Frozen Butter Homogenizer / Reworker FBHG

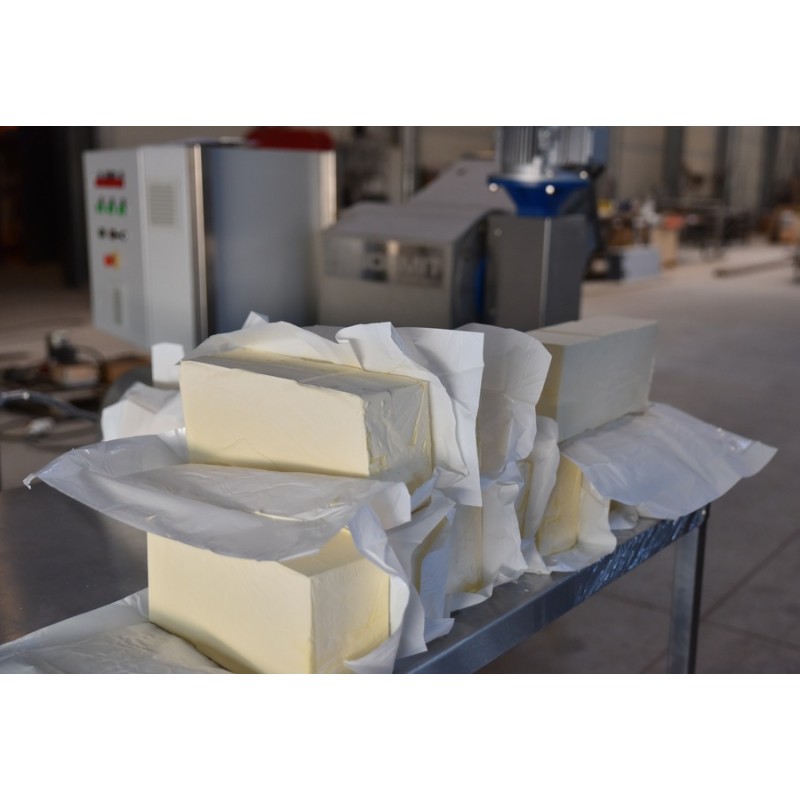

The butter texturizer FBHG is intended for mechanical processing of frozen blocks of butter, animal fat, margarine and other plan fats, without prior defrosting.

The homogenization of butter is carried out in order to improve the butter's consistency and taste stability especially during storage.

In the process of plasticization, a uniform distribution of moisture and other components is achieved, which ensures a long shelf life of the product, preserves the organoleptic properties, and shortens the time required for defrosting.

Suitable products:

- Butter

- Margarine

- Animal fat

- VegetableĀ fat

- Cheese

- Cottage cheese

- Soap

Features:Ā

- No need for prior defrosting

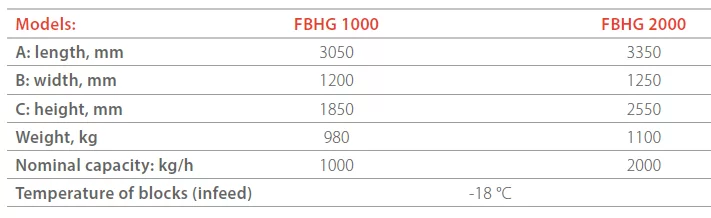

- From -18Ā°C at input up to 8Ā°C at output with a capacity up to 2000 kg/h (depends on chosen model) of continuous operation

- Processing butter blocks with a weight of up to 25 kg

- No microbial contamination

- No loss of moisture

- Air content in end product: max. 0.5%

Advantages

- There is no need for prior defrosting of butter or margarine blocks before packaging or using the blocks in your manufacturing process. This significantly saves space and time. The process takes place in an continuous mode, which considerably increases the capacity of production and decreases manpower costs.

- No microbial contamination. Frozen products gain plasticity quickly and evenly thanks to mechanical processing and the high pressure inside the processing chamber, and blocks can be placed into retail packaging with minimal increase in temperature (depending on the possibilities of the packaging device).

- The product is evenly processed. Unlike with traditional methods of defrosting, where the internal part of the block remains frozen and the outside part is already susceptible to bacteria and oxygen, frozen blocks are processed in the reworker evenly and without harming the properties of parts of the product.

- Uniform distribution of moisture. The special design of the operating parts helps to increase product plasticity and ensure even distribution of moisture, which provide long-term product storage, preservation of organoleptic properties and shortening of defrosting time.

- No air in end product. The unique design allows you to reduce the air content in the product down to 0.5% without the need for a vacuum chamber. Elimination of air is achieved by gradual narrowing of the processing area and extremely high pressure during the process of plastification. For obtaining the best result, the supply of the product into the reworker should be synchronized capacity-wise so that the so-called ābutter rollerā effect can be created, which prevents additional entrance of air into the area where the mixing screws operate.

- Very high level of hygiene. The homogenizer has been designed in such a way that it can be completely disassembled, with convenient access to all internal surfaces. There are no areas that are difficult to access. The working parts ā screw conveyors ā have a self-cleaning design. After the work is finished, the product does not remain on the screw conveyors, and therefore no product is wasted.

- Reliability and high quality of manufacturing. The reworker is made entirely from AISI304 or AISI316L grade stainless steel, depending on the customerās request. The reinforced construction, which is designed for uninterrupted operation at high pressure, and the high-quality seals ensure uninterrupted processing without loss of product.

Technical characteristics:

- Material: Stainless steel

- Principle of operation: Continuous mode

You might also like

The homogenization of butter is carried out in order to improve the butter's consistency and taste stability under storage conditions.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The cost is specified for the basic modification without a heating system

Fat block melters are designed for melting frozen, solid blocks of animal or vegetable fat, as well as maintaining them in a molten state at a specified temperature. We produce models with the option to connect steam as a coolant to the melting grid, separate electric heating systems, or configurations with built-in electric heating for supply into the jacket and melting grid.

- Large area of the melting grid where the coolant circulates

- Special shape of the melting grid, cutting blocks during melting

- Greater versatility in terms of the coolant and its source

- Mirror surface of the melting grid, ensuring high hygiene

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 200l/ 300l/ 500l/ 1000l

Intense fat melting machines MixMelters are designed for melting frozen, solid blocks of animal and vegetable fat such as butter and margarine as well as to maintain them in a melted state at a given temperature. Working volume up to, l: 200 l.

- Material: Stainless steel

- Heating power, kW: 12/ 24/ 48

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 200 l

Twin-screw extruder is designed for effective extruding, homogenization, pumping over of plastic masses (butter, margarine, honey, curd products, confectionery mixtures), and forming it into bars and rolls.

- Productivity: 400 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Weight: 115 kg

The circulation type homogenizer is designed for emulsifying thick fluids and other viscous materials within the food, chemical and cosmetic industries. Its working principle is based on the rotor/stator principle.Ā

- Material: Stainless steel

- Engine power, kW: 1,1/ 7,5 kW

- Country of origin: Slovakia

The vacuum homogenizer with an inclined design is designed for processing and manufacturing a wide range of liquid, pasty and viscous products with different requirements for their production conditions and other products including those with a high viscosity.

- Material: Stainless steel

- Engine power, kW: 1,5 KW

- Principle of operation: Batch mode

- Country of origin: Slovakia

The price is set for the basic version of the installation without additional equipment.

The vacuum homogenizer is designed for a wide range of processes such as for the production of mayonnaise, ketchup, various sauces, confectionery pastes and fillings, liquid or paste like products with a homogeneous structure. It is also suitable for the production of various creams, gels, shampoos and other products in the cosmetic industry.

- Built-in Ultra Shear bottom homogenizer

- Mixing device with movable scrapers

- Tilting version for easy unloading

- Wide range of applications

- Entirely made of food grade stainless steel AISI304/ AISI316 - option

- Compact design

- Lots of additional options to choose from

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 20l/ 50l

- Total power, kW: 2,3/ 2,4

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

The price is indicated for the basic version of the set of equipment with a homogenizer

The equipment for the production of ice cream mixtures is based on a universal vacuum reactor with a coolant jacket and a multi-stage dispersant/homogenizer in an external circulation loop.

- Special type of a stirring device for easy disassembly and cleaning

- Processing with minimal product loss

- The bottom outlet valve is included in the basic version of the installation

- Multi-stage disperser for intensive wetting and homogenization of the flowing mixture

- External circulation circuit with a three-way valve for operation/washing of the equipment

- Reinforced agitator drive for thick and viscous mixtures

- Built-in vacuum pump

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Total power, kW: 3

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The homogenization of butter is carried out in order to improve the butter's consistency and taste stability under storage conditions.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Vacuum homogenizer VMG M is the ideal solution for the production of pilot batches and the industrial production of a wide range of products of small and medium production. The price depends on the production capacity.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Max vacuum: -0,8 Bar

- Working volume: 50-80l

A honey homogenizer is a batch-type device designed to improve the product's structure and organoleptic properties. It ensures a uniform consistency and stable texture of honey.

Homogenization is a processing technology that makes honey flowable and uniform, as well as inhibits crystal growth, thus meeting the needs of producers and consumers. The design, size, and angle of the rotary auger achieve a high level of homogenization, which also reduces raw material processing time.

- High level of homogenization, aimed at increasing stability and improving the honey's structure without altering the product's flavor.

- No dead spots or corners due to the inclined bottom of both the working tank and the auger mixer.

- The working tank is equipped with a jacket and a built-in water heating system.

- Large-diameter outlet valve installed at the lowest hydraulic point.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 4/ 7

- Loading, kg: 500/ 1100

A professional mixer for the production of mayonnaise, sauces, soups and other homogenized products. The price depends on your production capacity, as well as the technological requirements.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 200l

- Total power, kW: 6

A twin-screw mixer with a homogenizer is an ideal solution for the production of creamy cheese, such as feta cheese, including with various flavors and seasonings. Thanks to mechanical homogenization, the cheese acquires a delicate structure without changing the individual taste properties of the product. It is used for plasticizing, creaming and softening butter, margarine and other fats.

- Capacity of the receiving hopper 50L

- Compact tabletop design for convenient operator maintenance

- A powerful independent drive for each screw with a reverser

- Easy maintenance and cleaning of the equipment

- Productivity: 250 kg/h/ 1500 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 3,5

- Voltage: 380-400V

The price depends on the required capacity.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 18

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 350 l

- Total power, kW: 1,5

Highly efficient production of a high viscosity pharmaceutical and cosmetic products.

- Material: Stainless steel

- Principle of operation: Batch mode

- Geometric volume: 500 l/ 800 l

The universal cooking boiler with an integrated homogenizer and a capacity of 1200 liters is designed for efficient mixing, heating, cooking and homogenizing of products for food, pharmaceutical and cosmetic industries such as jams, marmalades, syrups, fruit juices, nectars, beers, creams, ointments, soaps and many others.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

The homogenizer is designed to homogenize, mix and disintegrate / grind different fluids and components into small particles.

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Model VMG S is an effective and reliable vacuum homogenizing unit designed to produce a wide range of liquid, pastry and viscous products with different requirements for the production conditions.

Vacuum mixer processing plant for viscous products is an ideal solution for the production of pilot batches and the industrial manufacturing of a wide range of products from small to medium capacity.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l