Electric cream cooker MK-series

Modern equipment with a wide range of applications in pastries, bakeries, catering facilities.

The universal kettle of the MK series is a modern food processing device with a wide range of applications in confectionery, bakeries and other catering establishments.

High-quality materials used in the manufacture of the machine ensure a long service life and trouble-free operation. The entire structure is made of AISI 304 food grade steel, resistant to corrosion and most acids, sterilization solutions, most organic chemicals and dyes. The unit evenly heats the entire contents of the working tank up to a maximum temperature of 150¬įC. Simultaneous heating and mixing is possible.

Thanks to its well-thought-out design, the universal cooker can be used for many technological processes, such as:

- preparation of puddings, jelly, kaymak, milk, sauces, soups, vegetables, etc.

- preparation of choux pastry and custards,

- preparation of tiramisu, fillings, jams and preserves, risotto, fruit mousses

- melting chocolate and fudge, icing,

- frying vegetables, fruits, onions

- and many more.

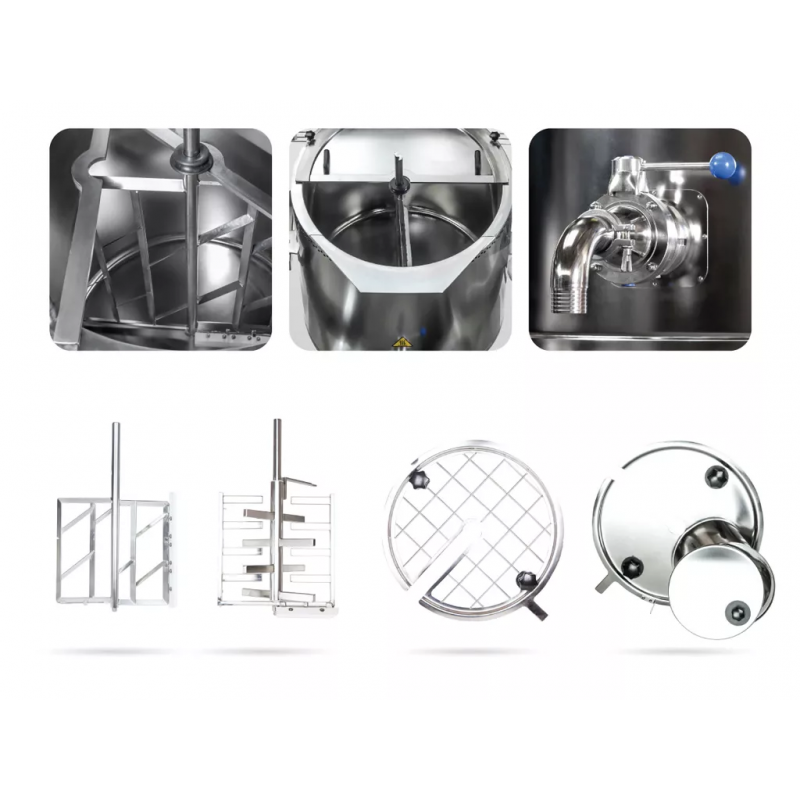

The mixing process is carried out using a special mixer, which is equipped with scrapers that prevent sticking and burning of the product. Scrapers collect the product from the walls and bottom of the pressure cooker. The heating of the product is carried out by heating the oil between the two walls of the kettle, which ensures the uniformity of heating, and the product does not burn. The product is heated evenly throughout the volume.

The universal kettle of the MK series is additionally equipped with a third outer shell to limit the return of temperature to the environment. Machines of the MK series have two operating speeds and the ability to heat the mass to the required temperature max. 150¬įC. At the request of the customer, it is possible to block the maximum temperature level. If necessary, the value of the maximum temperature can be increased. All elements in direct contact with the food product are made of high quality acid-resistant steel and materials approved for contact with food products.

The Cream Cooker has a tilting tank that allows easy unloading of the product and cleaning of the working container, the kettle can also be equipped with a drain valve - it can be easily disassembled for cleaning / rinsing. The valve has a protection function against accidental opening. The choux pastry and cream machine has a lid with an inlet to control the process and add ingredients without stopping the machine. All important electrical components are located in the electrical box on the side of the machine to protect against fumes and high temperatures. Timer with sound signal - automatic or manual mode.

Machines of the MK series are designed for the production and preparation of choux pastry, creams, chocolate, fudge, jams, glazes, fillings and various mixtures according to original recipes, as well as for any product that requires uniform heating and smooth mixing. Often used in confectioneries and bakeries. It can also be used in the cosmetic industry, for the preparation of sugaring paste.

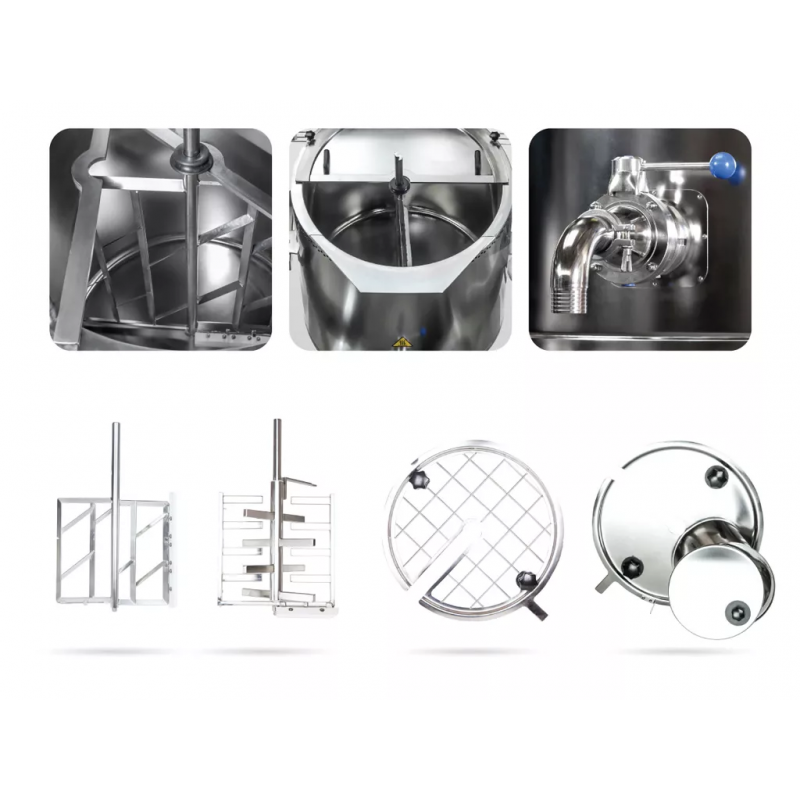

The mixing process is carried out by mixing tools with side and bottom scrapers, which prevent sticking and burning of the mixture. Scrapers are designed to collect layers of mixture from the walls and bottom of the bowl.

- Quick scraper removal system with no tools to clean or replace

- Thermal oil poured between two layers of ‚Äújacket‚ÄĚ provides even heat distribution, safe during operation.

- The outer, third layer of the bowl prevents heat loss from the machine.

- 2 working speeds (variable on request)

- Maximum temperature up to 150¬įC, on request max. temperature can be set to another, lower level.

- All parts in contact with food are made of high quality acid-resistant steel or food-grade materials.

- Tilt bowl with stop in any position for easy emptying and cleaning - motorized wheel for models MK-200/300/500

- Bowl lid with viewing window to monitor the process and add ingredients without having to stop the machine.

- All important electrical components are inside the electrical box on the side to prevent smoke and high temperatures.

- Timer - manual or automatic operation

- Protective thermal switch

- Ball valve Du-80 ‚Äď standard for MK-200/300 and 500 series.

- Each machine can be equipped with a crane (on request)

- Mobile, on wheels

Additionally:

- Variable speed (inverter)

- Cooling system with cooler ‚Äď available for all models

- Bowl Lid/Grid ‚Äď available for all models

- Special double agitator ‚Äď available for all models

- LCD ‚Äď 7‚Ä≤ ‚Äď fully programmable control panel with recipes

- Laser product temperature sensor.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 200l/ 300l/ 500l

You might also like

If you need to cook the product at low temperatures, to better preserve the appearance and nutritional properties of the product, or to add components that are sensitive to heat, we recommend using the universal TiltCook boiler.

- Heating: Electricity Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 250l/ 300l

Equipment for the production of creamed honey, soufflé honey, whipped creamy honey. The machine is produced both in atmospheric and vacuum versions, the loading capacity ranges from 70 to 3500 kg of honey.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

This 265 liter stainless steel cooker is great for boiling or roasting a variety of ingredients. It is made of stainless steel and equipped with a convenient drain valve.

- Heating: Gas

- Material: Stainless steel

- Principle of operation: Batch mode

Cooking kettles for cooking under pressure are designed for highly efficient heat treatment of a wide range of food products at temperatures up to 110 ¬įC and pressure up to 0.5 bar.

- Heating: Electricity Steam

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 220 l/ 500l/ 600l/

The automatic screw cooker is designed for cooking or blanching various food products in continuous mode, saving both time and energy during production.

