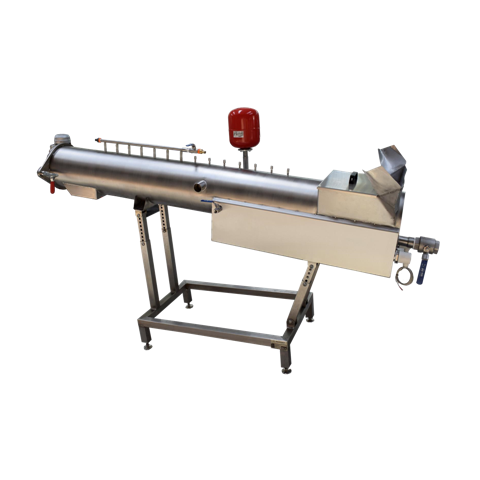

The screw cooker efficiently mixes and cooks ingredients in a continuous process, ensuring uniform heating and thorough blending of flavors in the final product.

Suitable products:

- vegetables,

- mushrooms,

- french fries,

- soft seafood like mussels without armor or shrimps,

- many others.

Adjustable legs

Inclined screw cooker are an effective method of moving certain materials in a production line while blanching or cooking them. Our inventory is composed of stainless steel screw cookers. It is possible to adjust the feet of the cooker to fit other equipment in your production line

Universality

The equipment can be used for many different processes such as blanching, cooking or defrosting raw materials.

Processes:

- Softening process

- Enzymes deactivation - it reduces or interrupts enzymes action which can damage the product color, taste and smell.

Advantages of the screw cooker

One of the screw cooker advantages is its universality. The plant can be configured in the way to process different kind of products, such as seafood, mushrooms and vegetables. It is possible to adjust the equipment to fit your production line.

How it works

Screw cooker is equipped with a product feed hopper. Hot water is located at the bottom of the device. The product is transported by movement of the screw. At the top of the device, nozzles for water injecting are placed.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

You might also like

The Batch Blancher Cook & Chill is designed for boiling, frying, heating and cooling of a wide range of products.

Price depends on the chosen option.┬Ā

- Material: Stainless steel

- Country of origin: Slovakia

- Voltage: 380-400V

The blancher is designed for blanching and cooking fruits, vegetables, meat, fish, mushrooms.

The price depends on the selected options.

- Material: Stainless steel

- Working volume: 700l

- Geometric volume: 1000 l

- Dimensions, mm: 3180x1860x1080

The blancher is primarily intended for blanching lumpy products such as mushrooms and vegetables.

Price depends on the chosen options.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 450

- Geometric volume: 550 l

- Dimensions, mm: 1770x899x997

Price depends on the required production capacity.

- Material: Stainless steel

- Heating power, kW: 90

- Dimensions, mm: 3549x1919x1490

- Blanching section, mm: 400x1800

- Cooling section, mm: 400x900

Model VMG S is an effective and reliable vacuum homogenizing unit designed to produce a wide range of liquid, pastry and viscous products with different requirements for the production conditions.

A vacuum cooker is used in the food processing industry to cook ingredients under reduced pressure, typically in a vacuum environment. This method allows for precise temperature control and faster cooking times while preserving the quality and flavor of the ingredients.

We offer different vacuum cookers.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 2500 l

The stated price does not include the steam generator

The unique sectional cooking kettle is intended for high-performance cooking/blanching/frying of a wide range of products with subsequent cooling to avoid damaging their structure. An essential part of this technology is the efficient cooling section, necessary for halting the cooking process after unloading. This function is also necessary when processing vegetables to the "aldente" state, when vegetables retain their structure and natural color after thermal treatment. This model provides heating by direct injection of purified steam into the heating section (steam generator - option).

- Suitable for cooking small-sized products

- Fast and intense heating due to direct steam injection

- Intensive hydro-stirring

- Automatic basket lifting system

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 2x250l/ 3x250l

- Voltage: 380-400V

- Working volume: 2x175l/ 3x175l

A Vacuum cooker is a versatile device used in culinary settings to cook food under vacuum conditions, enhancing flavors and textures while also reducing cooking times.

We offer various different cookers.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 380-400V

The 1000 L vacuum cooker is used for cooking, concentrating, and evaporating food products under reduced pressure, allowing gentle heat treatment, improved flavor retention, and precise control of moisture content.

For a price quote, send us a request.

- Heating: Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 1000l

- Dimensions, mm: 1385x1283x1892

Tilting pans with mixers cook the product with continuous stirring and subsequently discharge the food into receiving trolleys, ensuring the discharge spout remains at a constant height from the ground. Designed for the catering industry, large kitchens, school cafeterias, restaurants, and other food production businesses.

- Heating: Electricity Gas Steam

- Material: Stainless steel

- Engine power, kW: 0,75

- Heating power, kW: 24/ 36/ 48

- Volume: 200l/ 300l/ 500l

- Steam consumption, kg/h: 85/ 100/ 115

Unbeatable price, excellent cooking results, designed to be placed in tight spaces where sharp edges or corners may create problems. We have different capacities boiling cookers.

- Material: Stainless steel

- Heating power, kW: 18

- Volume: 150l

- Voltage: 380-400V

Chocolate heating pump is the perfect solution to upgrade your production line. You can easily connect the pump to any device (such as a chocolate enrobing machine).

- Principle of operation: Batch mode

- Voltage: 380-400V

The price is stated including the unheated conical side panels

The frying pan of the WOK type with direct electric heating is designed for fast and intensive heat treatment of products with a maximum heating temperature of up to 220 degrees. This equipment allows you to saut├®, fry, stew, boil, cook and concentrate various products, including thick and viscous ones thanks to the frame mixing device and an automatic tilting system for unloading the final product.

- Fast and efficient heating of up to 220 degrees

- Automatic tilting and unloading system

- Lid opening sensors for safe operation

- Safe steam exhaust system on the top lid

- Lid latches in the open position

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 45

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 46

- Voltage: 380-400V

Universal cooking kettle with a built-in mixer, used for cooking and stirring a variety of food products, cosmetic emulsions, creams and much more.

- Easily removable self-adjusting scrapers

- Lid opening sensor for safe stirrer maintenance

- Hygienic temperature sensor for the product

- Large diameter outlet valve

- Safe steam outlet on top of the boiler lid

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

Universal cooking kettle with a built-in steam generator up to 0.5 bar, frame stirring device and an automatic tilt and unloading system is a convenient and safe solution for processing various liquid products in large volumes.

- Safe design with a jacket (duplicator) and outer casing with insulation

- Intensive steam heating through the jacket using the built-in electric steam generator

- Automatic multi-stage tilt and unloading system

- Frame stirring device for dissolving, mixing, kneading ingredients

- Unloading of the product into rolling carts is possible due to the offset tilted axis

- Heating: Mixed

- Material: Stainless steel

- Country of origin: Slovakia

- Total power, kW: 13,5

The universal cooking boiler with an integrated homogenizer and a capacity of 1200 liters is designed for efficient mixing, heating, cooking and homogenizing of products for food, pharmaceutical and cosmetic industries such as jams, marmalades, syrups, fruit juices, nectars, beers, creams, ointments, soaps and many others.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

Universal cooking kettle for thick mixtures: it works on the principle of a water bath and can be used in confectionery shops, bakeries and other catering establishments. Offers a wide variety of models.

- Mechanical tilting system for unloading

- Safety grill for the mixer drive

- Built-in electric heating up to 150 degrees

- Mobile support structure on wheels

- Heating: Electricity

- Principle of operation: Batch mode

- Volume: 30l/ 60l/ 80l/ 120l

The compact line of double-type vacuum cooking kettles comprises a complex of batch food cooking units designed for periodic thermal processing, vacuum mixing, and deaeration of various products under sub-atmospheric pressure.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 2x300l/ 2x600l

Wide range of catering equipment for restaurants, canteens and all kinds of food serving establishments.

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: EU

- Voltage: 380-400V

Round cooking boiling pan combines together the advantages of cooking with automatic mixing. Designed for catering industry, school kitchens, restaurant kitchens or food industry. Capacity ranges from 100l to 500l. The available heating options are - steam boiling or indirect electric heating.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 200l/ 300l/ 500l