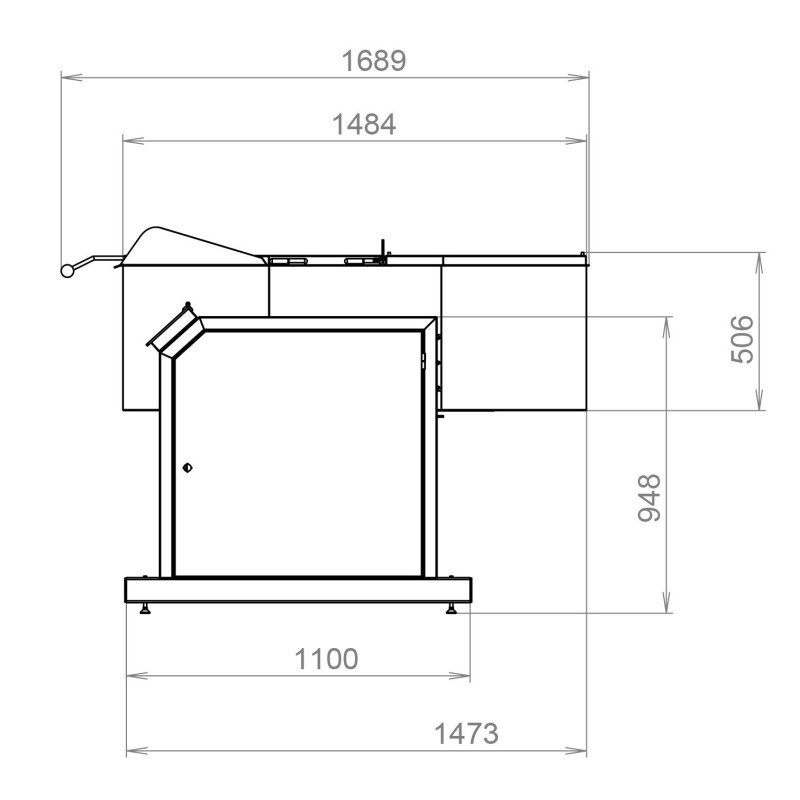

Tilting pan with a stirrer PESK 250/26

The Price is specified for the version with a hydraulic lift.

The industrial electric frying pan using thermal oil is an optimal and economical solution for small-scale industrial food production. It allows for low energy and operating costs while ensuring uniform and intense heating for the entire working bowl. The system's thermal inertia helps maintain the required temperature for an extended time, making it effective for frying onions, carrots, sautéing flour and vegetables, and preparing sauces, soups, side dishes, stews, and more.

- Low energy consumption

- Uniform heating

- Heated conical sides

- Adjustable heating intensity

- Controller with a hygienic housing directly on the supporting structure

- Lid opening handles located in the cold zone

- Automatic lifting/tilting system

The frying pan, commonly referred to as a skillet, serves a crucial role in both pre-processing and cooking various ingredients and raw materials used in the production of semi-finished products. It proves indispensable in crafting popular condiments, such as the crispy fried onion topping, now an integral component of fast and street food.

Due to the large heat transfer area in a frying pan, you can quickly and efficiently cook, boil, fry, stew, bake, deep-fry the following products:

|

|

|

|

|

|

|

|

|

|

Using the large cooking surface equipped with a mixing device, you can efficiently prepare almost any product requiring industrial-scale heat treatment.

Advantages:

- Large heat transfer area ‚Äď 0.94 m2

- 90 degree working bowl angle

- Easily removable mixing device, which ensures quick and convenient cleaning and maintenance

- Built-in autonomous hydraulic station for automatic tilting and unloading of the working vessel

- Heating intensity adjustment (3 degrees)

- Mixing device scrapers are included in the basic version.

- The heat carrier in the form of thermal oil reduces the temperature drop when loading a large amount of cold raw materials

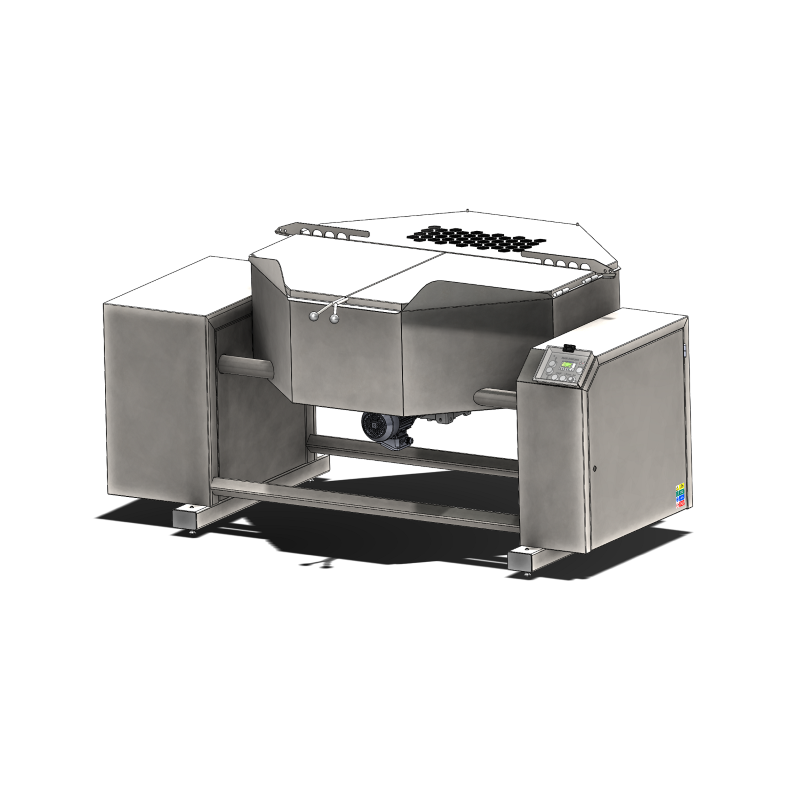

- The frying pan is constructed out of AISI304 food-grade stainless steel, the inner wall of the bowl is made out of polished food-grade stainless steel with a surface roughness of Ra 0.8 microns, the seams are carefully sanded

Basic version

The frying pan consists of a flat, round frying surface with inclined rounded sides, immersed in a special heating jacket containing the heating medium. Heating is carried out with the help of a coolant - thermal oil, providing uniform and intense heating across the entire heat transfer surface.

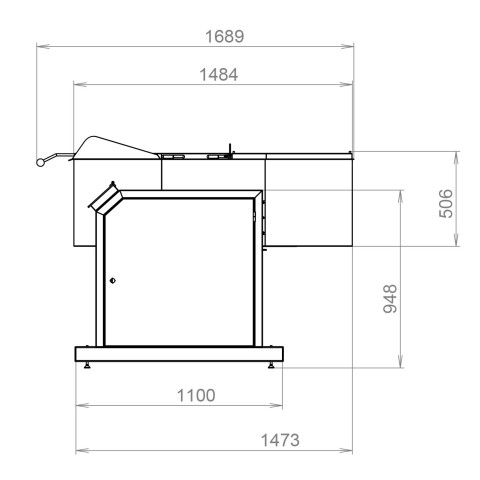

The basic version includes a frying bowl with a heating ‚Äújacket‚ÄĚ, suspended on a supporting structure using the rotary shaft. The rotary shaft is offset relative to the center of the installation in such a way as to facilitate the tilting and unloading of the pan filled with the finished product.

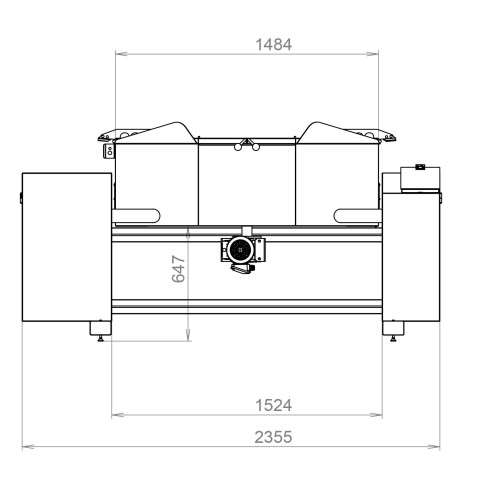

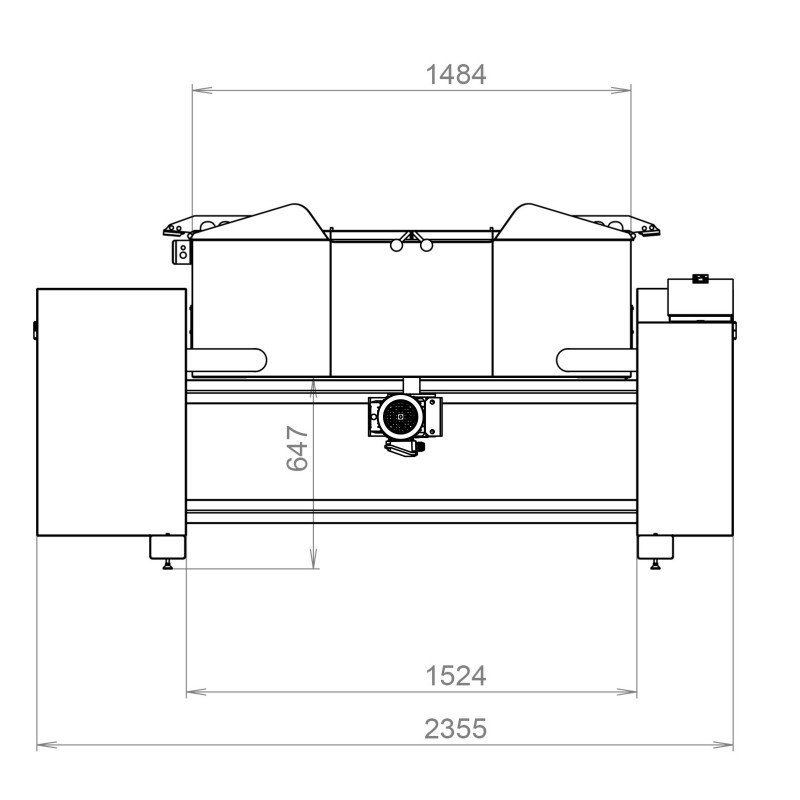

All systems are integrated into the fryer's floor-mounted load-bearing structure. The frying pan control unit is installed on the right support of the supporting structure. A special protective casing protects the control panel from water and product ingress during processing, unloading, washing or cleaning.

An automatic tilting system for the working bowl is installed into the left support of the supporting structure, allowing for tilting to a perpendicular position (90 degrees).

The basic version is equipped with an easily removable hybrid mixing device, the inclination of the working surfaces of which guarantees a tight fit for the scrapers and the frying surface, as well as to the sides of the pan. The mixer also has a vertical blade that performs the function of agitating the product layers; it is installed at an angle to help lift the product and move it closer to the center, thereby turning it over and mixing it into the total mass.

The frying pan is equipped with a sectional opening lid with a special mesh for excess vapor removal. The vapor outlet is located in the stationary part of the lid, at a safe distance from the personnel. Sectional covers are designed in such a way that the holders are positioned in the ‚Äúcold‚ÄĚ zone; the handles are specially elongated and bent for this purpose. Their special bent shape also helps to reduce the force required to lift the lid flaps.

The maximum heating temperature depends on the thermal oil used by the consumer.

Additional options:

- High temperature scrapers made out of food grade stainless steel AISI304

- Additional power for the heating system: +5kW, +9kW

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 26

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

- Total power, kW: 28

- Voltage: 380-400V

- Duplicator volume: 106l