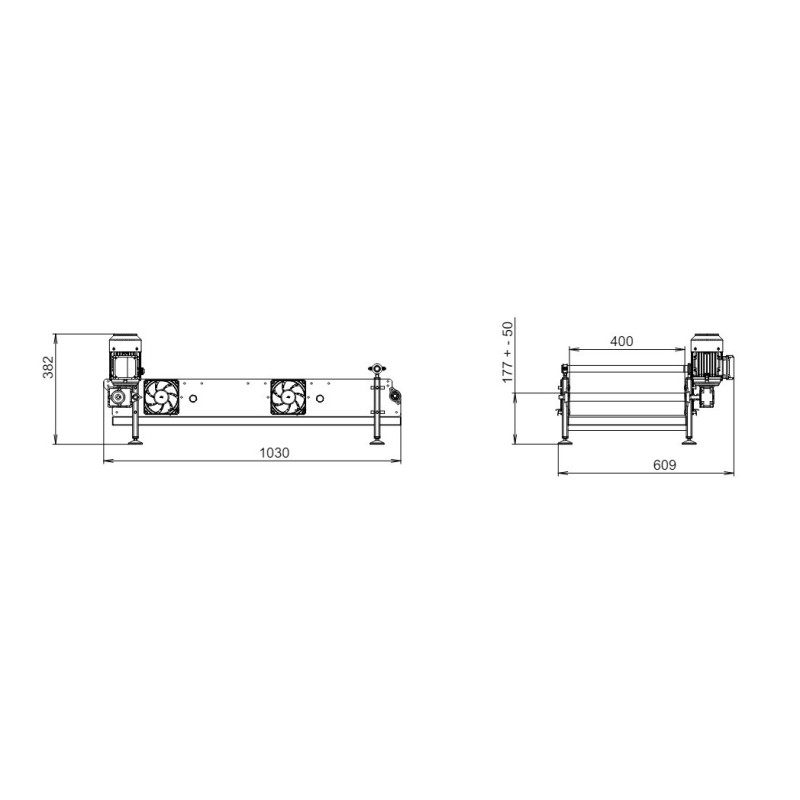

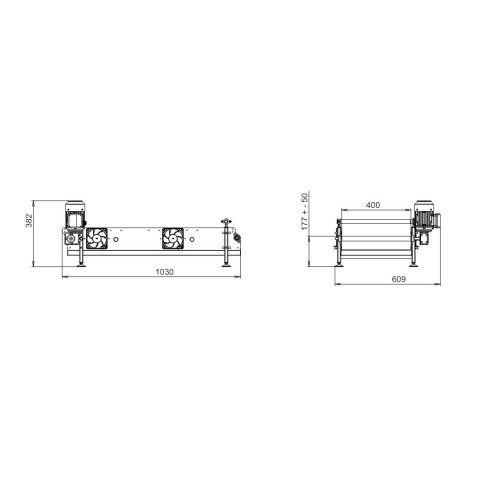

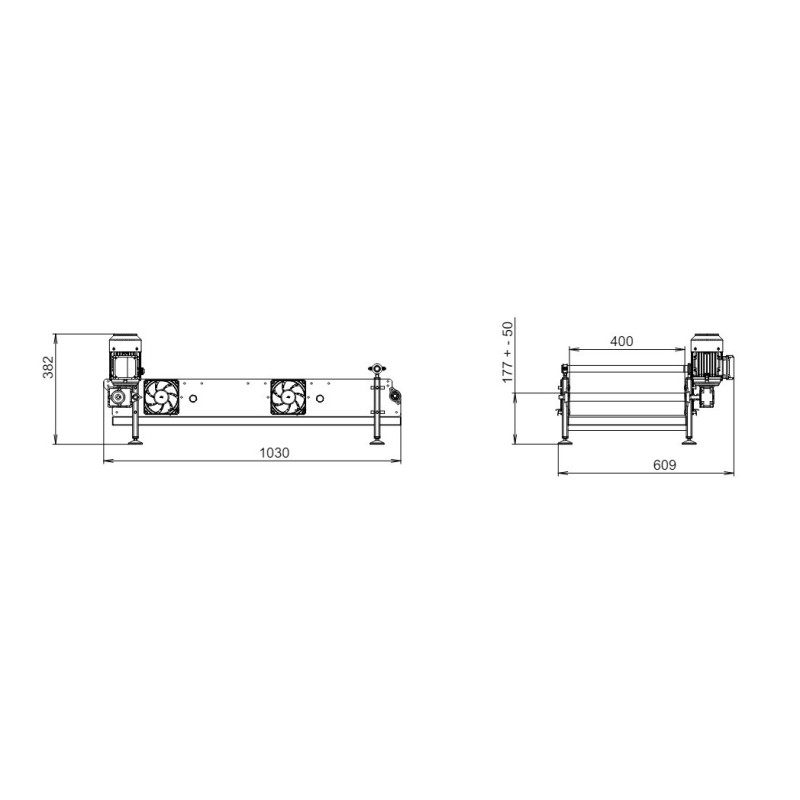

VzduchovĆ½ chladicĆ dopravnĆk M 400/1000

ModulĆ”rnĆ chladicĆ dopravnĆk se vyrĆ”bĆ ve standardnĆ stolovĆ© verzi s dĆ©lkou Ćŗseku 1000 mm; k nÄmu si mÅÆžete objednat nerezovĆ½ stÅÆl nebo rĆ”movou nosnou konstrukci. VzduchovĆ½ chladicĆ dopravnĆk lze sekÄnÄ prodloužit o požadovanĆ½ poÄet sekcĆ.

- KompaktnĆ, snadnĆ” instalace na jakoukoli pracovnĆ plochu

- Je vybaven jemnozrnnou sĆÅ„kou z nerezovĆ© oceli pro vysokĆ© teploty a malĆ© rozmÄry vĆ½robkÅÆ.

- SnadnĆ” kombinace se stolnĆ fritĆ©zou 400/1100/12

- SnadnĆ” Ćŗdržba a ÄiÅ”tÄnĆ

Obsah tĆ©to strĆ”nky byl pÅeložen do ÄeÅ”tiny automatickĆ½m pÅekladem. PÅÆvodnĆ verze je v angliÄtinÄ. DÄkujeme za pochopenĆ.

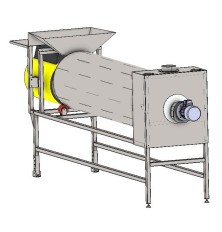

