Universal cooking kettle with a mixer Premium

Universal cooking kettle with a built-in mixer, used for cooking and stirring a variety of food products, cosmetic emulsions, creams and much more.

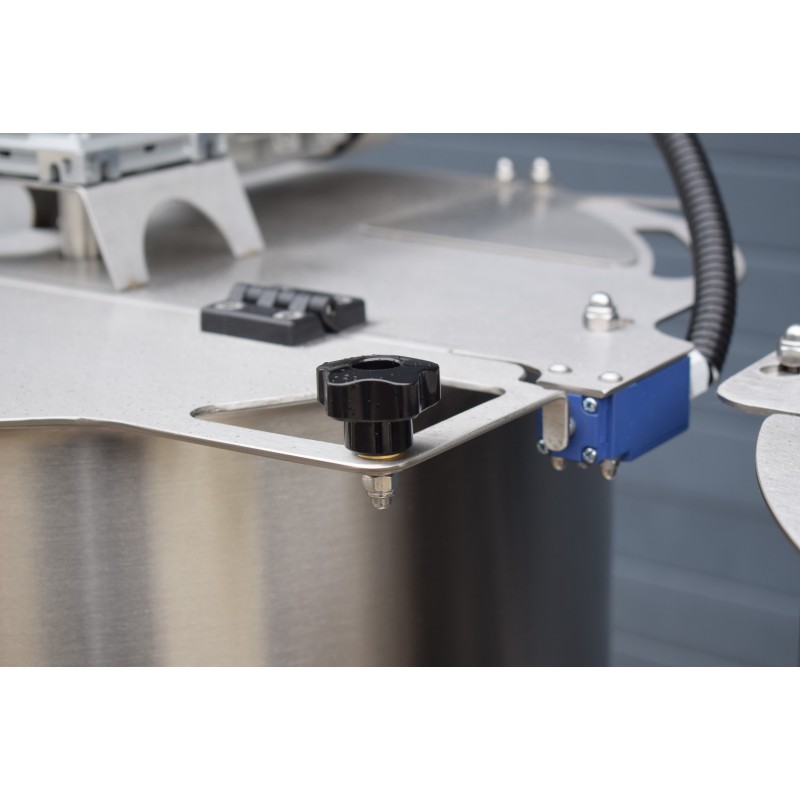

- Easily removable self-adjusting scrapers

- Lid opening sensor for safe stirrer maintenance

- Hygienic temperature sensor for the product

- Large diameter outlet valve

- Safe steam outlet on top of the boiler lid

The cooking kettle is an essential equipment for professional kitchens, designed to meet the needs of constant use in professional settings. It combines a simple design with useful features and high-quality materials, to provide uniform and consistent cooking results across a wide range of dishes.

Additionally, we offer a variety of attachable mixers and scrapers.

The cooking kettle allows you to efficiently cook, mix, boil and concentrate the following products:

|

|

|

|

|

|

|

|

Advantages of the Premium version:

- Completely made out of AISI304 stainless steel

- Used for thick and viscous products

- Mixing device with movable stainless steel scrapers (Teflon scrapers available for lower temperatures) without blind spots, the product is effectively mixed, which ensures that there are no areas for the accumulation of various microorganisms

- Hygienic design for easy and quick cleaning of the unit

- Tank holders on each side for convenient and easy handling of the cooker in the cold zone - safe working conditions for the operator

- High maintenance safety (safety grille, sensor for switching off the operation of the mixing device when the hatch is opened)

- Convenient and simple 230V connection

- Special steam outlets with the handle in the cold zone - safe conditions for the operator

- Easy and quick cover removal for cleaning and maintenance

Basic┬Āversion

The basic version of the cooking kettle includes:

- working vessel,

- mixing device with scrapers,

- reinforced shaft and mixer drive for the possibility of processing thick and viscous products,

- sectional opening hatch for loading the product, visual control, providing access to the mixer without the need to remove the entire cover,

- thermal sensor for the product enables visual monitoring of the processing temperature,

- hatch opening safety sensor,

- large diameter outlet valve for unloading the product at the bottom of the working tank.

The cooking pot is made out of polished food grade stainless steel (internal surface - RA Ōēż 1.6 ┬Ąm). Manufactured in EU to meet high safety standards. The cooking kettles are available in 50, 100 and 150 liter capacities.

Our cooking kettles are suitable for induction heating and can be used with our reinforced induction stoves designed for 50ŌĆō100 L pots.

For easy transport of our large cooking pots, we recommend using a mobile base with caster wheels.

