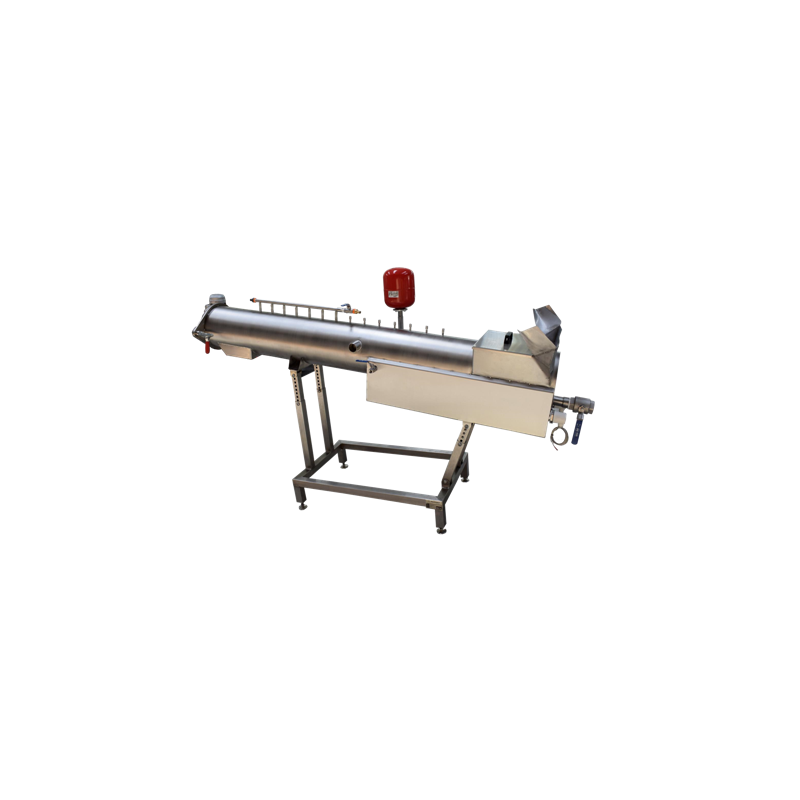

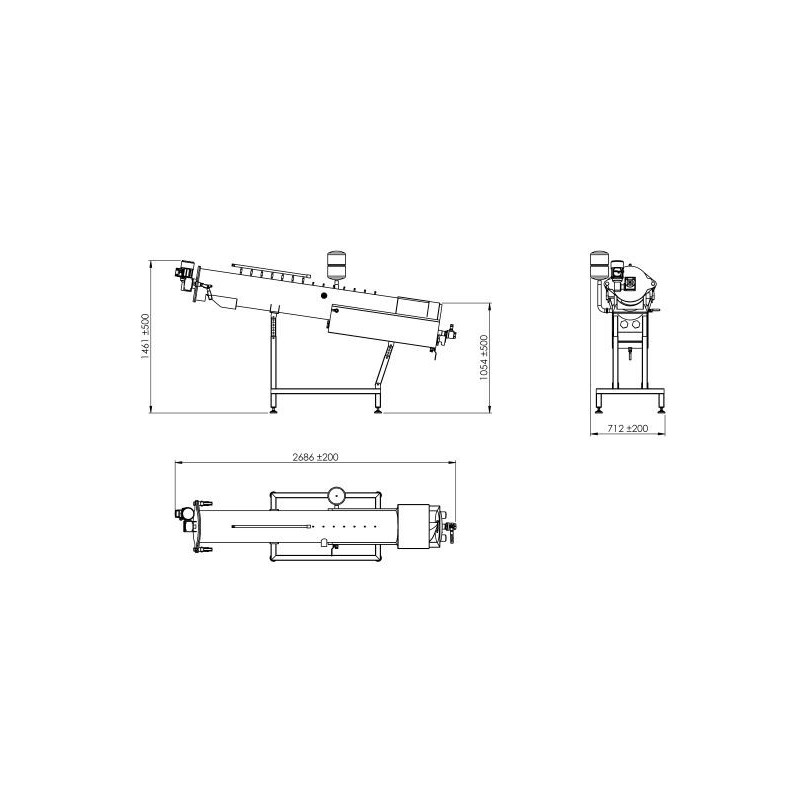

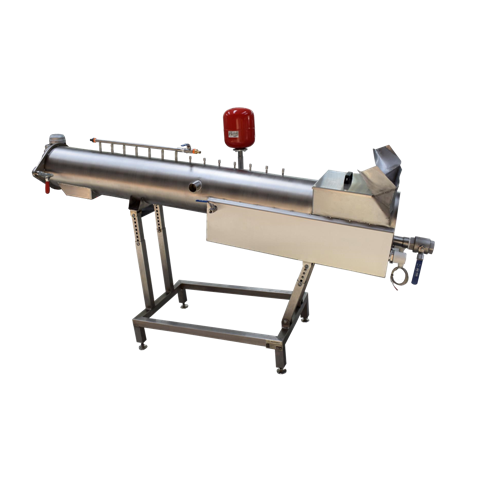

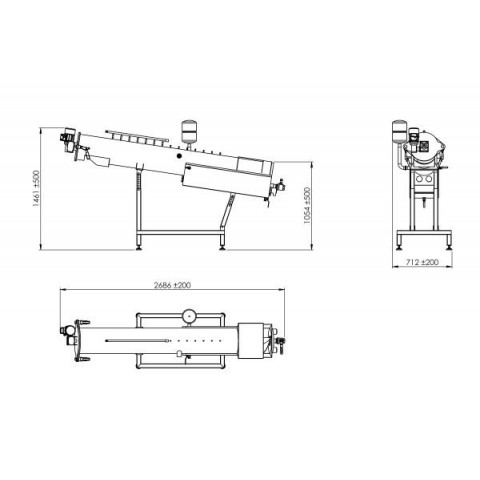

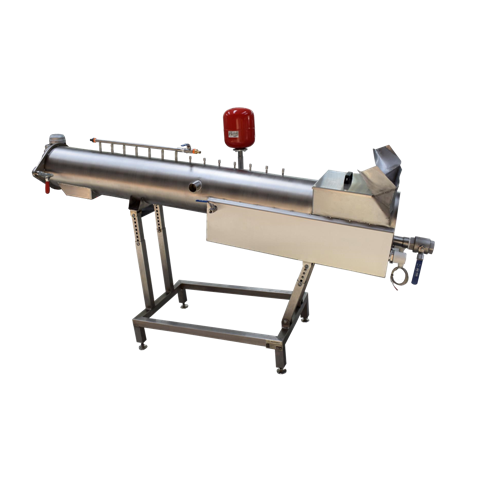

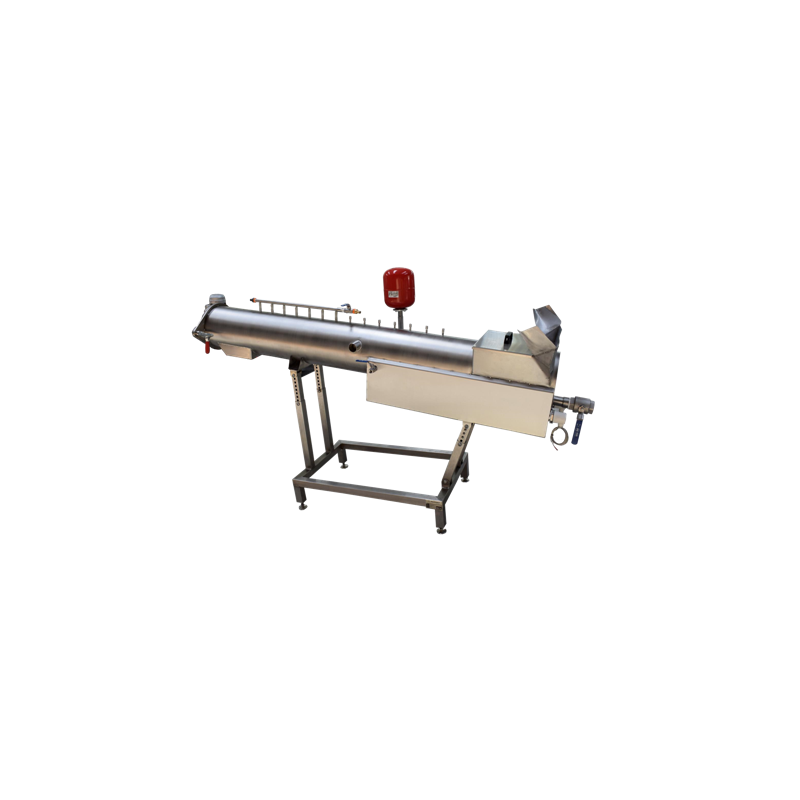

Inclined screw blancher Screw I

Designed for blanching vegetables, fruits, legumes, pasta, seafood before preservation and freezing.

The blanching process is an alternative way of cooking and sometimes it is the only one way of culinary processing for products which are heat sensitive.

The blanching activity principle: The blancher is determined for blanching of vegetables, fruits, leguminous plants, pasta products, seafood before conservation and freezing.

A short processing by steam or warm water enables to clean a product from microbes and moulds after that it becomes safe for a consumer. One of the blancher advantages is its universality.

The plant can be configured in the way to process different kind of products, such as:

- soft seafood like mussels without armor or shrimps,

- vegetables,

- mushrooms,

- and many others.

It is used for:

- Softening process - blanched products need shorter time for final preparation.

- Enzymes deactivation - it reduces or interrupts enzymes action which can damage the product colour, taste and smell. Some products obtain light coloration during the blanching process.

- Partial air removal from product aids to increase the durability after additional conservation and freezing and it also minimizes the product volume.

- Partial water removal helps with the additional product freezing at assembly lines of fruits, vegetables, leguminous plants and seafood.

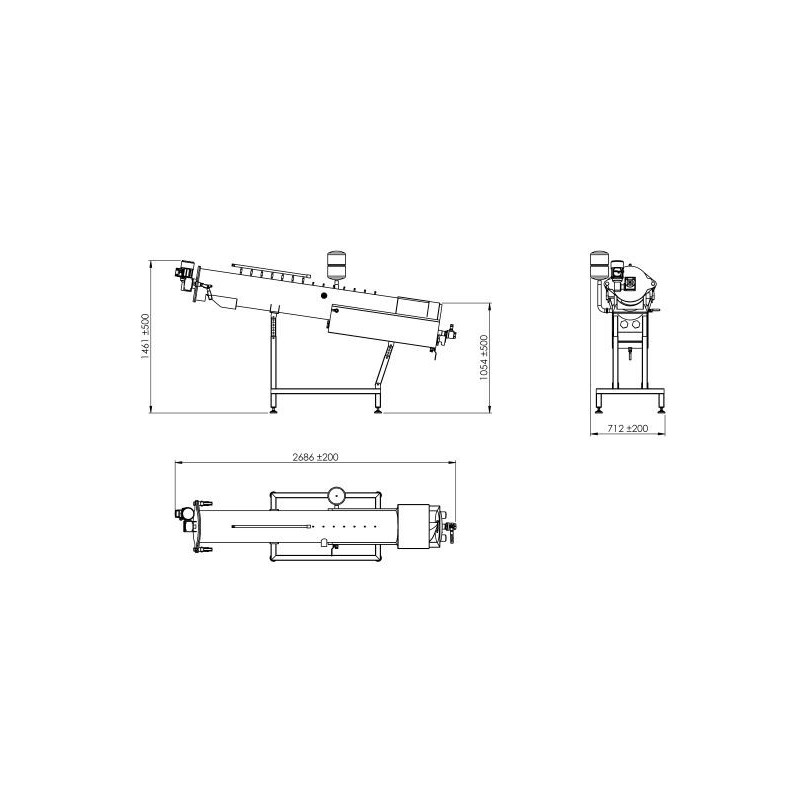

The screw blancher is equipped with a product feed hopper. Hot water is located at the bottom of the device. The water heater is implemented through a duplicator. The product is transported by movement of the screw. At the top of the device, nozzles for water injecting are placed.

Advantages:

- Universality. A plant can be used for steam and water blanching. The time of blanching process varies according to change of the tilt angle and its rotary speed which enables to vary the time of blanching process approximately 10-15 times.

- It can be also used for freezing raw materials.

- Reliability - the blancher is determined for intensive long-lasting operation. The plant is produced in our manufactures by using high-quality European materials and components.

- Good manufacturing features. The radial construction reduces the possibility of shaft damage.

- Easy maintenance and access to internal surfaces.

- Low level of vibration and noise.

- Possible additional section of preliminary thawing for using raw materials.

Universality / Options:┬Ā

- The wide range of configuration options allows to select the optimal plant for any usage.

- The blanching process is possible to realize by water or steam.

- The integrated or extended section of water or air cooling.

- The installation variety of optional additional equipment.

- The variable performance. The performance of screw blancher is determined by the specific product density and processing time.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Screw Blancher

You might also like

The Batch Blancher Cook & Chill is designed for boiling, frying, heating and cooling of a wide range of products.

Price depends on the chosen option.┬Ā

- Material: Stainless steel

- Country of origin: Slovakia

- Voltage: 380-400V

The blancher is designed for blanching and cooking fruits, vegetables, meat, fish, mushrooms.

The price depends on the selected options.

- Material: Stainless steel

- Working volume: 700l

- Geometric volume: 1000 l

- Dimensions, mm: 3180x1860x1080

The blancher is primarily intended for blanching lumpy products such as mushrooms and vegetables.

Price depends on the chosen options.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 450

- Geometric volume: 550 l

- Dimensions, mm: 1770x899x997

Price depends on the required production capacity.

- Material: Stainless steel

- Heating power, kW: 90

- Dimensions, mm: 3549x1919x1490

- Blanching section, mm: 400x1800

- Cooling section, mm: 400x900

We offer many different types of blanchers including continuous models as well as batch blanchers.

- Material: Stainless steel

- Heating power, kW: 72

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

- Working Area Width: 420 mm

Pouring Blancher┬ĀShowerBlanch is designed for heat treatment of a wide range of products whose fine structure requires to minimize mechanical influence in the blanching or cooking process. Unlike a drum blancher, in which the product is blanched in a process of single directional mixing and rolling and a screw blancher, in which the product passes through a working chamber by means of a screw, in the belt type blancher the product lies motionless on the conveyor belt and is processed without damaging its surface.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The blancher is designed for blanching and cooking fruits, vegetables, meat, fish, mushrooms.

The price depends on the selected options.

- Material: Stainless steel

- Working volume: 700l

- Geometric volume: 1000 l

- Dimensions, mm: 3180x1860x1080

The stated price does not include the steam generator

The unique sectional cooking kettle is intended for high-performance cooking/blanching/frying of a wide range of products with subsequent cooling to avoid damaging their structure. An essential part of this technology is the efficient cooling section, necessary for halting the cooking process after unloading. This function is also necessary when processing vegetables to the "aldente" state, when vegetables retain their structure and natural color after thermal treatment. This model provides heating by direct injection of purified steam into the heating section (steam generator - option).

- Suitable for cooking small-sized products

- Fast and intense heating due to direct steam injection

- Intensive hydro-stirring

- Automatic basket lifting system

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 2x250l/ 3x250l

- Voltage: 380-400V

- Working volume: 2x175l/ 3x175l

The price is set for the basic fryer version without additional modules. If purchasing the fryer together with both of the additional conveyor modules ŌĆō the double conveyor fryer and the paddle conveyor fryer ŌĆō we offer a discount of 300 EUR.

The versatile modular conveyor fryer with a single conveyor belt is used for the continuous frying of a variety of products with a low moisture content, that do not require forced immersion beneath the surface of the oil for even frying.

- Adjustable frying time from a few seconds up to an hour!

- Ability to use the unit as a continuous blancher or boiler for cooking products with a delicate structure

- Modular system, expanding functions with each new module

- Compact, desktop version

- Possibility of periodic frying of products with automatic unloading

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Oil volume: 60l

- Voltage: 380-400V

Blanching helps keeping the vitamins and nutritional properties of the product, as well as an outer appearance with bright and natural color.

- Heating: Electricity Steam

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

SnackPro blancher will prepare different types of products making it a great solution for blanching large volumes of fruits and vegetables in a short time.┬Ā

- Heating: Electricity

- Heating power, kW: 40/ 90

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The cost is indicated without the price of the baskets

A batch blancher with indirect electric or steam heating is used for blanching vegetables, mushrooms, meat, fish, and seafood. This type of blancher is ideal for use in catering kitchens and hospitals.

- Simple controls

- Built-in electric heating

- Large outlet valve

- Safe operation

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 18/ 24/ 30/ 36

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 200l/ 300l

Blanchers are used to quickly heat or steam vegetables or fruits, often for the purpose of softening, preserving color, or removing skins before further processing. Geometrical volume 400 l.

- Material: Stainless steel

- Heating power, kW: 18

- Type of the equipment: Individual machine

- Country of origin: EU

- Weight: 300 kg

- Voltage: 380-400V

- Geometric volume: 400 l

Designed for cooking or blanching vegetables, fruits, legumes, pasta, seafood and other products in a continuous manner.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Price depends on the required production capacity.

- Material: Stainless steel

- Heating power, kW: 90

- Dimensions, mm: 3549x1919x1490

- Blanching section, mm: 400x1800

- Cooling section, mm: 400x900

The VFB vacuum fryer with a built-in blancher is intended for drying and frying a wide range of products as well as for the production of chips and crisps from potatoes, carrots, onions, celery, parsley, beetroot and many other types of fruits, vegetables, and different snacks made out of meat, pork skin and fish.

- Material: Stainless steel

- Type of the equipment: Individual machine

- Country of origin: Slovakia

Excellent blancher and cooker for efficient handling of vegetables and other food products.

- Principle of operation: Continuous mode

- Working Area Width: 600 mm

- Voltage: 380-400V

The blancher is primarily intended for blanching lumpy products such as mushrooms and vegetables.

Price depends on the chosen options.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 450

- Geometric volume: 550 l

- Dimensions, mm: 1770x899x997

This multifunctional cooking machine with two baskets is designed for different ways of use and is suitable for a lot of variety of businesses - any enterprise or any participant of the HoReCa market. With the help of this equipment, you can cook, pasteurize, or blanch.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 135 +135 / 220+220

This compact batch blancher is designed for efficient and simple blanching in smaller-scale food processing. Price depends on the chosen option.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 450l/