Vacuum cooling lab for bread and pastries

The vacuum bread cooler is well-suited for application in small bakeries or as a laboratory unit in industrial enterprises. This enables the post-baking of bread under vacuum conditions, influencing both its shape and structure.

- Built-in deep vacuum system

- Built-in vapor removal and condensation system

- Built-in refrigeration system

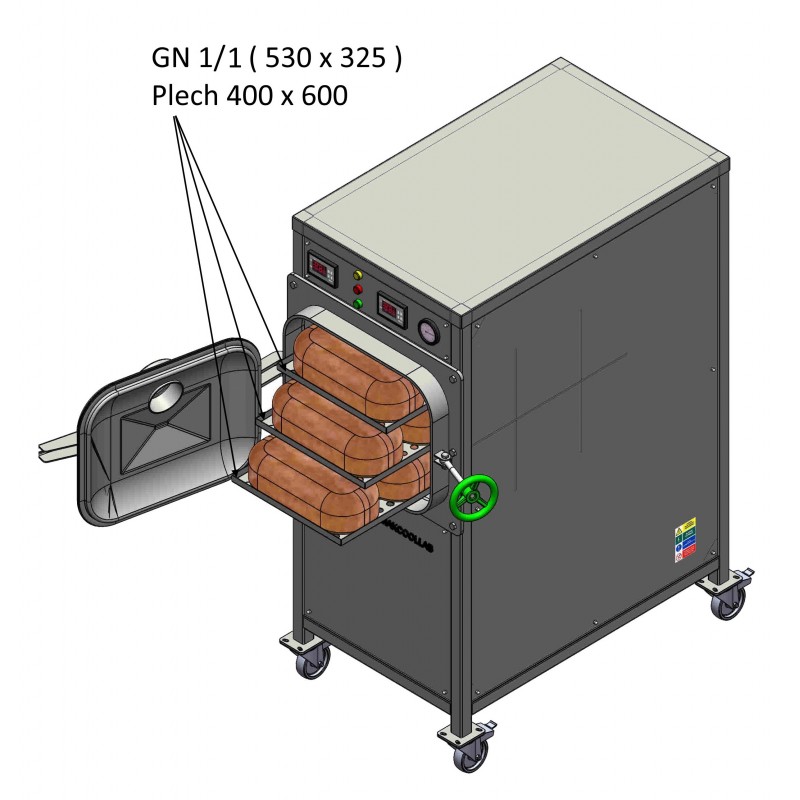

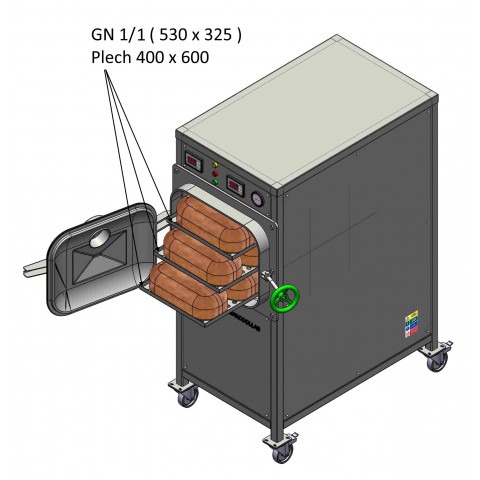

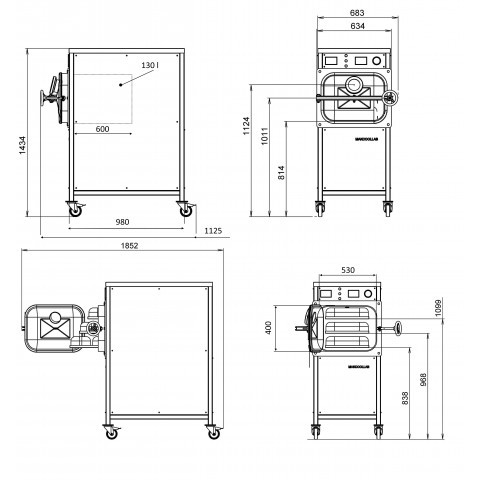

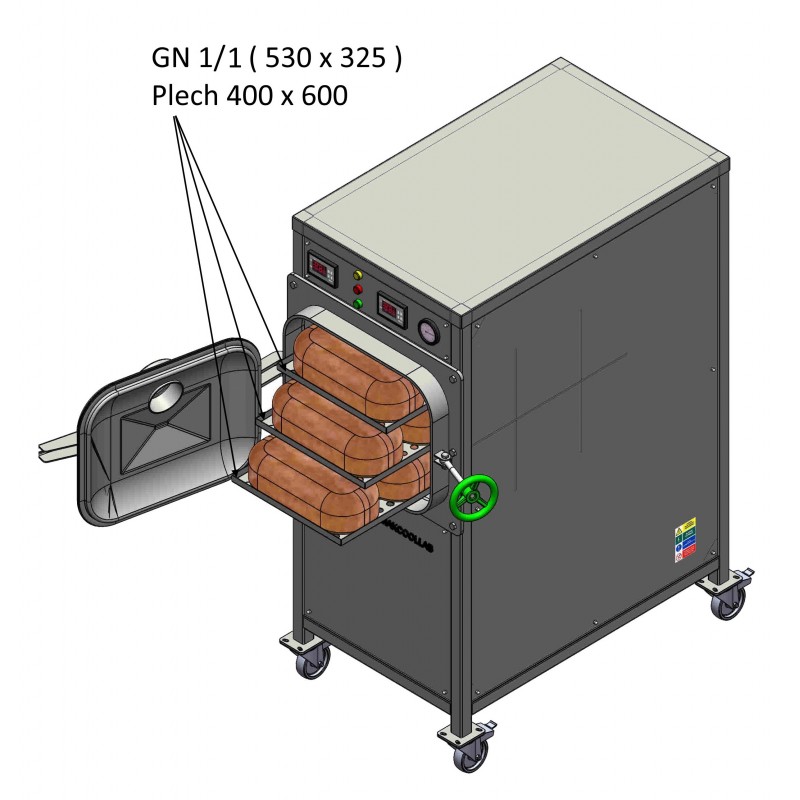

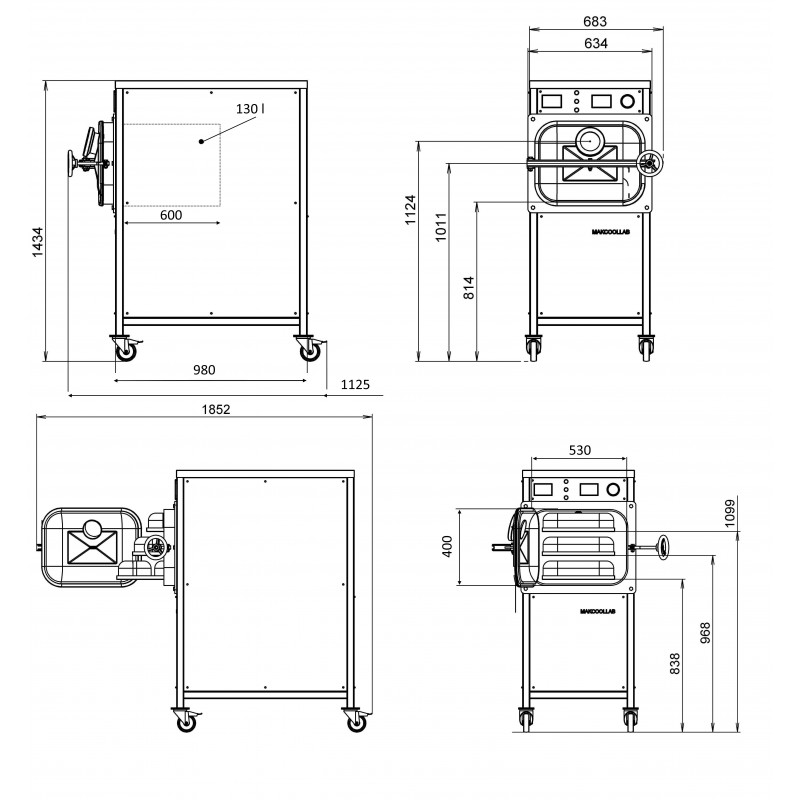

- The chamber is designed for 3 gastro containers size GN 1/1, or pallets: 400x600/530x325 mm

- Compact and mobile installation

Vacuum cooling is quickly gaining popularity in food production, particularly in the baking of bread and pastries. This method significantly reduces baking time as the post-baking process occurs within the vacuum cooling chamber. Besides saving energy, vacuum cooling minimizes the space and time required for bread to cool before vacuum packaging, consequently lowering the risk of potential contamination.

Suitable for cooling various types of baked goods: rolls, croissants, baguettes and other types of bread.

Advantages of vacuum cooling bakery products:

- Cooling time is significantly reduced

- Baking time is reduced, which entails lower energy costs and increased productivity

- Extends product shelf life

- The product acquires an attractive appearance, the bread becomes voluminous and airy

- Does not require such a large area, as with the convective cooling method

Basic version

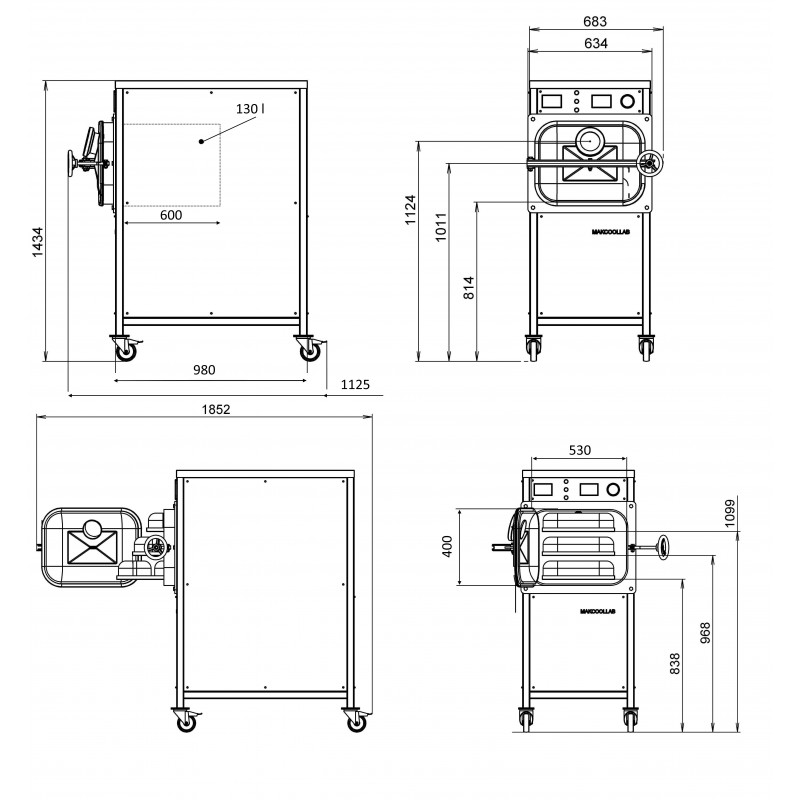

The vacuum cooler consists of a working chamber mounted on a wheeled support, featuring a hatch positioned at the upper part. This hatch includes an inspection window with lighting and a scraper for cleaning. Inside the chamber, there are guides designed for the placement of standard baking trays or gastro containers. The installation is equipped with a vacuum system, a condenser (with a vacuum depth: mBar - 20 (17┬░C)), a condensate collection tank and a chiller. The control includes a thermal controller with a temperature sensor to control the cooling temperature. ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā┬Ā

Technical requirements

For proper operation of the unit, it is necessary to fill the chiller tank with water before the first start-up.

Principle of operation

Effortless and convenient control ensures the virtually automatic execution of all processes; once the product is loaded, the operator inserts the temperature sensor into the product, sets the temperature, closes the hatch, and initiates the process. Upon reaching the preset temperature in the product, the process automatically stops, the vacuum is released, and following a signal, the operator can open the hatch and retrieve the product.

The baking process of the product continues within the vacuum cooler at a pressure below atmospheric, allowing for a reduction in the boiling point of water inside the product. As secondary steam evaporates from the product under vacuum conditions, it also undergoes cooling. Meanwhile, the gelatinization process in the product remains uninterrupted. Following the operation of the installation, it will be necessary to release the container for collecting condensate. It is recommended to connect it to the sewer.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 130l

- Voltage: 380-400V

You might also like

An air cooling conveyor is a system that uses moving belts and airflow to cool down products as they are transported along the conveyor line.

For additional information or a price quote, send us a request.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 500 mm

The stated price does not include the steam generator

The unique sectional cooking kettle is intended for high-performance cooking/blanching/frying of a wide range of products with subsequent cooling to avoid damaging their structure. An essential part of this technology is the efficient cooling section, necessary for halting the cooking process after unloading. This function is also necessary when processing vegetables to the "aldente" state, when vegetables retain their structure and natural color after thermal treatment. This model provides heating by direct injection of purified steam into the heating section (steam generator - option).

- Suitable for cooking small-sized products

- Fast and intense heating due to direct steam injection

- Intensive hydro-stirring

- Automatic basket lifting system

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 2x250l/ 3x250l

- Voltage: 380-400V

- Working volume: 2x175l/ 3x175l

Cooling tunnel with a length of 15.2 meters. The standard design consists of 13 sections with removable top. For more information, send us a request.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 400 mm

Designed for "cold" vacuum drying of products sensitive to high temperatures, also suitable for liquid and viscous products.

The modular cooling conveyor is produced as a standard tabletop version with a section length of 1000 mm; in addition to it, you can order a stainless table or a frame supporting structure. The air cooling conveyor can be sectionally increased in length by the required number of sections.

- Compact, easy to install on any work surface

- Features a fine-grained stainless steel mesh for high temperatures and small-sized products

- Easily combined in line with a tabletop fryer 400/1100/12

- Easy maintenance and cleaning

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 400 mm

The Milk Cooler has a simple design, which allows for easy and safe operation. it meets the requirements of all dairy production facilities.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 200l/ 300l

- Voltage: 380-400V

It is intended for pre-cooling after cooking or frying vegetables and fruit, meat, fish and seafood and other products.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 600 mm

Milk cooler tank designed for cooling milk and other dairy products. The tank is available in 13 different capacities, covering a range from 50 liters all the way up to 2,500 liters, capable of meeting the needs of all dairy & cheese production facilities. We offer 2 or 4 milking options. Prices are displayed for the milk cooling tank with 4 milking.

- Material: Stainless steel

- Principle of operation: Batch mode

An air cooling conveyor is a system that uses moving belts and airflow to cool down products as they are transported along the conveyor line.

For additional information or a price quote, send us a request.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 500 mm

Vacuum homogenizer VMG M is the ideal solution for the production of pilot batches and the industrial production of a wide range of products of small and medium production. The price depends on the production capacity.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Max vacuum: -0,8 Bar

- Working volume: 50-80l

The stated price does not include the steam generator

The unique sectional cooking kettle is intended for high-performance cooking/blanching/frying of a wide range of products with subsequent cooling to avoid damaging their structure. An essential part of this technology is the efficient cooling section, necessary for halting the cooking process after unloading. This function is also necessary when processing vegetables to the "aldente" state, when vegetables retain their structure and natural color after thermal treatment. This model provides heating by direct injection of purified steam into the heating section (steam generator - option).

- Suitable for cooking small-sized products

- Fast and intense heating due to direct steam injection

- Intensive hydro-stirring

- Automatic basket lifting system

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 2x250l/ 3x250l

- Voltage: 380-400V

- Working volume: 2x175l/ 3x175l

An air cooling conveyor is used to rapidly cool products in food processing industries by circulating cool air over them as they move along a conveyor belt. This efficient cooling process helps preserve product quality and reduce the time between processing stages, facilitating smoother production workflows.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

Heating: electric and steam - combination

- Material: Stainless steel

- Principle of operation: Continuous mode

This air cooler and heater is multifunctional. It can be used as air cooler, heater. The compact and lightweight air cooler / heater contains. 4 caster wheels make it easy to move the unit.

The cooling tank is designed for storing milk and other beverages.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

The vacuum diffusion cooling unit is a multifunctional device not only for vegan processors.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

Air cooling conveyor with MULTI AIR KNIFE is a system for┬Ā intensive┬Āremoving excess water or oil and preliminary cooling.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 500 mm

Cooling tunnel with a length of 15.2 meters. The standard design consists of 13 sections with removable top. For more information, send us a request.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 400 mm

ACM mixing tank is intended for efficient cooling, heating, tempering and storing of mayonnaise, sour cream, chocolate, oil and similar products after their production.

- Material: Stainless steel

- Principle of operation: Batch mode

CAC Air cooling conveyors are designed for intensive cooling and removal of excess water or oil (air knife section) from products after frying, cooking or blanching.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 500 mm

- Voltage: 380-400V