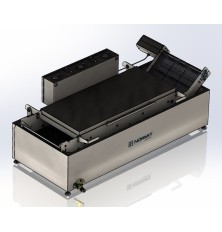

Vacuum fryer VF30

The price is set based on the basic built-in heating option of 24 kW.

The vacuum fryer is designed for frying foods in oil at low temperatures, allowing for the production of healthy snacks such as vegetable and fruit chips. The vacuum feature enables you to reduce the frying temperature of oil down to 110-120 degrees!

- «Cold roast» is a tasty and healthy method of processing the product

- Drying and frying without caramelizing the sugars contained in the product

- Large frying tank - for processing foods with a higher water content

- Modular heating system which allows you to increase the heating power up to 108 kW (optional)

- Circulating heating of oil through a heat exchanger minimizes oil spoilage and prevents localized overheating

The vacuum fryer is intended for use in industrial and experimental institutions (laboratories) for food production. It is also suitable for small-scale food production and catering establishments.

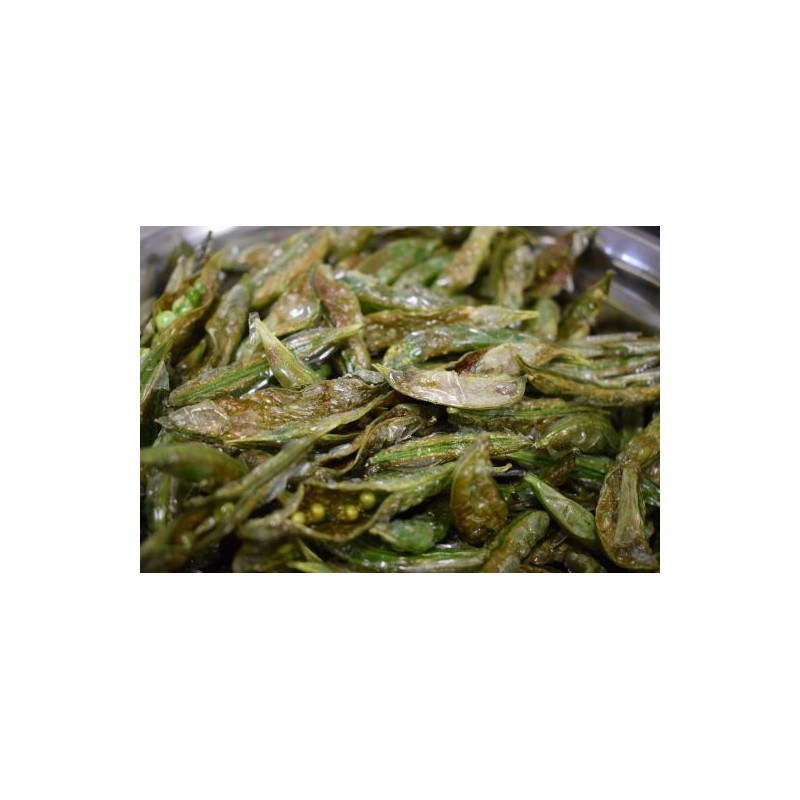

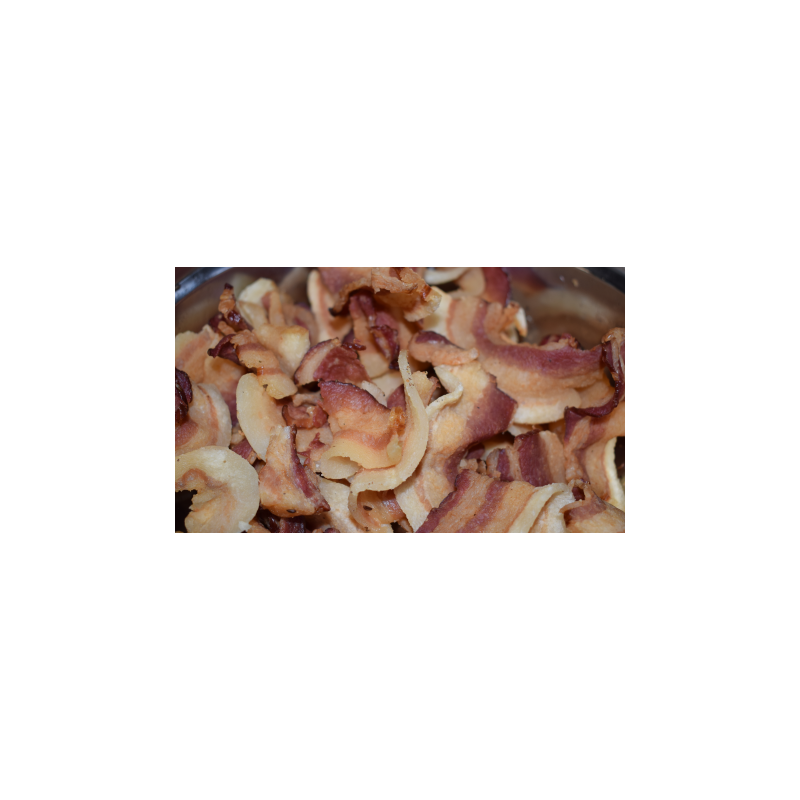

The vacuum frying unit is designed for a wide range of products such as:Â

|

|

|

|

|

|

|

|

A vacuum frying system allows you to experiment with a wide range of food products, including obtaining intermediate raw materials for further processing or production.

Advantages:

- Deep frying under vacuum conditions is a modern technological method aimed at reducing both the time and temperature needed for processing the product. This results in a healthy final product with a crispy crust and a minimal amount of oil. The product is fried in its own juices, due to the rapid formation of deep fat that protects against excessive saturation of the product with oil.

- Frying at low temperatures prevents the oil from becoming rancid and carcinogenic. The oil stays fresh longer and consumption is significantly reduced compared to traditional atmospheric fryers.

- Uniform frying is achieved by supplying oil into the working frying chamber from below. The basket gradually fills with oil from the bottom up, ensuring thorough frying of the product throughout all layers of the basket.

- Heating occurs due to the circulation of oil through a heat exchanger with heating elements, which protects the oil from local overheating and guarantees fast and efficient heating and heat transfer.

