Plant-based milk & beverages production system

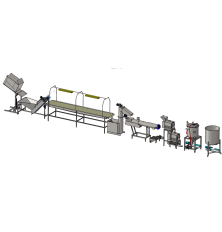

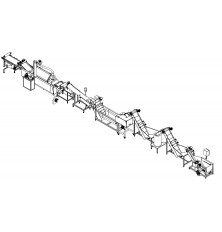

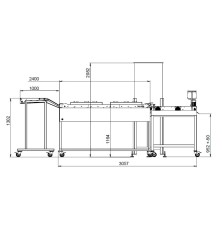

Complete set of equipment for processing shelled beans, and the production of a soy base with a capacity of 800-1000 liters per hour.

The equipment set for the production of milk alternatives includes 4 main modules:

Module 1 - moisture-thermal preparation of seeds, which consists of a washing conveyor and a vacuum cooker,

Module 2 â extraction module, which consists of a vegetable milk homogenizer (Veggie Milk) and containers for a NaHCO3 solution,

Module 3 - suspension separation and sterilization, consists of a centrifuge, a press as an additional option, storage tank, cooler for the insoluble sediment,

Module 4 - deodorization of soy base, consists of a sterilizer, a holder, a deodorizer / deaerator.

The quality of the resulting base and mass (insoluble residue) for soy:

- Foundation - 85%

- Weight - 15%

The complete set of each module varies depending on the recipe of the Customer, can be changed, corrected or supplemented.

Module 1 provides:

- washing with simultaneous transportation of soybean seeds,

- moisturization.

Washing conveyor for washing and subsequent loading of grains and legumes made out of stainless steel.

In case the raw materials are supplied in big bags, the system can be equipped with a station for unloading big bags. Washing is carried out using a washing conveyor with a hopper.

The washing conveyor is designed for washing raw materials and loading them into the basket of a vacuum pan. The conveyor is designed with adjustable speed, equipped with a system of watering / spraying water over the working belt, in the lower part there is a receiving hopper.

Washing water is supplied into the receiving hopper, which removes contaminated water through the outflow valves and discharges it into the sewerage system. The conveyor belt gradually takes the raw material out of the bunker, during the movement it is additionally rinsed due to the nozzles of the irrigation system located above it, after which the washed product enters the basket of the diffuser.

It consists of a receiving hopper, a conveyor with a drive (motor-reducer), an irrigation system with nozzles, a frequency converter is provided for adjusting the speed of movement.

Vacuum diffuser intended for pulsation-saturation of leguminous products with water 350/700 (soaking alternative)

Vacuum diffuser for saturating raw materials with liquid. The principle of operation is based on vacuum diffusion, when, due to the extraction of air from the working container and the product in it, various solutions / liquids and additives are absorbed from the opened pores, enveloping the surface of the product. With regular release of the vacuum, the intensity of saturation of the product with solutions/compositions increases.

It consists of a working container, into which with the help of a hoist, a basket with the product is loaded, liquid is supplied into the working container using a dosing pump. The unit is equipped with a vacuum system with a residual pressure of up to 0.2 bar.

- The volume of the working basket is 350 liters.

- Capacity - 700 liters.

- Material: AISI304 stainless steel.

The hoist and basket lifting system are not included in the scope of delivery.

The basket is equipped with an opening bottom hatch for easy and convenient unloading, the size of the cell is determined based on the specific product. The standard cell size for the basket is 1 mm.

The package includes 1 basket.

It is recommended to purchase 2-3 extra baskets for convenient continuous operation.

Module 2 is responsible for hydrodynamic thermal extraction of substances due to high shear cutting of intercellular membranes:

- mixing ingredients

- grinding,

- hydration,

- adding a solution of NaHCO3 of the required concentration and pH until achieving the complete extraction of extractive substances from seeds,

- partial pasteurization due to direct steam injection.

Extraction is carried out with the help of two technological methods: the use of chemical reactions and mechanical processing (combined method)

For the above-described rated capacity, two parallel units must be installed.