Operating principle

The cooking kettle is made out of high quality stainless steel, which ensures long service life and resistance to corrosion. Robust design and reliable components guarantee stable operation and minimal maintenance costs.

The caramel cooking pot is equipped with a mixing device - a geared agitator that allows you to constantly stir and mix the product during cooking in order to avoid burning the product at the bottom of the unit, as well as to ensure uniform heat transfer and heat distribution in the product during processing.

Heating can be carried out by contact heating from an external source up to a maximum of 220┬░C. The heating can be performed with a gas or an electric stove, which are offered as additional options. It is not recommended to use Teflon scrapers with the electric stove as the heating source.

The cooking kettle with automatic mixing offers various operating modes such as boiling, tempering, cooking, concentrating and much more, which in turn allows you to prepare a variety of sauces, jams, syrups and other liquid paste like products with different textures and tastes.

The cooker's user-friendly design enhances convenience and efficiency in the production process.

Options/Additional equipment

- Electric stove-stool

- Side scrapers (video can be seen here)

- Special valve for thick products

- Frequency converter

- Safety grid for visual control

- Selecting the rotation speed of the mixing device depends on the gear motor (from 14.5-373 rpm), when choosing an inverter - up to 600 rpm

- Directional stainless steel hopper with a plastic cone on top for loading components

- Extended version of the outlet valve

- 25 cm Probe thermometer (-50┬░C to +150┬░C)

If you're looking for a cooking kettle with a mixing device for better dissolution and the production of various emulsions -┬Āwe recommend the high-speed mixer TurboMix.

If you're interested in processing thicker products like caramel or syrup, we also offer a heavy-duty cooking kettle with powerful mixing, suitable for viscous materials.

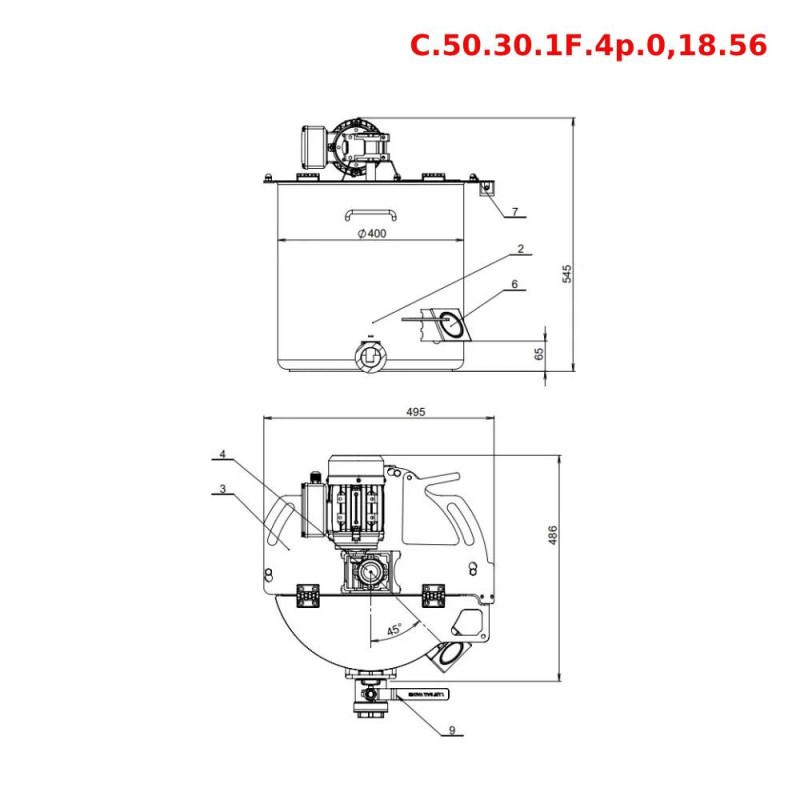

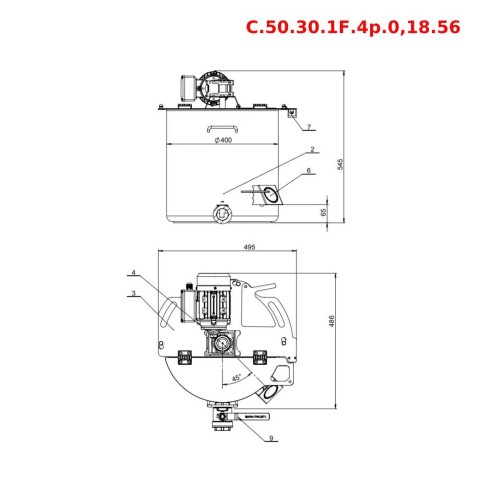

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

You might also like

The 5 kw stool-type electric heating stove with a diameter of 40 cm is designed to heat large pots and pans with a volume of up to 100 liters.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Type of the equipment: Optional equipment

The durable single gas stove serves a versatile purpose, suitable for heating large cooking kettles. 7 kW.

- Heating: Gas

- Heating power, kW: 7

Designed for a load of up to 200 kg!

The 5 kW induction cooker is the best alternative to traditional electric and gas stoves. It reduces energy costs, improves safety, and minimizes air pollution, making it suitable for both stationary kitchens and mobile catering setups. Its compact design also makes it a practical choice for small kitchens where space and efficiency matter.

- 10-step power (500ŌĆō5000 W) or 10-step temperature (60ŌĆō280 ┬░C) control

- Connection - 230 Volt

- Compact dimensions: 410x500x200 mm

- Temperature range from 60 to 280 degrees

- Heating power, kW: 5

- Voltage: 220-230V

A hydraulic crane hoist with a hook is a mechanical device designed to lift and move heavy machinery or engines, commonly used in industrial settings as well as automotive repair for safe and efficient handling of heavy loads.

- Type of the equipment: Optional equipment

A thermometer is a precision tool used to measure product temperature in food processing, ensuring accurate control during cooking, mixing, and other food production processes. It helps to maintain consistency, optimize processing conditions, and meet safety standards in industrial food processing equipment like cooking kettles, blanchers and fryers.

- Material: Stainless steel

- Type of the equipment: Optional equipment

The innovative cooking device combines the advantages of cooking with automatic mixing and compact dimensions.

- Heating: Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 50l/ 150l/ 200l/ 300l/ 500l

A modern cooking and mixing device with a wide range of applications in confectionery, bakeries, catering establishments.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 200l/ 300l/ 500l

This electric cooking pot has a volume of 60 liters and is used to prepare a large number of dishes. It is comfortable to use and easy to clean.

- Material: Stainless steel

- Volume: 60l/

- Voltage: 380-400V

This multifunctional cooking machine with two baskets is designed for different ways of use and is suitable for a lot of variety of businesses - any enterprise or any participant of the HoReCa market. With the help of this equipment, you can cook, pasteurize, or blanch.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 135 +135 / 220+220

These gas boiling cookers are manufactured for professional kitchens and also for other food processing factories. This is 150l capacity.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 150l

This is a 400 l capacity heating boiler, we offer different capacity commercial cooking boilers.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 25

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 400l

- Voltage: 380-400V

Cooking kettles for cooking under pressure are designed for highly efficient heat treatment of a wide range of food products at temperatures up to 110 ┬░C and pressure up to 0.5 bar.

- Heating: Electricity Steam

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 220 l/ 500l/ 600l/

This kettle is designed to be used by catering companies, canteens, restaurants, small productions and food manufactures.┬Ā

- Heating: Steam

- Material: Stainless steel

- Volume: 100l/ 150l/ 200l/ 300l/ 500l

A vacuum evaporator is a device used to evaporate liquids at lower temperatures by creating a vacuum environment, which reduces the boiling point of the liquid and enables efficient evaporation without thermal degradation of sensitive materials. Working volume up to, l: 1900 l.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: up to 1900 l

This 160L or 220L professional cooking pot is indispensable in the professional kitchen. It allows you to easily prepare the most delicious soups, broths, sauces and creams.

- Material: Stainless steel

- Heating power, kW: 18/ 27

- Voltage: 380-400V

Double-jacket stainless steel cooker for marmalade and jam production.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Principle of operation: Batch mode

- Volume: 100l/ 200l/ 300l

- Voltage: 380-400V

Heating: integrated electric. Price depends on the production capacity and product.┬Ā

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l

Unbeatable price, excellent cooking results, designed to be placed in tight spaces where sharp edges or corners may create problems. We have different capacities boiling cookers.

- Material: Stainless steel

- Heating power, kW: 18

- Volume: 150l

- Voltage: 380-400V

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

This 265 liter stainless steel cooker is great for boiling or roasting a variety of ingredients. It is made of stainless steel and equipped with a convenient drain valve.

- Heating: Gas

- Material: Stainless steel

- Principle of operation: Batch mode

The automatic screw cooker is designed for cooking or blanching various food products in continuous mode, saving both time and energy during production.

- Heating: Mixed

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia