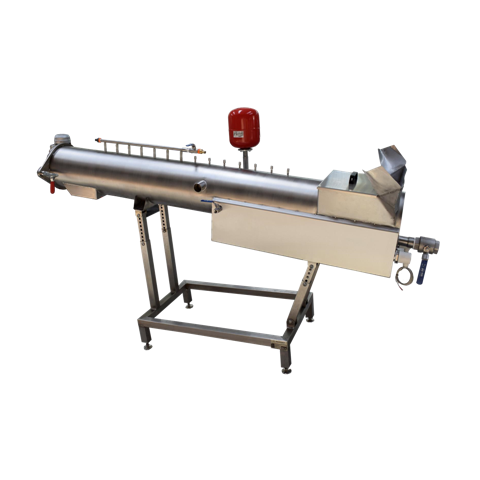

The screw cooker efficiently mixes and cooks ingredients in a continuous process, ensuring uniform heating and thorough blending of flavors in the final product.

Suitable products:

- vegetables,

- mushrooms,

- french fries,

- soft seafood like mussels without armor or shrimps,

- many others.

Adjustable legs

Inclined screw cooker are an effective method of moving certain materials in a production line while blanching or cooking them. Our inventory is composed of stainless steel screw cookers. It is possible to adjust the feet of the cooker to fit other equipment in your production line

Universality

The equipment can be used for many different processes such as blanching, cooking or defrosting raw materials.

Processes:

- Softening process

- Enzymes deactivation - it reduces or interrupts enzymes action which can damage the product color, taste and smell.

Advantages of the screw cooker

One of the screw cooker advantages is its universality. The plant can be configured in the way to process different kind of products, such as seafood, mushrooms and vegetables. It is possible to adjust the equipment to fit your production line.

How it works

Screw cooker is equipped with a product feed hopper. Hot water is located at the bottom of the device. The product is transported by movement of the screw. At the top of the device, nozzles for water injecting are placed.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

You might also like

The Batch Blancher Cook & Chill is designed for boiling, frying, heating and cooling of a wide range of products.

Price depends on the chosen option.┬Ā

- Material: Stainless steel

- Country of origin: Slovakia

- Voltage: 380-400V

The blancher is designed for blanching and cooking fruits, vegetables, meat, fish, mushrooms.

The price depends on the selected options.

- Material: Stainless steel

- Working volume: 700l

- Geometric volume: 1000 l

- Dimensions, mm: 3180x1860x1080

The blancher is primarily intended for blanching lumpy products such as mushrooms and vegetables.

Price depends on the chosen options.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 450

- Geometric volume: 550 l

- Dimensions, mm: 1770x899x997

Price depends on the required production capacity.

- Material: Stainless steel

- Heating power, kW: 90

- Dimensions, mm: 3549x1919x1490

- Blanching section, mm: 400x1800

- Cooling section, mm: 400x900

A vacuum cooker is used in the food processing industry to cook ingredients under reduced pressure, typically in a vacuum environment. This method allows for precise temperature control and faster cooking times while preserving the quality and flavor of the ingredients.

We offer different vacuum cookers.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 2500 l

The gas cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, pots, pasta, milk dishes, teaspoon cooking, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared meals, heating or steaming. This cooking equipment is not suitable for roasting or baking.

- Heating: Gas

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 80l/ 100l/ 150l/ 200l/ 300l

Universal cooking kettle with a built-in mixer, used for cooking and stirring a variety of food products, cosmetic emulsions, creams and much more.

- Easily removable self-adjusting scrapers

- Lid opening sensor for safe stirrer maintenance

- Hygienic temperature sensor for the product

- Large diameter outlet valve

- Safe steam outlet on top of the boiler lid

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

We offer wide range of catering equipment for restaurants, canteens and all kinds of food serving establishments. Price depends on the chosen option.

- Heating: Gas Steam

- Productivity: 300 l 600 l 1000 l

- Operation mode: Automatic

- Type of the equipment: Individual machine

The kettle is designed for cooking qualitative jam, marmalade, confiture from different fruits, vegetables and berries. It's an ideal and affordable solution for cooking various products.

- Material: Stainless steel

- Heating power, kW: 9/ 12/ 18/ 24

- Principle of operation: Batch mode

- Volume: 80l/ 120 l/ 200l/ 300l

The cost is indicated without the control panel, which can be selected and offered separately

A versatile cooking system, featuring an inclined reactor, a duplicator for heating and a frame mixing device, it is designed for processing a diverse range of products through methods such as cooking, boiling, and concentrating at atmospheric pressure. This system is commonly used for the production of syrups, jams, confiture, and honey processing.

- Slanted design with gravity mixing - 25% more efficient!

- External decorative casing made out of polished stainless steel with insulation

- Jacket for the bottom and the walls of the working container along the entire height

- Lid opening sensor for safe operation

- Scrapers are already included in the basic version of the installation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 300l/ 430l/ 600l/ 1000l

- Voltage: 220-230V 380-400V

Cooking kettles for cooking under pressure are designed for highly efficient heat treatment of a wide range of food products at temperatures up to 110 ┬░C and pressure up to 0.5 bar.

- Heating: Electricity Steam

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 220 l/ 500l/ 600l/

The steam cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, pots, pasta, milk dishes, teaspoon cooking, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared, ready-to-cook meals, heating or steaming.

The cooking equipment is not suitable for roasting or baking.┬Ā

- Material: Stainless steel

- Volume: 100l/ 150l/ 200l/ 300l

- Steam consumption, kg/h: 50/ 60/ 70/ 90

The price is indicated for the basic version of the set of equipment with a homogenizer

The equipment for the production of ice cream mixtures is based on a universal vacuum reactor with a coolant jacket and a multi-stage dispersant/homogenizer in an external circulation loop.

- Special type of a stirring device for easy disassembly and cleaning

- Processing with minimal product loss

- The bottom outlet valve is included in the basic version of the installation

- Multi-stage disperser for intensive wetting and homogenization of the flowing mixture

- External circulation circuit with a three-way valve for operation/washing of the equipment

- Reinforced agitator drive for thick and viscous mixtures

- Built-in vacuum pump

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Total power, kW: 3

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Multifunctional vacuum unit MINI5 - is ideal for cooking, drying, concentrating, mixing and much more. Suitable for laboratories and small-scale production.

- Processing heat-sensitive products at lower temperatures

- Ideal for making creamed honey

- Possibility of vacuum drying honey

- Material: Stainless steel

- Engine power, kW: 0,12

- Country of origin: Slovakia

- Volume: 5l

Universal cooking kettle with a built-in steam generator up to 0.5 bar, frame stirring device and an automatic tilt and unloading system is a convenient and safe solution for processing various liquid products in large volumes.

- Safe design with a jacket (duplicator) and outer casing with insulation

- Intensive steam heating through the jacket using the built-in electric steam generator

- Automatic multi-stage tilt and unloading system

- Frame stirring device for dissolving, mixing, kneading ingredients

- Unloading of the product into rolling carts is possible due to the offset tilted axis

- Heating: Mixed

- Material: Stainless steel

- Country of origin: Slovakia

- Total power, kW: 13,5

A vacuum evaporator is a device used to evaporate liquids at lower temperatures by creating a vacuum environment, which reduces the boiling point of the liquid and enables efficient evaporation without thermal degradation of sensitive materials. Working volume up to, l: 1900 l.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: up to 1900 l

Model VMG S is an effective and reliable vacuum homogenizing unit designed to produce a wide range of liquid, pastry and viscous products with different requirements for the production conditions.

The price is indicated with a semi-automatic control panel

The vacuum cooking kettle is designed for use in public catering establishments (restaurants, hotels, catering companies) and small manufacturing businesses. This equipment enables boiling, blanching, frying, evaporation, pasteurization, mixing or stirring.

- A unique multifunctional device

- Possibility to cook/fry under atmospheric or vacuum conditions

- Laboratory version of a Vacuum Fryer

- Built-in condensation and secondary steam removal system

- Intense electric heating

- Sectional basket with a lid

- Built-in system for separating and removing excess liquid from the product

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Volume: 20l

- Oil volume: 8l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

This stainless steel cooking pot will always ensure cooking, baking or boiling different foods.

- Material: Stainless steel

- Voltage: 380-400V

- Working volume: 100

MP cooker is a reliable and extremely functional solution for cooking, pasteurizing in the same tank thus saving equipment cost, space. All material are most reliable in European market so guarantee a long and trouble free operation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU