Mixer-homogenizer for creamy cheese

A twin-screw mixer with a homogenizer is an ideal solution for the production of creamy cheese, such as feta cheese, including with various flavors and seasonings. Thanks to mechanical homogenization, the cheese acquires a delicate structure without changing the individual taste properties of the product. It is used for plasticizing, creaming and softening butter, margarine and other fats.

- Capacity of the receiving hopper 50L

- Compact tabletop design for convenient operator maintenance

- A powerful independent drive for each screw with a reverser

- Easy maintenance and cleaning of the equipment

The GM homogenizer-mixer can also be used for processing butter, margarine, the production of curd cheeses, spreads and much more. A special feature of this unit is the ability to mechanically soften fats without damaging their structure, heating or changing their characteristic properties. Homogenizers are used to homogenize butter and margarine before packaging. This function is necessary to restore the properties of the butter to the state as before freezing. The homogenizer can also be used in the confectionery and bakery industries when it is necessary to prepare butter and other fats to be incorporated into dough by mixing them in without melting them.

add and mix fats without melting, since when heated they can delaminate and lose their structure.

Cream homogenizers are designed for mechanical processing: grinding and softening blocks of products such as:

|

|

|

|

|

|

|

|

Advantages

- A wide hopper into which standard 20 kg blocks of butter, margarine, and other fats can be loaded, measuring 380x253x228 mm.

- The ability to process chilled blocks of the product with a temperature of 8 degrees C, which reduces the time needed for defrosting frozen blocks before processing.

- A powerful independent drive for each plasticizer - screw, which allows for mixing additional additives into the product in the mixer section to achieve the desired consistency (with both forward and reverse screw rotation) and then transferring the product to the discharge outlet through the homogenizer.

- High safety: extended outlet from the homogenizer section, which reduces the possibility of the operator touching the rotating parts of the unit. Various nozzles can be created and customized individually.

- Due to mechanical processing, moisture is evenly distributed in the product, preventing delamination and ensuring that it has a uniform structure.

- After plasticization and homogenization, the product achieves a uniform, stable consistency with attractive consumer characteristics, preserving organoleptic properties and extending its shelf life.

- Easy maintenance and cleaning.

- The control is located directly on the supporting structure of the unit.

- Robust design with height-adjustable legs and the option for tabletop installation and assembly.

Basic version

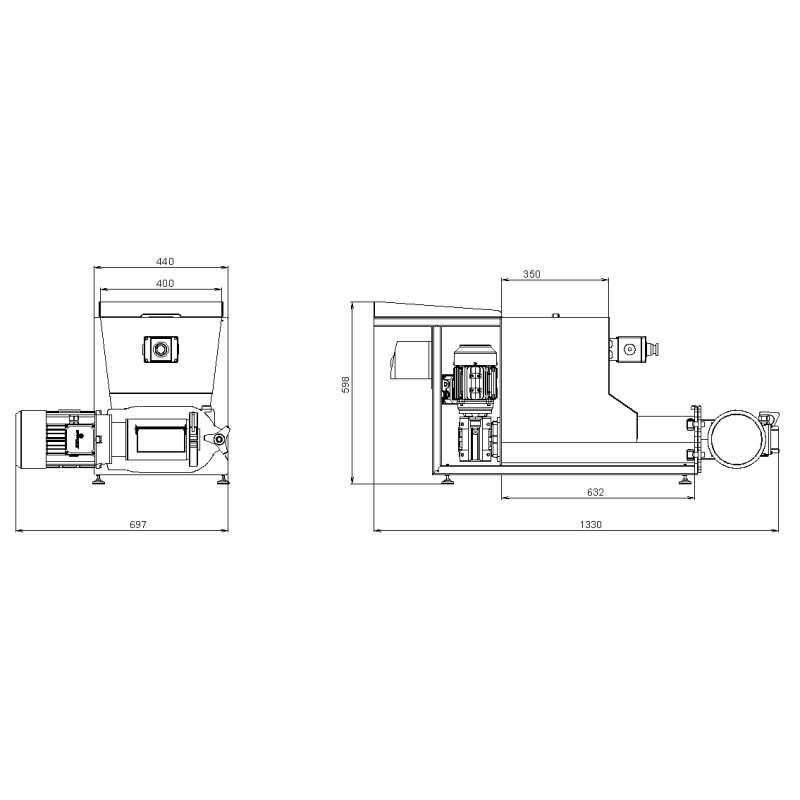

The mixing device with a crusher (homogenization section) consists of two screws with an individual electric drive, a homogenizer with an electric drive, a hopper, a support structure and a control panel.

Technical parameters:

- Productivity from 250 to 1500 kg / hour

- Product temperature at the input 8C - 13C degrees

- Product temperature at the output 11C - 15C

- Number of screws - 2 pcs.

- Rotor (number of blades) - 12 pcs

- Material AISI 304

- Productivity: 250 kg/h/ 1500 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 3,5

- Voltage: 380-400V

You might also like

A professional mixer for the production of mayonnaise, sauces, soups and other homogenized products. The price depends on your production capacity, as well as the technological requirements.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 200l

- Total power, kW: 6

The price is set for the basic version of the installation without additional equipment.

The vacuum homogenizer is designed for a wide range of processes such as for the production of mayonnaise, ketchup, various sauces, confectionery pastes and fillings, liquid or paste like products with a homogeneous structure. It is also suitable for the production of various creams, gels, shampoos and other products in the cosmetic industry.

- Built-in Ultra Shear bottom homogenizer

- Mixing device with movable scrapers

- Tilting version for easy unloading

- Wide range of applications

- Entirely made of food grade stainless steel AISI304/ AISI316 - option

- Compact design

- Lots of additional options to choose from

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 20l/ 50l

- Total power, kW: 2,3/ 2,4

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

Vacuum homogenizer VMG M is the ideal solution for the production of pilot batches and the industrial production of a wide range of products of small and medium production. The price depends on the production capacity.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Max vacuum: -0,8 Bar

- Working volume: 50-80l

The vacuum homogenizer is designed for whipping mayonnaise, ketchup, various sauces, confectionery pastes and fillings, condensed milk, jams and marmalades, canned goods, as well as similar liquid or pasty products with a homogeneous structure.

- Homogenizer in an external circulation loop

- Built-in vacuum generation and retention system

- Modular design with numerous options

- Possibility of automatic dosing of ingredients (optional)

- No additional pump required for loading/unloading

- Automatic top cover lifting system

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 13,5

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Equipment for mixing multi-component mixtures of products, such as vegetable salads with various dressings, including thick and viscous ones like mayonnaise, thick sour cream and other similar sauces.

- Hydraulic tilting system is included in the basic version

- The controls are located directly on the frame supporting structure

- Eccentrically offset working shaft for rotating/tilting the working tank

- Low loading height

- The installation is made entirely out of food grade stainless steel

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 600l/ 1000l

Industrial churning machine available in two capacities. Simple production of butter.

- Geometric volume: 30 l/ 70 l

The periodic drum coating/seasoning machine is designed to saturate and infuse a diverse range of products with flavorful aromas, vitamins, and various taste additives. It is utilized in the production of snacks, chips, cereals, and nuts, offering a wide array of flavor enhancements.

- Mechanical system for tilting the working bowl with fixation points in intermediate positions

- Special perforated blades for gentle product turning

- Powerful drum rotation drive

- Entirely made out of food grade stainless steel AISI304

- Easy control via an inverter (optional): speed control and reverse

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Total power, kW: 0,55

Grinder is used for grinding both fresh meat and food products, such as cheese, fruits.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 380-400V

The vacuum cutter is intended for large processing enterprises dealing in the confectionery, fruit and vegetable processing industries. They are intended for processing food down to a homogenous mixture with minimal air content.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

A spiral mixer with a fixed bowl and an electronic control panel. Available in various different capacities.

- Principle of operation: Batch mode

- Volume: 60l/ 80l/ 120 l/ 160 l/ 200l/ 250 l

- Voltage: 380-400V

The coating machine is designed for uniform application, impregnation of oil and fat mixture, dyes and flavors, enzymes, vitamins and other additives, various products with a high level of hygiene.

- Material: Stainless steel

- Engine power, kW: 2,2

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 281 kg

- Volume: 500l

Vacuum paddle mixers are designed for fast and precise mixing meat-mass in a vacuum. Used in meat production in meat processing factories.┬Ā

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 150l/ 200l/ 300l/ 400l/ 600l/ 850/ 3000

This mixing machine is intended for mixing┬Āsauerkraut with carrots, beets, salt, spices, also for salad, kimchi mixing etc.

- Material: Stainless steel

- Engine power, kW: 2,2

- Volume: 300l/ 600l/

The home cheese making unit is a simple and compact solution for producing homemade cheeses right in your kitchen or for small-scale food production, it can also be used as a laboratory unit for testing new cheese recipes in industrial factories. The unit is designed for processing milk and producing various cheeses and cheese-based products.

- Options to choose electric or gas heating (additional options)

- Special stirrer for automatic mixing, which prevents possible burning of milk

- Visual control during operation thanks to a special safety grid on the upper sectional opening hatch

- Quick-release lid with a stirrer for easy unloading of the product or cleaning of the unit

You can also choose a version of the cooking kettle with a thermometer and an outlet valve, making it suitable for milk pasteurization as well.

- Material: Stainless steel

- Engine power, kW: 0,12 0,18/ 0,25

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

The AA50 adjustable industrial mixer is designed for efficient, high-performance mixing of liquid, viscous and pasty products, as well as for dispersing dry ingredients (pigments, dyes and other materials) in a liquid medium to obtain highly dispersed suspensions, emulsions and pastes.

- Material: Stainless steel

The KWS mixing vessel is engineered for versatile operations, including heating, cooling, and mixing of liquid products, with a maximum heating temperature of 60 ┬░C.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Geometric volume: 100 l

Tilting atmospheric cooking kettle is designed for homogeneous cooking and mixing of sauces, smoothies, jams, spreads, soups, pasta, yoghurts, ice cream, curd desserts, mousse, air confectionery masses, pastry cream, fillings for sweets, waffles, rolls, chocolate, gingerbread, cookies, muffins, rolls, pastilla, marshmallows, meringues, marshmallows, brewed dough, sponge cake.

For a price quote, send us a request.

- Heating: Electricity Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

- Voltage: 380-400V

- Geometric volume: 330

- Dimensions, mm: 1700x1030x1500

A Vacuum cooker is a versatile device used in culinary settings to cook food under vacuum conditions, enhancing flavors and textures while also reducing cooking times.

We offer various different cookers.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 380-400V

The Y-shaped food mixer contains a double vessel with a 90┬░ apex angle. This mixing system is designed for mixing, pre-mixing liquid, viscous, dry and bulk components to obtain homogeneous mixtures.

- Special shape designed for fragile products that may break when exposed to centrifugal force

- Effective mixing of products with different components to obtain a homogeneous structure quickly and with minimal energy consumption

- Gentle mixing and tumbling due to complex random trajectories of product movement

- Compact installation

- Easy maintenance and high level of safety - safety bar with a position sensor

- Material: Stainless steel

- Engine power, kW: 0,75

- Volume: 150l

Grinding mill for continuous grinding of meat and ingredients such as seeds, small bones and cartilages that are unwanted in the final product.

- Engine power, kW: 3

- Principle of operation: Continuous mode

- Voltage: 380-400V