Veggie Milk 120/150 plant milk homogenizer for extraction and the creation of base suspension

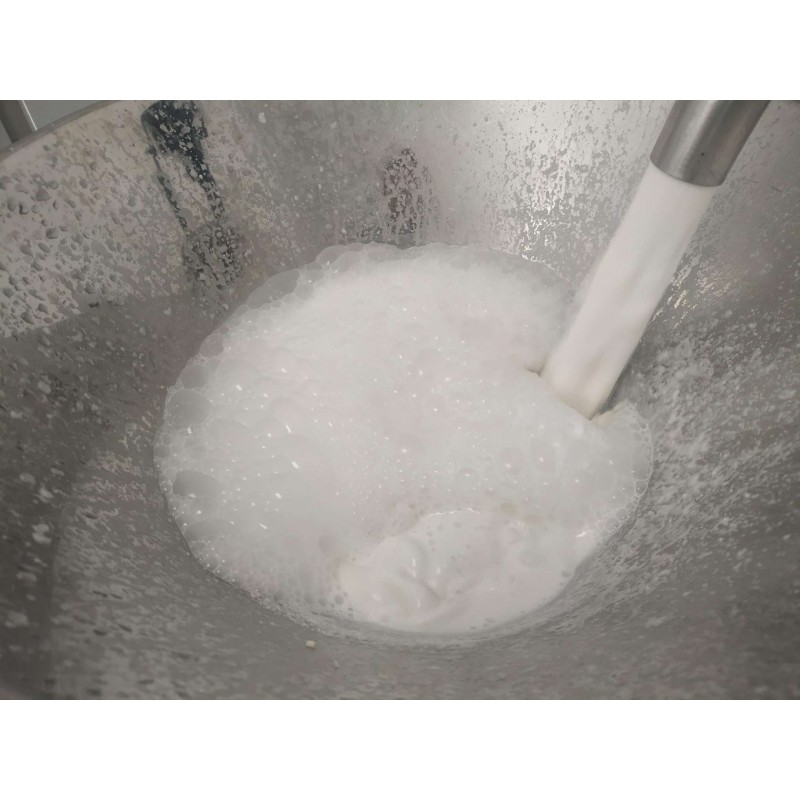

The plant-based milk homogenizer is used for hydrodynamic thermal extraction of substances from legumes & nuts and creating a finished base suspension. It consists of a cylindrical work vessel with a two-layer casing with thermal insulation, a circulation circuit and an Ultra Shear in-line homogenizer located in the lower part of the plant, equipped with direct steam supply to the product.

The pre-saturated raw material is unloaded from the basket of the vacuum pan into the homogenizer with the help of a hoist through the upper body of the plant, which opens in sections. The lid is equipped with a safety system that disables the operation of the homogenizer when the top hatch is opened.

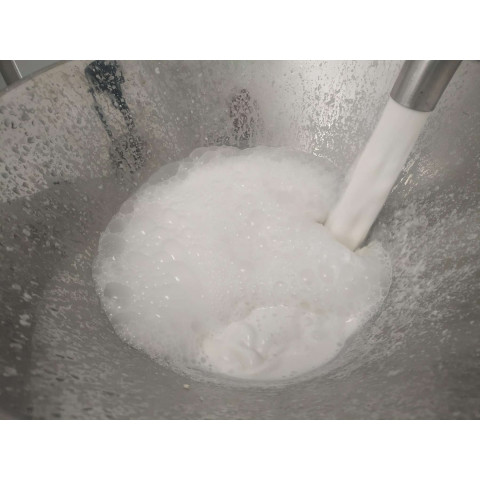

The homogenizer performs grinding in a humid environment with the external circulation circuit turned on.

Steam is supplied to the lower part of the apparatus through a special bubbling system, due to which intensive heat transfer is carried out, hydrodynamic mixing, fusion, and absorption are carried out.

A cooling system (open type) is provided for the mechanical seal of the homogenizer. In one cycle, up to 100 liters of base with a particle size of up to 100 microns can be produced.

- Processing time - 5-10 minutes

- Installed power - 7.5 kW

- Material: AISI304 stainless steel.

Customer's purified saturated steam source. (not included)

Two homogenizers are interconnected by piping for alternate supply of mass to the separator.

Module 3 provides:

- separating the insoluble residue (mass) from the soy base,

- pressing okara with a press,

- cooling of the insoluble residue.

The separation of the base is carried out in a universal centrifuge. After the centrifuge, the insoluble residue (soybean mass) is sent into a press for additional squeezing of okara, and then cooling. After the centrifuge, the soy base is subsequently collected in a collector and then sent for sterilization.

Separator - atmospheric centrifugal plant with the possibility of continuous loading and a removable working basket 80 l

The separator is designed to separate the liquid form of the base from the thick residue with the help of centrifugal force when the basket rotates in the working container.

The container is mounted on a working frame with a vibration damping system, inside, a working basket is installed on the shaft. The mass is fed through the upper manhole for the separator from vegetable milk homogenizers. The liquid form of the mass flows into the chute and is discharged into the storage tank, the thick form fills the basket, which, due to rotation, separates the remaining liquid from the mass.

