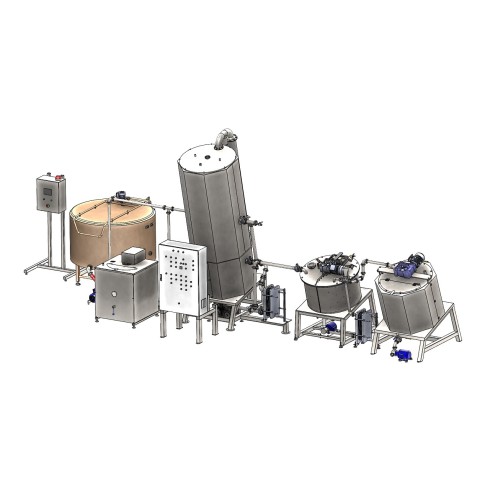

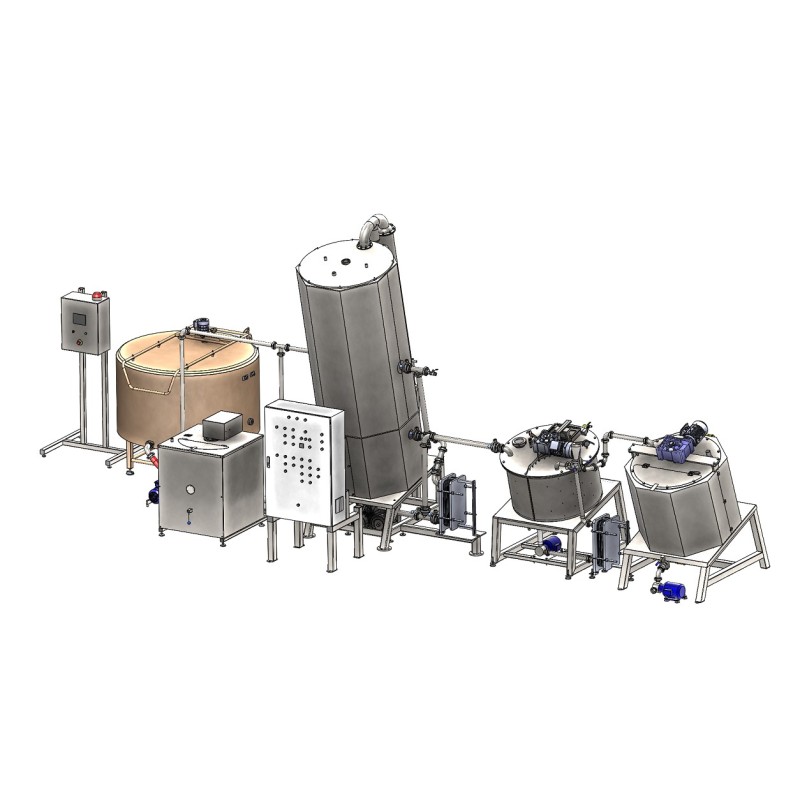

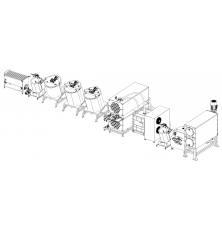

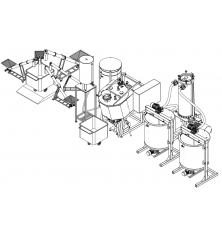

Sweetened condensed milk production line

Equipment for the production of condensed milk from pre-pasteurized milk. This equipment can be manufactured with a capacity of 50 to 500 kg/hour, or on request. We also manufacture condensed milk lines according to TU from dry milk or normalized milk concentration lines.

Equipment for the production of milk and sweetened condensed cream, vacuum crystallization.

