Pilot chocolate ball mill

The price is stated for the basic version of the installation without balls.

The mill is designed for mechanical grinding of raw materials for the production of chocolate, nut butters and obtaining a creamy, homogeneous product structure with a fraction size of up to 20 microns.

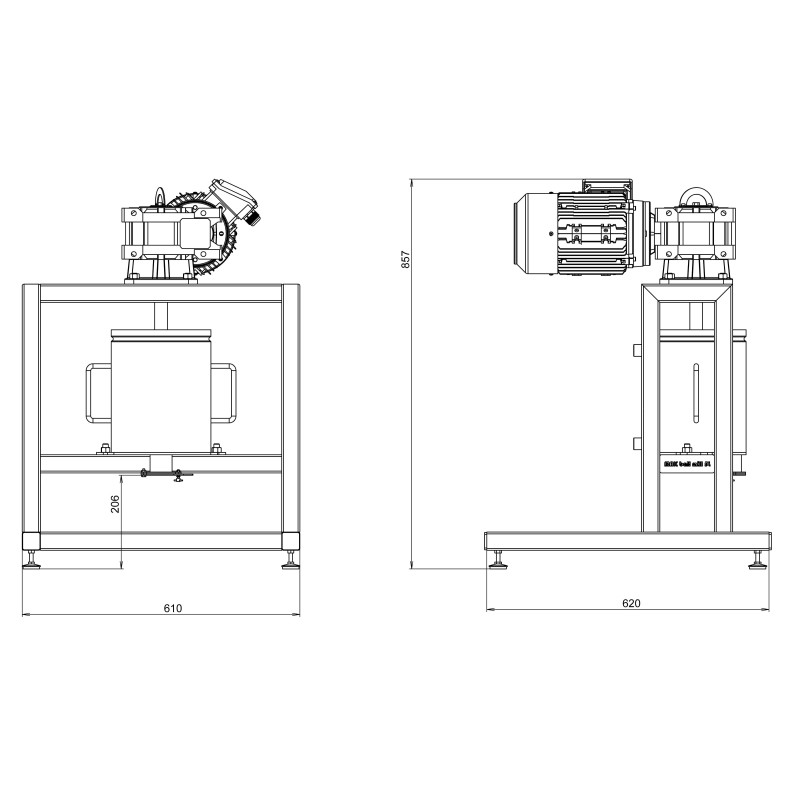

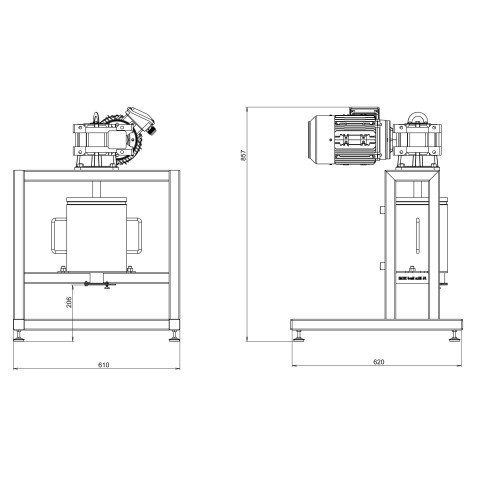

- Compact installation on a self-supporting structure

- Simple and convenient maintenance

- Plexiglas cover for visual inspection

- Removable stirring device

- Jacket for the heat transfer medium

The compact version of the ball mill is suitable not only for laboratory purposes, but also for small industries, confectionery shops that produce exclusive chocolate products and chocolate spreads as well as other businesses. The installation allows you to produce chocolate according to individual recipes with different taste preferences. The chocolate ball mill can be used as a better alternative to a melangeur in a Bean-to-Bar production line, or similar chocolate processing equipment.

The ball mill is used to create a delicate structure and the production of the following products:

|

|

|

|

|

|

|

|

|

Advantages:

- The presence of a jacket (duplicator) for the coolant is included in the basic version

- The installation is made entirely out of food grade stainless steel

- Spiral pin stirrer

- Special release valve for thick and viscous products

- Reinforced working capacity

- Balanced support structure to reduce vibration during the units operation

- Possibility to adjust the rotation speed of the mixing device (connection via IF option)

- Detachable work container with quickly removable clamps on the supporting structure

- Low operating costs

- Fast and high-quality processing of raw materials

Basic version

The installation consists of a cylindrical container with a coolant jacket, installed on top of a working platform with a supporting structure and a specially shaped submersible mixing device. The jacket is intended for servicing purposes such as heating the product residues to make it easier to clean the installation after work, or it can also be used to cool certain products during operation, the components of which are sensitive to overheating. The presence of the jacket allows you to expand the possibilities of performing laboratory tests for new products. This mill is the ideal solution for efficient grinding of heat-sensitive materials to prevent overheating from mechanical forces.

Operating principle

Processing inside the working chamber of the ball mill is achieved by mixing and rubbing the product with the help of metal balls, the movement of which is carried out by a special stainless steel stirrer. To adjust the rotation speed of the mixing device, it is recommended to select an additional option in the form of a frequency converter. The mixing device can be easily dismantled for convenient cleaning and maintenance of the unit.

For this model, it is recommended to purchase steel balls measuring 6 mm.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 5l

- Total power, kW: 1,5

- Voltage: 380-400V

You might also like

Compact, reliable, and easy to use. The frequency converter ensures smooth starting and stopping of the device's motor, reducing inrush currents, and adjusting the motor speed. It can also be connected to your smartphone via Bluetooth for convenient configuration and parameter adjustment.

Key benefits:

- Precise digital control at the touch of a button.

- Application macros.

- Switch between Industrial, Pump, and Fan modes for optimized operation.

- It is used and mounted directly on the equipment, eliminating the need for electrical cabinets. It can also be wall-mounted.

We also offer programming and installation of the frequency converter to ensure seamless integration and optimal functionality for your equipment.

- Type of the equipment: Optional equipment

Steel balls for grinding chocolate are essential components used in ball/bead mills. These 6 mm diameter balls are made out of hardened steel and are considered as consumables required for operating the BALL MILL 5.

- Spherical shape with a diameter of 6 mm

- High hardness steel

- Supplied in 10 kg boxes

- The mill requires 2 boxes (20 kg in total).

- Type of the equipment: Spare parts

The colloid mill is used for continuous grinding of nuts, to obtain a finished nut paste of various viscosities with one pass through, without requiring additional processing or preparation!

- Simple and easy operation

- Three-point grinding adjustment

- Possibility of producing both creamy and crunch-type nut butters

- Compact design

- High performance

- Productivity: 180-240 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

Ball mills are used for the production of a chocolate mass, various types of chocolate glazes, nut and chocolate pastes (such as Nutella) and similar products.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

We offer different types of washing equipment for various different fruits and vegetables.

- Productivity: 1500 kg/h

- Material: Stainless steel

- Engine power, kW: 3

- Weight: 200

The knife mill is used for grinding products such as sugar, pepper, dry leaves and other products that are used during the production of spices and sauces.

- Adjustable grinding size

- Easy maintenance

- Support structure

- Large capacity hopper

- Material: Stainless steel

- Engine power, kW: 5,5

- Principle of operation: Continuous mode

- Voltage: 380-400V

- Hopper volume, l: 30

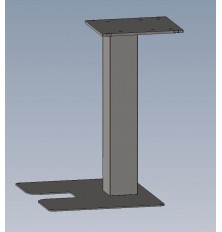

Stand (support structure) for colloid mill machine - additional option for the colloid mill 132

- Type of the equipment: Optional equipment

The pistachio paste mill is a colloid type mill. Its operating principle is based on grinding nut kernels between a rotor and stator to achieve colloid-sized particles.

Pistachio paste obtained using this type of mill has a uniform fine texture, natural taste and aroma.

Advantages:

- Easy to operate

- High productivity

- Compact size

- Flexible adjustment settings

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

The crusher is used for crushing fruits such as berries before pressing. The price depends on your production.┬ĀFor more information, send us a request.┬Ā

- Productivity: 3000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

The industrial meat grinder is made out of food-grade stainless steel. The kit includes various accessories such as a sausage attachment and an attachment with two cross blades. The productivity of the meat grinder is around 120 kg of minced meat per hour.

- Compact

- Professional

- With anti-slip rubber feet

- Stainless steel housing

- Productivity: 120 kg/h

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Continuous mode

- Total power, kW: 0,75

- Voltage: 220-230V

The nut grinding machine is used for processing sesame seeds to produce a tahini or a sesame paste.

- Material: Stainless steel

- Country of origin: Slovakia

This is a highly efficient equipment designed for fine grinding and homogenization of solid products. Thanks to its unique design and high speed, the mill provides fine mixing and crushing of particles, which makes it indispensable in a variety of industries.

- Compact design - tabletop installation

- Possibility of using different feeder models

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Voltage: 220-230V

Grinding mill for continuous grinding of meat and ingredients such as seeds, small bones and cartilages that are unwanted in the final product.

- Engine power, kW: 3

- Principle of operation: Continuous mode

- Voltage: 380-400V

The block cutter is designed for chopping frozen blocks of meat, fish, poultry, meat by-products, juice, butter or margarine without prior defrosting. This is a convenient and quick method of preparing the products for further processing, which saves time and reduces the likelihood of product contamination.

- Efficiently slices the product into thin layers while preserving its texture

- Safe pneumatic feeding of the product into the grinding section

- Special fixation system for the product container during unloading

- Low product losses during processing

- A powerful blade drive

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 600 mm

- Total power, kW: 11

- Voltage: 380-400V

Fruit crushing mill, entirely made of AISI 304 stainless steel is suitable for fruit, vegetables and for many other products such as apples, pears, carrots, lemons and others; easy to use, high productivity. It can be supplied with one or more sieves (screens or riddles).

- Productivity: 800 kg/h/ 1500 kg/h/ 3000 kg/h

- Engine power, kW: 1,35/ 2,1/ 2,6

- Hopper volume, l: 30/ 60/ 100

The mill is designed for milling whole fruit or vegetable before further processing. Price depends on the chosen fruit and production capacity.

For more information, send us a request.┬Ā

- Productivity: 6000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

We offer different capacity ball mills, from laboratory mills to industrial mills at great price and highest quality which produce exceptional chocolate.

- Material: Stainless steel

- Principle of operation: Continuous mode

A grain mill made out of stainless steel, it is sturdy and durable grinder, with increased wear resistance.

- Material: Stainless steel

- Engine power, kW: 3