- Heating: Mixed

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The device is designed for the pasteurization of a wide range of products in various types of packaging material such as cans and jars.

- Heating: Mixed

- Productivity: 300 l 400 l 500 l

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

Tilting pans with mixers cook the product with continuous stirring and subsequently discharge the food into receiving trolleys, ensuring the discharge spout remains at a constant height from the ground. Designed for the catering industry, large kitchens, school cafeterias, restaurants, and other food production businesses.

- Heating: Electricity Gas Steam

- Material: Stainless steel

- Engine power, kW: 0,75

- Heating power, kW: 24/ 36/ 48

- Volume: 200l/ 300l/ 500l

- Steam consumption, kg/h: 85/ 100/ 115

The gas cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, pots, pasta, milk dishes, teaspoon cooking, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared meals, heating or steaming. This cooking equipment is not suitable for roasting or baking.

- Heating: Gas

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 80l/ 100l/ 150l/ 200l/ 300l

The kettle is designed for cooking qualitative jam, marmalade, confiture from different fruits, vegetables and berries. It's an ideal and affordable solution for cooking various products.

- Material: Stainless steel

- Heating power, kW: 9/ 12/ 18/ 24

- Principle of operation: Batch mode

- Volume: 80l/ 120 l/ 200l/ 300l

A modern cooking and mixing device with a wide range of applications in confectionery, bakeries, catering establishments.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 200l/ 300l/ 500l

Professional cooking boiler with a stirrer for particularly thick and viscous products. An excellent technical solution for the production of caramel, syrups and sugar paste for sugaring. The heating source is selected separately.

- The kettle can be used on all types of cooking surfaces, including induction

- The basic version has easily removable, self-aligning stainless steel scrapers

- High torque of the stirrer with 14-18 revolutions per minute

- Professional 3-phase industrial motor

- The stirrer is turned on independently using a remote control with IP66 protection, connected to the boiler using quick-release connectors

- The unit can be connected to a 220-230 volt network even with a 3-phase motor!

- Material: Stainless steel

- Engine power, kW: 0,25/ 0,37

- Volume: 20l/ 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

The price is set for the basic version of the reactor without additional options and the control panel

The vacuum vessel with a coolant duplicator and a mixing device is a universal solution for processing various products at sub-atmospheric pressure. Based on this simple device, you can select and modulate it into complex installations such as a vacuum evaporator, a vacuum cooking kettle, and a unit for the production of cream honey.

- Sloped Design - Gravity Mixing

- Bottom valve DN40 included in the basic version

- Small-volume duplicator - low costs for coolant heating/cooling

- Modular system: customization of the equipment and its functionalities by ordering additional options

- An easy to disassemble mixing device

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Round cooking boiling pan combines together the advantages of cooking with automatic mixing. Designed for catering industry, school kitchens, restaurant kitchens or food industry. Capacity ranges from 100l to 500l. The available heating options are - steam boiling or indirect electric heating.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 200l/ 300l/ 500l

The steam cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, pots, pasta, milk dishes, teaspoon cooking, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared, ready-to-cook meals, heating or steaming.

The cooking equipment is not suitable for roasting or baking.

- Material: Stainless steel

- Volume: 100l/ 150l/ 200l/ 300l

- Steam consumption, kg/h: 50/ 60/ 70/ 90

Automatic cooker made for continuous batch production. Different types of food can be boiled, like pasta, rice, vegetables, meat etc. Options: direct gas, indirect steam boiling or direct electric.

Price depends on chosen option.

- Heating: Electricity Gas Steam

- Material: Stainless steel

- Heating power, kW: 2x25

- Volume: 2x135l/ 2x220l

- Steam consumption, kg/h: 2x70/ 2x100

Universal cooking kettle with a built-in steam generator up to 0.5 bar, frame stirring device and an automatic tilt and unloading system is a convenient and safe solution for processing various liquid products in large volumes.

- Safe design with a jacket (duplicator) and outer casing with insulation

- Intensive steam heating through the jacket using the built-in electric steam generator

- Automatic multi-stage tilt and unloading system

- Frame stirring device for dissolving, mixing, kneading ingredients

- Unloading of the product into rolling carts is possible due to the offset tilted axis

- Heating: Mixed

- Material: Stainless steel

- Country of origin: Slovakia

- Total power, kW: 13,5

It's compact cooking equipment for catering and gastronomic sphere: cafes, bars, canteens. The cooking equipment is designed for boiling, stewing, frying and mixing products of different viscosity.

These gas boiling cookers are manufactured for professional kitchens and also for other food processing factories. We offer 100l, 150l, 250l and 300l.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 150l/ 200l/ 300l