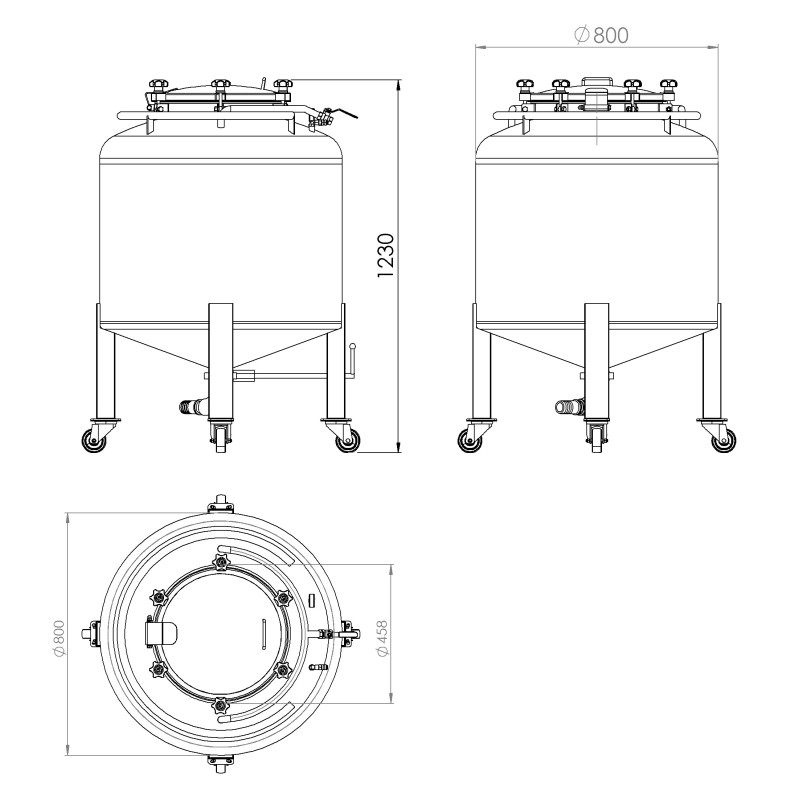

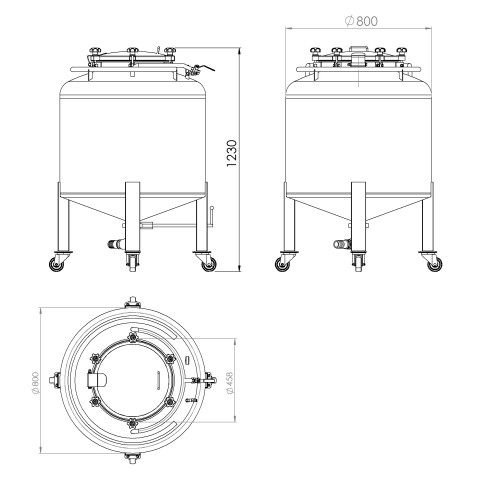

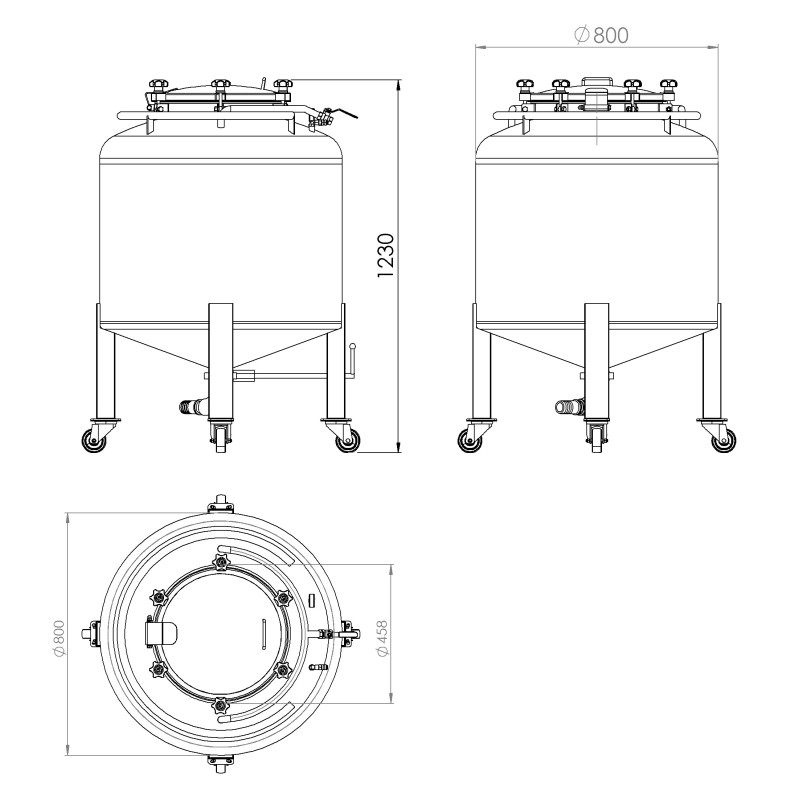

Pressure vessel for vertical product transfer 300 BIN

The 300 BIN pressure vessel is a mobile stainless steel unit designed for transferring liquid and semi-liquid products by applying controlled internal pressure. It also serves as a mobile container for moving batches within the production facility. It is suitable for hygienic food processing environments where pumping is not possible or practical.