VzduchovĆ½ chladicĆ dopravnĆk slouÅ¾Ć k odvĆ”dÄnĆ pÅebyteÄnĆ©ho tuku z vĆ½robku, ÄĆmž zastavĆ smaženĆ vĆ½robku a umožnĆ jeho povrchovĆ© ochlazenĆ. Tento chladicĆ systĆ©m je nezbytnou fĆ”zĆ po smaženĆ vĆ½robku ve fritĆ©ze a pÅed dalÅ”Ćm zpracovĆ”nĆm/balenĆm.

ChladicĆ dopravnĆk je vhodnĆ½ pro použitĆ po prÅÆbÄžnĆ©m fritovĆ”nĆ rÅÆznĆ½ch vĆ½robkÅÆ, a to jak v profesionĆ”lnĆ kuchyni, tak v malĆ©m mÄÅĆtku pÅi vĆ½robÄ rÅÆznĆ½ch potravinĆ”ÅskĆ½ch polotovarÅÆ, jako jsou:

|

|

|

|

|

|

|

A mnoho dalÅ”Ćch produktÅÆ, kterĆ© lze zpracovĆ”vat na prÅÆbÄžnĆ½ch dopravnĆkovĆ½ch fritĆ©zĆ”ch o Å”ĆÅce 400 mm.

VĆ½hody

- ModulĆ”rnĆ systĆ©m, pracovnĆ dĆ©lku si mÅÆžete zvolit podle konkrĆ©tnĆho vĆ½robku a požadovanĆ©ho stupnÄ chlazenĆ, kterĆ©mu musĆ bĆ½t podroben.

- Lze použĆt jako souÄĆ”st vĆ½robnĆ linky, 100% kompatibilnĆ s naÅ”Ć vĆ½robnĆ linkou. kompaktnĆ modulĆ”rnĆ fritĆ©za 400/1100/12.

