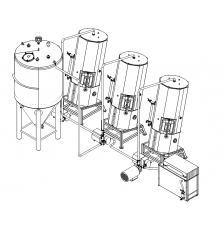

Komplex zaЕҷГӯzenГӯ na vГҪrobu termostabilnГӯch ovocnГҪch nГЎplnГӯ

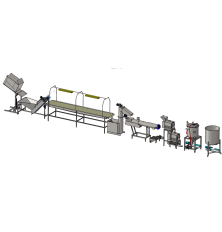

VГҪrobnГӯ linka na termostabilnГӯ ovocnГ© nГЎplnДӣ, kterГ© se hojnДӣ pouЕҫГӯvajГӯ pЕҷi vГҪrobДӣ peДҚiva, pekaЕҷskГҪch vГҪrobkЕҜ a rЕҜznГҪch polotovarЕҜ, ale i tvarohЕҜ, krГ©mЕҜ a dokonce i zmrzliny.

- ZГӯskГЎnГӯ prvotЕҷГӯdnГӯch termostabilnГӯch nГЎplnГӯ pЕҷi zachovГЎnГӯ zГЎkladnГӯch Еҫivin a vitamГӯnЕҜ.

- KompaktnГӯ systГ©m s jednotnГҪm ovlГЎdacГӯm panelem, kterГҪ zajiЕЎЕҘuje snadnГ© a jednoduchГ© ovlГЎdГЎnГӯ.

- RychlГЎ a ГәДҚinnГЎ recyklace je souДҚГЎstГӯ standardnГӯ vГҪbavy.

- ModulГЎrnГӯ konstrukce s mnoha dalЕЎГӯmi moЕҫnostmi pЕҷizpЕҜsobenГӯ.

Obsah tГ©to strГЎnky byl pЕҷeloЕҫen do ДҚeЕЎtiny automatickГҪm pЕҷekladem. PЕҜvodnГӯ verze je v angliДҚtinДӣ. DДӣkujeme za pochopenГӯ.

TepelnДӣ stabilnГӯ vГҪplnДӣ si zachovГЎvajГӯ svГ© fyzikГЎlnГӯ vlastnosti i pЕҷi vystavenГӯ vysokГҪm teplotГЎm; nerozpГӯjejГӯ se, nebublajГӯ, nesmrЕЎЕҘujГӯ se, a dokonce ani nehoЕҷГӯ. ZachovГЎvajГӯ si svou barvu a objem i pЕҷi zmrazenГӯ a nГЎslednГ©m rozmrazenГӯ.

Komplex pro vГҪrobu termostabilnГӯch ovocnГҪch nГЎplnГӯ je vhodnГҪ pro zpracovГЎnГӯ produktЕҜ, jako jsou:

|

|

|

|

|

|

|

|

VГҪhody:

- Komplex zaЕҷГӯzenГӯ lze pЕҷizpЕҜsobit na zГЎkladДӣ poЕҫadovanГ© ГәrovnДӣ zpracovГЎnГӯ a vstupnГӯch surovin, vДҚetnДӣ pЕҷГӯpravnГҪch fГЎzГӯ, jako je manipulace s ovocem, mytГӯ, mletГӯ a klГӯДҚovГҪch technologickГҪch procesЕҜ, jako je mГӯchГЎnГӯ, vaЕҷenГӯ ve vakuu a bobtnГЎnГӯ s chlazenГӯm.

- Pro vГҪrobnГӯ linku nabГӯzГӯme pestrou ЕЎkГЎlu dalЕЎГӯch moЕҫnostГӯ a zaЕҷГӯzenГӯ, vДҚetnДӣ zГЎkladnГӯch technologickГҪch prvkЕҜ, jako jsou inline homogenizГЎtory, a pomocnГҪch komponentЕҜ, jako jsou stanice na ledovou vodu, parnГӯ generГЎtory a dalЕЎГӯ.

- K dispozici jsou rЕҜznГ© ГәrovnДӣ automatizace technologickГҪch procesЕҜ podle rЕҜznГҪch receptur, od dГЎvkovГЎnГӯ podle hmotnosti aЕҫ po automatickГ© dГЎvkovГЎnГӯ prostЕҷednictvГӯm systГ©mu prЕҜtokomДӣrЕҜ.

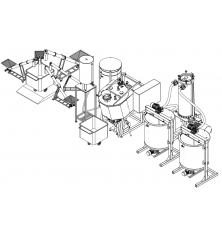

PЕҷi vГҪrobДӣ tДӣchto ovocnГҪch nГЎplnГӯ se bДӣЕҫnДӣ pouЕҫГӯvajГӯ zaЕҷГӯzenГӯ, jako jsou fermentory pro vГҪrobu sirupu, vakuovГ© odpaЕҷovacГӯ zaЕҷГӯzenГӯ pro vaЕҷenГӯ ovocnГ©/jahodovГ© sloЕҫky a specializovanГЎ mГӯchadla pro rozpouЕЎtДӣnГӯ a mГӯchГЎnГӯ rЕҜznГҪch pЕҷГӯsad. Aby se ovocnГ© nГЎplni dodaly tepelnДӣ odolnГ© vlastnosti, obvykle se do nГӯ pЕҷidГЎvГЎ Еҷada pЕҷГӯsad. TradiДҚnГӯ postupy zahrnujГӯ pЕҷidГЎvГЎnГӯ pektinu a ЕЎkrobu do vaЕҷenГ© ovocnГ© hmoty spolu se sirupem.

VГҪrobnГӯ proces se obvykle dДӣlГӯ na dvДӣ ДҚГЎsti, kterГ© probГӯhajГӯ paralelnДӣ:

- vaЕҷenГӯ sirupu/ovocnГ© a bobulovГ© hmoty pЕҷi teplotДӣ pЕҷibliЕҫnДӣ 85-88 stupЕҲЕҜ.

- mГӯchГЎnГӯ s vodou, rozpouЕЎtДӣnГӯ suchГҪch sloЕҫek (pЕҷГӯsad): pektinu, ЕЎkrobu atd.

PotГ© se obДӣ hmoty smГӯchajГӯ v jednu, aby se aktivoval proces bobtnГЎnГӯ, zatГӯmco se hmota ochlazuje.

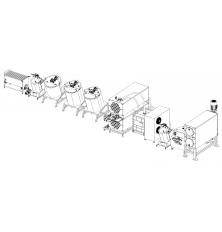

K vГҪrobДӣ sirupu se pouЕҫГӯvajГӯ atmosfГ©rickГ© vaЕҷiДҚe sirupu vybavenГ© mГӯchadlem s rГЎmovou kotvou, v nichЕҫ se cukr rozpouЕЎtГӯ a vznikГЎ roztok o teplotДӣ 60В° Brix.

Pro vaЕҷenГӯ ovoce v roztoku o teplotДӣ 60В° Brix se pouЕҫГӯvajГӯ vakuovГ© odpaЕҷovacГӯ jednotky. PЕҷГӯtomnost vakua je nezbytnГЎ pro snГӯЕҫenГӯ teploty varu smДӣsi a zajiЕЎtДӣnГӯ jejГӯho udrЕҫenГӯ pod 85-88 stupni Celsia. Teplota vyЕЎЕЎГӯ neЕҫ 90 stupЕҲЕҜ mЕҜЕҫe zpЕҜsobit, Еҫe se cukr vrГЎtГӯ do kapalnГ© formy. I po pЕҷidГЎnГӯ pektinu, ЕЎkrobu nebo jinГҪch nГЎplnГӯ mЕҜЕҫe dojГӯt k naruЕЎenГӯ jeho termostabilnГӯch vlastnostГӯ, coЕҫ vede k roztГӯrГЎnГӯ a vytГ©kГЎnГӯ bДӣhem peДҚenГӯ.

Po procesu vaЕҷenГӯ ovocnГ© hmoty se postupnДӣ pЕҷidГЎvajГӯ roztoky pektinu se ЕЎkrobem, kyselinou citronovou a mouДҚkovГҪm cukrem. SmДӣs se nechГЎ nabobtnat a ochladit na pЕҷibliЕҫnДӣ 70 В°C, potГ© se pЕҷeДҚerpГЎ do dГЎvkovacГӯ nebo skladovacГӯ nГЎdoby. DalЕЎГӯ ochlazenГӯ na pЕҷibliЕҫnДӣ 45 stupЕҲЕҜ probГӯhГЎ po dobu 50-60 minut, coЕҫ napomГЎhГЎ vytvoЕҷenГӯ ЕҫelatinovГ© struktury nezbytnГ© pro zachovГЎnГӯ vitamГӯnЕҜ a barev v nГЎplni.

