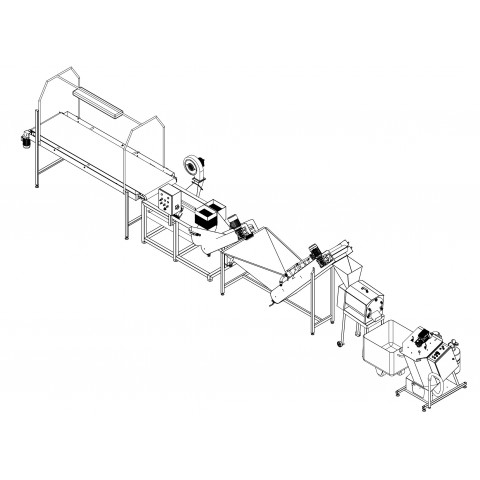

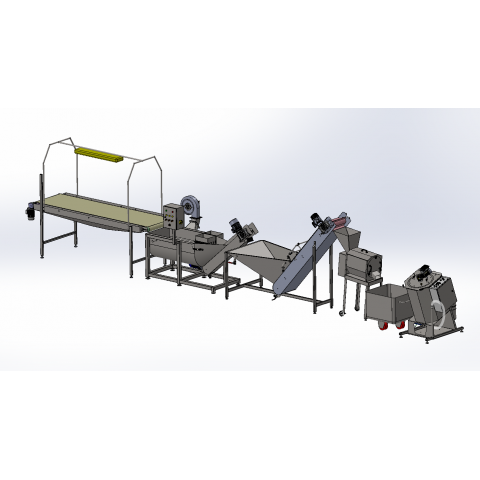

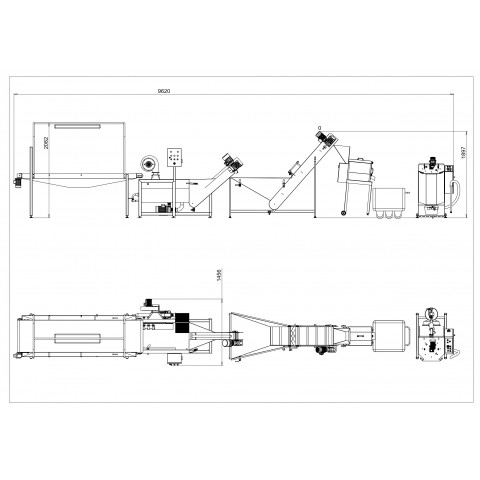

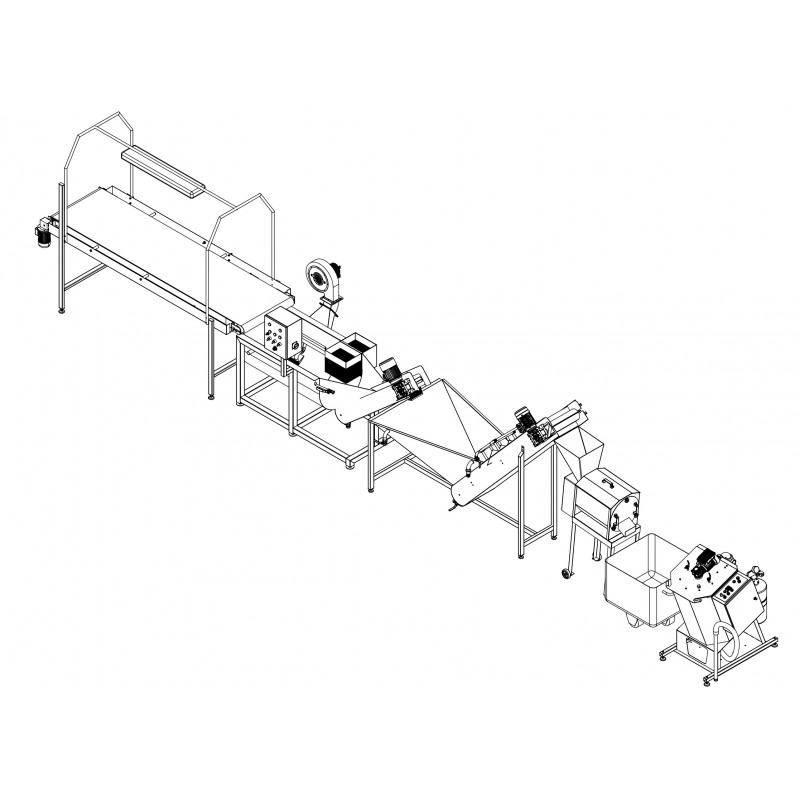

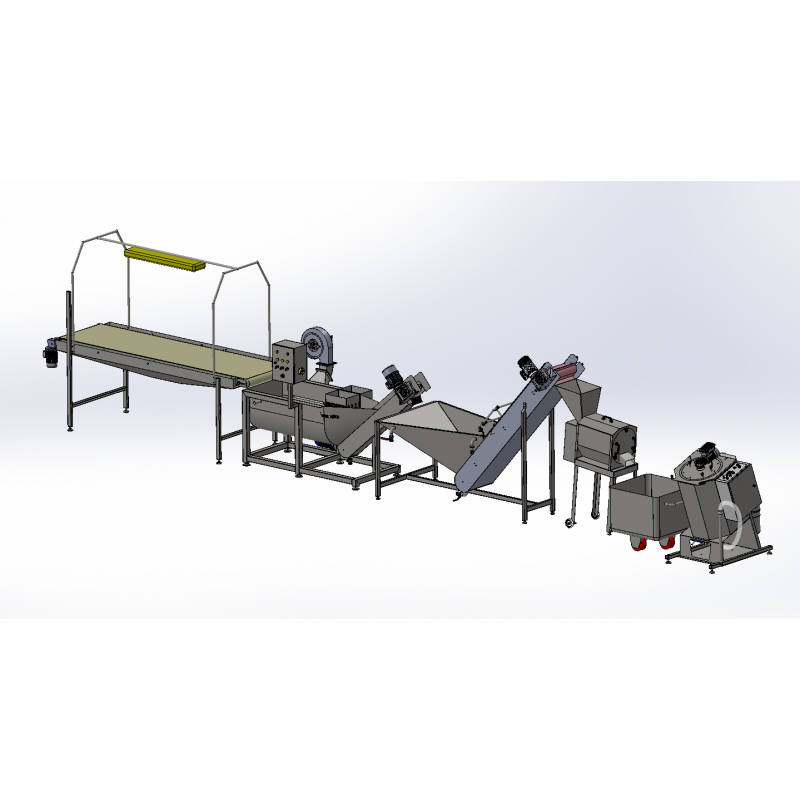

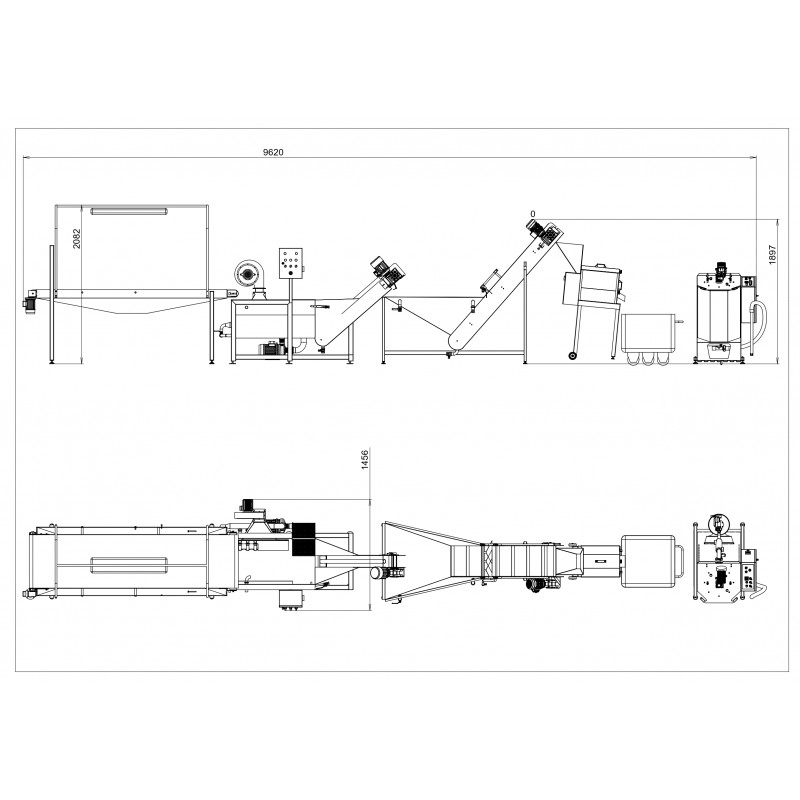

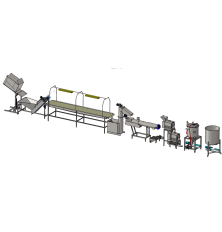

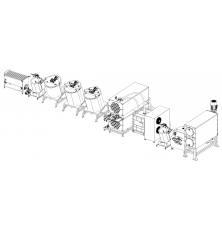

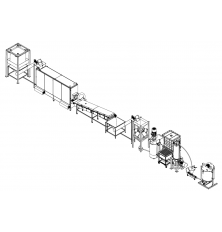

Jam production line for processing fruits and berries

This jam production line allows you to get ready-made jam at the exit from whole fruits at the entrance! Equipment options may vary depending on the customer's technology.

For additional information, please contact us at sales@foodtechprocess.com

Equipment for the production of jam depends primarily on the raw input materials, we offer different configurations at the request of the customer.