- NÄkolik možnostĆ instalace: stolnĆ verze, na samostatnĆ©m pohyblivĆ©m rĆ”mu nebo na pojĆzdnĆ©m stole na koleÄkĆ”ch.

- JednoduchĆ© a snadnĆ© ÄiÅ”tÄnĆ usnadÅuje vaniÄka instalovanĆ” po celĆ© dĆ©lce dopravnĆku, kterĆ” je urÄena k zachycenĆ pÅebyteÄnĆ©ho oleje po vyfouknutĆ; lze ji snadno vyjmout a umĆ½t.

- SpeciĆ”lnĆ uspoÅĆ”dĆ”nĆ ventilĆ”torÅÆ umožÅuje smÄrovat vzduch jak nad vĆ½robek, tak pod sĆÅ„, a tĆm jej ovĆvat ze vÅ”ech stran.

- NerezovĆ” sĆÅ„ka dopravnĆku nebrĆ”nĆ rozvodu vzduchu a zajiŔńuje snadnĆ½ a rychlĆ½ prÅÆtok zbytkovĆ©ho oleje perforovanĆ½m pĆ”sem do zĆ”sobnĆku oleje umĆstÄnĆ©ho pod nĆm.

ZĆ”kladnĆ verze

SklĆ”dĆ” se z dopravnĆku s jemnĆ½m sĆtem z nerezovĆ© oceli s elektrickĆ½m pohonem, vany po celĆ© dĆ©lce dopravnĆku, vzduchovĆ©ho nože na vstupu do produktu a nÄkolika ventilĆ”torÅÆ rovnomÄrnÄ rozmĆstÄnĆ½ch po celĆ© dĆ©lce dopravnĆku.

Možnosti

- NerezovĆ½ stÅÆl

- Struktura rƔmu

- StÅÆl s opÄrnĆ½m koleÄkem

- PodpÄra koleÄek pro rĆ”movou konstrukci

- FrekvenÄnĆ mÄniÄ pro nastavenĆ rychlosti dopravnĆku

- ModulĆ”rnĆ systĆ©m dĆ©lky dopravnĆku, možnost jeho zvÄtÅ”ovĆ”nĆ po ĆŗsecĆch

- VzduchovĆ½ nÅÆž na vstupu pro efektivnĆ odfouknutĆ zbytkovĆ©ho oleje z povrchu produktu. Tato možnost vyžaduje zdroj stlaÄenĆ©ho vzduchu s tlakem 6-12 barÅÆ, 300 l/min.

- MateriƔl: Nerez

- Princip provozu: KontinuĆ”lnĆ režim

- Å ĆÅka pracovnĆ plochy: 400 mm

You might also like

Cena je stanovena pro zĆ”kladnĆ verzi bez dalÅ”Ćch modulÅÆ. PÅi zakoupenĆ fritĆ©zy spoleÄnÄ s obÄma pÅĆdavnĆ½mi moduly dopravnĆku ā dvojitĆ½m dopravnĆkem a lopatkovĆ½m dopravnĆkem ā nabĆzĆme slevu 300 EUR.

VÅ”estrannĆ” modulĆ”rnĆ dopravnĆ fritĆ©za s jednĆm pĆ”sem se použĆvĆ” pro kontinuĆ”lnĆ fritovĆ”nĆ rÅÆznĆ½ch vĆ½robkÅÆ s nĆzkĆ½m obsahem vlhkosti, kterĆ© nevyžadujĆ nucenĆ© ponoÅenĆ pod povrch oleje.

- NastavitelnĆ” doba smaženĆ od nÄkolika sekund až po hodinu!

- Možnost použitĆ jednotky jako kontinuĆ”lnĆho blanÅ”ĆrovaÄe nebo kotle pro vaÅenĆ produktÅÆ s choulostivou strukturou.

- ModulĆ”rnĆ systĆ©m, rozÅ”iÅujĆcĆ funkce s každĆ½m novĆ½m modulem

- KompaktnĆ verze pro stolnĆ poÄĆtaÄe

- Možnost pravidelnĆ©ho smaženĆ vĆ½robkÅÆ s automatickĆ½m vyklĆ”dĆ”nĆm

- OhÅev: ElektÅina

- MateriƔl: Nerez

- VĆ½kon ohÅevu, kW: 12

- Princip provozu: KontinuĆ”lnĆ režim

- ZemÄ pÅÆvodu: Slovensko

- DĆ©lka pracovnĆ plochy: 1100 mm

- Å ĆÅka pracovnĆ plochy: 400 mm

- Objem oleje: 60l

- NapÄtĆ: 380-400V

Cena je stanovena pro kombinaci zĆ”kladnĆho modelu fritĆ©zy a pÅĆdavnĆ©ho modulu s otoÄnĆ½mi lopatkami.

UniverzĆ”lnĆ modulĆ”rnĆ fritĆ©za vybavenĆ” pÅĆdavnĆ½m lopatkovĆ½m modulem je urÄena ke smaženĆ tenkĆ½ch plĆ”tkÅÆ vĆ½robkÅÆ, kterĆ© vyžadujĆ ponoÅenĆ pod hladinu oleje.

- NastavitelnĆ” doba smaženĆ od nÄkolika sekund až po hodinu

- KompaktnĆ stolnĆ verze

- LopatkovĆ½ dopravnĆk se instaluje na hornĆ ÄĆ”st zĆ”kladnĆ fritĆ©zy.

- BezpeÄnostnĆ termostaty na každĆ©m topnĆ©m ÄlĆ”nku

- OhÅev: ElektÅina

- MateriƔl: Nerez

- Princip provozu: KontinuĆ”lnĆ režim

- ZemÄ pÅÆvodu: Slovensko

- DĆ©lka pracovnĆ plochy: 1100 mm

- Å ĆÅka pracovnĆ plochy: 400 mm

- CelkovĆ½ vĆ½kon, kW: 12

- Objem oleje: 60l

- NapÄtĆ: 380-400V

BezolejovĆ½ ÄtyÅvĆ”lcovĆ½ pĆstovĆ½ kompresor je ideĆ”lnĆm ÅeÅ”enĆm pro ty, kteÅĆ si cenĆ jak vĆ½konu, tak ticha.

- Vybaveno dvÄma dvoupĆstovĆ½mi jednotkami se samostatnĆ½mi motory.

- ÄtyÅi vzduchovĆ© filtry

- MechanickĆ½ tlakovĆ½ spĆnaÄ

- TichĆ½ provoz (minimĆ”lnÄ o 25 % tiÅ”Å”Ć než u tradiÄnĆch kompresorÅÆ).

- RukojeÅ„ pro pÅenĆ”Å”enĆ a podpÄra pro pojĆzdnĆ© koleÄko

- Princip provozu: KontinuĆ”lnĆ režim

- CelkovĆ½ vĆ½kon, kW: 1,5

- NapÄtĆ: 220-230V

CC chladicĆ dopravnĆky zajiŔńujĆ rychlĆ© ochlazenĆ potravin po tepelnĆ©m zpracovĆ”nĆ pomocĆ proudu vzduchu. SnižujĆ teplotu bÄhem nÄkolika sekund, odstraÅujĆ pÅebyteÄnĆ½ olej nebo vodu a optimalizujĆ pÅĆpravu produktu na balenĆ. VhodnĆ© pro hranolky, maso, nugety, zeleninu Äi chipsy.

- RychlĆ© ochlazenĆ bÄhem nÄkolika sekund

- EfektivnĆ odstranÄnĆ pÅebyteÄnĆ©ho oleje nebo vody

- SnadnĆ” Ćŗdržba a ÄiÅ”tÄnĆ

- Å ĆÅku lze pÅizpÅÆsobit požadavkÅÆm zĆ”kaznĆka

- MateriƔl: Nerez

- Princip provozu: KontinuĆ”lnĆ režim

- ZemÄ pÅÆvodu: Slovensko

- NapÄtĆ: 380-400V

MĆchacĆ nĆ”drž ACM 2060 je urÄena pro chlazenĆ, ohÅev, temperovĆ”nĆ a skladovĆ”nĆ hustĆ½ch a viskĆ³znĆch potravinĆ”ÅskĆ½ch produktÅÆ. PoužitĆ samostatnĆ© nĆ”drže pro tepelnĆ© zpracovĆ”nĆ vĆ½raznÄ zvyÅ”uje vĆ½robnĆ kapacitu a zĆ”roveÅ minimalizuje energetickĆ© ztrĆ”ty zpÅÆsobenĆ© ÄastĆ½m pÅepĆnĆ”nĆm mezi ohÅevem a chlazenĆm v hlavnĆm procesu.

