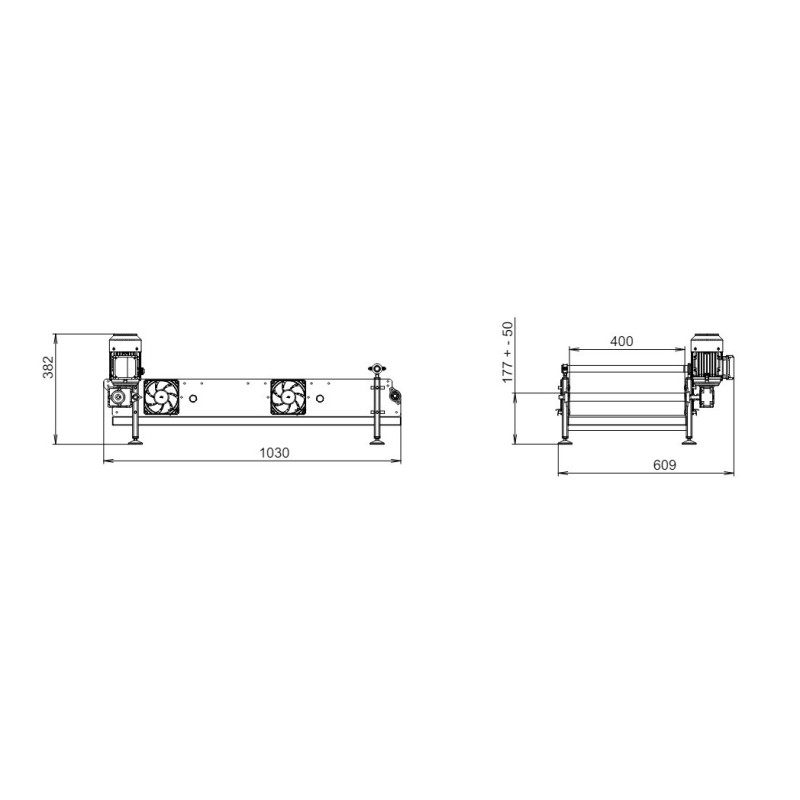

Air cooling conveyor M 400/1000

The modular cooling conveyor is produced as a standard tabletop version with a section length of 1000 mm; in addition to it, you can order a stainless table or a frame supporting structure. The air cooling conveyor can be sectionally increased in length by the required number of sections.

- Compact, easy to install on any work surface

- Features a fine-grained stainless steel mesh for high temperatures and small-sized products

- Easily combined in line with a tabletop fryer 400/1100/12

- Easy maintenance and cleaning

An air cooling conveyor is used to remove excess fat from the product, thereby stopping the frying of the product and allowing for surface cooling. This cooling system is a necessary phase after frying the product in a deep fryer and before further processing/packing.

The cooling conveyor is suitable for use after the continuous deep-frying of various products, both in a professional kitchen and in small scale food production of various semi-finished products, such as:

|

|

|

|

|

|

|

And many other products that can be processed on continuous conveyor fryers with a width of 400 mm.

Advantages

- Modular system, you can choose the working length depending on the specific product and the required degree of cooling that it has to undergo.

- Can be used as part of a production line, 100% compatible with our┬Ācompact modular 400/1100/12 fryer.

- Several installation options: desktop version, on an independent movable frame, or on a mobile table mounted on a wheeled support.

- Simple and easy cleaning is facilitated by a tray installed along the entire length of the conveyor, designed to collect excess oil after blowing; it can be easily removed for washing.

- The special arrangement of the fans allows air to be directed both above the product and below the mesh, blowing it from all sides.

- The stainless steel mesh conveyor does not obstruct air distribution ensuring that the residual oil flows easily and quickly through the perforated belt into the oil tray located underneath.

Basic version

It consists of a conveyor with a fine mesh made out of stainless steel with an electric drive, a bath along the entire length of the conveyor, an air knife at the product inlet and several fans evenly spaced along the entire length of the conveyor.

Options

- Stainless steel table

- Frame structure

- Table with caster support

- Caster support for the frame structure

- Frequency converter for adjusting the conveyor speed

- Modular conveyor length system, the possibility of increasing it in sections

- An air knife at the inlet to effectively blow away residual oil from the surface of the product. This option requires a compressed air source with a pressure of 6-12 bar, 300 l/min.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 400 mm

You might also like

The price is set for the basic fryer version without additional modules. If purchasing the fryer together with both of the additional conveyor modules ŌĆō the double conveyor fryer and the paddle conveyor fryer ŌĆō we offer a discount of 300 EUR.

The versatile modular conveyor fryer with a single conveyor belt is used for the continuous frying of a variety of products with a low moisture content, that do not require forced immersion beneath the surface of the oil for even frying.

- Adjustable frying time from a few seconds up to an hour!

- Ability to use the unit as a continuous blancher or boiler for cooking products with a delicate structure

- Modular system, expanding functions with each new module

- Compact, desktop version

- Possibility of periodic frying of products with automatic unloading

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Oil volume: 60l

- Voltage: 380-400V

The price is set for the combination of a basic fryer model and an additional module with rotating paddles.

The universal modular SnackPro fryer equipped with an additional paddle module is designed for frying thin slices of products that require immersion beneath the oil level.

- Adjustable frying time from a few seconds up to an hour

- Compact, tabletop version

- The paddle conveyor is installed on top of the basic fryer

- Safety thermostats on each heating element

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Total power, kW: 12

- Oil volume: 60l

- Voltage: 380-400V

The oil-free four-cylinder piston compressor is the ideal solution for those who value both performance and silence.

- Equipped with two twin-piston units with separate engines

- Four air filters

- Mechanical pressure switch

- Quiet operation (at least 25% quieter than traditional compressors)

- Carrying handle and mobile wheel support

- Principle of operation: Continuous mode

- Total power, kW: 1,5

- Voltage: 220-230V

The water chiller CHWHE consists of a cooling unit in the upper part and a pump plus isolated water tank (made of stainless steel) in the lower section. We offer different capacities.

- Volume: 120 l/ 300l

- Voltage: 380-400V

The cooling units have a compact design. They are space-saving and easy to assemble. The chiller in standard version can work at water outlet temperatures from +10┬░C to +25┬░C.

For more information, send us an email to sales@normit.com┬Ā

- Volume: 18 l/ 30l

- Voltage: 220-230V

This air cooler and heater is multifunctional. It can be used as air cooler, heater. The compact and lightweight air cooler / heater contains. 4 caster wheels make it easy to move the unit.

Cooling tunnel with a length of 15.2 meters. The standard design consists of 13 sections with removable top. For more information, send us a request.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 400 mm

This multi layer belt dryer with integrated cooling system works as a dryer and cooler in one installation.

- Material: Stainless steel

- Principle of operation: Continuous mode

Heating: electric and steam - combination

- Material: Stainless steel

- Principle of operation: Continuous mode

The vacuum homogenizer is designed for whipping mayonnaise, ketchup, various sauces, confectionery pastes and fillings, condensed milk, jams and marmalades, canned goods, as well as similar liquid or pasty products with a homogeneous structure.

- Homogenizer in an external circulation loop

- Built-in vacuum generation and retention system

- Modular design with numerous options

- Possibility of automatic dosing of ingredients (optional)

- No additional pump required for loading/unloading

- Automatic top cover lifting system

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 13,5

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The Milk Cooler has a simple design, which allows for easy and safe operation. it meets the requirements of all dairy production facilities.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 200l/ 300l

- Voltage: 380-400V

The stated price does not include the steam generator

The unique sectional cooking kettle is intended for high-performance cooking/blanching/frying of a wide range of products with subsequent cooling to avoid damaging their structure. An essential part of this technology is the efficient cooling section, necessary for halting the cooking process after unloading. This function is also necessary when processing vegetables to the "aldente" state, when vegetables retain their structure and natural color after thermal treatment. This model provides heating by direct injection of purified steam into the heating section (steam generator - option).

- Suitable for cooking small-sized products

- Fast and intense heating due to direct steam injection

- Intensive hydro-stirring

- Automatic basket lifting system

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 2x250l/ 3x250l

- Voltage: 380-400V

- Working volume: 2x175l/ 3x175l

The cooling tank is designed for storing milk and other beverages.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

A chiller is a cooling machine that removes heat from a liquid through vapor compression and absorption in a cyclic manner.

- Principle of operation: Continuous mode

- Cooling performance l/h: 100 / 200 l/ 300

The rotary drum cooler is designed for efficient pre-cooling, stopping the cooking process, and cooling of boiled, blanched, fried, baked, or thermally processed foods. The rotating perforated drum ensures uniform cooling together with the additional water supply.

- Uniform cooling

- Adjustable drum speed

- Made entirely out of stainless steel

- Suitable for a wide range of food products

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 1,1

Milk cooler tank designed for cooling milk and other dairy products. The tank is available in 13 different capacities, covering a range from 50 liters all the way up to 2,500 liters, capable of meeting the needs of all dairy & cheese production facilities. We offer 2 or 4 milking options. Prices are displayed for the milk cooling tank with 4 milking.

- Material: Stainless steel

- Principle of operation: Batch mode

The AS series┬Āchillers belong to the top professional cooling devices for quick┬Ābeverages' chilling in restaurants, cafes, catering industry facilities, and pubs. The chiller is suitable for cooling┬Āwater, spark or soft drinks, beer, wine, strong alcohol drinks, and others.

- Principle of operation: Continuous mode

- Country of origin: EU

- Cooling performance l/h: 160 l/h / 200 l/h

The NWT PLUS chillers have a compact design. They take little space and are very easy to install and to start. The units are mobile on wheels. We offer different capacities.

- Heating: integrated

- Voltage: 380-400V

Fixed cooling unit wit different capacities from 67 kW up to 226 kW. Unit are solid and ensure long-life base operation.

- Country of origin: EU