger to increase the heat transfer area

- Forced circulation circuit with an inline homogenizer for the possibility of using the installation as a vacuum homogenizing module

- A system for product spraying in the working vessel with the presence of a forced circulation circuit

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

- Working volume: 50-80l

- Condensing capacity, l/h: 45-55

- Steam consumption, kg/h: up to 150