- Designed for operating pressures up to 0.5 bar, allowing for vertical transfer of liquids without a pump.

- Six hand-tightened lid screws ensure secure sealing during pressurized or vacuum operation.

- Mounted on caster wheels for easy movement within the production area.

Pressure vessel for easy vertical product transfer up to 3-5 meters

The 300 BIN pressure container with an outlet valve at the bottom of the vessel, is intended for the controlled transfer of liquid and viscous products using compressed air. By applying pressure inside the vessel, the product can be moved upward or through a piping system to a defined height, depending on product density and viscosity. With a volume of 300 liters, the vessel is well suited for small and medium-scale food processing operations where gentle handling of the product is required. The design eliminates the need for mechanical pumping, making it suitable for products sensitive to shear stress or aeration.

The vessel is rated for operation up to 0.5 bar. At the same time, the robust stainless steel construction provides a high safety margin and long service life in industrial conditions. The lid is secured using six hand screws, providing even pressure distribution and reliable sealing during operation. The vessel is mounted on four caster wheels, allowing it to be easily transported between different processing stations or production rooms.

Typical applications

The pressure vessel can be used for transferring and handling:

- liquid and semi-liquid food products

- sauces and dressings

- syrups and sugar solutions

- juices and concentrates

- liquid dairy products

- brines and marinades

- fermentation liquids and food intermediates

- non-edible liquids

and most other liquids

Advantages

- Gentle product transfer without mechanical pumps, reducing shear and aeration.

- Simple pressure-based operation using compressed air.

- Working pressure up to 0.5 bar simplifies installation and use.

- Secure lid fastening with six hand screws ensures safe operation.

- Mobile design on caster wheels allows flexible integration into production lines.

- Suitable for a wide range of liquid and relatively viscous food products.

- Compact footprint for easy placement in processing areas.

The basic version includes

The unit consists of a stainless steel pressure vessel with a working volume of 300 liters, equipped with a sealed lid secured by six manual hand screws. The vessel features a bottom outlet connection for controlled product discharge and an inlet connection for compressed air supply. The entire assembly is mounted on a mobile frame with four caster wheels, allowing easy transport within the production facility.

Operating principle

The product is filled into the vessel through the top opening. Once the lid is secured, compressed air is introduced into the vessel, creating internal pressure. This pressure forces the product out through the outlet connection and into the connected piping or processing equipment.

The transfer height and flow rate depend on the applied pressure and the viscosity of the product. After discharge, pressure is released, the lid is opened, and the vessel can be refilled or moved to another station.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

You might also like

Twin-screw extruder is designed for effective extruding, homogenization, pumping over of plastic masses (butter, margarine, honey, curd products, confectionery mixtures), and forming it into bars and rolls.

- Productivity: 400 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Weight: 115 kg

The tank is designed for heating and mixing chocolate, butter, margarine, honey and similar products.

- Material: Stainless steel

The cost is indicated without the control panel, which can be selected and offered separately

A versatile cooking system, featuring an inclined reactor, a duplicator for heating and a frame mixing device, it is designed for processing a diverse range of products through methods such as cooking, boiling, and concentrating at atmospheric pressure. This system is commonly used for the production of syrups, jams, confiture, and honey processing.

- Slanted design with gravity mixing - 25% more efficient!

- External decorative casing made out of polished stainless steel with insulation

- Jacket for the bottom and the walls of the working container along the entire height

- Lid opening sensor for safe operation

- Scrapers are already included in the basic version of the installation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 300l/ 430l/ 600l/ 1000l

- Voltage: 220-230V 380-400V

The cylindrical conical tank is a designed for the fermentation of the beer and other beverages.┬Ā

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

It is ideal for cooking jams, marmalades, syrups, sauces, creams and other products.

Price depends on the chosen option.┬Ā

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l

- Geometric volume: 350 l

The price is indicated with a semi-automatic control panel

The vacuum cooking kettle is designed for use in public catering establishments (restaurants, hotels, catering companies) and small manufacturing businesses. This equipment enables boiling, blanching, frying, evaporation, pasteurization, mixing or stirring.

- A unique multifunctional device

- Possibility to cook/fry under atmospheric or vacuum conditions

- Laboratory version of a Vacuum Fryer

- Built-in condensation and secondary steam removal system

- Intense electric heating

- Sectional basket with a lid

- Built-in system for separating and removing excess liquid from the product

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Volume: 20l

- Oil volume: 8l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The vacuum cooking and mixing tank is used to boil products at low temperatures, which helps preserve the natural color, taste and nutrients in the product.

Vacuum equipment is used for cooking premium-quality jams, sauces, fruit and vegetable concentrates.

- Inclined design

- Efficient emptying

- High hygiene standards

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

The tank is designed for heating and mixing chocolate, butter, margarine, honey and similar products.

- Material: Stainless steel

The vacuum evaporation unit is specially designed for thickening dense food products in industrial quantities. The evaporator can be used for the production of thick syrups, caramel masses, dense fruit masses, as well as for the production of pectin, or heat-stable fillings with a high productivity.

- High performance

- Rotary spraying system with a powerful electric drive

- Evaporation in a thin layer with a large heat transfer area

- Low investment installation costs

- Tangential entry for product swirling

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

This 800-liter capacity dissolver with a circulation pump is designed for preparing liquid solutions by dissolving substances directly in water or other working fluids. It is used in the food and beverage industries for ensuring uniform dissolution through hydrodynamic mixing in a forced recirculation loop.

Recirculation with a food-grade pump ensures rapid and uniform dissolution without sedimentation or the formation of stagnant zones. The working tank is mounted on a mobile platform with wheels, allowing for easy and quick movement between production areas.

- Fast and uniform dissolution without sediment thanks to hydrodynamic mixing

- Forced recirculation loop with product pump/inline homogenizer (optional)

- Mobile stainless steel platform on wheels

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Geometric volume: 800 l

A vacuum evaporator is a device used to evaporate liquids at lower temperatures by creating a vacuum environment, which reduces the boiling point of the liquid and enables efficient evaporation without thermal degradation of sensitive materials. Working volume up to, l: 1900 l.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: up to 1900 l

Highly efficient production of a high viscosity pharmaceutical and cosmetic products.

- Material: Stainless steel

- Principle of operation: Batch mode

- Geometric volume: 500 l/ 800 l

The price is set for the basic version of the installation without additional equipment.

The vacuum homogenizer is designed for a wide range of processes such as for the production of mayonnaise, ketchup, various sauces, confectionery pastes and fillings, liquid or paste like products with a homogeneous structure. It is also suitable for the production of various creams, gels, shampoos and other products in the cosmetic industry.

- Built-in Ultra Shear bottom homogenizer

- Mixing device with movable scrapers

- Tilting version for easy unloading

- Wide range of applications

- Entirely made of food grade stainless steel AISI304/ AISI316 - option

- Compact design

- Lots of additional options to choose from

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 20l/ 50l

- Total power, kW: 2,3/ 2,4

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

The vacuum cutter is intended for large processing enterprises dealing in the confectionery, fruit and vegetable processing industries. They are intended for processing food down to a homogenous mixture with minimal air content.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

The price is set for the basic version of the vacuum evaporation unit with basic controls (mixer motor switch) and without additional options. The control unit is customized based on individual customer requirements. The pump is also selected separately depending on the product.

A compact vacuum evaporation unit that allows you to concentrate solutions, mixtures, and various products by evaporating the solvent. A modular version based on the basic version of the 110/100 vacuum reactor.

- Gravity mixing - 25% more efficient

- Reinforced agitator design with no blind spots

- Bottom ball valve with no dead zones

- Condensation and secondary vapor removal system

- Easy to disassemble mixing device

- Large heat exchange area

- Ability to measure and monitor condensate volume (optional)

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

- Working volume: 50-80l

- Condensing capacity, l/h: 45-55

- Steam consumption, kg/h: up to 150

The sorption filter 3000l refers to non-pressure equipment of periodic action for filtering liquids using bulk filtering agents and different sorbents.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Volume: 3000

The laboratory vacuum cutter mixer is designed for uniform grinding, emulsifying and mixing of food, cosmetic and pharmaceutical products, chemical mixtures with the addition of oil, dyes, concentrates or liquid flavors.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

The vacuum crystallizer-cooler is specifically designed for sweetened condensed milk. Crystallization with cooling is one of the most important stages in the production of condensed milk according to GOST and is necessary before dosing and packing the finished product.

- After crystallization, condensed milk has a delicate structure with small crystals

- Condensed milk has a homogeneous shape and attractive consumer properties

- The shelf life of condensed milk is extended without changing the quality of the product

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 300l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar