Tilting Cooker with a Mixer

Tilting pans with mixers cook the product with continuous stirring and subsequently discharge the food into receiving trolleys, ensuring the discharge spout remains at a constant height from the ground. Designed for the catering industry, large kitchens, school cafeterias, restaurants, and other food production businesses.

The innovative design of this system seamlessly integrates continuous stirring during cooking and subsequent efficient discharge into the receiving trolleys, maintaining a constant height of the discharge spout from the ground.

The mixing blades are customizable to suit different product types. Automation of the cooking parameters enhances the final product quality and significantly reduces the required kitchen personnel.

Cooking Tank

- Bottom in AISI 316 polished stainless steel

- Walls in AISI 304 stainless steel

Lid

- Balanced lid in AISI 304 stainless steel with a heat-resistant handle

Duplicator

- Bottom as well as the walls of the jacket are made out of AISI 304 stainless steel

Tilting Mechanism

- Automatic tilting via an electric or hydraulic actuator mechanism

- Automatic stop in case of damage

- Down and up button

- Electric supply: 400V - 3N - 50Hz

- Controlled by a dedicated PLC and a serial monitor

Mixing System

- Mixer with adjustable speed and automatic reverse

- Radial arms or scraping blades in stainless steel

- Scraper inserts made of stainless steel

- The mixer can be easily removed for cleaning or maintenance

Support Frame and Panels

- Stainless steel frame

- Thermal insulation out of high-density ceramic fiber 64/128

- Panels out of stainless steel with a fine satin finish

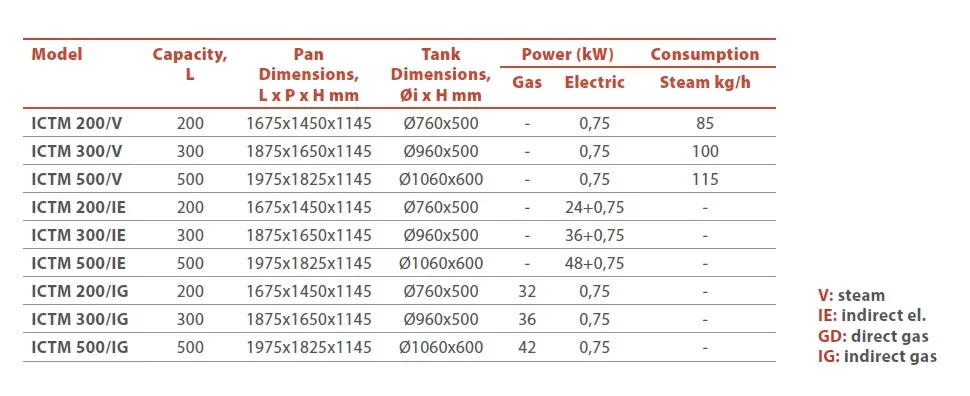

Available Capacities

- 200L model

- 300L model

- 500L model

HEATING OPTIONS

- Indirect steam heating

- Indirect electric heating

- Indirect gas heating

Heating System - Indirect Gas Version

- Heating through the high-efficiency stainless steel tube burners

- Ignition by manual piezo-electric lighter and a pilot flame

- Valve-controlled safety tap with a thermocouple

- Venting grid

- Set of jets for different gas types

- Automatic system to stop the burners during tilting

- Jacket water level control taps max/min with an option of automatic filling

- Jacket pressure control via a spring-loaded safety relief valve calibrated at 0.5 bar, vacuum valve, and a pressure gauge

- Option for the automatic venting of air inside the duplicator

Indirect Electric Version

- Heating by INCOLOY heating elements with an adjustable power regulator

- Safety thermostat to prevent overheating

- Jacket water level control taps max/min with an option of automatic filling

- Jacket pressure control with a working pressure switch and spring-loaded safety relief valve calibrated at 0.5 bar, vacuum valve, and a pressure gauge

- Standard power supply: 400V - 3N - 50Hz

Indirect Steam Version

- Heating by steam (from the userâs own source) with a throttle valve allowing gradual steam inlet

- Jacket pressure control via a spring-loaded safety relief valve calibrated at 0.5 bar, vacuum valve, and a pressure gauge. (A steam generator can be offered separately as the source of steam for the indirect steam heating option.)

- Heating: Electricity Gas Steam

- Material: Stainless steel

- Engine power, kW: 0,75

- Heating power, kW: 24/ 36/ 48

- Volume: 200l/ 300l/ 500l

- Steam consumption, kg/h: 85/ 100/ 115

You might also like

Heating boilers are designed to cook sausages, hams and oï¬al. Technology for superior performance and hygiene.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l/ 400l/ 500l/ 600l/ 800 l / 1000l/ 1200l/

The electric cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, broths, pasta, milk dishes, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared meals, heating or steaming. The equipment is not suitable for roasting or baking.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 18/ 24/ 30/ 36

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 100l/ 150l/ 200l/ 300l

Automatic cooker made for continuous batch production. Different types of food can be boiled, like pasta, rice, vegetables, meat etc. Options: direct gas, indirect steam boiling or direct electric.

Price depends on chosen option.Â

- Heating: Electricity Gas Steam

- Material: Stainless steel

- Heating power, kW: 2x25

- Volume: 2x135l/ 2x220l

- Steam consumption, kg/h: 2x70/ 2x100

Automatic tilting cooking pots, with lateral support upright designed for cooking solid foods that are transferred by tipping of the container. Options: steam boiling, indirect electric, indirect gas, direct gas. Capacity options: 50, 100, 150, 200, 300, 500l.

- Heating: Electricity Gas Steam

- Material: Stainless steel

- Volume: 50l/ 100l/ 150l/ 200l/ 300l/ 500l

- Voltage: 380-400V

If you need to cook the product at low temperatures, to better preserve the appearance and nutritional properties of the product, or to add components that are sensitive to heat, we recommend using the universal TiltCook boiler.

- Heating: Electricity Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 250l/ 300l

Automatic tilting cooking pots, with lateral support upright designed for cooking solid foods that are transferred by tipping of the container. Options: steam boiling, indirect electric, indirect gas, direct gas. Capacity options: 50, 100, 150, 200, 300, 500l.

- Heating: Electricity Gas Steam

- Material: Stainless steel

- Volume: 50l/ 100l/ 150l/ 200l/ 300l/ 500l

- Voltage: 380-400V

The innovative cooking device combines the advantages of cooking with automatic mixing and compact dimensions.

- Heating: Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 50l/ 150l/ 200l/ 300l/ 500l

Unbeatable price for highest quality material, modern technology, cylinder design. We offer different capacity catering cookers, electric, steam or gas.

- Heating: Steam

- Material: Stainless steel

- Volume: 150l/ 200l

Atmospheric cookers AC are designed for efficient mixing, heating and cooking products for the food, pharmaceutical and cosmetic industries. Working volume up to, l: 300 l.

- Material: Stainless steel

- Engine power, kW: 1,5 KW

- Heating power, kW: 13,5

- Principle of operation: Batch mode

- Working volume: 300 l

- Geometric volume: 350 l

The price is set for the basic fryer version without additional modules. If purchasing the fryer together with both of the additional conveyor modules â the double conveyor fryer and the paddle conveyor fryer â we offer a discount of 300 EUR.

The versatile modular conveyor fryer with a single conveyor belt is used for the continuous frying of a variety of products with a low moisture content, that do not require forced immersion beneath the surface of the oil for even frying.

- Adjustable frying time from a few seconds up to an hour!

- Ability to use the unit as a continuous blancher or boiler for cooking products with a delicate structure

- Modular system, expanding functions with each new module

- Compact, desktop version

- Possibility of periodic frying of products with automatic unloading

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Oil volume: 60l

- Voltage: 380-400V

The price is set for the basic version of the installation without additional equipment.

The vacuum homogenizer is designed for a wide range of processes such as for the production of mayonnaise, ketchup, various sauces, confectionery pastes and fillings, liquid or paste like products with a homogeneous structure. It is also suitable for the production of various creams, gels, shampoos and other products in the cosmetic industry.

- Built-in Ultra Shear bottom homogenizer

- Mixing device with movable scrapers

- Tilting version for easy unloading

- Wide range of applications

- Entirely made of food grade stainless steel AISI304/ AISI316 - option

- Compact design

- Lots of additional options to choose from

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 20l/ 50l

- Total power, kW: 2,3/ 2,4

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

MP cooker is a reliable and extremely functional solution for cooking, pasteurizing in the same tank thus saving equipment cost, space. All material are most reliable in European market so guarantee a long and trouble free operation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

Cooking tank with a bottom out of stainless steel AISI 316. Capacity of 150 liters.

- Heating: Steam

- Material: Stainless steel

- Volume: 150l

The vacuum cooking and mixing tank is used to boil products at low temperatures, which helps preserve the natural color, taste and nutrients in the product.

Vacuum equipment is used for cooking premium-quality jams, sauces, fruit and vegetable concentrates.

- Inclined design

- Efficient emptying

- High hygiene standards

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

The brewery boiler comprises a two-pot-shaped assembly, in which the integrated frame is a built-in lauter tun, a mash tank, a whirlpool, a laboratory sink and a control panel.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 1800l

This multifunctional cooking machine with two baskets is designed for different ways of use and is suitable for a lot of variety of businesses - any enterprise or any participant of the HoReCa market. With the help of this equipment, you can cook, pasteurize, or blanch.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 135 +135 / 220+220

The atmospheric batch cooker model UniCook E or UniCook S, featuring a stirrer, is tailored to meet the diverse cooking needs of various food production businesses in industrial settings.

- Heating: Steam

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 1000l

The tilting cooker is produced in 2 versions: with gas or electric heating. The pan is designed for use in the food, hospital, catering industry and in large kitchens for making pasta, stewing and frying meat, fish, vegetables, mushrooms, frozen or semi-prepared, ready-to-cook meals, etc.

- Principle of operation: Batch mode

- Volume: 50l/ 80l/ 120l

- Voltage: 380-400V

The electric kettle with a stirring device and manual tilting is suitable for a wide range of applications in food production or professional kitchens. It has an independent frame and built-in intensive electric heating with a wok-shaped, multi-layer âsandwichâ base, allowing the heating temperature to reach up to 200 °C.

- High processing temperatures of up to 200 °C

- Built-in, powerful 2,6 kW / 6,5 kW electric heating

- Manual tilting and unloading system with three working positions, allowing a maximum tilt angle of 110°

- Professional high-temperature thermometer with a probe in the product

- Air insulation of the outer casing

- Stirring device with stainless steel scrapers for high-temperatures

- Material: Stainless steel

- Engine power, kW: 0,06/ 0,25/ 0,37

- Heating power, kW: 2,6 / 6,5

- Volume: 30l/ 50l/ 100l

- Stirrer speed, rpm: 18

The cost is indicated without the control panel, which can be selected and offered separately

A versatile cooking system, featuring an inclined reactor, a duplicator for heating and a frame mixing device, it is designed for processing a diverse range of products through methods such as cooking, boiling, and concentrating at atmospheric pressure. This system is commonly used for the production of syrups, jams, confiture, and honey processing.

- Slanted design with gravity mixing - 25% more efficient!

- External decorative casing made out of polished stainless steel with insulation

- Jacket for the bottom and the walls of the working container along the entire height

- Lid opening sensor for safe operation

- Scrapers are already included in the basic version of the installation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 300l/ 430l/ 600l/ 1000l

- Voltage: 220-230V 380-400V

Unbeatable price, excellent cooking results, designed to be placed in tight spaces where sharp edges or corners may create problems. We have different capacities boiling cookers.

- Material: Stainless steel

- Heating power, kW: 18

- Volume: 150l

- Voltage: 380-400V