FRENCH FRIES, POTATOES

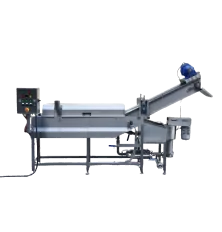

The continuous conveyor deep fryer is a reliable and versatile solution suitable for high-performance frying of a wide range of products by immersing them in hot oil.

- Universal application

- Quick transition for frying new types of products

- Possibility of using special frying modes

- Minimal amount of oil in the system

- Trouble-free oil filtration

- High oil exchange ratio

- High efficiency and productivity with compact design

- Manufactured to the highest quality standards using materials and components made in Europe.

The price is set for the combination of a basic fryer model and an additional module with rotating paddles.

The universal modular fryer equipped with an additional paddle module is designed for frying thin slices of products that require immersion beneath the oil level.

- Adjustable frying time from a few seconds up to an hour

- Compact, tabletop version

- The paddle conveyor is installed on top of the basic fryer

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Total power, kW: 12

- Oil volume: 60l

- Voltage: 380-400V

Used for blanching products in water, it is suitable for processing various vegetables, legumes, grains, mushrooms and other products. This versatile machine also functions as a water separator centrifuge which is activated after the blanching processes.

More information: sales@foodtechprocess.com

- Capacity: 30l/ 90l

- Material: Stainless steel

The paddle module for the 400/1100/12 Universal Tabletop Modular Fryer is a conveyor with specially curved paddles for gentle frying of fragile and light foods.

For additional information, please contact us at sales@foodtechprocess.com

The MPP 8 vegetable root peeler is an industrial peeling machine with a stainless steel body.

For frying foods in oil, deep-frying, suitable for frying onions, seeds, nuts, vegetable snacks and chips, and other products, including breaded or covered in liaison. Can also be used as an oil separating centrifuge for deep fryer.

- Two in one: a deep fryer and a centrifuge to remove excess oil

- Possibility of frying small and fragile products

- Obtaining a ‚Äúdry product‚ÄĚ after frying

- Low carbonization of oil due to the cleaning feature after frying

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 30l/ 90l

- Total power, kW: 11

- Voltage: 380-400V

The set of individual equipment for the production of French fries may differ depending on the initial raw materials. We offer various modifications from washing to frying with subsequent dehumidification starting from 50 kg/h for the final product.

For more information, please contact us at: sales@foodtechprocess.com

The Price is specified for the version with a hydraulic lift.

The industrial electric frying pan using thermal oil is an optimal and economical solution for small-scale industrial food production. It allows for low energy and operating costs while ensuring uniform and intense heating for the entire working bowl. The system's thermal inertia helps maintain the required temperature for an extended time, making it effective for frying onions, carrots, sautéing flour and vegetables, and preparing sauces, soups, side dishes, stews, and more.

- Low energy consumption

- Uniform heating

- Heated conical sides

- Adjustable heating intensity

- Controller with a hygienic housing directly on the supporting structure

- Lid opening handles located in the cold zone

- Automatic lifting/tilting system

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 26

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

- Total power, kW: 28

- Voltage: 380-400V

- Duplicator volume: 106l

Potato and root vegetable peelers are manufactured in all-stainless steel casing. The device is directly ready for use (no installation required), it is supplied for a 3x400 V power supply.

For more information on the device and a price offer, contact the sales department of sales@foodtechprocess.com

The price is set based on the basic built-in heating option of 24 kW.

The vacuum fryer is designed for frying foods in oil at low temperatures, allowing for the production of healthy snacks such as vegetable and fruit chips. The vacuum feature enables you to reduce the frying temperature of oil down to 110-120 degrees!

- ¬ęCold roast¬Ľ is a tasty and healthy method of processing the product

- Drying and frying without caramelizing the sugars contained in the product

- Large frying tank - for processing foods with a higher water content

- Modular heating system which allows you to increase the heating power up to 108 kW (optional)

- Circulating heating of oil through a heat exchanger minimizes oil spoilage and prevents localized overheating

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 24

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 30l

- Oil volume: 200l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The digitally controlled continuous conveyor system ensures the frying of a wide range of products at a consistent level. Thanks to the possibilities of deep frying, this model is suitable for a wide range of products from spring rolls, onion bhajis and falafel to fish fingers, burgers and chicken nuggets. The fryer is available in widths of 200, 300, 400 and 600 mm.

For additional information, please contact us at sales@foodtechprocess.com

Excellent blancher and cooker for efficient handling of vegetables and other food products.

For a price quote or more information, email us at sales@foodtechprocess.com

SnackPro blancher will prepare different types of products making it a great solution for blanching large volumes of fruits and vegetables in a short time.

For more information and price quote email us at sales@foodtechprocess.com

The cost is indicated without the price of the baskets

A batch blancher with indirect electric or steam heating is used for blanching vegetables, mushrooms, meat, fish, and seafood. This type of blancher is ideal for use in catering kitchens and hospitals.

- Simple controls

- Built-in electric heating

- Large outlet valve

- Safe operation

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 18/ 24/ 30/ 36

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 200l/ 300l

Designed for cooking or blanching vegetables, fruits, legumes, pasta, seafood and other products in a continuous manner.

For a free consultation, email us at sales@foodtechprocess.com

The screw conveyor with heating is a device designed for the transportation of material using a screw mechanism, while heat is applied to the product to facilitate easier transfer. This type of conveyor is often used to simplify the transfer of various bulk materials.

For more information, send us an email to sales@foodtechprocess.com

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product and size of the conveyor.

For more information, send us an email to sales@foodtechprocess.com

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product and size of the conveyor. For more information, send us an email to sales@foodtechprocess.com

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product and size of the conveyor.