The following is an indicative set of equipment that includes all of the main processes used in the processing of whole fruits, vegetables and berries into jam. The complex includes:

- Inspection conveyor for sorting "input" raw materials

Dimensions and automation depend on the desired processing volumes. This equipment is auxiliary, if the raw materials are supplied in different sizes and not the same in quality.

- Washing machine for fruits and vegetables

Washing is one of the most important and obligatory processes in the processing of raw materials. We offer different types, depending on the type of product being processed.

For example, brush washers, which are selected with significantly contaminated raw materials, when their mechanical cleaning is necessary. In the production of jams from vegetables, this washer is ideal for cleaning root crops. It is equipped with soft brushes that clean the product mechanically. Soft brushes are made from non-toxic materials that can be in direct contact with food. The brushes are easily dismantled for cleaning after recycling. The washer is equipped with an extended conveyor for the outflow of excess water, the speed of which is regulated by a frequency converter. The water is gradually renewed, so there is no need to stop the washing process to change the water.

With fragile raw materials, such as berries, it is recommended to choose a bubble washer. Bubbling washer uses the power of the water flow for cleaning, a special bubbling system creates a forced reverse flow of water and bubbles by supplying pressurized gas through the water flow. This process of "boiling" water intensively cleans the products in a non-contact way, without damaging it mechanically. We offer various models of this type of washer, depending on the volume and performance.

Depending on the automation of processes, conveyors can be installed between specific stages of processing to supply raw materials, including pre-rinsing, or blowing to remove excess water on the product, for example, after washing.

- Crusher / Destoner (for pitting)

The performance of the model depends on the volume of processing of specific raw materials

When using raw materials with pits, such as peaches, plums, nectarines, cherries, cherries, apricots, when it is necessary to separate the pit, it is recommended to use a destoner. The fruits are crushed, rubbed through a special sieve and safely separated from the stone and stem. The resulting fruit puree contains pieces of the product, the size of the pieces depends on the sieve cell through which they are pressed. The sieve size can be from 1.5 to 12 mm. The fruit is loaded into the hopper of the pulping machine by means of a feeding conveyor, the plant can run continuously with continuous uniform feeding. Through the hopper, the product enters the working chamber of the rotor with the help of a drive auger. Special rotor blades (knives) move the raw material to the sieve walls. The pulp of the fruit is pressed through its cells, the bones, skin and stalks remain in the rotor chamber and are unloaded along the inclined rear part of the installation. Juice with softness flow out at the bottom of the working chamber.

When processing berries and fruits that do not need to be pitted, fruit crushers can be used, which grind the raw material to a fraction installed inside the sieve crusher.

When processing various fruits and berries, as an additional step, a press can be used to squeeze the crushed raw materials from the pulp. Syrup can be boiled out of the juice, and the pulp can be used to make jam. It all depends on the recipe and technology of the customer for processing raw materials to obtain the desired end product.

- Vacuum evaporator

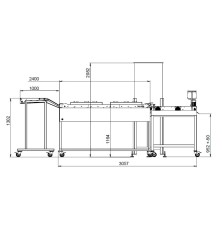

The vacuum evaporator volume depends on the desired processing volumes. It is recommended to choose a unit with a working volume of up to 50% of the geometric volume of the reactor.

For boiling and concentration of products. It is used as a universal installation for cooking jams at low temperatures by lowering the boiling point at a pressure below atmospheric pressure (under vacuum). Many manufacturers choose this method of cooking jams in order to preserve as much as possible all the useful substances and elements contained in fruits, berries and vegetables, which are destroyed at high temperatures. When boiling under vacuum, products retain their original taste and color, boiled jam acquires a denser structure, the level of foam and air content in the final product decreases, which directly affects the increase in the shelf life of the product.

The vacuum evaporator is an inclined vacuum reactor equipped with a gravitational mixing system (a frame mixing device with PTFE scrapers) with an electric drive, a ‚Äújacket‚ÄĚ for a coolant with an inlet pressure of up to 0.5 bar. The unit is equipped with a vacuum system and a system for removing and condensing the secondary steam generated during evaporation. For the correct operation of the installation and depending on the type of vacuum generator, it is necessary to provide the following media from external sources:

- source of compressed air with min. pressure 6-10 bar

- a source of ice water with a temperature of 5-7 degrees for forced supply to the unit's condenser

- source of heat carrier (source of hot water supply or steam)

All this must be ordered additionally or provided at the place of production by the Customer.

Depending on the modification, raw materials can be loaded using a vacuum and a vacuum hose with a nozzle from a storage bin on wheels, where fruit puree is unloaded from a crusher or a masher.

- Food pump

Our company offers various types of food pumps, including high temperature pumps and special pumps for products that are viscous or contain pieces of berries and fruits.

With the help of these pumps, the finished jam is fed to the packaging, or to the accumulator for further processing or use.