Cheese Pasteurizer MIP Y

MIP Y Pasteurizers are designed for the thermal processing of milk, for the production of yoghurt, white cheese (feta), hard cheese, ice cream and many other milk products.

A cheese pasteurizer is an excellent unit manufactured by people who know perfectly the secrets of milk storage, maintenance and processing.

Yogurt Pasteurizer is made of high-quality materials using the latest machinery and technology. All materials are extremely reliable in the European market and guarantee lasting work. MIP Pasteurizing machines are heat exchangers for the heat treatment of milk, manufacturing of feta cheese, yogurt, hard cheese, ice cream, plus others. We offer dairy pasteurizers in volumes of 50, 100, 200, 300, 400, 500, 650 l.┬Ā

Example for time pasteurization of 100l model with heating element 12kW:

Simple milk pasteurization from 4┬░C ŌåÆ 65┬░C, the pasteurization time is approximately 30-35 minutes

High milk pasteurization from 4┬░C ŌåÆ 95┬░C , the pasteurization time is approximately 55-60 minutes

Types of dairy pasteurizers:

- Milk, Yoghurt Pasteurizer

- Cheese Pasteurizer

- Ice cream Pasteurizer

Milk Pasteurizing equipment - Features

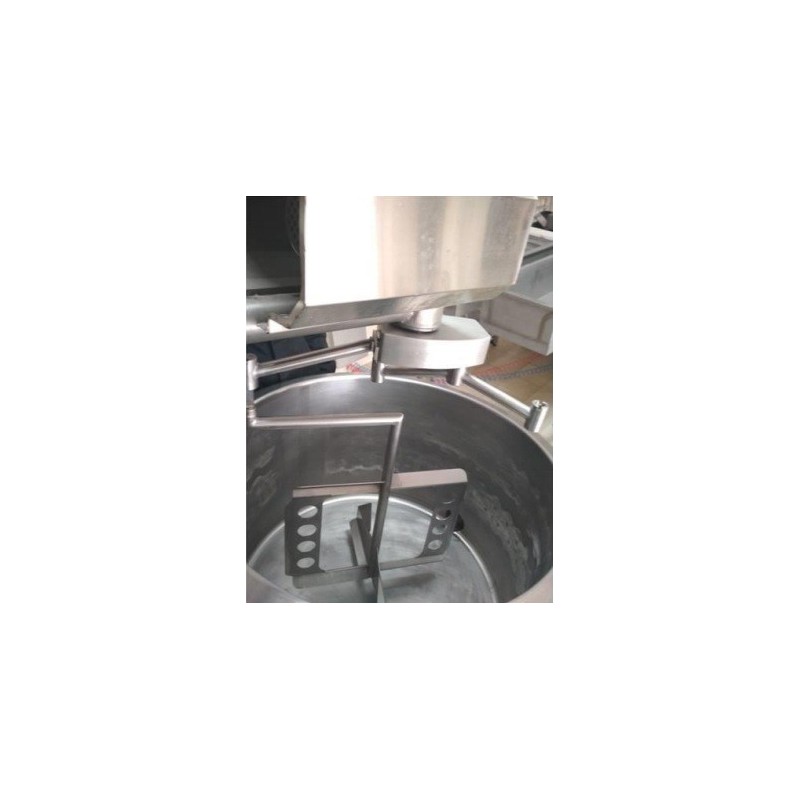

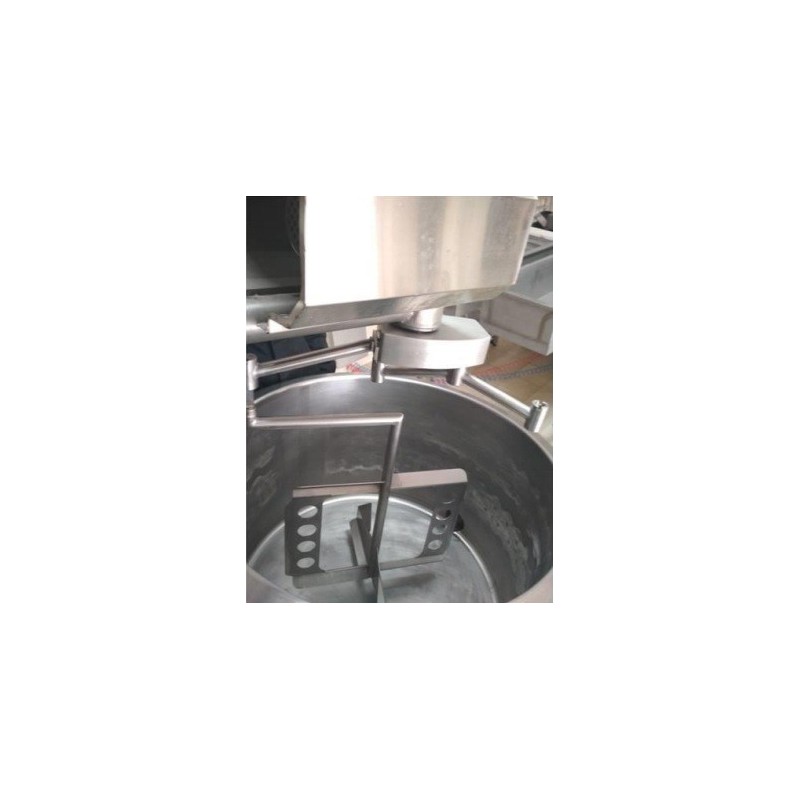

- Ergonomically constructed using stainless steel AISI 304.

- Exceptional insulated vessel with a double wall and environmentally good polyurethane foam.

- Heat exchanger constructed using laser machinery, made for quicker movement providing optimum effectiveness, combining energy preserving plus greater durability.

- Installed a stirring engine with a unique mixer.

- Amendable strong stainless steel legs for use on irregular floors.

- Stainless steel dipping stick to measure the product.

- Immersing sensor NTC IP68 AISI316 for controlling the temperature.

- Possible in various volumes.

- Computerized control panel with a touch screen.

Attributes

- Thermic milk treatment (warming, chilling, mixing) is entirely regulated by software that can be configurated.

- Automated start, stop for the mixer.

- Visual alarm for completing every step.

AVAILABLE:

HEATING Warm water supply to the pasteurizing circuit may be accomplished with gas or oil boiler or electric heater

CHILLING Cool water supply to the pasteurizing circuit may be achieved with ice-banks.

MILK PASTEURIZING PLANT

MIP milk pasteurizing equipment was constructed specially for the heat treatment of milk as a commercial version.

Technical features

- May be connected to an assembly line for cheese.

- Lower speed stirring engine (30 rpm), integrated on a unique raised base on the cover, for simple washing and maintenance.

- Stainless steel totally openable cover.

- Equipped with a detachable arm with a detachable big stirrer and two half lids.

- Material: Stainless steel

- Volume: 50l/ 100l/ 200l/ 300l/ 400l/ 500l/ 650l

You might also like

Pasteurizer, cheese boiler is designed for processing milk, yogurt, fruit juice or other liquids.┬Ā

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Volume: 200l/ 300l/ 500l

The Milk Cooler has a simple design, which allows for easy and safe operation. it meets the requirements of all dairy production facilities.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 200l/ 300l

- Voltage: 380-400V

Milk cooler tank designed for cooling milk and other dairy products. The tank is available in 13 different capacities, covering a range from 50 liters all the way up to 2,500 liters, capable of meeting the needs of all dairy & cheese production facilities. We offer 2 or 4 milking options. Prices are displayed for the milk cooling tank with 4 milking.

- Material: Stainless steel

- Principle of operation: Batch mode

Pasteurization dipping tub is suitable for the heat treatment of packaged fruit preparations, (jams, fillings, hams) or fermented preparations (vinegar, beer) and pickles to preserve them, and to eliminate harmful microorganisms.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 200l/ 300l

Tell us if you are producing cheese, milk, yoghurt or ice cream. The difference between the milk pasteurizer and the yoghurt pasteurizer is that the yoghurt pasteurizer is equipped with a detachable arm with a detachable big stirrer and two half lids.