NГЎplЕҲ mЕҜЕҫe bГҪt buДҸ hladkГЎ a homogennГӯ, nebo mЕҜЕҫe bГҪt proklГЎdГЎna rЕҜznГҪmi frakcemi ovoce nebo bobulovin. K dosaЕҫenГӯ homogennГӯ nГЎplnДӣ lze pouЕҫГӯt ЕҷadovГҪ homogenizГЎtor, obvykle instalovanГҪ v cirkulaДҚnГӯm okruhu vakuovГ© odpaЕҷovacГӯ jednotky (volitelnДӣ).

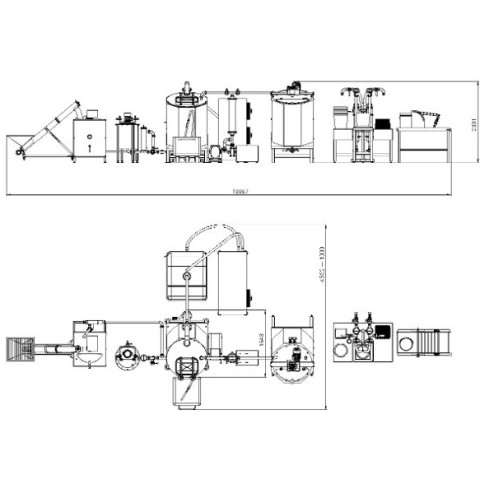

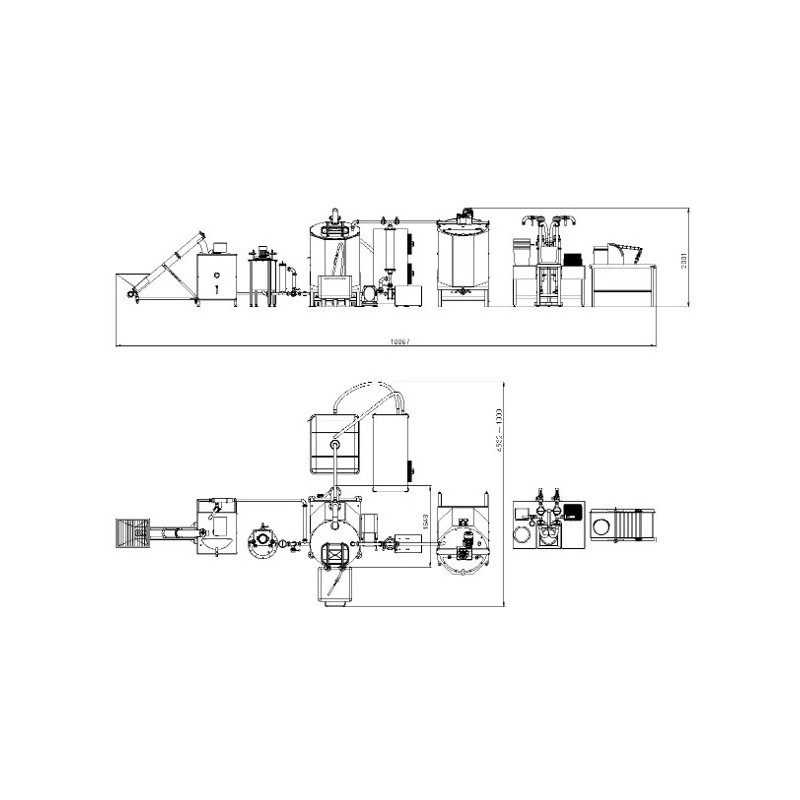

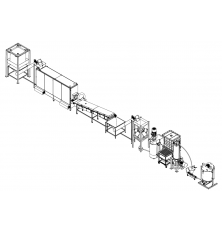

ZГЎkladnГӯ verze

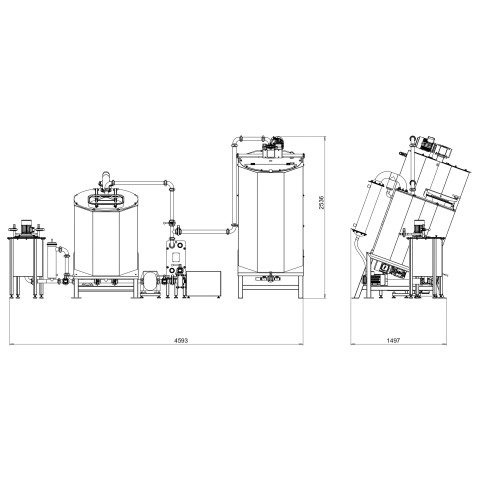

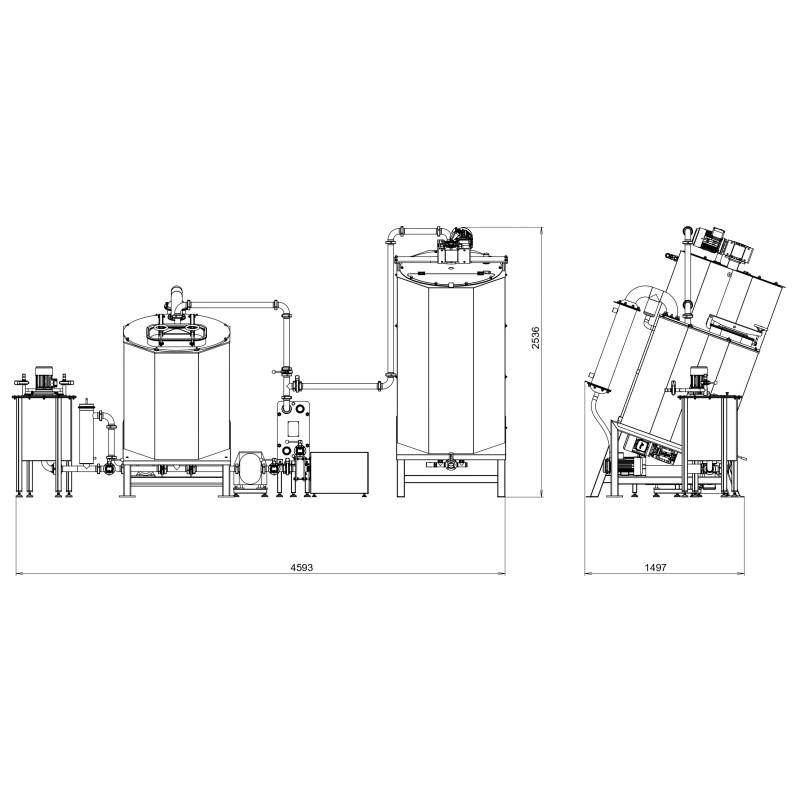

150litrovГҪ mixГ©r urДҚenГҪ pro tДӣЕҫko smГЎДҚitelnГ© a ЕЎpatnДӣ rozpustnГ© prГЎЕЎky. UsnadЕҲuje pЕҷГӯpravu smДӣsi obsahujГӯcГӯ pektin, ЕЎkrob, mouДҚkovГҪ cukr a kyselinu citronovou rozpuЕЎtДӣnou ve vodДӣ. MГӯchaДҚka je vybavena specializovanГҪm vysokorychlostnГӯm mГӯchadlem - vrtulГӯ, kterГ© zajiЕЎЕҘuje ГәДҚinnГ© mГӯchГЎnГӯ a rozpouЕЎtДӣnГӯ prГЎЕЎkЕҜ pro dosaЕҫenГӯ homogennГӯho roztoku. Tato smДӣs roztokЕҜ se pak pomocГӯ vГҪvДӣvy pЕҷidГЎvГЎ do vakuovГ© odpaЕҷovacГӯ jednotky.