- The standard cell size of the basket is 0.5 mm (included in the price). The grid for the product can be selected separately by the customer.

- The installed drive power of the centrifugal unit is 2.2 kW

- Material: AISI304 stainless steel.

Equipped with a pump without seal ("dry running") to supply the liquid form of the base into the accumulator.

Belt press for dehydration of mash, and squeezing out dense sediment

It is used for additional extraction of dense sediment. The mass is placed on the belt, which is advanced and pressed by the press cylinder, the liquid immediately begins to flow into the tray, the distance between the press cylinder and the liquid collection tray is reduced to prevent foaming.

Installed capacity - 0.37 kW

For proper operation, it is necessary to provide a compressed air drive (not included in the scope of supply) with a pressure of 6-10 bar.

Continuous screw cooler with a duplicator for the coolant

The screws carry out the function of mixing, intense heat transfer during mixing, pushing and supplying the product for further processing or packaging.

A coolant is supplied into the duplicator - cold water for the cooling process.

The unit is equipped with a frequency converter for adjusting the rotation speed of the augers and the speed of product advancement.

- Duplicator (Jacket) for coolant - 0.5 bar (g)

- Installed drive power - 0.75 kW

- The equipment is made entirely out of stainless steel AISI304.

Accumulative storage tank (emergency) with a volume of 1000 l with a level tube

Designed to accumulate the base after periodic operation of the installations (vacuum diffuser and vegetable milk homogenizers) to ensure continuous supply to the sterilizer.

Equipped with a level tube.

Atmospheric tank with a âjacketâ for a coolant with a pressure of up to 0.5 bar (excess)

Additionally, based on the level of automation, the issue of equipping an automatic level sensor can be considered.

Module 4 includes:

- sterilization

- aging

- deaeration/deodorization

Sterilization of the soy base is carried out in a sterilizer through direct contact of the suspension with live steam. After that, it is aged and then deodorized under vacuum. The base enters the vacuum apparatus through the holder, where instantaneous degassing takes place with a simultaneous decrease in the temperature of the product (cooling).

After the deodorizer, the sterilized soy base enters the receiving storage tanks (customer storage tanks).

Sterilizer

The sterilizer is designed for continuous heat treatment of the product.

It comprises a cylindrical apparatus, inside which a pipe with holes is located, steam is supplied in a counter flow with respect to the product flow supplied from below. When water vapor is injected, small vapor bubbles penetrate the heated liquid product, raising the temperature to about 130°C. This heating process is one of the fastest, suitable for heating heat sensitive products to process products with low viscosity.

Since the steam is in direct contact with the product, it is necessary to carefully prepare and clean the steam from drinking quality water.

Heat carrier - saturated purified steam, source and supply of purified saturated steam: source, filter, control, shut-off, safety fittings are not included in the delivery set.

The product is fed into the sterilizer using a screw pump.

AISI 304 material.

The retainer for aging / holding oven

Designed to hold the product at the temperature of pasteurization/sterilization.

The holder is a coil consisting of pipes and elbows connected to each other by means of nuts, mounted on a support. After sterilization, the blower with live steam enters the holder, and, passing through it, withstands 15-2- seconds at the set temperature, then removes the product furthering it into the deodorizer / deaerator.

Deodorizer / Static Deaerator

Designed for removing odors from the base.

Foods containing fat absorb substances from the environment, that impart an extraneous odor and taste. Therefore, products can acquire foreign smell and taste. Deodorization is used to counter it. The essence of the deodorization process is the processing of hot raw materials under conditions of rarefaction. Most odorizing substances form azeotropic mixtures with water vapor. The boiling point of the resulting mixtures is lower than the boiling point of water. This allows steam distillation of the odorants.

It is a universal vacuum reactor with a vacuum generation system.

The base is fed from the holding tank into the evaporation chamber, where it spreads in a thin layer using an "umbrella" supply system (an umbrella is a disk with a wide diameter, practically repeating the diameter of the working chamber), the moisture, falling into a zone of low pressure in a thin layer, is intensively evaporated and in the form the vapor-air mixture is drawn out of the vacuum chamber. This version applies to Static models.

- Geometric volume - 100 l.

- Vacuum system (vacuum generator) with residual pressure up to 0.2 bar

- Material â AISI304

Additionally, centrifugal pumps can be selected (for supplying the NaHCO3 solution, for unloading the product from the separator and filling the storage tank), for supplying the base to the sterilizer and holding tank, we offer various screw pumps from European manufacturers.

The control system depends on the requested degree of automation and is agreed upon additionally after selecting the equipment.

- Productivity: 800 l/h

- Material: Stainless steel

- Country of origin: Slovakia