- Material: Stainless steel

- Country of origin: EU

- Volume: 50l/ 100l/ 200l/ 300l/ 400l/ 500 l/ 650l 800 l / 1000l/ 1250l/ 1500l

The device is designed for the pasteurization of a wide range of products in various types of packaging material such as cans and jars.

- Heating: Mixed

- Productivity: 300 l 400 l 500 l

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

Electric pasteurizer suitable for pasteurizing beverages as well as filling up bottles or bag-in-boxes. We offer 3 production capacities. The basic pasteurizer model comes without the manual BiB filler module.

- Productivity: 180 l/h / 300l

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 380-400V

Unbeatable price, excellent cooking results, designed to be placed in tight spaces where sharp edges or corners may create problems. We have different capacities boiling cookers.

- Material: Stainless steel

- Heating power, kW: 18

- Volume: 150l

- Voltage: 380-400V

For a price quote or for a free consultation, send us a request.

- Productivity: 90l

- Material: Stainless steel

- Heating power, kW: 6/

- Principle of operation: Continuous mode

- Voltage: 380-400V

We offer different types of dairy pasteurizers. Tell us if you are producing cheese, milk, yoghurt or ice cream and we will help you pick the right pasteurizer for you.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

- Volume: 200l/ 300l/ 500 l/ 800 l / 1000l

The universal bath pasteurizer is used for processing a wide range of different food products, such as ready meals, sausages, hams or liquid products. Effective temperature regulation and a hygienic stainless steel design.

The pasteurizer equipment MGGP is suitable for the heat treatment of low viscosity liquids as well as drinking water.

- Productivity: 500 l/h/ 800 l/h

- Material: Stainless steel

- Principle of operation: Continuous mode

The electric pasteurizer is ideal for the heat treatment of various fruits, including apples, pears, blackberries, strawberries, blueberries, elderberries, currants, carrots, greens, quince, beets, sea buckthorn, rowan berries, and onions.

- Material: Stainless steel

- Principle of operation: Continuous mode

This multifunctional cooking machine with two baskets is designed for different ways of use and is suitable for a lot of variety of businesses - any enterprise or any participant of the HoReCa market. With the help of this equipment, you can cook, pasteurize, or blanch.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 135 +135 / 220+220

This multifunctional cooking machine is designed to be used in a variety of different ways and is suitable for the majority of professional kitchens and catering businesses - any small enterprise or any participant of the HoReCa market. With the help of this equipment, you can cook, pasteurize, or blanch.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Voltage: 380-400V

The professional yogurt making machine is designed to produce a wide range of yogurt production, e.g. creamy, liquid drinking, greek, white, organic, fruit yogurts. The machine can be used by farms and small dairy factories.

- Material: Stainless steel

- Principle of operation: Batch mode

The plate pasteurizer is designed for partial decrystallization and pasteurization of honey preheated to a temperature of 30-35 degrees.

- Principle of operation: Continuous mode

- Country of origin: EU

We offer different pasteurizers for different applications.

- Heating: Gas

- Productivity: 300 l

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Continuous mode

- Country of origin: EU

- Voltage: 220-230V

A 15-liter pasteurizer with a water bath that has a flat bottom and two canning racks, featuring a large capacity and made out of food grade 304 stainless steel.

- Material: Stainless steel

- Principle of operation: Batch mode

The pasteurization kettle with manual tilting is a modern device designed for gentle heat treatment of milk and dairy products, which allows for their effective pasteurization, extends shelf life and increases safety, while preserving the original taste and nutritional values. The 6-stage heating regulation of the powerful integrated heater, allows the milk to be reliably pasteurized directly in the container with a sandwich bottom, ensuring even heat distribution.

- Ideal solution for small-scale and home production of dairy products

- Removable lid for easy inspection and manual mixing of the product

- Option to equip it with a drain valve for discharging liquid products

- Even heating without burning thanks to the sandwich bottom

- Easy connection to a single-phase 230 V power supply

- Material: Stainless steel

- Heating power, kW: 6,5

- Volume: 50l/ 100l

- Voltage: 380-400V

The pasteurization equipment MGGP is suitable for the heat treatment of low viscosity foods as well as drinking water.

- Productivity: 500 l

- Material: Stainless steel

- Principle of operation: Continuous mode