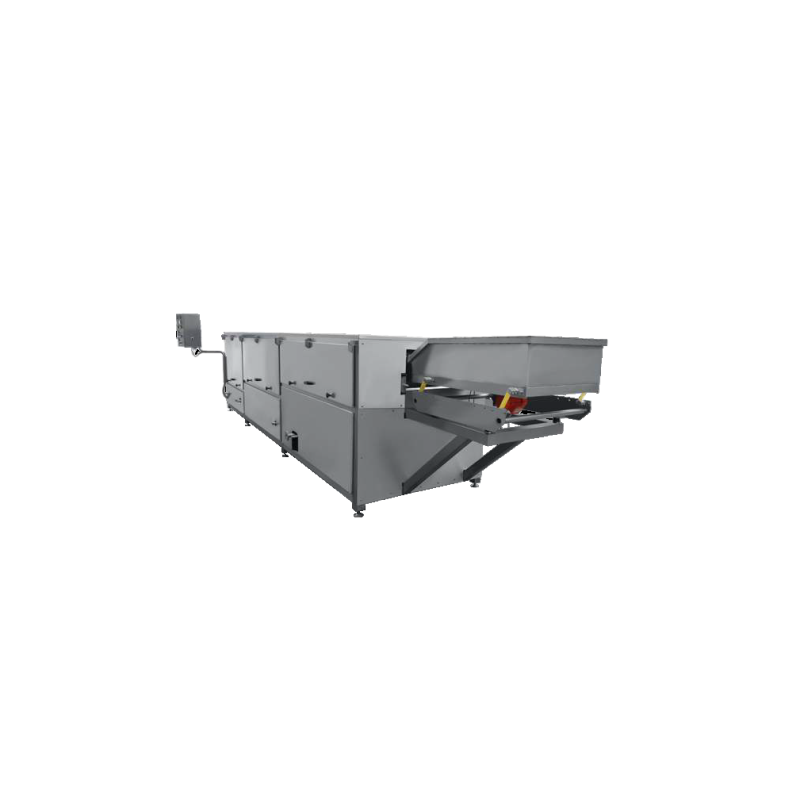

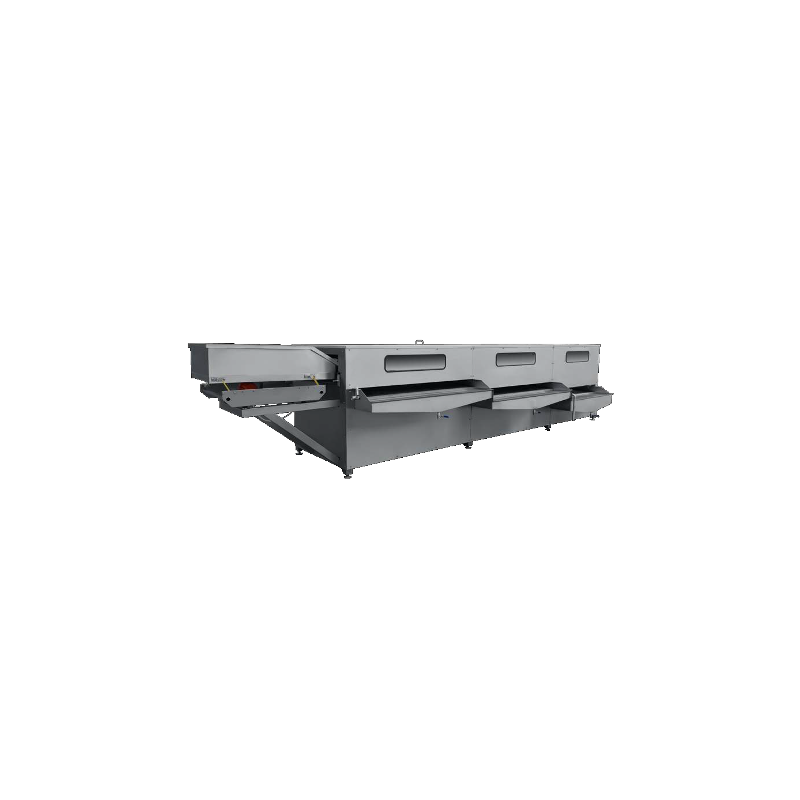

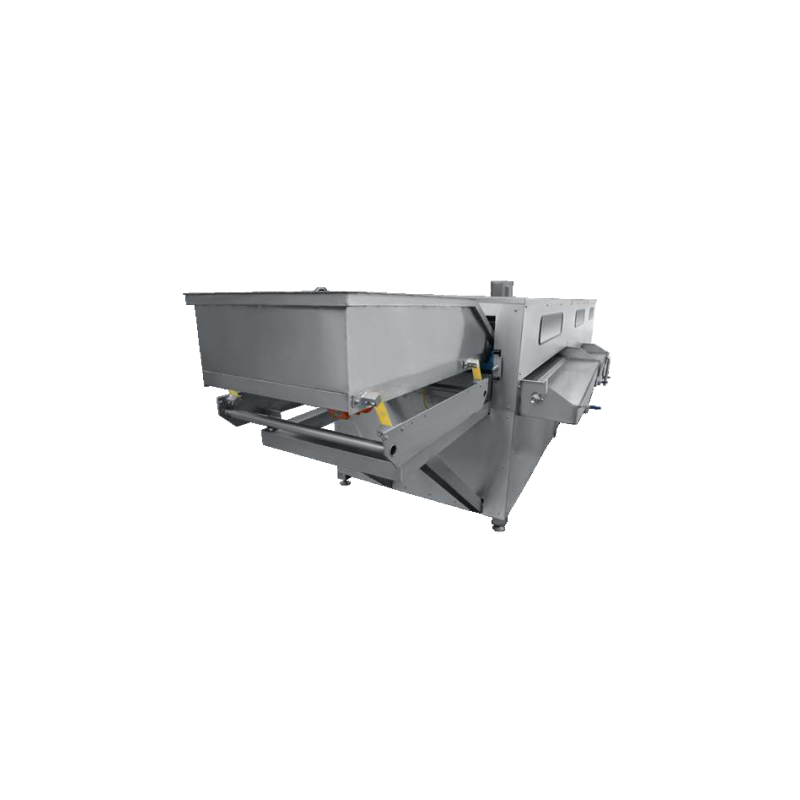

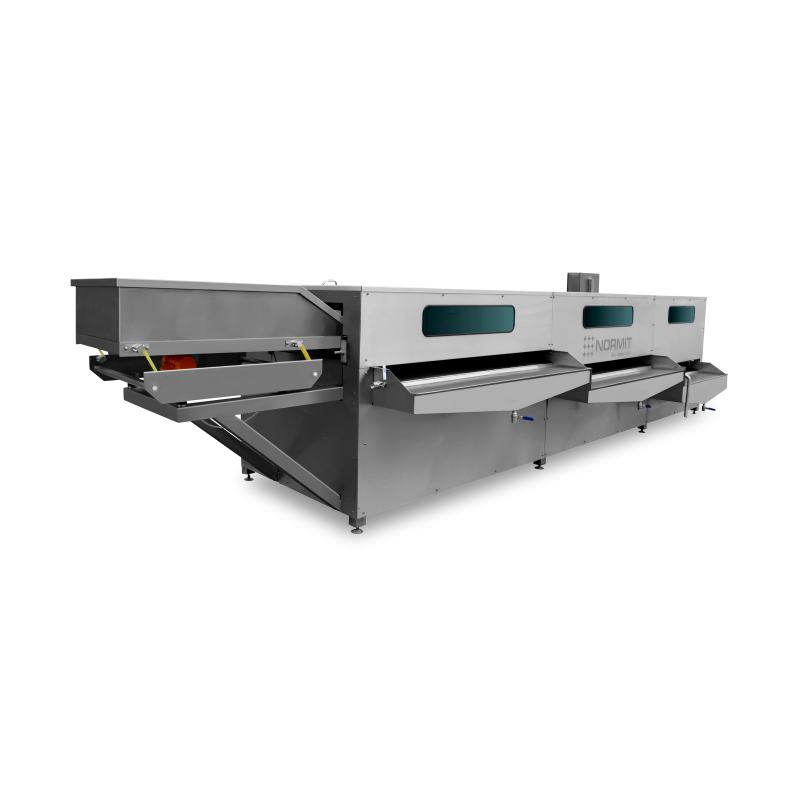

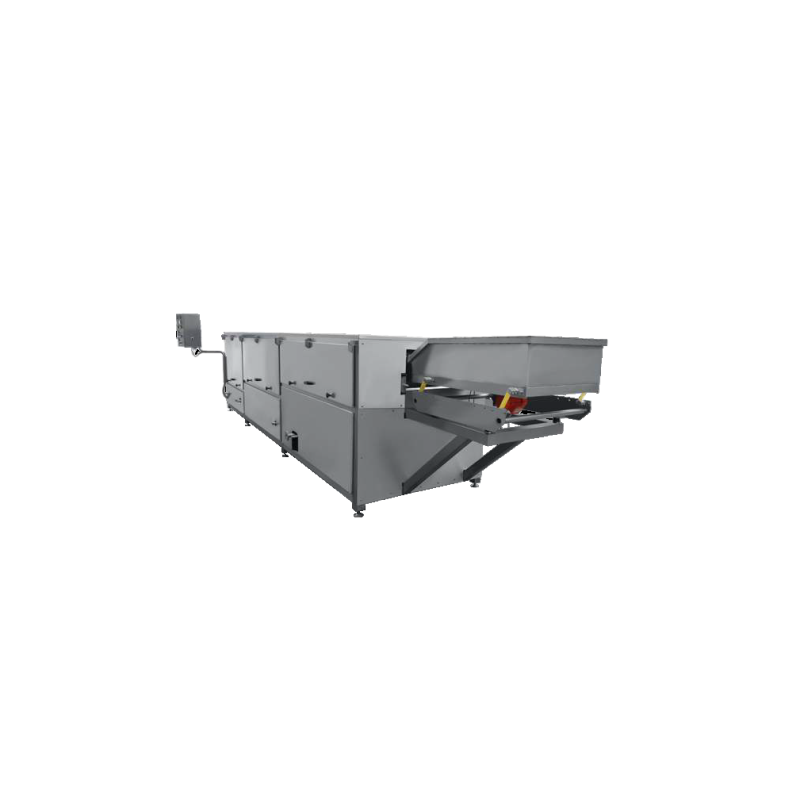

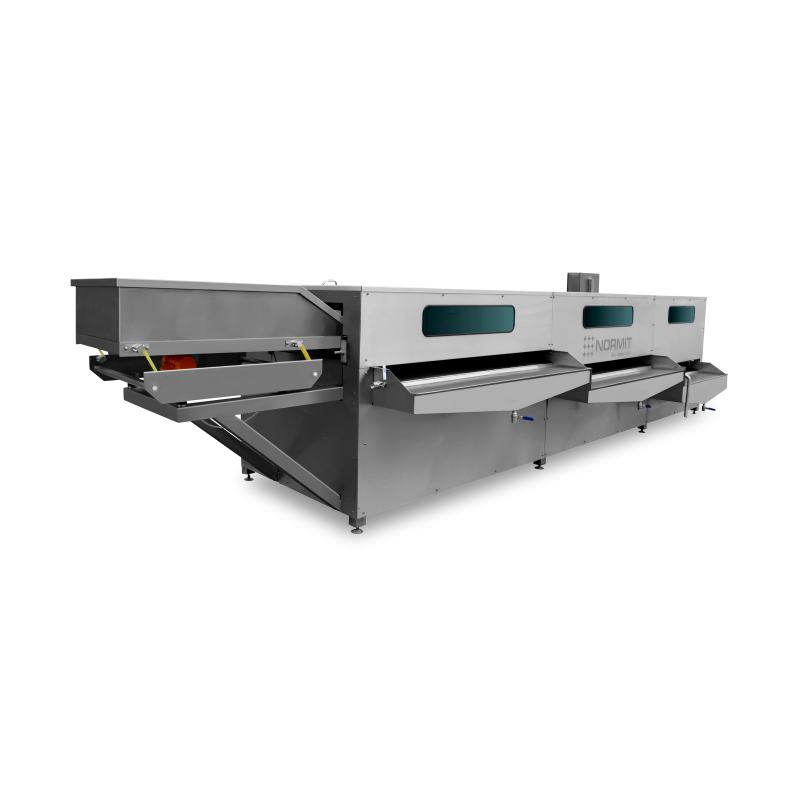

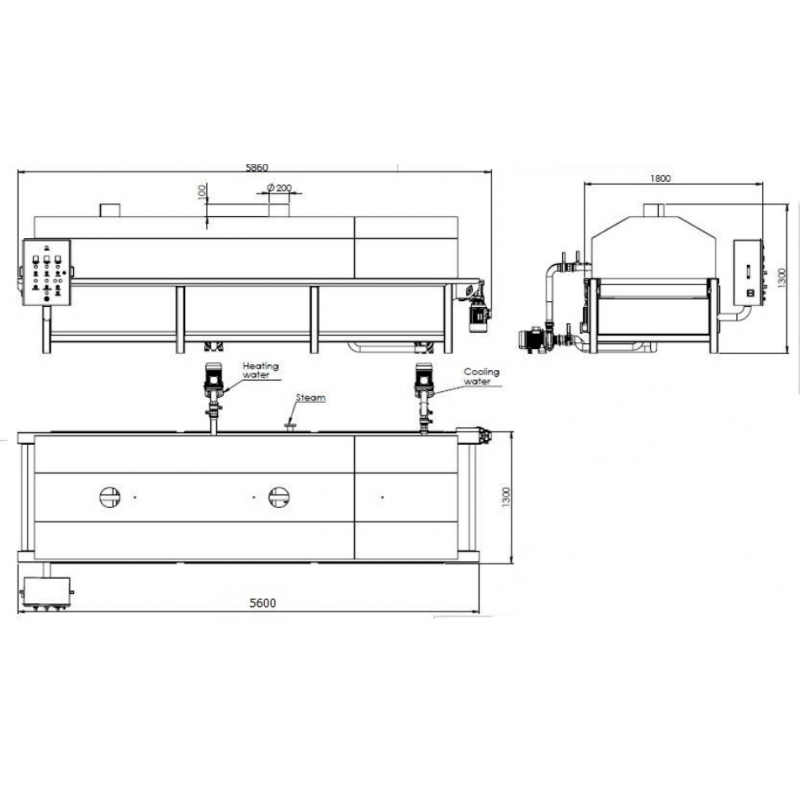

The plant is determined for blanching and cooling. It is a high-quality professional plant which works continuously with using low energy demand.

The processed product is without any damages at final phase, it saves all the beneficial substances, vitamins and nutrients.

One of the blancher advantages is its universality. The plant can be configured in the way to process different kind of products, such as:

- soft seafood like mussels without shell or shrimps

- vegetables

- mushrooms

- and many others

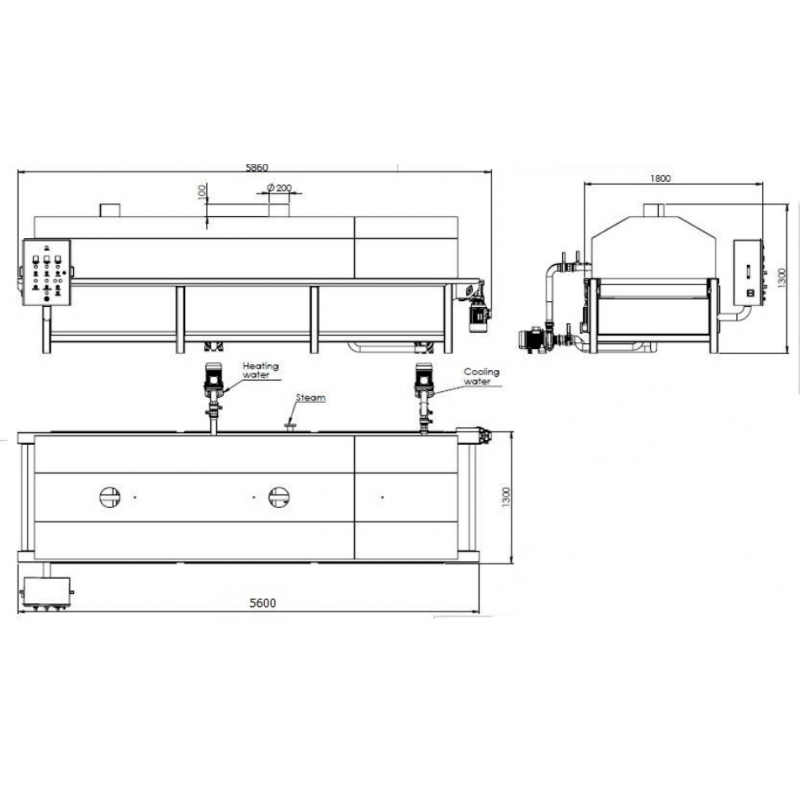

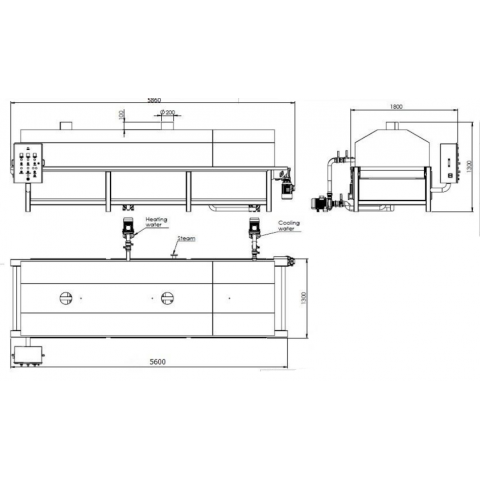

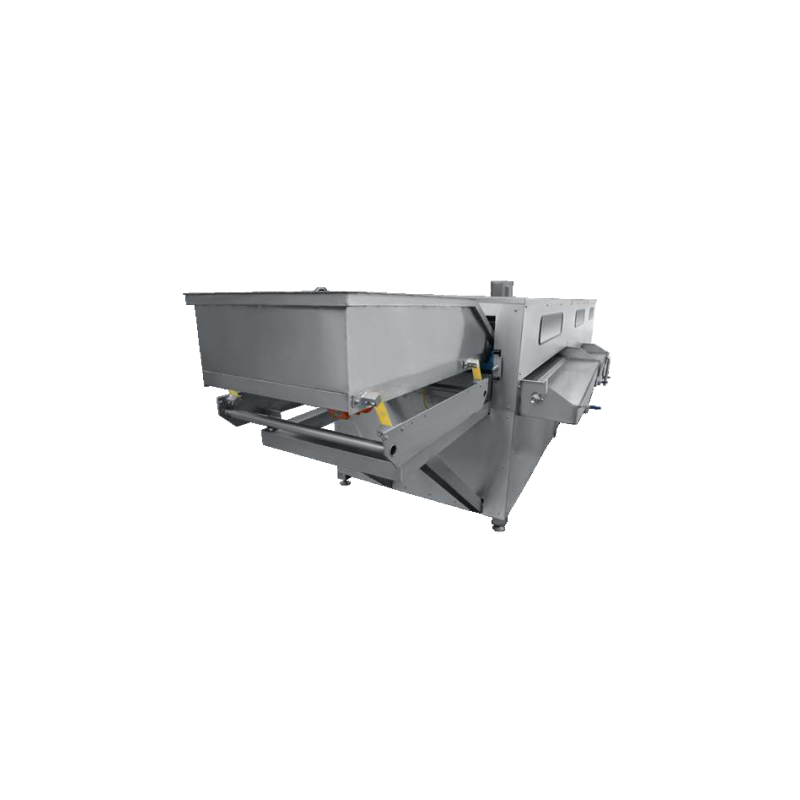

The plant performs blanching and then cooling of products. The blancher consists of a vibration dosing device for steady product dosage. The continuous blancher CB is determined for heat-treating of wide product range whose soft structure requires to minimize a mechanic influence during the process of blanching.

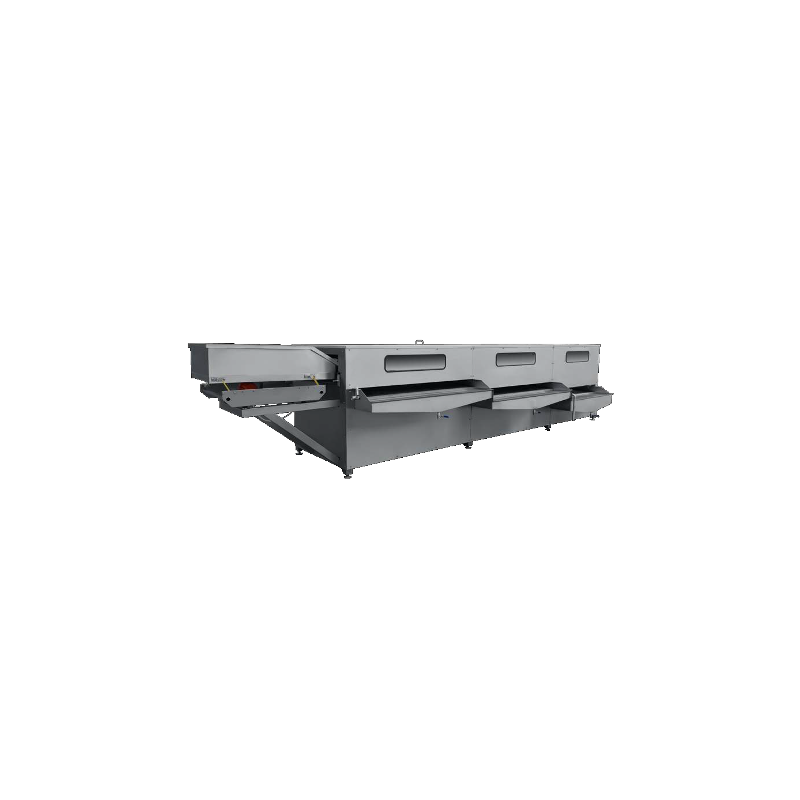

The process of continuity blanching and cooling is ensured by the independent conveyors belt in each section. Sections are in cascades what means that each section is lower than the previous. It enables an automatic product rotation during its shifting at conveyor belt from section to section.

Each section consists of the special direct water â steam injection system with continual filtration and water circulation. The plant is constructed from a system which can minimize costs for water/steam consumption.

The product cooling process can be realized by water, air or by their combination. The heating system is a hybrid system which enables to select the most optimal processing method for each product.

The plant allows a regulation of:

- vibration dosing device,

- conveyors speed,

- temperature and time.

According to customers request, it is possible to add next sections, such as pre-washing, preheating, additional cooling and so on.

The heating system The blancher continuous CB can be equipped with of steam, electric or gas heating system. When using steam heating process there is used high-efficient water heating system based on steam flow which enables to decrease a temperature loss decrease to zero and ensures the maximum economic plant efficiency.

If there is only the steam with low pressure in customer factory, the conveyor blancher can be equipped with additional heating section which ensures an effective plant usage during steam pressure from 1 bar.

When using electricity, the heating is ensured through thermal exchanger. The wide range of configuration options allows to select the optimal plant for any usage.

- The blanching process is possible to realize by water or steam.

- The stainless or PVC conveyor belt.

- The integrated or extended section of water or air cooling.

- The installation variety of optional additional equipment.

- The variable performance. The performance of conveyor blancher is determined by the specific product density on belt and processing time.

The blanching/cooking process The blanching process can be realized by steam, warm water or by steam and air combination depending on the type of processed product and required temperature. The CB blancher can be used as a steam sterilizer when using clean steam. The continuous blancher NORMIT CB sections The basic version of the continuous blancher comprises the product loading sector, work sector with heating and unloading sector. For the process of blanching is possible to use watering or spraying steam/water method.

According to customer request, the blancher can be equipped with a section of disposable or multiple product rotation which provides steady heat-treating all the sides. The blancher can be equipped additionally with spraying steam/warm water system from the bottom part of the conveyor belt. The continuous blanchers CB are equipped by integrated or extended cooling section. The cooling process can be performed by immersing into ice water respectively by ice water pouring or cold air spraying. For removing redundant water and soft product elements, it is possible to install a section called âair knifeâ after cooling section on demand. The continuous blanchers CB are made from specific food stainless steel AISI304.

For information, visit the link blancher

- Material: Stainless steel

- Principle of operation: Continuous mode

You might also like

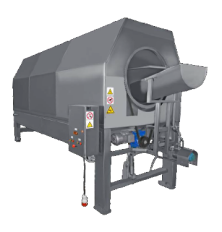

The Batch Blancher Cook & Chill is designed for boiling, frying, heating and cooling of a wide range of products.

Price depends on the chosen option.Â

- Material: Stainless steel

- Country of origin: Slovakia

- Voltage: 380-400V

Price depends on the required production capacity.

- Material: Stainless steel

- Heating power, kW: 90

- Dimensions, mm: 3549x1919x1490

- Blanching section, mm: 400x1800

- Cooling section, mm: 400x900

Designed for blanching vegetables, fruits, legumes, pasta, seafood before preservation and freezing.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Blanching helps keeping the vitamins and nutritional properties of the product, as well as an outer appearance with bright and natural color.

- Heating: Electricity Steam

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The cost is indicated without the price of the baskets

A batch blancher with indirect electric or steam heating is used for blanching vegetables, mushrooms, meat, fish, and seafood. This type of blancher is ideal for use in catering kitchens and hospitals.

- Simple controls

- Built-in electric heating

- Large outlet valve

- Safe operation

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 18/ 24/ 30/ 36

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 200l/ 300l

The universal bath pasteurizer is used for processing a wide range of different food products, such as ready meals, sausages, hams or liquid products. Effective temperature regulation and a hygienic stainless steel design.

Price depends on the chosen option.Â

- Material: Stainless steel

- Principle of operation: Continuous mode

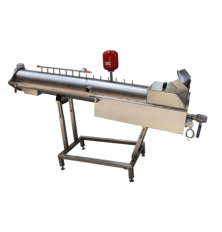

Pouring Blancher ShowerBlanch is designed for heat treatment of a wide range of products whose fine structure requires to minimize mechanical influence in the blanching or cooking process. Unlike a drum blancher, in which the product is blanched in a process of single directional mixing and rolling and a screw blancher, in which the product passes through a working chamber by means of a screw, in the belt type blancher the product lies motionless on the conveyor belt and is processed without damaging its surface.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Blancher AQ Deep is designed for heat treatment of a wide range of products whose fine structure requires to minimize mechanical influence in the blanching or cooking process. Unlike a drum blancher, in which the product is blanched in a process of single directional mixing and rolling and a screw blancher, in which the product passes through a working chamber by means of a screw, in the belt type blancher the product lies motionless on the conveyor belt and is processed without damaging its surface.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The blancher is primarily intended for blanching lumpy products such as mushrooms and vegetables.

Price depends on the chosen options.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 450

- Geometric volume: 550 l

- Dimensions, mm: 1770x899x997

This compact batch blancher is designed for efficient and simple blanching in smaller-scale food processing. Price depends on the chosen option.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 450l/

This multifunctional cooking machine with two baskets is designed for different ways of use and is suitable for a lot of variety of businesses - any enterprise or any participant of the HoReCa market. With the help of this equipment, you can cook, pasteurize, or blanch.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 135 +135 / 220+220

The VFB vacuum fryer with a built-in blancher is intended for drying and frying a wide range of products as well as for the production of chips and crisps from potatoes, carrots, onions, celery, parsley, beetroot and many other types of fruits, vegetables, and different snacks made out of meat, pork skin and fish.

- Material: Stainless steel

- Type of the equipment: Individual machine

- Country of origin: Slovakia

The price is indicated with a semi-automatic control panel

The vacuum cooking kettle is designed for use in public catering establishments (restaurants, hotels, catering companies) and small manufacturing businesses. This equipment enables boiling, blanching, frying, evaporation, pasteurization, mixing or stirring.

- A unique multifunctional device

- Possibility to cook/fry under atmospheric or vacuum conditions

- Laboratory version of a Vacuum Fryer

- Built-in condensation and secondary steam removal system

- Intense electric heating

- Sectional basket with a lid

- Built-in system for separating and removing excess liquid from the product

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Volume: 20l

- Oil volume: 8l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Blancher pouring AQ is designed for heat treatment of a wide range of products whose fine structure requires to minimize mechanical influence in the blanching or cooking process. Unlike a drum blancher, in which the product is blanched in a process of single directional mixing and rolling and a screw blancher, in which the product passes through a working chamber by means of a screw, in the belt type blancher the product lies motionless on the conveyor belt and is processed without damaging its surface.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

The stated price does not include the steam generator

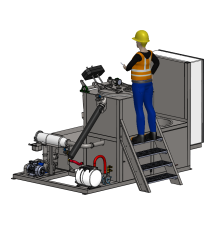

The unique sectional cooking kettle is intended for high-performance cooking/blanching/frying of a wide range of products with subsequent cooling to avoid damaging their structure. An essential part of this technology is the efficient cooling section, necessary for halting the cooking process after unloading. This function is also necessary when processing vegetables to the "aldente" state, when vegetables retain their structure and natural color after thermal treatment. This model provides heating by direct injection of purified steam into the heating section (steam generator - option).

- Suitable for cooking small-sized products

- Fast and intense heating due to direct steam injection

- Intensive hydro-stirring

- Automatic basket lifting system

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 2x250l/ 3x250l

- Voltage: 380-400V

- Working volume: 2x175l/ 3x175l

Designed for blanching vegetables, fruits, legumes, pasta, seafood before preservation and freezing.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

SnackPro blancher will prepare different types of products making it a great solution for blanching large volumes of fruits and vegetables in a short time.Â

- Heating: Electricity

- Heating power, kW: 40/ 90

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The automatic screw cooker is designed for cooking or blanching various food products in continuous mode, saving both time and energy during production.

- Heating: Mixed

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The price is set for the basic fryer version without additional modules. If purchasing the fryer together with both of the additional conveyor modules â the double conveyor fryer and the paddle conveyor fryer â we offer a discount of 300 EUR.

The versatile modular conveyor fryer with a single conveyor belt is used for the continuous frying of a variety of products with a low moisture content, that do not require forced immersion beneath the surface of the oil for even frying.

- Adjustable frying time from a few seconds up to an hour!

- Ability to use the unit as a continuous blancher or boiler for cooking products with a delicate structure

- Modular system, expanding functions with each new module

- Compact, desktop version

- Possibility of periodic frying of products with automatic unloading

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Oil volume: 60l

- Voltage: 380-400V