VakuovГЎ odpaЕҷovacГӯ jednotka s kapacitou 600 litrЕҜ., je urДҚena k vaЕҷenГӯ ovocnГ© smДӣsi s roztokem 60В° Brix. VГҪsledkem tohoto procesu je hmota s obsahem 48-53 % suЕЎiny. Po ochlazenГӯ na 70 В°C se roztok na bГЎzi pektinu smГӯchГЎ se vzniklou ovocnou nГЎplnГӯ. Odparka, navrЕҫenГЎ jako ЕЎikmГЎ verze tЕҷГӯvrstvГ©ho vakuovГ©ho reaktoru s gravitaДҚnГӯm mГӯchГЎnГӯm, je vybavena rГЎmovГҪm mГӯchacГӯm zaЕҷГӯzenГӯm s posГӯlenГҪm elektrickГҪm pohonem a fluoroplastovГҪmi ЕЎkrabkami vhodnГҪmi pro hustГ© a viskГіznГӯ produkty. VakuovГЎ odpaЕҷovacГӯ jednotka je navГӯc vybavena vnДӣjЕЎГӯm okruhem nucenГ©ho obДӣhu, vДҚetnДӣ vzdГЎlenГ©ho vГҪmДӣnГӯku tepla a vakuovГ©ho systГ©mu. Pro tuto komplexnГӯ Гәpravu je k dispozici chladicГӯ mГ©dium, konkrГ©tnДӣ pГЎra dodГЎvanГЎ z externГӯho zdroje. PЕҷГӯpojka pГЎry, uzavГӯracГӯ a regulaДҚnГӯ ventily pro pГЎru vЕЎak nejsou souДҚГЎstГӯ dodГЎvky a musГӯ je zajistit certifikovanГЎ firma v souladu s mГӯstnГӯmi pЕҷedpisy.

ЕҳГӯzenГӯ komplexu je poloautomatickГ©, uzavГӯracГӯ a regulaДҚnГӯ ventily majГӯ mechanickou funkci.

ZГЎkladnГӯ verze neobsahuje vaЕҷiДҚ sirupu, protoЕҫe cukr lze rozpustit pЕҷГӯmo ve vakuovГ© odpaЕҷovacГӯ jednotce.

MoЕҫnosti:

- VГҪrobnГӯk sirupu pro ГәДҚinnГ© rozpouЕЎtДӣnГӯ cukru a zГӯskГЎnГӯ nasycenГ©ho roztoku/sirupu.

- Inline homogenizГЎtor pro vytvoЕҷenГӯ homogennГӯ struktury v ovocnГҪch nГЎplnГӯch.

- PrЕҜtokovГҪ filtr z nerezovГ© oceli umГӯstДӣnГҪ pЕҷed vstupem do vakuovГ© odpaЕҷovacГӯ jednotky pЕҷi pЕҷidГЎvГЎnГӯ sirupu z vaЕҷiДҚe sirupu nebo mГӯchaДҚky pektinu.

- PlГЎЕЎЕҘ vakuovГ© odpaЕҷovacГӯ jednotky urДҚenГҪ pro teplonosnГ© mГ©dium.

- NГЎdoba na hotovГҪ vГҪrobek s plГЎЕЎtДӣm na teplonosnГ© mГ©dium (1000 l).

- FrekvenДҚnГӯ mДӣniДҚe pro smДӣЕЎovacГӯ systГ©my smДӣЕЎovaДҚЕҜ a vakuovГҪch odpaЕҷovaДҚЕҜ.

- SystГ©m pro shromaЕҫДҸovГЎnГӯ a odvГЎdДӣnГӯ kondenzГЎtu za ГәДҚelem zvГҪЕЎenГӯ odpaЕҷovГЎnГӯ (kompletnГӯ systГ©m vaЕҷenГӯ) pЕҷi pouЕҫitГӯ nedehydratovanГ©ho ovoce nebo bobulovin.

- NastavenГӯ hloubky vakua.

- Hlavy CIP pro mytГӯ.

TechnickГ© poЕҫadavky

Pro zajiЕЎtДӣnГӯ sprГЎvnГ© funkce systГ©mu jsou nutnГ© nГЎsledujГӯcГӯ podmГӯnky:

- Zdroj ledovГ© vody o teplotДӣ 5-7 stupЕҲЕҜ pro pЕҷГӯvod do kondenzГЎtoru vakuovГ© odpaЕҷovacГӯ jednotky (je-li zvolena tato moЕҫnost).

- Zdroj pГЎry o tlaku 0,7/3 bar jako pЕҷГӯvod do plГЎЕЎtДӣ vakuovГ© odpaЕҷovacГӯ jednotky/vГҪmДӣnГӯku tepla.

- PЕҷipojenГӯ k vodovodnГӯmu a kanalizaДҚnГӯmu systГ©mu.

- MateriГЎl: Nerez

- Princip provozu: KontinuГЎlnГӯ reЕҫim

- ZemДӣ pЕҜvodu: Slovensko

- NapДӣtГӯ: 380-400V