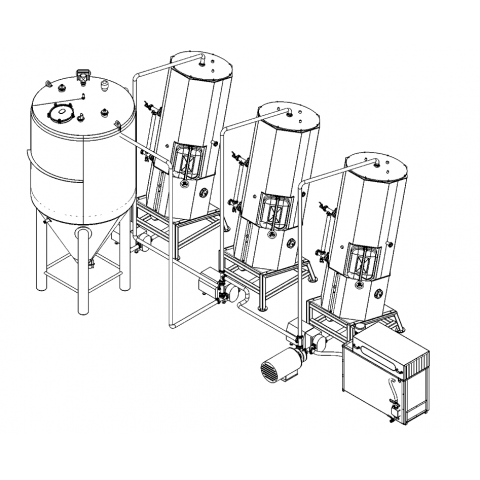

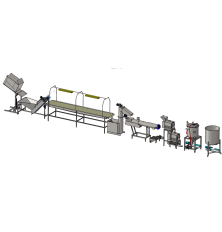

Production complex for condensed milk from powdered milk

This set of equipment for the production of condensed milk from dry components by restoring the milk. This production line can be manufactured with a capacity of up to 500 kg/h or can be customized based on specific requirements.

Equipment for the production of condensed milk from powdered components includes:

- The Reactor / Milk Restorer is intended for swelling up the protein mass and to mix the stable homogeneous mixture

Pre-measured dry components are loaded out of the container from above through the hatch of the reactor (milk powder, sugar), fat is fed through the injector and supplied into the circulation circuit of the reactor. Additional small ingredients in accordance with the recipe can be loaded by pouring them into the pipeline of the injector supply used to circulate mass in the reactor. To accelerate the supply of components pre-measured in the bunker, a conveyor/transporter can be installed.

Milk recovery: dry mass is introduced into preheated drinking water in accordance with the recipe, after dissolving, the mixture intended for swelling proteins is held while cooling is carried out. In accordance with the recipe, other components are also supplied: fat, sugar, etc.

The reactor has a double-layer casing, an atmospheric inclined design, equipped with a āduplicatorā for a thermal carrier with a pressure of up to 0.5 bar, a frame mixing device with an electric drive and a gravitational mixing system, which is 20-25% more effective than usual. The reactor is equipped with a sectionally opening hatch on the upper case, on the upper body there is an "entrance" for preliminary heated water. Installation can have additional options, such as Teflon scrapers for the mixing device, SIP/CP cuts for washing, thermal insulation, the upper decorative casing of polished stainless steel.

The reactor can be equipped with a compulsory circulation circuit where the inline-homogenizer and the injection supply of components are connected.

As an option, a vacuum version of the reactor with a vacuum generation system can be selected. The vacuum system accelerates the cooling process, due to the pulsation operation of the vacuum, the intensity of saturation/swelling of the proteins increases on the principle of vacuum diffusion during constant mixing. The vacuum system also allows partial deaeration. Excessive air content of restored milk can: with pasteurization can get burnt, rise/expand, foam formation, fat can be oxidized, the effectiveness of homogenization can decrease, etc.Ā

Technical specifications:

- Volume - 1000 l

- "duplicator" for the coolant up to 0.5 bar

- Atmospheric performance, 2-layer casing

- Material - AISI304

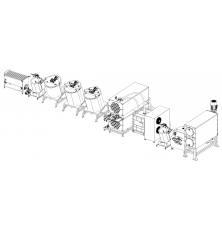

- Fat Melter

Fat in a solid form is measured in the required amount per 1 cycle of loading (in accordance with the recipe), it is loaded on top of the coater on the "lattice", after which it is supplied into the system of circulation of the milk reactor. The installation of periodic action is designed for melting solid, frozen fat blocks, animal oil and plant oils, followed by retention of the molten state in the container below. The peculiarity of the design lies in the presence of a special grate āmeltingā installed in the upper part of the container, and a coil for heating the product in the container which the steam circulates through.

Technical specifications:

- Volume - 80 l

- Material - stainless steel AISI304.

A source of steam, steam supply system (safety, adjusting and locking fittings) is not included in the basic set of equipment.

- Inline-Homogenizer

Homogenizer - horizontal emulsifier refers to the continuous equipment used for homogenization, grinding fat compounds, emulsifying of difficult to mix liquids with rotating crop-cavity effects. It can also be used to dissolve poorly wetted powders and rough emulsions. It can be connected to the circulation circuit of various reactors.

The basic version of the installation includes: a high-speed electric motor, on the shaft of which a rotor with a special form is installed, a single end seal of the shaft.

- Product input - DN 60

- Product release - DN 50

- Electric power engine power - 5.5/ 7.5/ 15 kW/ 2850 rpm

- Material - AISI304

As an additional option, a double end seal, a frequency converter for adjusting the speed of work can be offered.

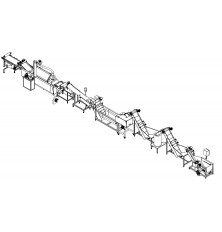

- A filtering system before supplying mass into the pasteurizer

The bare minimum solution is the installation of a flowing stainless steel filter for the equipment. For convenient and uninterrupted operation, it is recommended to install the Double by Pass system, which using the valves redirects the stream along the contour through one, in case of clogging up, through the second filter. Inside each filter there is a filter cartridge made of stainless steel, which is easily washed in a stream of water.

The size of the filter cartridge is 500 microns, you can additionally order cartridges with a cell size from 100 microns to 1000 microns.

- Batch pasteurizer

Pasteurization of the mixture is carried out at an average temperature of 90-95 degrees. For this, batch pasteurization equipment is used. The inclined atmospheric reactor with a 4-layer casing of thermal insulation and an external hygienic stainless steel case.

Equipped with a āduplicatorā for a coolant (steam) with a pressure of up to 0.5 bar, a frame mixing device with electric drive and gravitational mixing. The mixture from the reactor is carried out using the pump of the circulation circuit. The installation is equipped with a sectionally opening upper case. As additional options it can be pre-equipped with Teflon scrapers, SIP/CIP sip heads, a forced circulation circuit with a pump for thick and viscous products. To increase the intensity of the heating process, a plate heat exchanger can be installed in the external circulation circuit.

- Volume - 1000 liters.

- Material - stainless steel AISI304.

A source of steam, steam supply system (safety, adjusting and locking fittings) is not included in the basic set of equipment.

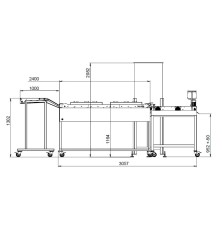

- Vacuum crystallizer - cooler

Before sealing and packaging, it is recommended to cool the finished condensed milk, as well as vacuum crystallization - controlled crystallization according to the model with the addition of seeding (lactose), or about 10% of condensed milk from the previous batch. This will allow you to get a homogeneous, smooth product with a similar crystal size, which will not change its structure during storage.

The device can be produced in sizes from 100 to 1000 liters, it consists of a vacuum inclined reactor equipped with a frame mixing device with an electric drive and Teflon scrapers and a gravitational mixing design, a vacuum system with a vacuum generator, and a hatch for the upper body.

The crystallizer provides the function of controlled crystallization at a set temperature and constant mixing under the conditions of a vacuum. In the crystallizer, secondary deaeration is also underway.

The process of cooling is carried out by supplying the coolant into the āduplicatorā (maximum pressure up to 0.5 bar) with a temperature of 5-7 Ā°C. The heat carrier source is not included in the basic set of equipment, but can be ordered additionally.

The vacuum generator can be chosen from: a water-ring vacuum pump, or an ejector working with compressed air. With a vacuum pump, it is necessary to provide a sufficient amount of water for it to cool, with an ejector - a compressed air source (compressor) with a pressure of 6-10 bar.

To increase the cooling rate to the crystallization temperature, it is recommended to install a plate heat exchanger in the equipment of the product before the āinputā of the product.

As additional options, the crystallizer can be pre-equipped with SIP/CIP heads for washing, an observation window, an external forced circulation circuit, ejector feed and many others!

The control system is calculated and proposed separately depending on the degree of automation of processes.

Additionally, storage containers for storing the finished product can be supplied as well.

- Material: Stainless steel