For more information, send us an email to sales@foodtechprocess.com

A universal conveyor with a PVC belt with horizontal sections, a volumetric storage, adjustable in height and angle of inclination, which can easily be adapted to existing installations for lifting the product to a certain height. The conveyor has its own independent drive, the speed of which can be adjusted using an inverter (optional).

- Lightweight: the supporting structure of the conveyor is made out of aluminum profiles

- Hopper made out of food grade stainless steel

- Bearing frame on wheeled supports with position locks

- High sidewalls made out of stainless steel

- White PVC tape for transporting products with temperatures of up to 80 degrees

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 500 mm

- Volume: 50l/

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. The price depends on the product as well as the size of the conveyor.

For more information, send us an email at sales@foodtechprocess.com

The price is indicated with a semi-automatic control panel

The vacuum kettle is designed for use in public catering establishments (restaurants, hotels, catering companies) and small manufacturing businesses. This equipment enables boiling, blanching, frying, evaporation, pasteurization, mixing, or stirring.

- A unique multifunctional device

- Possibility to cook/fry under atmospheric or vacuum conditions

- Laboratory version of a Vacuum Fryer

- Built-in condensation and secondary steam removal system

- Intense electric heating

- Sectional basket with a lid

- Built-in system for separating and removing excess liquid from the product

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Volume: 10l

- Oil volume: 8l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

An air cooling conveyor is used to rapidly cool products in food processing industries by circulating cool air over them as they move along a conveyor belt. This efficient cooling process helps preserve product quality and reduce the time between processing stages, facilitating smoother production workflows.

For a price quote or a free consultation, send us an email to sales@foodtechprocess.com

EcoFry is designed for frying onion rings, seafood, dumplings, spring rolls, pies, vegetables, nuggets and hamburgers with the help of pouring hot oil. A smaller capacity, efficient frying equipment intended for small to medium sized production facilities.

For a quote, please send us an email at sales@foodtechprocess.com

The series of Continuous Fryers Pour Oil is the boom in the market of frying and roasting equipment. The new construction designed by our engineers, based on existing practical experience in the production and use of conveyor fryers, provides the best example of environmental friendliness.

For more information please email sales@foodtechprocess.com

The continuous pouring fryer is designed to fry meat, fish, vegetables and pasta products as well as chicken drumsticks, cutlets, nuggets, croutons, sliced zucchini or eggplant, and etc. using immersion frying and hot oil pouring methods.

For more information please send us an email at sales@foodtechprocess.com

Our continuous fryer is designed for frying cutlets, potatoes, meatballs, croquettes, fish, vegetables and many other products. Working volume up to l: 300 l.

For a price quote, send us an email to sales@foodtechprocess.com

A pouring fryer is a specialized equipment used in commercial kitchens for frying foods using a continuous pouring method. It offers precise control over the frying process by continuously pouring oil over the food, ensuring even cooking and consistent results.

Price depends on the chosen option. Please email sales@foodtechprocess.com

A rotating drum unit designed for continuous coating operations and product saturation with seasonings and flavor additives, utilized in production lines for chips, snacks, and various semi-finished products.

- Adjustment of the Drum Tilt Angle

- Hygienic design and execution: mirror-polished inner surface of the drum

- Various blade options for gently turning the product (optional)

- Dispensers for dry and wet flavorings (optional)

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 0,25

- Voltage: 380-400V

We offer many different types of blanchers including continuous models as well as batch blanchers.

For a free consultation, send us an email at sales@foodtechprocess.com

We can help you choose the right continuous fryer suited for your needs. For a free consultation or a quote, please send us an email at sales@foodtechprocess.com

We sell different types of deep fryers, for a price quote or for a free consultation, send us an email to sales@foodtechprocess.com

USED PRODUCT - 1 LEFT IN STOCK

Continuous deep fryer OIL MINI is designed for gastronomy and catering. It is ideal for deep frying of meat, ravioli, meatballs, seafood, poultry and vegetables. It ensures continuous frying and stable frying results. The heating elements are located in a double thick aluminum bottom, the so-called "sandwich bottom", which prevents the product from sticking to the heating elements and burning, thus you can use the oil many times more!

Basic price - 5960‚ā¨. The possibility of adding an oil spraying module (combifry), for an additional cost of 3980 ‚ā¨ (RECOMMENDED OPTION)

For more information please email us at sales@foodtechprocess.com

We have various types of continuous or batch fryers. Just tell us what kind of product you wish to fry and we will help you choose the right deep fryer.

For a quote or additional information, send us an email at sales@foodtechprocess.com

We offer different types of continuous fryers, let us know which product you wish to fry and we will help you choose the right fryer for your business.

For more information, contact us at sales@foodtechprocess.com

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

Cutter for french fries with automatic hopper. Approx. 25 kg of French fries 12mm per minute. Cutting blocks are ordered separately. For more information, send us an email to sales@foodtechprocess.com

It is possible to order tubs with four perforated walls and bottom, with or without outlet drain or with a tap. For more information, email us at sales@foodtechprocess.com

The cutting machine is designed for slicing, shredding and grating fruits and vegetables.

For more information, please contact s at sales@foodtechprocess.com

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product as well as size of the conveyor.

Our continuous fryer is ideally used for frying escalopes, potatoes, croquettes and many other products.

Designed for blanching vegetables, fruits, legumes, pasta, seafood before preservation and freezing.

For additional information, contact us at sales@foodtechprocess.com

For a price quote or more information, send us a request.

Air cooling conveyor with MULTI AIR KNIFE is a system for  intensive removing excess water or oil and preliminary cooling.

The machine is used for brushing, cleaning as well as prewashing various root vegetables.

For additional information, please contact us at sales@foodtechprocess.com