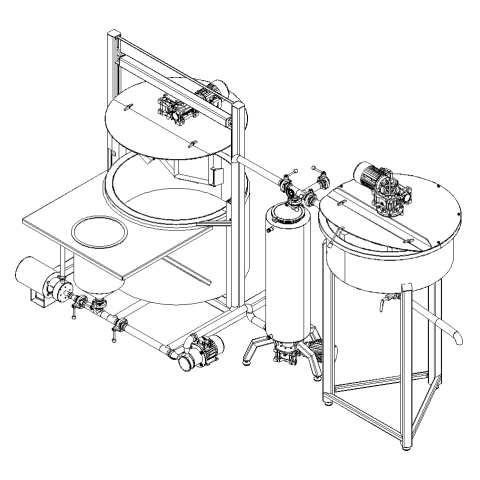

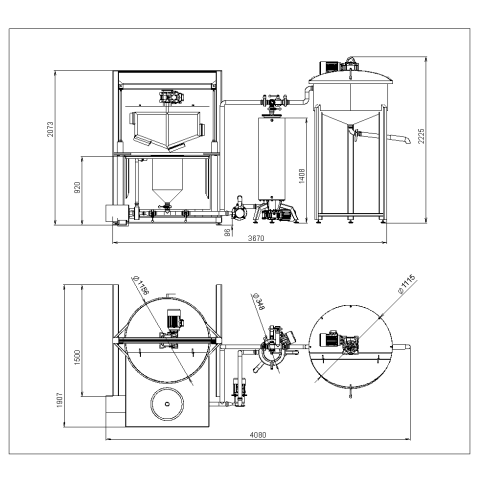

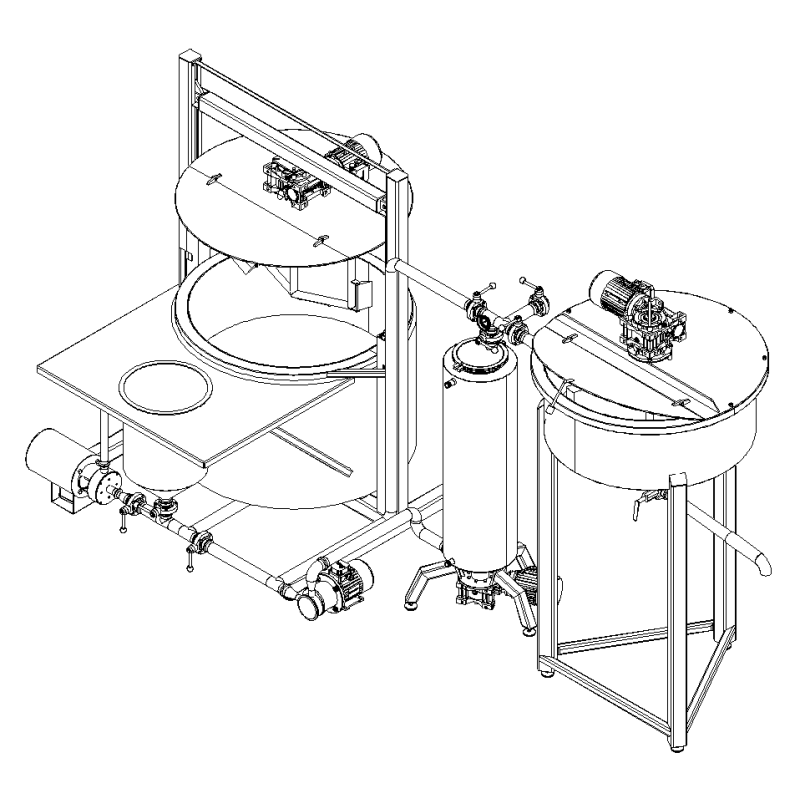

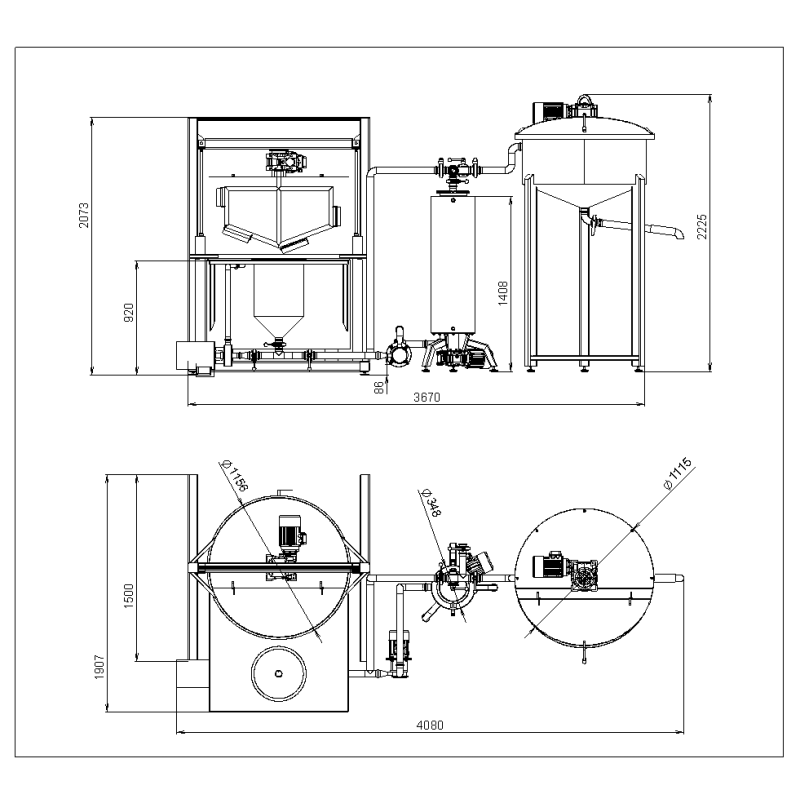

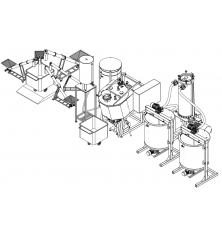

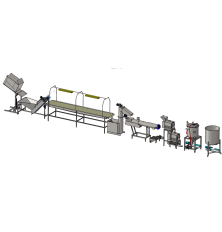

Mayonnaise, mustard and ketchup production system

This equipment set can be used for the production of a diverse array of sauces, as well as various vegetarian products based on nuts, soy and rice. It is capable of processing around 300/600 liters of product per batch.

The complex of equipment has a universal character, as it allows for a wide range of technological functions, therefore it can be used for the production of yogurt, creams, sour cream, mayonnaise, ketchup and other sauces, as well as vegetarian products based on nuts, soy and rice.

Includes:

- Universal atmospheric reactor - digester

- Inline homogenizer

- Scraped heat exchanger

- Accumulator for dosing

UNIVERSAL ATMOSPHERIC REACTOR - COOKING KETTLE

The atmospheric reactor set up on a supporting structure, is equipped with a frame mixer with an electric drive, a sectionally opening upper body / hatch, a heating duplicator up to 0.5 bar, thermal insulation and an external hygienic casing, a heating system and a circulation system with an inline homogenizer, piping with a cone loading into the flow as well as mechanical valves for adjusting the work circuit.

This equipment allows you to perform the following functions:

- heat treatment / cooking / pasteurization

- stirring / mixing

- homogenization

Technical specifications:

- Volume - 300/600 l

- Mixing device drive power - 1.5 kW (suitable for processing thick and viscous and especially viscous products).

- The power of the heating system is 18 kW, with a 600 l boiler there is no built-in heating, it can be offered separately. (It is recommended to use demineralized water as a heating medium.)

- Material - AISI 304

- The unit can be retrofitted with a pneumatic lifting for the upper body, Teflon stirrer scrapers, CIP cleaning heads.

- Outlet / circulation pipes - DN50, with 600 l version - DN65

A useful feature of this installation is a cone for loading additional ingredients during operation, the supply of dry components into the stream improves wetting and mixing of powders into the total mass.

INLINE HOMOGENIZER ULTRA SHEAR

It is a high-speed rotary type homogenizer intended for creating stable emulsions, used to combine and homogenize fat, wet and dry components. Equipped with special knives, teeth on the rotor and stator. In the production of emulsions, it can reach a fraction size of up to 1 micrometer. The homogenizer also performs the function of a pump, like a rotary pulsation unit. It is installed in the external circulation circuit of the universal atmospheric reactor. The high rotor speed ensures mixing, while the high vacuum ensures that liquids/mixtures are pumped into the rotor/stator. Centrifugal force drives the product along the circumference of the working part of the homogenizer, where mixing takes place. The product is intensively mixed at high speed, after which it enters the pipeline through the holes in the stator.

Technical specifications:

- Electric motor drive power - 2.2 kW, with 600 l modification of the complex - 7.5 / 15 kW (optional)

- Speed - 3000 rpm

- Inlet - DN50, with 7.5/15 kW homogenizer version - DN65

- Outlet - DN32, with 7.5/15 kW homogenizer version - DN50

- Equipped with an open mechanical seal cooling system. Use water with an inlet pressure of 3-3.5 bar as a heat carrier.

- Can be equipped with an external protective cover made out of brushed stainless steel.

SCRAPED HEAT EXCHANGER

This is a special heat exchanger for thick and viscous products, equipped with a heating / cooling duplicator for a coolant up to 0.5 bar, a mixing device with Teflon scrapers. The product is loaded into the heat exchanger using a special pump for thick and viscous products (technical parameters and type are selected individually based on the properties of the product). The heat exchanger can be manufactured both in a vertical and a horizontal position. For this complex, we have produced a model with a heat exchange area of ŌĆŗŌĆŗ0.6 m2. The heat exchanger is a complex thermomechanical system consisting of a stationary cylindrical heat exchanger with a central movable shaft. Attached to the shaft are teflon blades/scrapers that abrade the product from the cylinder walls and thereby improve the heat transfer efficiency. The product (vertical version) enters the heat exchanger through the bottom inlet and moves up the pipe. In this case, the source of the external coolant supplies the coolant (warm or cold liquid) into the "jacket", which indirectly heats or cools the product. The product moves in countercurrent relative to the movement of the coolant. The efficiency of heat transfer is achieved due to the rate of circulation of the coolant. The heated/cooled product is discharged through the top outlet of the heat exchanger. If the product is not yet sufficiently heated or cooled, the feedback valve opens and the whole process is repeated. The product temperature can be controlled by an analog thermometer located on top of the heat exchanger. It is recommended to install a frequency converter to control the rotation speed of the agitator.

Technical specifications:

- Mixer drive power - 0.75 kW

- Heat exchange area - 0.6 m2

- "duplicator" for the coolant - up to 0.5 bar, the coolant source is not included in the delivery.

With the 600 liter version of the complex, 2 scraped surface heat exchangers are installed in series.

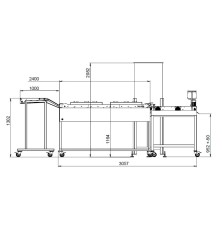

DOSING TANK

Designed to receive the finished product and for further dosing, equipped with an outlet valve at the bottom of the container, as well as an elongated supporting structure, which allows you to install a container for packaging under the outlet. It consists of the atmospheric reactor equipped with a stirring device with electric drive.

Technical specifications:

- Volume 300/600 l

- Mixer drive power - 0.75 kW / 1.5 kW (power depends on the density and viscosity of the final product)

- Can be retrofitted with Teflon scrapers and a frequency converter to adjust the rotation speed of the agitator, temperature sensor and more.

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 300l/ 600l/

- Voltage: 380-400V