Milk pasteurization boiler MAK MIX

The pasteurization boiler with manual tilting is a modern device designed for gentle heat treatment of milk and dairy products, which allows for their effective pasteurization, extends shelf life and increases safety, while preserving the original taste and nutritional values. Thanks to the 6-stage heating regulation of the powerful integrated heater, milk can be reliably pasteurized directly in a container with a sandwich bottom, which ensures even heat distribution.

- Ideal solution for small-scale and home production of dairy products

- Removable lid for easy inspection and manual mixing of the product

- Option to equip with a drain valve and a cooling/heating jacket (duplicator)

- Even heating without burning thanks to the sandwich bottom

- Easy connection to a single-phase 230 V power supply

The pasteurization boiler with a tilting system is an effective solution for the heat treatment and stabilization of milk and dairy products.

This tilting pasteurizer is ideal for small producers, farmers, artisanal milk processors who want to obtain consistent results or for home production of cheese, yogurt and other dairy products. It allows for simple and reliable pasteurization of milk directly in a stainless steel container with a sandwich bottom, which guarantees even heat distribution, reducing the risk of burning the product. The temperature can be monitored with an optional thermometer.

The device can also be used for the pasteurization of sauces, jams, syrups, juices or soups, where it is important to preserve the natural taste, color and quality.

Thanks to the removable lid, the product can be visually inspected during pasteurization and manually stirred using a hand harp, which simplifies the production of cheeses and other dairy products. Optionally, the device can be equipped with a drain valve for convenient draining of the finished product or whey. Another option is a jacket (duplicator), through which cold water can be supplied for faster cooling after pasteurization.

The basic version of the device is equipped with an electric heater with a power of up to 2.6 kW, which can be connected to a single-phase 230 V power supply, without the need for a three-phase industrial electrical connection.

Suitable for:

- pasteurization of milk, cream and whey

- production of cheese and yoghurt

- pasteurization of syrups, sauces, broths, juices and juices

- heat treatment of baby food or plant-based drinks

Advantages:

- Compact and robust device suitable for domestic and commercial use

- Hygienic all-stainless steel design made out of food-grade AISI 304 steel

- Even heating without burning thanks to the sandwich bottom

- Removable lid - easy cleaning and possibility of visual inspection during pasteurization

- Manual stirring (e.g. harpfo) option when producing cheese or yoghurt

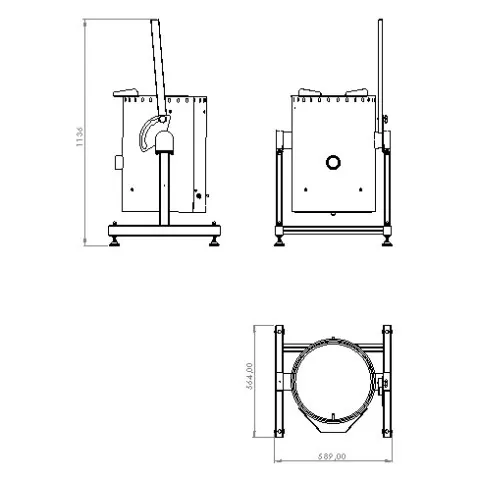

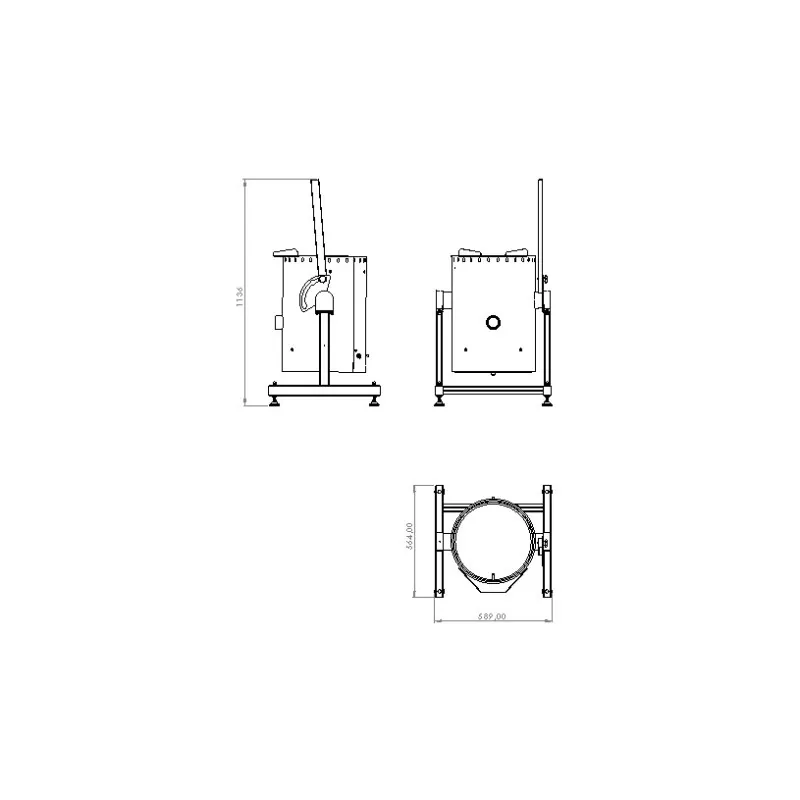

- Manual tilting system with 3 working positions and an angle of up to 110┬░ for easy emptying of the container

- Safe heating - 2600 W, single-phase power supply (230 V)

- Optional: drain valve for draining the product or whey

- Optional: cooling via a water jacket (duplicator) for faster cooling

The basic version includes:

- Pasteurization vessel with an insulating jacket

- Support structure with a manual tilting system (3 positions, angle up to 110┬░)

- Integrated heating with a power of up to 2.6 kW

- Precise temperature sensor located directly in the product or on the lid

- Wheels for easy transport of the device (optionally, legs can be selected)

Principle of operation:

Milk or other product is poured into the vessel, where it is gradually heated to the desired temperature. The layered bottom ensures uniform heating without burning and stable temperature maintenance throughout the entire pasteurization phase.

After the specified time, the product can be cooled either naturally or, in the version with a duplicator - by means of supplying cold water into the duplicator. After the process is finished, the container is simply emptied by tilting it manually or via the optional drain valve.

Optional equipment:

- Drain valve for the finished product or whey

- Jacket (duplicator) for cold water supply

- Height-adjustable legs instead of wheels

- Frequency converter as a control panel for mixing adjustment (IP65)

- Submersible and removable thermometer through the container lid

Technical characteristics:

- Material - Stainless steel AISI 304

- Volume - 50 / 100 l

- Heating power - 2.6 / 5 / 6.5 kW

- Power supply - 230 V (1-phase) or 400 V (3-phase, for higher powers)

- Pasteurization temperature - up to 100 ┬░C

- Material: Stainless steel

- Heating power, kW: 6,5

- Volume: 50l/ 100l

- Voltage: 380-400V