This batch catering cooking equipment is made in four types of supply: oil, gas, electricity, and steam.

The catering cookers are designed to operate in automatic mode by using the controller to control the technological process.

BENEFITS OF A PROFESSIONAL HEAT BOILER / COOKER:

Heat Boilers are fed with oil, gas, or electricity and have a double heat jacket. In the case of a heating boiler with an electric supply, the heaters are filled with heating oil shell heat transfer s2. The use of a double heat jacket has two advantages:

- The first advantage is that the product doesnât burn.

- The second advantage is that the oil is cooling down more slowly so that in everyday work it starts from a higher temperature than the ambient temperature, thanks to which it heats up more quickly.

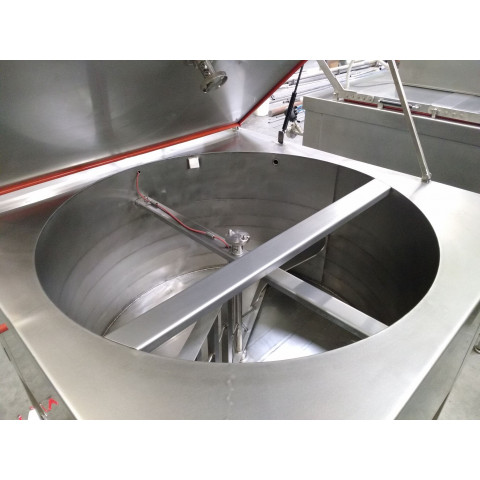

When melting lard in heat boilers, a rotary arm is used to mix the product during the process. External dimensions can be changed according to the customerâs needs. Double heated jacket filled with heating oil Shell Heat Transfer Oil S2. 3 x temperature measurement: oil, water, batch construction, a basket made entirely of stainless steel.

COMMERCIAL COOKER 300L

- supply medium: electricity, steam, oil, gas

- installed power (kW): 15

- power supply (V/Hz): 3x400/50

- external dimensions [LxWxH mm] 600x1300x1100

- controller: mikster INDU 50

- water connection: 1/2 inch

- External dimensions can be changed for the customer's needs

CATERING COOKING EQUIPMENT 400L

- supply medium: electricity

- installed power (kW): 25

- power supply (V/Hz): 3x400/50

- dimensions [mm] 1300x1250x1050

- controller: mikster INDU 50

- water connection: 1/2 inch

- Double heat jacket filled with heating oil Shell Heat Transfer Oil S2

- water connection: 3/4''

BATCH COOKING MACHINE 500L

- supply medium: electricity

- installed power (kW): 30 kW

- power supply (V/Hz): 3x400/50

- dimensions [mm] 1450x1250x1050

- controller: Mikster INDU 50 (among others function of the timer, that allows to set time of beginning of cooking)

- water connection: 3/4''

- Double heat jacket filled with heating oil Shell Heat Transfer Oil S2

- 3 x temperature measurement: oil, water, batch

- construction, a basket made entirely of stainless steel

PROFESSIONAL KITCHEN EQUIPMENT 600L

- external dimensions â 1600x1250x1050mm

- microcontroller: Mikster INDU 50

- measurement of three temperatures (oil, water, batch)

- max temperature of oil: 140 C

- Double heat jacket filled with heating oil Shell Heat Transfer Oil S2

- heat jacket capacity: 200 L

- water connection: 3/4''

- water drain: 2''

PROFESSIONAL TILTING COOKER 800LÂ

- external dimensions - 1900x1250x1050mm

- heating medium â electricity

- heating power- 50 kW

- microcontroller: Mikster INDU 50

- measurement of three temperatures (oil, water, batch)

- max temperature of oil: 140 C

- Double heat jacket filled with heating oil Shell Heat Transfer Oil S2

- water connection: 3/4''

- heat jacket capacity: 250 L

HEAT BOILER WITH TILTING BASKET 1000LÂ

- external dimensions - 2100x1250x1050 mm

- heating power- 60 kW

- microcontroller: Mikster INDU 50

- measurement of three temperatures (oil, water, batch)

- max temperature of oil: 140 C

- water connection: 3/4''

- Double heat jacket filled with heating oil Shell Heat Transfer Oil S2

- heat jacket capacity: 300 L

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l/ 400l/ 500l/ 600l/ 800 l / 1000l/ 1200l/

You might also like

Automatic cooker made for continuous batch production. Different types of food can be boiled, like pasta, rice, vegetables, meat etc. Options: direct gas, indirect steam boiling or direct electric.

Price depends on chosen option.Â

- Heating: Electricity Gas Steam

- Material: Stainless steel

- Heating power, kW: 2x25

- Volume: 2x135l/ 2x220l

- Steam consumption, kg/h: 2x70/ 2x100

The Batch Blancher Cook & Chill is designed for boiling, frying, heating and cooling of a wide range of products.

Price depends on the chosen option.Â

- Material: Stainless steel

- Country of origin: Slovakia

- Voltage: 380-400V

The blancher is primarily intended for blanching lumpy products such as mushrooms and vegetables.

Price depends on the chosen options.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 450

- Geometric volume: 550 l

- Dimensions, mm: 1770x899x997

The steam cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, pots, pasta, milk dishes, teaspoon cooking, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared, ready-to-cook meals, heating or steaming.

The cooking equipment is not suitable for roasting or baking.Â

- Material: Stainless steel

- Volume: 100l/ 150l/ 200l/ 300l

- Steam consumption, kg/h: 50/ 60/ 70/ 90

The gas cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, pots, pasta, milk dishes, teaspoon cooking, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared meals, heating or steaming. This cooking equipment is not suitable for roasting or baking.

- Heating: Gas

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 80l/ 100l/ 150l/ 200l/ 300l

The cream-cooking kettle with manual tilting is designed for controlled heating, concentration, and thermal treatment of cream and cream-based products. Its adjustable temperature control, gentle handling, and uniform heat distribution enable processes such as thickening, reduction, pasteurization, and the preparation of dessert bases.

- 6-stage heating intensity adjustment

- Uniform heat distribution for a consistent product consistency

- Manual tilting system for complete and convenient emptying

- Suitable for cream, dairy desserts, sauces, and similar products

- Smooth stainless steel interior for easy cleaning and maintenance

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 220l/ 500 l

These gas boiling cookers are manufactured for professional kitchens and also for other food processing factories. This is 150l capacity.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 150l

This kettle with a radiator cooling system ranging from 30 to 500 liters is ready to cook according to the principle of a water bath.

- Material: Stainless steel

- Volume: 30l/ 60l/ 80l/ 120 l/ 200l/ 300l

- Voltage: 380-400V

The kettle is designed for cooking qualitative jam, marmalade, confiture from different fruits, vegetables and berries. It's an ideal and affordable solution for cooking various products.

- Material: Stainless steel

- Heating power, kW: 9/ 12/ 18/ 24

- Principle of operation: Batch mode

- Volume: 80l/ 120 l/ 200l/ 300l

An evaporating unit is utilized to remove moisture from sweet substances through heating, transforming them into concentrated syrups or solutions.

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

- Geometric volume: 200 l

This is a 400 l capacity heating boiler, we offer different capacity commercial cooking boilers.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 25

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 400l

- Voltage: 380-400V

The electric kettle with a stirring device and manual tilting is suitable for a wide range of applications in food production or professional kitchens. It has an independent frame and built-in intensive electric heating with a wok-shaped, multi-layer âsandwichâ base, allowing the heating temperature to reach up to 200 °C.

- High processing temperatures of up to 200 °C

- Built-in, powerful 2,6 kW / 6,5 kW electric heating

- Manual tilting and unloading system with three working positions, allowing a maximum tilt angle of 110°

- Professional high-temperature thermometer with a probe in the product

- Air insulation of the outer casing

- Stirring device with stainless steel scrapers for high-temperatures

- Material: Stainless steel

- Engine power, kW: 0,25/ 0,37

- Heating power, kW: 2,6 / 6,5

- Volume: 50l/ 100l

- Stirrer speed, rpm: 18

A vacuum cooker is used in the food processing industry to cook ingredients under reduced pressure, typically in a vacuum environment. This method allows for precise temperature control and faster cooking times while preserving the quality and flavor of the ingredients.

We offer different vacuum cookers.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 2500 l

Automatic cooker made for continuous batch production. Different types of food can be boiled, like pasta, rice, vegetables, meat etc. Options: direct gas, indirect steam boiling or direct electric.

Price depends on chosen option.Â

- Heating: Electricity Gas Steam

- Material: Stainless steel

- Heating power, kW: 2x25

- Volume: 2x135l/ 2x220l

- Steam consumption, kg/h: 2x70/ 2x100

The tilting cooker is produced in 2 versions: with gas or electric heating. The pan is designed for use in the food, hospital, catering industry and in large kitchens for making pasta, stewing and frying meat, fish, vegetables, mushrooms, frozen or semi-prepared, ready-to-cook meals, etc.

- Principle of operation: Batch mode

- Volume: 50l/ 80l/ 120l

- Voltage: 380-400V

The vacuum homogenizer is designed for whipping mayonnaise, ketchup, various sauces, confectionery pastes and fillings, condensed milk, jams and marmalades, canned goods, as well as similar liquid or pasty products with a homogeneous structure.

- Homogenizer in an external circulation loop

- Built-in vacuum generation and retention system

- Modular design with numerous options

- Possibility of automatic dosing of ingredients (optional)

- No additional pump required for loading/unloading

- Automatic top cover lifting system

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 13,5

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

This 60 liter cooking kettle is indispensable for cooking large amounts of food. Runs on gas and handles all basic cooking tasks with ease.

- Material: Stainless steel

- Principle of operation: Batch mode

- Working volume: 50

Thanks to the indirect heating system, this kettle is ideal for cooking liquid dishes. It is completely made of stainless steel and equipped with a convenient drain valve.

- Material: Stainless steel

- Heating power, kW: 18

- Voltage: 380-400V

You don't need professional equipment or special skills to brew beer at home; all you need is to buy a spacious kettle with an automatic stirring device!

- Special mixing device prevents malt from sticking to the bottom.

- The cooking kettle has two side handles for easy manipulation.

- The kettle, lid, and outlet valve are made entirely of stainless steel.

- The beer kettle can be used on any stove or you can purchase an electric base along with the kettle (optional).

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

Electric cooking boilers are cooking devices powered by electricity, designed for heating and cooking products intended for consumption. They are intended for use in catering kitchens, school kitchens, professional kitchens and other food processing plants.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 250l/ 300l/ 350l/