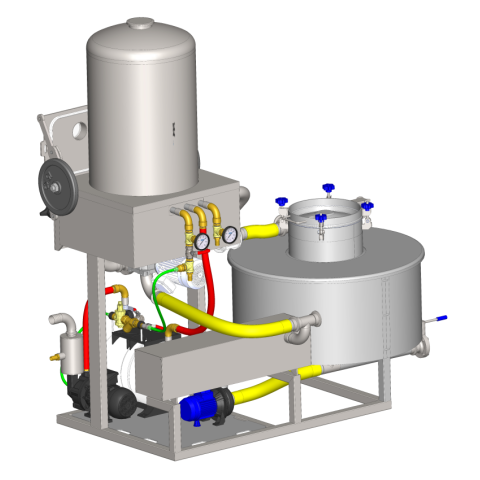

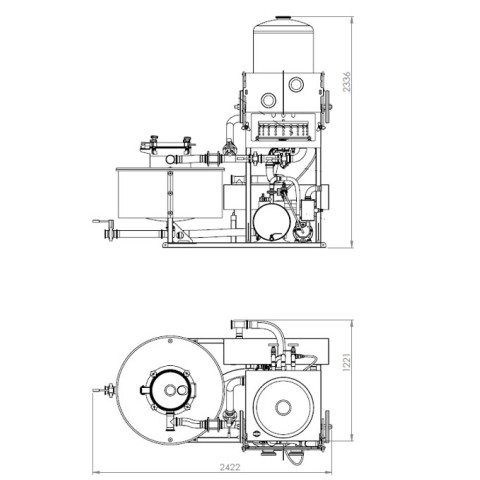

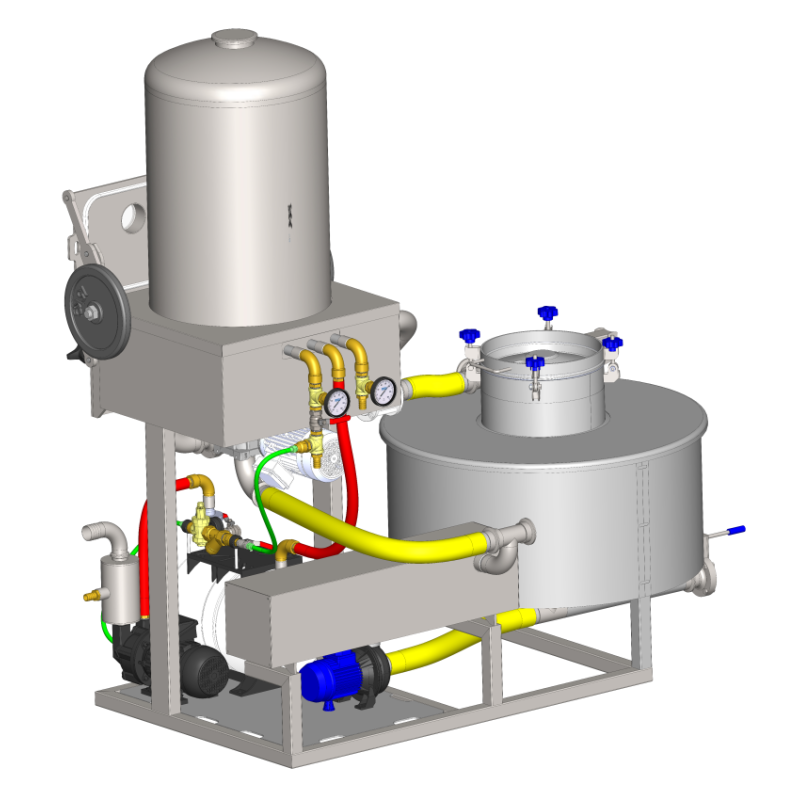

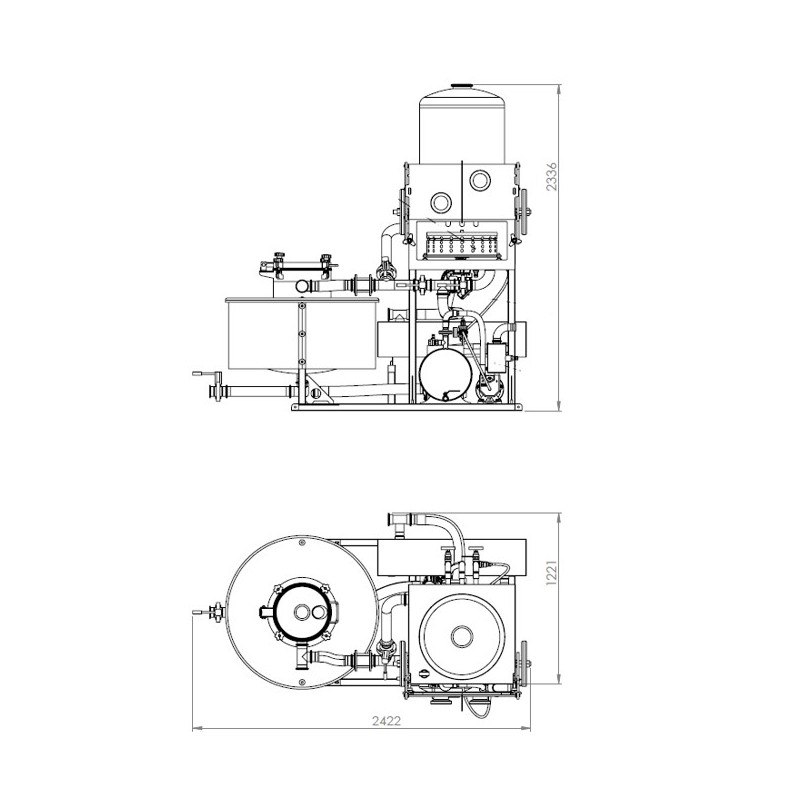

- Compact system on a common supporting structure: a closed container for storing oil, a frying chamber with a built-in centrifuge, a flow-through heat exchanger and a container for collecting condensate.

- Quick side loading into the frying chamber (no more than 2-3 minutes): convenient, safe, does not require additional lifting devices for loading/unloading the basket.

Basic version

The VacuFry system includes: an oil container, a working vessel for frying, a heating system (flow-through heat exchanger), a circulation system, 1 working basket for frying, a vacuum system including a vacuum generator, a vacuum holding and regulation system, a separation system for removing excess oil and a container for collecting condensate.

Principle of operation

The vacuum fryer allows, by creating a vacuum environment, to process the product at lower temperatures - âbelow the boiling pointâ under atmospheric conditions. An important feature of the installation is the centrifugal fat removal system, which allows you to obtain a âdryâ finished product. The technology for vacuum-frying products not only saves on energy costs, but also preserves the structure, color and taste of the finished product.

The dry product ready for processing is loaded into the basket of the frying container. After creating a vacuum in the system, the oil from the oil tank is pumped into the heat exchanger (flow-through heater), where it is heated. After reaching the required temperature, the oil is fed into the frying chamber from below until the basket is completely immersed in oil. During frying, steam arises, which is then converted into a liquid state (water) using a condenser; the condenser releases the water into a container for collecting condensate. After finishing work, the condensate is automatically released into the sewer. After frying, the fat removal process is activated - a centrifuge, which allows you to obtain a âdryâ finished product at the end of the work cycle.

Required conditions:

- The presence of a cold water source or ice water station to supply the condenser (30,000 liters per hour, pressure 4 bar, temperature at the condenser inlet no more than 7 degrees)

- A connection to the sewer system for the release of condensate from the condensate collection tank; it is necessary to install a grease trap before releasing water into the sewer system

- A source of compressed air (6-10 Bar, 900 l/min)

Options:

- Additional basket

- Increased heating max up to 108 kW

- A modified design for the 50-liter basket

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 24

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 30l

- Oil volume: 200l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar