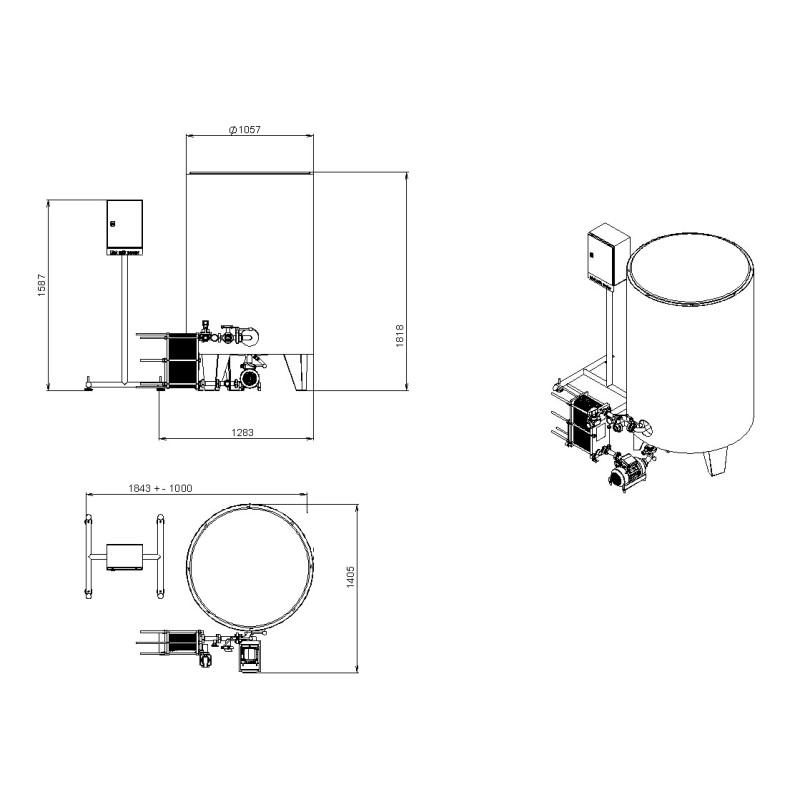

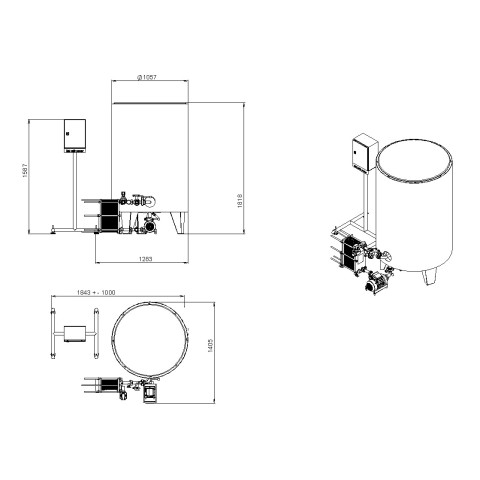

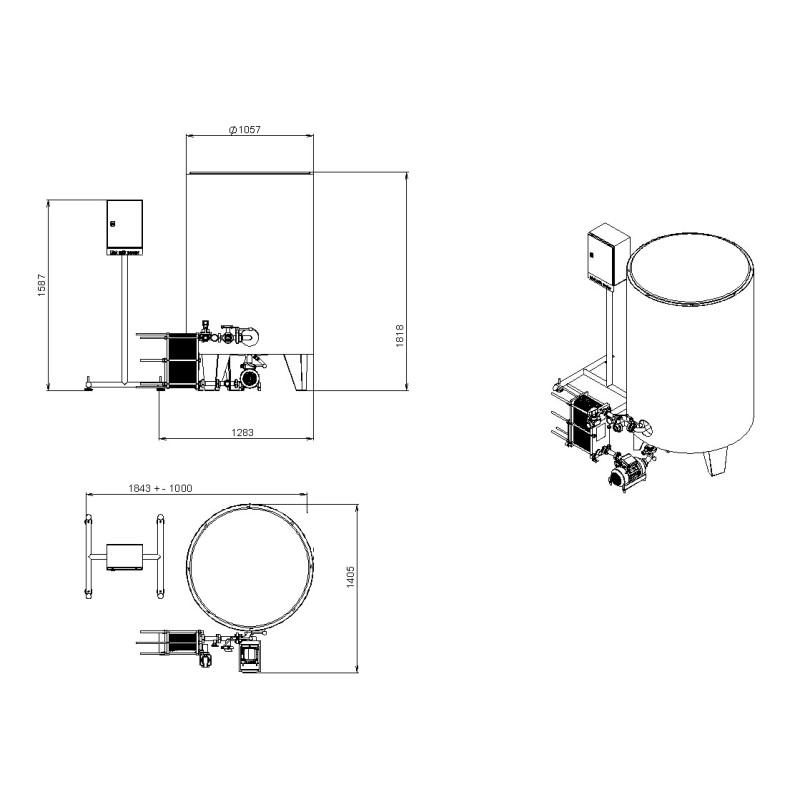

Long-term pasteurization tank - 1100 L

The long-term pasteurization tank is a compact solution for the heat treatment of milk, aiming to disinfect the microflora and eliminate harmful microorganisms. This unit belongs to the category of long-term pasteurization systems, heating milk between 63 and 95 degrees Celsius, and maintaining it at a specific temperature for a set period.

- Compact vertical design

- External forced circulation with a heat exchanger

- Highly efficient steam heating via the heat exchanger

- High-performance milk pump

The milk pasteurizer allows for heat treatment in long-term pasteurization mode with maintenance at a specific temperature. This allows for the destruction of almost 98% of bacteria and pathogenic microflora without destroying the protein and preserving all the organoleptic properties of milk.

The long-term pasteurization bath is an ideal solution for compact small-scale production involving the processing of milk in small volumes, such as the production of sweetened condensed milk from whole normalized milk.

Advantages:

- Highly efficient and intensive steam heating through a heat exchanger allows for the rapid attainment of the pasteurization temperature, with steam flow regulated by a temperature sensor.

- High milk flow rate is achieved due to the forced external circulation circuit. The unit is equipped with flow temperature sensors to prevent localized overheating or burning of the milk.

- Intensive heat transfer occurs through hydrodynamic mixing of the milk during constant circulation, which prevents possible stratification of the product into fractions. There is no need to install a mixing device!

- The unit is entirely made out of stainless steel, including the milk pump, all piping and shut-off valves in the circulation circuit.

- It features a compact vertical design with a freestanding control panel.

- Due to milk entering the circulation circuit below the liquid level, the likelihood of milk foaming during pasteurization is practically reduced to zero.

Basic Version:

It consists of a three-layer stainless steel tank (with thermal insulation and an external decorative casing), equipped with a forced external circulation circuit, a milk pump, a steam heat exchanger (up to 3 bar), a temperature sensor, and a control panel. Steam is supplied to the heat exchanger from an external source.

Options:

- Steam generator

- Touchscreen control panel

- Industrial controller-based control panel

- Heating: Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 1000l

The professional yogurt making machine is designed to produce a wide range of yogurt production, e.g. creamy, liquid drinking, greek, white, organic, fruit yogurts. The machine can be used by farms and small dairy factories.

For more information, send us an email to┬Āsales@foodtechprocess.com

The electric pasteurizer is ideal for the heat treatment of various fruits, including apples, pears, blackberries, strawberries, blueberries, elderberries, currants, carrots, greens, quince, beets, sea buckthorn, rowan berries, and onions.

Pasteurizers are used for the heat treatment (pasteurization) of juice before it is filled into bottles, containers or other types of packaging. Its compact, space-saving design and simple operation make it suitable for various production facilities.

For more information contact us at sales@foodtechprocess.com

MIP Y Pasteurizers are designed for the thermal processing of milk, for the production of yoghurt, white cheese (feta), hard cheese, ice cream and many other milk products.

For more information, email us at sales@foodtechprocess.com

Beverage Pasteurizer SB 750 refers to chamber types of pasteurizers used to pasteurize bottled beverages.

We offer different types of dairy pasteurizers. Tell us if you are producing cheese, milk, yoghurt or ice cream and we will help you pick the right pasteurizer for you.

Contact us at┬Āsales@foodtechprocess.com

We offer different pasteurizers for different applications.

For a price quote or for a free consultation, send us an email to sales@foodtechprocess.com┬Ā

The pasteurization equipment MGGP is suitable for the heat treatment of low viscosity foods as well as drinking water.

If you need more information, send us an email to sales@foodtechprocess.com

A 15-liter pasteurizer with a water bath that has a flat bottom and two canning racks, featuring a large capacity and made out of food grade 304 stainless steel.

The pasteurizer equipment MGGP is suitable for the heat treatment of low viscosity liquids as well as drinking water.

For more information, send us an email tat sales@foodtechprocess.com

A vat or cooking kettle for milk is a large container or vessel used for heating and processing milk, typically in dairy production, to pasteurize, cook, or produce various dairy products such as cheese or yogurt.

For more information or a free consultation, please contact us at sales@foodtechprocess.com

This multifunctional cooking machine with two baskets is designed for different ways of use and is suitable for a lot of variety of businesses - any enterprise or any participant of the HoReCa market. With the help of this equipment, you can cook, pasteurize, or blanch.

For a price quote, send us an email at sales@foodtechprocess.com

The device is designed for the pasteurization of a wide range of products in various types of packaging material such as cans and jars.

For more information, contact our sales department at sales@foodtechprocess.com

- Heating: Mixed

- Productivity: 300 l 400 l 500 l

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

Electric pasteurizer suitable for filling of bottles and bag-in-boxes as wellas pasteurizing beverages. We offer 3 production capacities. The pasteurizer comes without the manual BiB filler module.

If you wish to purchase the filler, please send us an email at sales@foodtechprocess.com