This batch catering cooking equipment is made in four types of supply: oil, gas, electricity, and steam.

The catering cookers are designed to operate in automatic mode by using the controller to control the technological process.

BENEFITS OF A PROFESSIONAL HEAT BOILER / COOKER:

Heat Boilers are fed with oil, gas, or electricity and have a double heat jacket. In the case of a heating boiler with an electric supply, the heaters are filled with heating oil shell heat transfer s2. The use of a double heat jacket has two advantages:

- The first advantage is that the product doesnŌĆÖt burn.

- The second advantage is that the oil is cooling down more slowly so that in everyday work it starts from a higher temperature than the ambient temperature, thanks to which it heats up more quickly.

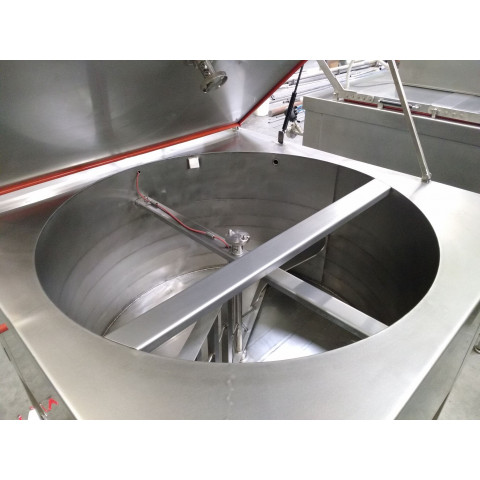

When melting lard in heat boilers, a rotary arm is used to mix the product during the process. External dimensions can be changed according to the customerŌĆÖs needs. Double heated jacket filled with heating oil Shell Heat Transfer Oil S2. 3 x temperature measurement: oil, water, batch construction, a basket made entirely of stainless steel.

COMMERCIAL COOKER 300L

- supply medium: electricity, steam, oil, gas

- installed power (kW): 15

- power supply (V/Hz): 3x400/50

- external dimensions [LxWxH mm] 600x1300x1100

- controller: mikster INDU 50

- water connection: 1/2 inch

- External dimensions can be changed for the customer's needs

CATERING COOKING EQUIPMENT 400L

- supply medium: electricity

- installed power (kW): 25

- power supply (V/Hz): 3x400/50

- dimensions [mm] 1300x1250x1050

- controller: mikster INDU 50

- water connection: 1/2 inch

- Double heat jacket filled with heating oil Shell Heat Transfer Oil S2

- water connection: 3/4''

BATCH COOKING MACHINE 500L

- supply medium: electricity

- installed power (kW): 30 kW

- power supply (V/Hz): 3x400/50

- dimensions [mm] 1450x1250x1050

- controller: Mikster INDU 50 (among others function of the timer, that allows to set time of beginning of cooking)

- water connection: 3/4''

- Double heat jacket filled with heating oil Shell Heat Transfer Oil S2

- 3 x temperature measurement: oil, water, batch

- construction, a basket made entirely of stainless steel

PROFESSIONAL KITCHEN EQUIPMENT 600L

- external dimensions ŌĆō 1600x1250x1050mm

- microcontroller: Mikster INDU 50

- measurement of three temperatures (oil, water, batch)

- max temperature of oil: 140 C

- Double heat jacket filled with heating oil Shell Heat Transfer Oil S2

- heat jacket capacity: 200 L

- water connection: 3/4''

- water drain: 2''

PROFESSIONAL TILTING COOKER 800L┬Ā

- external dimensions - 1900x1250x1050mm

- heating medium ŌĆō electricity

- heating power- 50 kW

- microcontroller: Mikster INDU 50

- measurement of three temperatures (oil, water, batch)

- max temperature of oil: 140 C

- Double heat jacket filled with heating oil Shell Heat Transfer Oil S2

- water connection: 3/4''

- heat jacket capacity: 250 L

HEAT BOILER WITH TILTING BASKET 1000L┬Ā

- external dimensions - 2100x1250x1050 mm

- heating power- 60 kW

- microcontroller: Mikster INDU 50

- measurement of three temperatures (oil, water, batch)

- max temperature of oil: 140 C

- water connection: 3/4''

- Double heat jacket filled with heating oil Shell Heat Transfer Oil S2

- heat jacket capacity: 300 L

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l/ 400l/ 500l/ 600l/ 800 l / 1000l/ 1200l/

You might also like

Automatic cooker made for continuous batch production. Different types of food can be boiled, like pasta, rice, vegetables, meat etc. Options: direct gas, indirect steam boiling or direct electric.

Price depends on chosen option.┬Ā

- Heating: Electricity Gas Steam

- Material: Stainless steel

- Heating power, kW: 2x25

- Volume: 2x135l/ 2x220l

- Steam consumption, kg/h: 2x70/ 2x100

The Batch Blancher Cook & Chill is designed for boiling, frying, heating and cooling of a wide range of products.

Price depends on the chosen option.┬Ā

- Material: Stainless steel

- Country of origin: Slovakia

- Voltage: 380-400V

The blancher is primarily intended for blanching lumpy products such as mushrooms and vegetables.

Price depends on the chosen options.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 450

- Geometric volume: 550 l

- Dimensions, mm: 1770x899x997

The steam cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, pots, pasta, milk dishes, teaspoon cooking, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared, ready-to-cook meals, heating or steaming.

The cooking equipment is not suitable for roasting or baking.┬Ā

- Material: Stainless steel

- Volume: 100l/ 150l/ 200l/ 300l

- Steam consumption, kg/h: 50/ 60/ 70/ 90

The gas cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, pots, pasta, milk dishes, teaspoon cooking, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared meals, heating or steaming. This cooking equipment is not suitable for roasting or baking.

- Heating: Gas

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 80l/ 100l/ 150l/ 200l/ 300l

These gas boiling cookers are manufactured for professional kitchens and also for other food processing factories. This is 150l capacity.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 150l

Wide range of catering equipment for restaurants, canteens and all kinds of food serving establishments.

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: EU

- Voltage: 380-400V

Thanks to the indirect heating system, this kettle is ideal for cooking liquid dishes. It is completely made of stainless steel and equipped with a convenient drain valve.

- Material: Stainless steel

- Heating power, kW: 18

- Voltage: 380-400V

The cooking boiler is equipped with a jacket for heating as well as a heating system, an electrically driven stirrer (with a geared motor) and Teflon scrapers, which allow for the processing of products with low to medium viscosity. The cooking device is also equipped with a vacuum system.

- Productivity: 100l

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

Tilting atmospheric cooking kettle is designed for homogeneous cooking and mixing of sauces, smoothies, jams, spreads, soups, pasta, yoghurts, ice cream, curd desserts, mousse, air confectionery masses, pastry cream, fillings for sweets, waffles, rolls, chocolate, gingerbread, cookies, muffins, rolls, pastilla, marshmallows, meringues, marshmallows, brewed dough, sponge cake.

For a price quote, send us a request.

- Heating: Electricity Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

- Voltage: 380-400V

- Geometric volume: 330

- Dimensions, mm: 1700x1030x1500

The price is set for the basic version of the reactor without additional options and the control panel

The vacuum vessel with a coolant duplicator and a mixing device is a universal solution for processing various products at sub-atmospheric pressure. Based on this simple device, you can select and modulate it into complex installations such as a┬Āvacuum evaporator, a┬Āvacuum cooking kettle, and a┬Āunit for the production of cream honey.

- Sloped Design - Gravity Mixing

- Bottom valve DN40 included in the basic version

- Small-volume duplicator - low costs for coolant heating/cooling

- Modular system: customization of the equipment and its functionalities by ordering additional options

- An easy to disassemble mixing device

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Model VMG S is an effective and reliable vacuum homogenizing unit designed to produce a wide range of liquid, pastry and viscous products with different requirements for the production conditions.

This stainless steel cooking pot will always ensure cooking, baking or boiling different foods.

- Material: Stainless steel

- Voltage: 380-400V

- Working volume: 100

The atmospheric batch cooker model UniCook E or UniCook S, featuring a stirrer, is tailored to meet the diverse cooking needs of various food production businesses in industrial settings.

- Heating: Steam

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 1000l

This kettle with a radiator cooling system ranging from 30 to 500 liters is ready to cook according to the principle of a water bath.

- Material: Stainless steel

- Volume: 30l/ 60l/ 80l/ 120 l/ 200l/ 300l

- Voltage: 380-400V

The kettle is designed for cooking qualitative jam, marmalade, confiture from different fruits, vegetables and berries. It's an ideal and affordable solution for cooking various products.

- Material: Stainless steel

- Heating power, kW: 9/ 12/ 18/ 24

- Principle of operation: Batch mode

- Volume: 80l/ 120 l/ 200l/ 300l

The price is stated including the unheated conical side panels

The frying pan of the WOK type with direct electric heating is designed for fast and intensive heat treatment of products with a maximum heating temperature of up to 220 degrees. This equipment allows you to saut├®, fry, stew, boil, cook and concentrate various products, including thick and viscous ones thanks to the frame mixing device and an automatic tilting system for unloading the final product.

- Fast and efficient heating of up to 220 degrees

- Automatic tilting and unloading system

- Lid opening sensors for safe operation

- Safe steam exhaust system on the top lid

- Lid latches in the open position

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 45

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 46

- Voltage: 380-400V

Vacuum evaporator with remote circulation using a heat exchanger is one of the most efficient evaporation methods. This evaporation system is suitable for boiling and concentrating heat-sensitive products such as milk, cream, etc.

- No mixing device required, the product has forced circulation!

- Modular system: possibility to choose the vacuum generator, power and heat exchanger type

- Inclined design and bottom valve for 100% product discharge without losses and blind spots

- Insulated upper hatch of the unit for heat retention and safety

- Tangential product inlet into the vacuum vessel for guaranteed evaporation in a thin layer

- Material: Stainless steel

- Volume: 50l/ 100l/ 300l

The Economy series of the cooking kettles comprise a thick-walled stainless steel container with an electric mixer mounted on the quick-release upper housing. The installation allows you to mix and stir products during processing. The thick bottom of the pot allows it to be installed on all types of heating surfaces (gas, induction or electric stove).

The Economy version is recommended for use with low-viscosity liquid products; If processing more thick and viscous products is necessary, we offer the Premium version of the cooking kettle┬Āor the caramel & syrup cooking kettle for extra thick substances.

- Sandwich bottom (multilayer) for use on all types of hobs, including induction

- Quick release lid with an electric stirrer

- Safety grid under the upper hull hatch - safe handling when stirring

- Possibility of visual inspection through the safety grid during processing

- Safe loading of components even during mixing

- Material: Stainless steel

- Engine power, kW: 0,12

- Volume: 30l/ 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

The Atmospheric Evaporating Pan efficiently concentrates liquids by evaporating them on a large surface area, while also being suitable for various cooking methods including braising, cooking, and roasting.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

The price is set for the basic version of the vacuum evaporation unit with basic controls (mixer motor switch) and without additional options. The control unit is customized based on individual customer requirements. The pump is also selected separately depending on the product.

A compact vacuum evaporation unit that allows you to concentrate solutions, mixtures, and various products by evaporating the solvent. A modular version based on the basic version of the 110/100 vacuum reactor.

- Gravity mixing - 25% more efficient

- Reinforced agitator design with no blind spots

- Bottom ball valve with no dead zones

- Condensation and secondary vapor removal system

- Easy to disassemble mixing device

- Large heat exchange area

- Ability to measure and monitor condensate volume (optional)

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

- Working volume: 50-80l

- Condensing capacity, l/h: 45-55

- Steam consumption, kg/h: up to 150