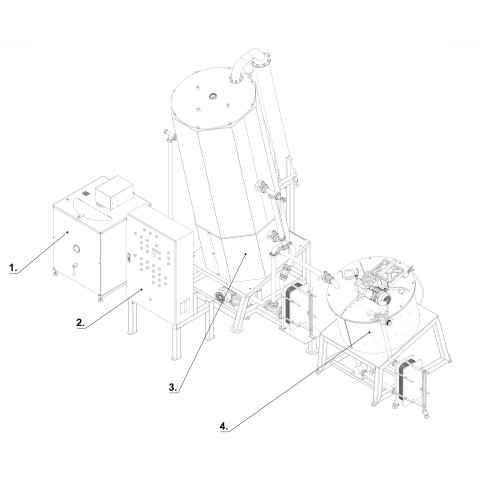

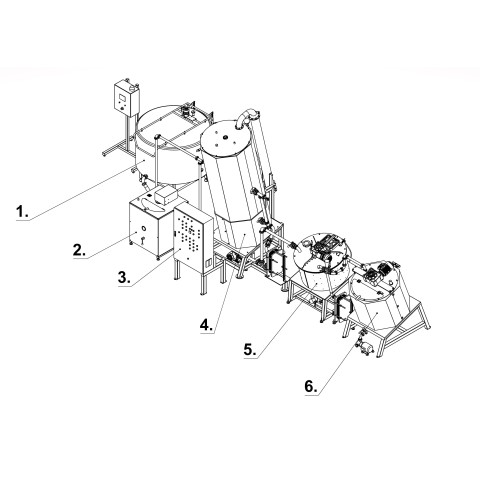

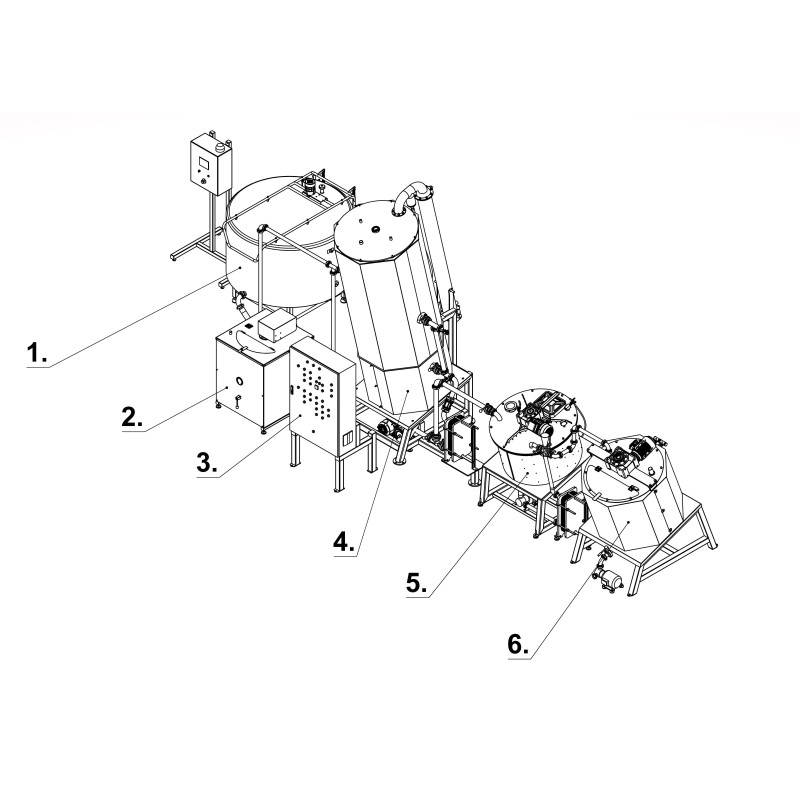

The basic version includes:

- Electric cooking kettle (cooker) for dissolving sugar and cooking the syrup

Preparation of the syrup is carried out by mixing granulated sugar with hot water, the temperature of which is 60-70 °C, and bringing the mixture to boil. Sugar syrups are recommended to be prepared with a sugar concentration of 65-70%. The boiling point of such syrups is about 105 °C, higher concentrations impair the thickening process and mix worse with milk due to the high viscosity. It is recommended that the finished syrup be filtered through a stainless steel flow filter before being fed into the vacuum evaporator to remove large mechanical impurities or undissolved sugar. It is recommended that sugar syrup be fed into the vacuum evaporator at the end of the milk thickening process. Syrup is boiled and milk is condensed in parallel.

Atmospheric working tank has a conical bottom, the unit is equipped with a built-in electric heating for thermal oil passing through a heating "jacket" (duplicator), with the help of a frame anchor agitator.

Ingredients are loaded through a sectional opening upper hatch, equipped with a safety grate. The heating system is equipped with a safety thermostat intended for adjusting the heating system.

The unit can be equipped with a forced circulation circuit with a stainless steel flow filter.

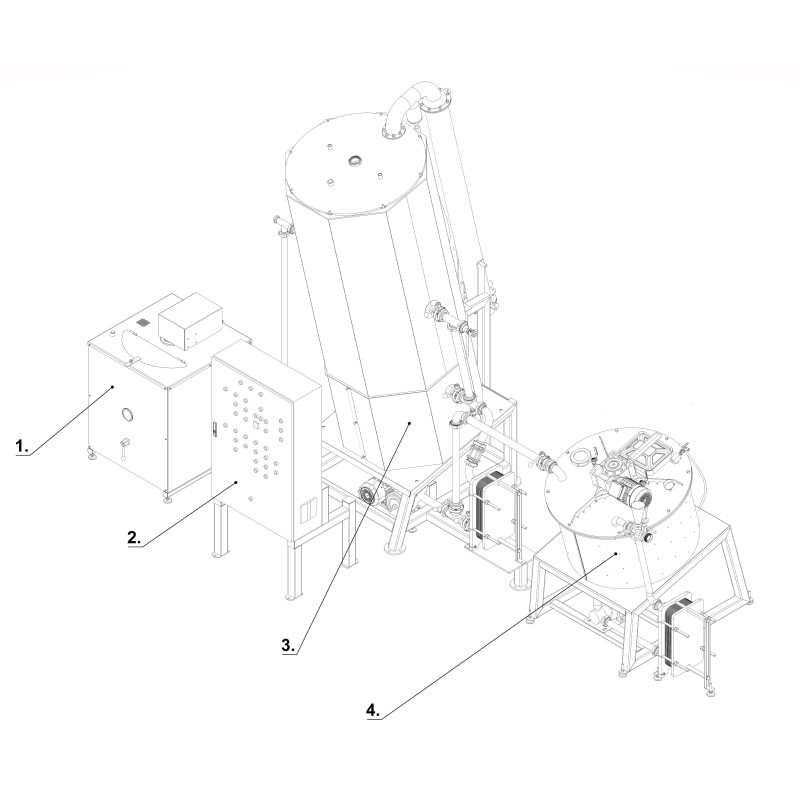

- Vacuum evaporator / vacuum evaporator for boiling, thickening pasteurized milk

This installation directly performs the functions of cooking-concentrating pre-pasteurized normalized milk.

It consists of an inclined vacuum reactor with a heating "jacket" along the entire length of the working vessel, including a bottom with thermal insulation and an external decorative casing, equipped with a frame agitator with an electric drive and scrapers made out of fluoroplastic, a vacuum generation system, a system for removing and condensing secondary steam, an external circulation circuit with plate heat exchangers and a product pump. Can be retrofitted with a sampling valve, viewing windows, CIP cleaning heads.

Normalized pre-pasteurized milk is fed directly from the milk pasteurizer at a temperature of 95-98 degrees in to the evaporator, where it is sprayed using a spray system. From finely dispersed droplets, the water content rapidly evaporates under vacuum conditions.

Drops of milk flow down as a thin film along the inner surface of the working container in the vacuum-evaporation unit due to the force of gravity, the scrapers of the mixing device pick them up and "unwind" them again, then they are mixed into the total mass due to the gravitational mixing method. The gravitational mixing method is 25% more efficient than conventional, and allows you to intensively mix thick and viscous products. The "duplicator" is specially designed to provide a high heat transfer area for intense steaming under vacuum. The device is part of the batch units, single-shell evaporators with an external circulation circuit with a pump and a flow-through remote heat exchanger for heating the product during recirculation before entering the vacuum evaporator. For effective steaming, milk must be fed into the machine chamber hot. Heating source - (external source) steam from the Customer. The maximum steam pressure at the inlet to the heating "jacket" is 0.5 bar, at the heat exchanger - depending on the type and model.

The secondary steam generated during the evaporation process will go through the "trap" to the steam removal system and the condenser, where the steam is converted into water (condensate) and removed by a pump to the condensate outlet, an additional condensate collection tank can be ordered. Checking the volume of condensate also allows you to control the evaporation process without the need for constant sampling of the product.

Normalized pasteurized milk thickens at a temperature of 50-60 degrees. Upon reaching the required concentration of milk, in accordance with the recipe, hot sugar syrup with a temperature of 90-95 degrees is supplied to the vacuum evaporator from an atmospheric syrup cooker, since at lower temperatures the viscosity of the syrup increases and it does not mix well with milk, while at higher levels, coagulation of condensed milk proteins is possible.

For the operation of the unit, it is necessary to provide steam with a pressure of 0.5 bar (ATTENTION! steam source, as well as control, shut-off and safety valves are not included in the delivery set). Saturated steam source - from the Customer. It is recommended to connect a steam trap when steam enters the heating "jacket", pipelines from the steam source must be thermally insulated. The condensate drain from the heating "jacket" must be connected to a condensate trap, which is not included in the delivery! It is recommended to connect the steam trap as close as possible to the condensate outlet.

For the correct operation of the condenser and the vacuum system, it is necessary to provide a source of ice water with a temperature of 5-7 degrees (ice water station) with a pump to transfer it to the condenser and into the vacuum pump cooling system.

The finished product - sweetened condensed milk is fed out of the plant into a storage tank for later use, or into a crystallizer if the condensed milk is later packaged for sale.

- Vacuum crystallizer-cooler

It is necessary for the controlled crystallization of condensed milk and the creation of a stable product structure with an identical particle size according to the sample. For controlled crystallization, it is necessary to add a seed/fuse (dry powdered lactose with a crystal size of 2-3 microns). As an alternative, you can also use condensed milk from previous batches after crystallization with a volume of at least 10%.

The unit consists of an inclined vacuum reactor equipped with a vacuum system, an electric frame stirrer, PTFE scrapers, and a cooling jacket. Ice water source not included! The unit can be retrofitted with an external circulation circuit with a pump for intensive cooling, as well as a heat exchanger installed in the circulation circuit for more intensive and faster cooling. Condensed milk must be cooled to the set temperature before the lactose is loaded. As additional options, the unit can be equipped with CIP wash heads, viewing windows and much more.

Uncooled condensed milk with sugar, contains lactose which is in the form of a saturated solution; when the product is cooled, the solution becomes supersaturated and its crystallization begins.

In the vacuum crystallizer, a second steaming of the product under vacuum also takes place. The crystallization process takes place with the help of constant stirring under vacuum while cooling, using an efficient gravitational stirring method.

For proper operation, it is necessary to ensure that ice water with a temperature of 5-7 degrees and a maximum inlet pressure of 0.5 bar is supplied to the cooling "jacket".

After the crystallization process, the finished product can be transferred for packaging or for further processing, for example, to the concentration section for the production of cooked condensed milk, for these purposes we can offer a separate universal installation:

ADDITIONAL EQUIPMENT

- Double-chamber plant for thermal processing of various products

This cooking unit is a complex of 2 inclined reactors on a single supporting structure, each one is equipped with a 4-layer casing with insulation, a "jacket" (duplicator) walls and bottom of the working tank for coolant up to 0.5 bar. The unit can be equipped with manholes, viewing windows, CIP wash heads and much more!

The boilers are made out of thick stainless steel, the design of which can withstand pressure up to 0.5 bar (overpressure) and vacuum up to 0.2 bar (residual). The tanks are interconnected by a system of pipelines with manual valves and a product pump, which allows for circulation within one boiler and between them.

At the request of the customer, the equipment can be equipped with a vacuum system for deaeration of the product after processing, which allows you to get rid of air bubbles contained after the heat treatment of the product and get a denser finished product.

The heating medium source is not included for the basic version! When using the concentrating unit, it is necessary to connect a source of saturated steam with a pressure of 0.5 bar at the inlet. The unit is not equipped with control, shut-off and safety fittings for connecting the heat carrier!

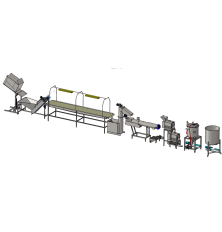

The units, depending on the automation, may have mechanical or pneumatic valves. The degree of automation is requested separately. The last photo showcases a shorter version of the condensed milk production line which is available as well.

Additional options:

- milk pasteurizer,

- storage tank (accumulator)

- two-body unit for thermal processing of various products

For a vacuum evaporation unit:

- a "jacket" for a coolant,

- a mixing device with an electric drive,

- a vacuum loader with a flexible hose,

- a steam generator or an ice water station

- and much more!

The units, depending on the automation, can have mechanical or pneumatic valves. The degree of automation is requested separately.