Automatic tilting bratt pan with a stirrer 450

The electric industrial WOK frying pan with a stirrer and automatic tilting system is suitable for intensive thermal processing, allowing you to stew, fry, boil, and concentrate large quantities of both solid and liquid products.

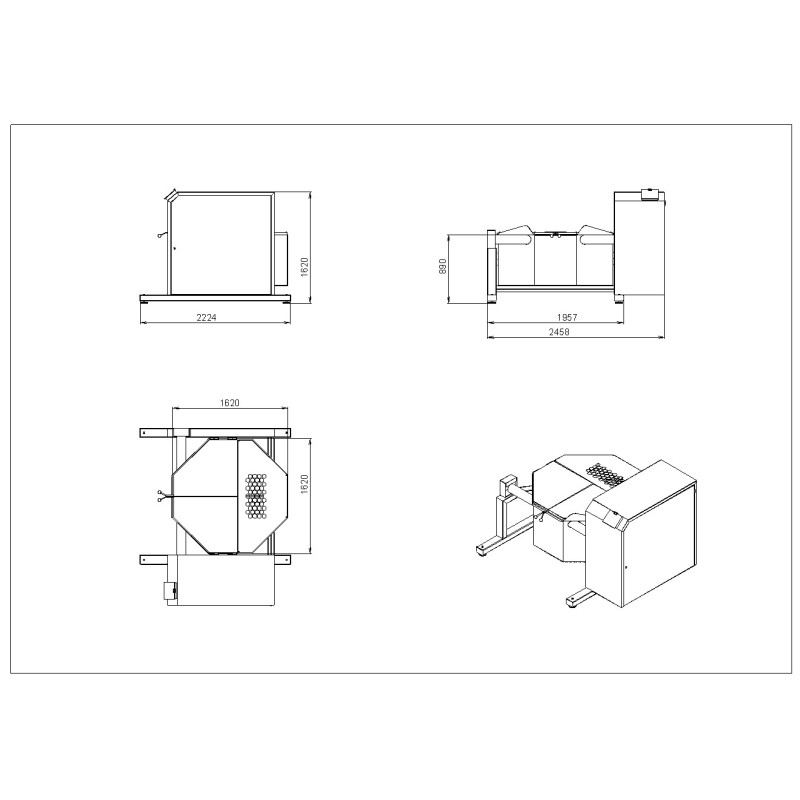

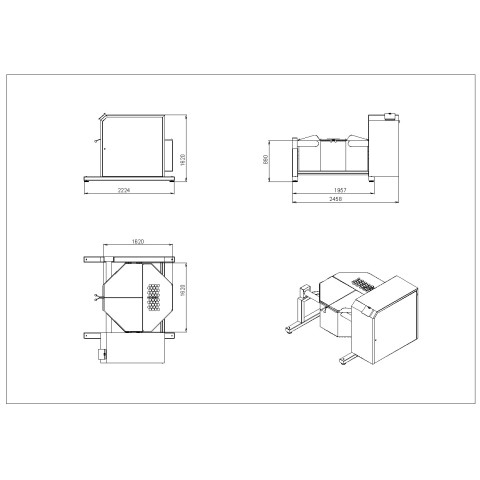

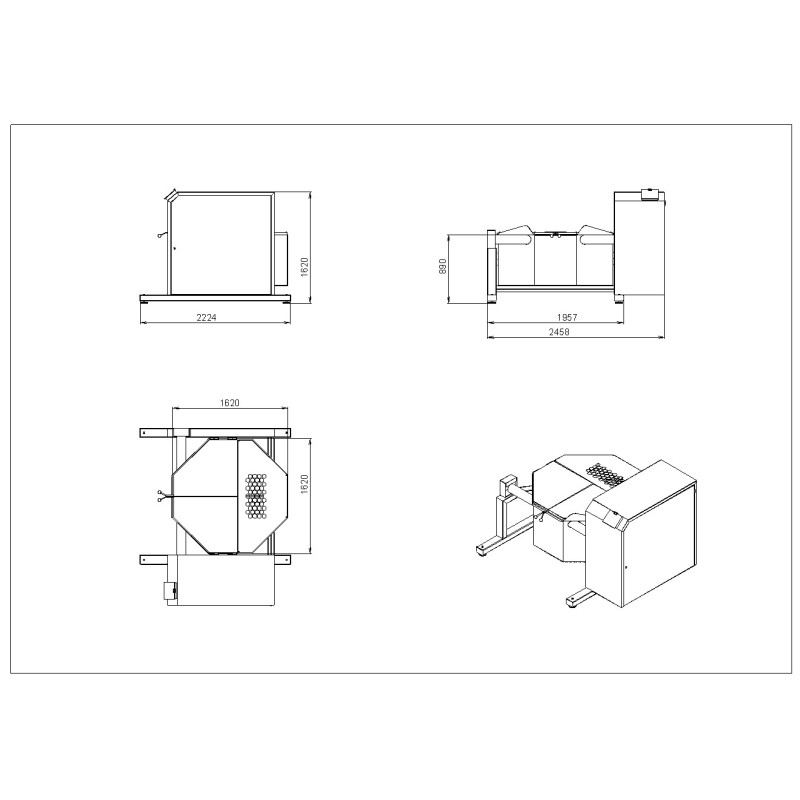

- Special eccentric working bowl tilting system, up to 90 degrees

- Low working height for loading and operation

- Hydraulic system for tilting and unloading the product

- Direct powerful electric heating of the bottom of the working bowl up to 220 degrees

- Heated walls of the working bowl (optional)

- Unloading of the product into standard 200 L trolleys (optional)

Tilting boiler/frying pan with stirrer and direct electric heating comprises a large-area frying surface, in which, thanks to the high walls, you can fully cook and safely unload both liquid and thick, viscous products.

Industrial frying pan with an automatic tilting and unloading system is suitable for processing large quantities of products, including:

|

cooking

|

blanching

|

frying

|

concentrating

|

stewing |

deep frying

|

|

|

|

|

|

|

Advantages

- A large capacity with relatively compact frying pan dimensions.

- Special three-section lid for safe removal of secondary steam from the operator's work area.

- Automatic tilting and unloading system with a built-in hydraulic system.

- High electric heating power due to the multi-layer bottom (sandwich), which quickly, intensively and evenly distributes heat across the entire width of the frying surface. Multi-stage heating power control system for setting an individual frying mode.

- High level of operator safety: automatic tilt, position sensor, holders (handles) of the upper hatch flaps are located in the cold zone, thermal insulation of the working container.

- Maximum emptying of the working bowl without product loss due to the ability to tilt the working container vertically.

- Special mixing device with scrapers installed at different angles for guaranteed product turning and mixing.

- Built-in control panel located directly on the supporting structure of the unit with a protective hygienic housing.

Basic version

The unit comprises a working bowl, eccentrically suspended on the shaft of the supporting structure, equipped with a special bottom - "sandwich" for uniform heating and heat distribution, built-in hydraulic tilt system, control panel with the ability to regulate the heating intensity, mixing device with scrapers.

Options

- Heated walls of the working bowl with a power of 12 kW

- Touch screen control

- 200 l rolling trolley

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 70+12

- Principle of operation: Batch mode

- Volume: 450

- Voltage: 380-400V

You might also like

The price is stated including the unheated conical side panels

The frying pan of the WOK type with direct electric heating is designed for fast and intensive heat treatment of products with a maximum heating temperature of up to 220 degrees. This equipment allows you to saut├®, fry, stew, boil, cook and concentrate various products, including thick and viscous ones thanks to the frame mixing device and an automatic tilting system for unloading the final product.

- Fast and efficient heating of up to 220 degrees

- Automatic tilting and unloading system

- Lid opening sensors for safe operation

- Safe steam exhaust system on the top lid

- Lid latches in the open position

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 45

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 46

- Voltage: 380-400V

The price is indicated with a semi-automatic control panel

The vacuum cooking kettle is designed for use in public catering establishments (restaurants, hotels, catering companies) and small manufacturing businesses. This equipment enables boiling, blanching, frying, evaporation, pasteurization, mixing or stirring.

- A unique multifunctional device

- Possibility to cook/fry under atmospheric or vacuum conditions

- Laboratory version of a Vacuum Fryer

- Built-in condensation and secondary steam removal system

- Intense electric heating

- Sectional basket with a lid

- Built-in system for separating and removing excess liquid from the product

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Volume: 20l

- Oil volume: 8l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The price is set for the basic fryer version without additional modules. If purchasing the fryer together with both of the additional conveyor modules ŌĆō the double conveyor fryer and the paddle conveyor fryer ŌĆō we offer a discount of 300 EUR.

The versatile modular conveyor fryer with a single conveyor belt is used for the continuous frying of a variety of products with a low moisture content, that do not require forced immersion beneath the surface of the oil for even frying.

- Adjustable frying time from a few seconds up to an hour!

- Ability to use the unit as a continuous blancher or boiler for cooking products with a delicate structure

- Modular system, expanding functions with each new module

- Compact, desktop version

- Possibility of periodic frying of products with automatic unloading

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Oil volume: 60l

- Voltage: 380-400V

Wide range of catering equipment for restaurants, canteens and all kinds of food serving establishments.

- Heating: Gas

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 60l/ 80l/ 100l/ 150l/ 200l/ 250l/ 300l

This is a cost-effective solution that meets the special cooking requirements of the Horeca segment. Fitted with a built-in mixer to reduce manual labor and prevent the product from sticking.

- Material: Stainless steel

- Heating power, kW: 4

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 19

A tilting frying pan with a stirrer and indirect electric heating using thermal oil is designed for processing small batches of raw materials, making it suitable for stewing and frying various foods. The automatic stirring feature enhances the preparation of vegetables, fish, meat, and sauces.

- Compact model

- Uniform heating due to the thermal oil

- Simple controls

- Electric tilt of the working bowl

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 18

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 140l

- Total power, kW: 19

This 160L or 220L professional cooking pot is indispensable in the professional kitchen. It allows you to easily prepare the most delicious soups, broths, sauces and creams.

- Material: Stainless steel

- Heating power, kW: 18/ 27

- Voltage: 380-400V

The price is stated including the unheated conical side panels

The frying pan of the WOK type with direct electric heating is designed for fast and intensive heat treatment of products with a maximum heating temperature of up to 220 degrees. This equipment allows you to saut├®, fry, stew, boil, cook and concentrate various products, including thick and viscous ones thanks to the frame mixing device and an automatic tilting system for unloading the final product.

- Fast and efficient heating of up to 220 degrees

- Automatic tilting and unloading system

- Lid opening sensors for safe operation

- Safe steam exhaust system on the top lid

- Lid latches in the open position

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 45

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 46

- Voltage: 380-400V

Wide range of catering equipment for restaurants, canteens and all kinds of food serving establishments.

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: EU

- Voltage: 380-400V

The tilting cooker is produced in 2 versions: with gas or electric heating. The pan is designed for use in the food, hospital, catering industry and in large kitchens for making pasta, stewing and frying meat, fish, vegetables, mushrooms, frozen or semi-prepared, ready-to-cook meals, etc.

- Principle of operation: Batch mode

- Volume: 50l/ 80l/ 120l

- Voltage: 380-400V

We offer wide range of catering equipment for restaurants, canteens and all kinds of food serving establishments. Price depends on the chosen option.

- Heating: Gas Steam

- Productivity: 300 l 600 l 1000 l

- Operation mode: Automatic

- Type of the equipment: Individual machine

The Atmospheric Evaporating Pan efficiently concentrates liquids by evaporating them on a large surface area, while also being suitable for various cooking methods including braising, cooking, and roasting.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

Rectangular tilting pan is designed for heat treatment of a wide range of meat and vegetable products in batch mode with the possibility of subsequent rapid cooling.┬Ā

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 270 l

This commercial frying pan with mixing and a tilt function is designed for frying, saut├®ing, searing, and cooking foods in small amounts of oil in large batches. An independent support frame with a tilt mechanism ensures easy unloading. The pan features adjustable heating with 6 intensity levels, making it suitable for professional kitchens and small food production businesses.

- Efficient heat distribution for even cooking.

- High performance for continuous batch processing.

- Rapid heating thanks to bottom electric contact heating.

- Mobile design allows for easy movement across the work area.

- Easy cleaning and maintenance.

This gas powered professional cooker is indispensable in professional kitchens. It allows you to easily prepare the most delicious soups, broths, sauces and creams.

- Heating: Gas

- Material: Stainless steel

- Working volume: 100l/ 150 l

Tilting bratt pans with mixer are frying the product with continuous stirring. Designed for catering industry, school kitchens, restaurants and food industry. Variants of heating systems: direct electric and direct gas. Capacity: 150, 200 or 300l.

- Material: Stainless steel

- Engine power, kW: 0,75

- Heating power, kW: 42

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: EU

- Volume: 150l/ 200l/ 300l

- Voltage: 380-400V

The Price is specified for the version with a hydraulic lift.

The industrial electric frying pan using thermal oil is an optimal and economical solution for small-scale industrial food production. It allows for low energy and operating costs while ensuring uniform and intense heating for the entire working bowl. The system's thermal inertia helps maintain the required temperature for an extended time, making it effective for frying onions, carrots, saut├®ing flour and vegetables, and preparing sauces, soups, side dishes, stews, and more.

- Low energy consumption

- Uniform heating

- Heated conical sides

- Adjustable heating intensity

- Controller with a hygienic housing directly on the supporting structure

- Lid opening handles located in the cold zone

- Automatic lifting/tilting system

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 26

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

- Total power, kW: 28

- Voltage: 380-400V

- Duplicator volume: 106l

This 550 l professional tilting kettle is gas-fired and is indispensable in the professional kitchen. It allows you to easily prepare the most delicious soups, broths, sauces and creams. With this tilting version, you can make your life even easier.

- Heating: Gas

- Productivity: 500 l

- Material: Stainless steel

Multifunctional pans function as a frying, cooking, and mixing device in one installation.

- Material: Stainless steel

- Principle of operation: Batch mode