- MultifunkÄnĆ zaÅĆzenĆ pro ohÅev, chlazenĆ, temperovĆ”nĆ, mĆchĆ”nĆ a skladovĆ”nĆ

- MĆchadlo se Å”krabkami pÅizpÅÆsobenĆ© pro hustĆ© a viskĆ³znĆ produkty

- Minimalizace tepelnĆ½ch ztrĆ”t dĆky izolovanĆ©mu duplikĆ”toru

- Å krabky zajiŔńujĆ kontakt s 99 % plochy stÄn a dna

- MateriƔl: Nerez

- Princip provozu: DĆ”vkovĆ½ režim

VzduchovĆ½ chladiÄ a ohÅĆvaÄ vzduchu je multifunkÄnĆ zaÅĆzenĆ, kterĆ© mÅÆže bĆ½t použito jak pro chlazenĆ, tak pro ohÅev vzduchu a zĆ”roveÅ pomĆ”hĆ” udržovat konstantnĆ teplotu. KompaktnĆ a lehkĆ½ chladiÄ / ohÅĆvaÄ vzduchu je vybaven ÄtyÅmi koleÄky, kterĆ” usnadÅujĆ jeho pÅesun.

- Funkce ohÅevu i chlazenĆ v jednom zaÅĆzenĆ

- VysokĆ½ chladicĆ vĆ½kon 3,5 kW a topnĆ½ vĆ½kon 2,5 kW

- NĆzkĆ” hluÄnost ā maximĆ”lnÄ 64 dB

SnĆženĆ teploty a vlhkosti chrĆ”nĆ vĆ½robek i bez chemickĆ©ho oÅ”etÅenĆ. ZaÅĆzenĆ se takĆ© použĆvĆ” k prÅÆbÄžnĆ©mu chlazenĆ vzduchem po tepelnĆ©m zpracovĆ”nĆ.

- MateriƔl: Nerez

- Princip provozu: KontinuĆ”lnĆ režim

- ZemÄ pÅÆvodu: Slovensko

ChladicĆ dopravnĆky Normit CAC jsou urÄeny pro rychlĆ© a efektivnĆ ochlazovĆ”nĆ produktÅÆ po smaženĆ, vaÅenĆ nebo blanÅ”ĆrovĆ”nĆ.

PomocĆ proudÄnĆ vzduchu pÅi teplotÄ okolĆ rychle snižujĆ teplotu, ÄĆmž zastavujĆ proces vaÅenĆ a pÅipravujĆ vĆ½robky na balenĆ.

- EfektivnÄ snižujĆ teplotu produktÅÆ po vaÅenĆ nebo smaženĆ, ÄĆmž zastavujĆ proces vaÅenĆ a pÅipravujĆ je na dalÅ”Ć zpracovĆ”nĆ nebo balenĆ.

- DĆky sekci vzduchovĆ©ho nože se ĆŗÄinnÄ odstraÅuje pÅebyteÄnĆ” vlhkost a olej, což zlepÅ”uje kvalitu a trvanlivost vĆ½robkÅÆ.

- Možnost regulace rychlosti pĆ”su a prÅÆtoku vzduchu umožÅuje pÅizpÅÆsobit dobu chlazenĆ rÅÆznĆ½m typÅÆm produktÅÆ a vĆ½robnĆm požadavkÅÆm.

- KompaktnĆ design a použitĆ kvalitnĆch materiĆ”lÅÆ (AISI304 / AISI316L) zaruÄujĆ snadnou integraci do stĆ”vajĆcĆch vĆ½robnĆch linek a nĆzkĆ© nĆ”roky na Ćŗdržbu.

- MateriƔl: Nerez

- Princip provozu: KontinuĆ”lnĆ režim

- ZemÄ pÅÆvodu: Slovensko

- Å ĆÅka pracovnĆ plochy: 500 mm

ChladicĆ nĆ”drž na mlĆ©ko je energeticky ĆŗspornĆ© zaÅĆzenĆ, kterĆ© je k dispozici v kapacitĆ”ch od 50 litrÅÆ do 2500 litrÅÆ, vhodnĆ© pro mlĆ©kĆ”rny a sĆ½rĆ”rny. NĆ”drž umožÅuje efektivnĆ chlazenĆ mlĆ©ka a je vybavena vĆ”Å¾enĆm s vysokou pÅesnostĆ (volitelnĆ©). Po ochlazenĆ mlĆ©ka je možnĆ© pÅidat dalÅ”Ć pÅedchlazenĆ© mlĆ©ko, ÄĆmž se zabrĆ”nĆ mĆsenĆ a rozvoji bakteriĆ.

- RychlĆ© a efektivnĆ chlazenĆ mlĆ©ka ā zabraÅuje rÅÆstu bakteriĆ a zvyÅ”ovĆ”nĆ kyselosti.

- Energeticky ĆŗspornĆ½ systĆ©m s modernĆm designem a robustnĆ konstrukcĆ.

- SnadnĆ” instalace, Ćŗdržba a možnost propojenĆ se systĆ©mem vĆ”Å¾enĆ s pÅesnostĆ Ā± 0,1 %.

- LopatkovĆ© mĆchadlo zajiŔńuje rovnomÄrnĆ© chlazenĆ a homogenizaci mlĆ©ka bez pÄnÄnĆ.

- MateriƔl: Nerez

- Princip provozu: DĆ”vkovĆ½ režim

- Objem: 50l/ 100l/ 200l/ 300l

- NapÄtĆ: 380-400V

ChladicĆ zaÅĆzenĆ chillery majĆ kompaktnĆ design. Jsou ĆŗspornĆ© a snadno se instalujĆ. ChladiÄ ve standardnĆm provedenĆ mÅÆže pracovat pÅi teplotĆ”ch od +10 Ā°C do +25 Ā°C.

NabĆzĆme tÅi rÅÆznĆ© velikosti chladicĆch jednotek s chladicĆm vĆ½konem od 2,4 kW až do 4,5 kW, kterĆ© jsou ideĆ”lnĆ pro rÅÆznĆ© potÅeby. Pokud mĆ”te specifickĆ© požadavky na vĆ½kon, rĆ”di vĆ”m pÅipravĆme chladicĆ jednotku s jinĆ½m vĆ½konem podle vaÅ”ich potÅeb.

- JednoduchĆ© ovlĆ”dĆ”nĆ a nastavenĆ teploty

- ĆspornĆ½ a ekologickĆ½ chladicĆ systĆ©m

- VhodnĆ© pro malĆ© vinaÅstvĆ, pivovary a vĆ½robce nĆ”pojÅÆ

- VysokĆ” spolehlivost a dlouhĆ” životnost

- Objem: 18 l/ 30l

- NapÄtĆ: 220-230V

IzolaÄnĆ kryt IBC kontejneru je navržen pro použitĆ ve stanicĆch s ledovou vodou s IBC kontejnery k udrženĆ studenĆ© chladicĆ kapaliny na nastavenĆ© teplotÄ.

- UmožÅuje snĆžit energetickĆ© nĆ”klady chladicĆho stroje - chilleru

- ChrĆ”nĆ pÅed krĆ”tkodobĆ½mi vĆ½kyvy okolnĆ teploty, odrĆ”Å¾Ć sluneÄnĆ zĆ”ÅenĆ (až 97 %)

- Kryt se snadno instaluje, otvory pro ventily jsou instalovĆ”ny pomocĆ suchĆ½ch zipÅÆ (suchĆ½ zip)

- Typ zaÅĆzenĆ: VolitelnĆ” vĆ½bava

NDJ chiller je kompaktnĆ a efektivnĆ strojnĆ chladicĆ zaÅĆzenĆ urÄenĆ© pro technologickĆ© procesy a uzavÅenĆ© tlakovĆ© systĆ©my. V zĆ”kladnĆ konfiguraci obsahuje Scroll kompresor, vzduchem chlazenĆ½ kondenzĆ”tor a deskovĆ½ vĆ½mÄnĆk tepla.

- Energeticky ĆŗspornĆ½, s nĆzkou hluÄnostĆ a pÅipravenĆ½ k okamžitĆ©mu spuÅ”tÄnĆ.

- IdeĆ”lnĆ pro tlakovĆ© okruhy a technickĆ© aplikace.

- KompaktnĆ a robustnĆ provedenĆ.

- Jednotka je plnÄ naplnÄna chladivem a pÅipravena k okamžitĆ©mu provozu.

- Princip provozu: KontinuĆ”lnĆ režim

- ZemÄ pÅÆvodu: EU

Cena se vztahuje na zĆ”kladnĆ verzi instalace bez volitelnĆ©ho pÅĆsluÅ”enstvĆ vakuovĆ©ho homogenizĆ”toru. HomogenizĆ”tor je navržen pro Å”irokĆ© spektrum aplikacĆ ā od potravinĆ”ÅskĆ½ch vĆ½robkÅÆ, jako jsou majonĆ©zy, keÄupy, omĆ”Äky, cukrĆ”ÅskĆ© pasty a nĆ”plnÄ, až po kosmetickĆ© produkty, vÄetnÄ krĆ©mÅÆ, gelÅÆ a Å”amponÅÆ.

- VakuovĆ© zpracovĆ”nĆ

- VĆ½roba emulzĆ a gelÅÆ

- Homogenizace a mĆchĆ”nĆ bez mrtvĆ½ch zĆ³n

- Možnost testovĆ”nĆ receptur

- <strongUniverzĆ”lnost napÅĆÄ prÅÆmysly

- KompaktnĆ rozmÄry a snadnĆ” obsluha

ZaÅĆzenĆ je vybaveno spodnĆm homogenizĆ”torem typu Ultra Shear, mĆchadlem s pohyblivĆ½mi stÄrkami, vĆ½klopnĆ½m mechanismem pro snadnĆ© vyprazdÅovĆ”nĆ, kompaktnĆ konstrukcĆ a možnostĆ volby mezi nerezovou ocelĆ AISI 304 nebo AISI 316. K dispozici je takĆ© Å”irokĆ” nabĆdka volitelnĆ©ho pÅĆsluÅ”enstvĆ.

- MateriƔl: Nerez

- Princip provozu: DĆ”vkovĆ½ režim

- ZemÄ pÅÆvodu: Slovensko

- Objem: 100l

- MaximĆ”lnĆ vakuum: -0,8 Bar

- PracovnĆ objem: 50-80l

DopravnĆky na chlazenĆ vzduchem Åady CAC efektivnÄ chladĆ vĆ½robky po smaženĆ, vaÅenĆ nebo blanÅ”ĆrovĆ”nĆ pomocĆ proudÄnĆ vzduchu pÅi teplotÄ okolĆ.

ZaÅĆzenĆ jsou navržena tak, aby odstranila pÅebyteÄnou vodu nebo olej z povrchu produktÅÆ, ÄĆmž se zajistĆ jejich kvalitnĆ zpracovĆ”nĆ pÅed balenĆm.

- VysokĆ½ chladicĆ vĆ½kon pÅi nĆzkĆ© spotÅebÄ energie

- FlexibilnĆ nastavenĆ vĆ½konu ventilĆ”toru a rychlosti pĆ”su

- VhodnĆ© pro rÅÆznĆ© druhy potravin ā i s obalem

- OdolnƔ a hygienickƔ konstrukce z nerezovƩ oceli

- MateriƔl: Nerez

- Princip provozu: KontinuĆ”lnĆ režim

- ZemÄ pÅÆvodu: Slovensko

- Å ĆÅka pracovnĆ plochy: 600 mm

ChladicĆ nĆ”drž na mlĆ©ko urÄenĆ” k chlazenĆ mlĆ©ka a dalÅ”Ćch mlĆ©ÄnĆ½ch vĆ½robkÅÆ. NĆ”drž je k dispozici ve 13 rÅÆznĆ½ch kapacitĆ”ch od 50 litrÅÆ až po 2 500 litrÅÆ, kterĆ© jsou schopny uspokojit potÅeby vÅ”ech mlĆ©kĆ”ren a vĆ½roben sĆ½rÅÆ. NabĆzĆme 2 nebo 4 možnosti dojenĆ. Ceny jsou uvedeny pro chladicĆ nĆ”drž na mlĆ©ko se 4 dojenĆmi.

- MateriƔl: Nerez

- Princip provozu: DĆ”vkovĆ½ režim

Cena je stanovena pro zĆ”kladnĆ verzi instalace bez dodateÄnĆ©ho vybavenĆ vakuovĆ©ho homogenizĆ”toru.

HomogenizĆ”tor je urÄen pro Å”irokou Å”kĆ”lu aplikacĆ ā od vĆ½roby majonĆ©z, keÄupÅÆ, omĆ”Äek, cukrĆ”ÅskĆ½ch past a nĆ”plnĆ až po kosmetickĆ© produkty, jako jsou krĆ©my, gely Äi Å”ampony.

- VakuovĆ½ provoz umožÅuje zpracovĆ”nĆ pÅi nižŔĆch teplotĆ”ch, ÄĆmž se zachovĆ”vajĆ citlivĆ© složky a snižuje riziko kontaminace.

- Ultra Shear spodnĆ homogenizĆ”tor zajiŔńuje intenzivnĆ cirkulaci produktu a efektivnĆ homogenizaci s velikostĆ ÄĆ”stic do 5ā10 mikronÅÆ.

- MĆchacĆ zaÅĆzenĆ s pohyblivĆ½mi stÄrkami zajiŔńuje rovnomÄrnĆ© promĆchĆ”nĆ produktu bez mrtvĆ½ch zĆ³n.

- VĆ½klopnĆ” verze usnadÅuje vyklĆ”dĆ”nĆ a ÄiÅ”tÄnĆ zaÅĆzenĆ.

- MateriƔl: Nerez

- Princip provozu: DĆ”vkovĆ½ režim

- ZemÄ pÅÆvodu: Slovensko

- Objem: 20l/ 50l

- CelkovĆ½ vĆ½kon, kW: 2,3/ 2,4

- NapÄtĆ: 220-230V

- MaximĆ”lnĆ vakuum: -0,8 Bar

VakuovĆ” chladniÄka chleba je vhodnĆ” pro použitĆ v malĆ½ch pekĆ”rnĆ”ch nebo jako laboratornĆ jednotka v prÅÆmyslovĆ½ch podnicĆch. UmožÅuje dopeÄenĆ chleba ve vakuu, což ovlivÅuje jeho tvar i strukturu.

- VestavÄnĆ½ systĆ©m hloubkovĆ©ho vysĆ”vĆ”nĆ

- VestavÄnĆ½ systĆ©m odvodu par a kondenzace

- VestavÄnĆ½ chladicĆ systĆ©m

- Komora je urÄena pro 3 gastronĆ”doby velikosti GN 1/1 nebo palety: 400x600/530x325 mm

- KompaktnĆ a mobilnĆ instalace

- MateriƔl: Nerez

- Princip provozu: DĆ”vkovĆ½ režim

- ZemÄ pÅÆvodu: Slovensko

- Objem: 130l

- NapÄtĆ: 380-400V

ChladiÄe NWT PLUS majĆ kompaktnĆ design. Zaberou mĆ”lo mĆsta a dajĆ se velmi snadno nainstalovat a spustit. ChladicĆ zaÅĆzenĆ jsou mobilnĆ na koleÄkĆ”ch. Jsou k dispozici ve tÅech velikostech a vĆ½konech od 6,4 ā 12,7 kW.

- IntegrovanĆ” funkce chlazenĆ i ohÅevu Å”etÅĆ mĆsto a zjednoduÅ”uje procesy.

- DĆky odnĆmatelnĆ½m boÄnĆm panelÅÆm je pÅĆstup k vnitÅnĆm komponentÅÆm rychlĆ½ a bezproblĆ©movĆ½.

- ZaÅĆzenĆ je na koleÄkĆ”ch a nezabere mnoho mĆsta, což je ideĆ”lnĆ pro menÅ”Ć provozy.

- EfektivnĆ technologie zajiŔńuje spolehlivĆ½ vĆ½kon s ohledem na energetickou Ćŗspornost.

- OhÅev: integrated

- NapÄtĆ: 380-400V

VakuovĆ” difuznĆ chladicĆ jednotka je multifunkÄnĆ zaÅĆzenĆ nejen pro veganskĆ© procesory.

- MateriƔl: Nerez

- Princip provozu: DĆ”vkovĆ½ režim

- ZemÄ pÅÆvodu: Slovensko