APPLICATIONS

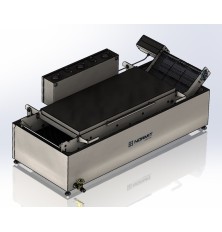

AutomatickГҪ stroj na tvarovГЎnГӯ a smaЕҫenГӯ koblih je vysoce kvalitnГӯ zaЕҷГӯzenГӯ, kterГ© je vhodnГ© pro vysokou produktivitu a kaЕҫdodennГӯ pouЕҫitГӯ.

- StolnГӯ systГ©m

- Obsahuje nГЎstavec pro uklГЎdГЎnГӯ

- KompaktnГӯ design

- KompletnДӣ z nerezovГ© oceli

- Material: Stainless steel

- Principle of operation: Continuous mode

- Total power, kW: 3

- Voltage: 220-230V

Cena je uvedena bez gastronГЎdob

Tuto celonerezovou vodnГӯ lГЎzeЕҲ pouЕҫГӯvejte k postupnГ©mu ohЕҷГӯvГЎnГӯ nebo vaЕҷenГӯ. ZaЕҷГӯzenГӯ je vybaveno praktickГҪm vypouЕЎtДӣcГӯm kohoutem pro snadnГ© vyprГЎzdnДӣnГӯ nГЎdoby a je vhodnГ© pro pouЕҫitГӯ s gastronГЎdobami.

- KompaktnГӯ instalace

- JednoduchГ© ovlГЎdГЎnГӯ

- BezpeДҚnГҪ provoz

- Е irokГЎ ЕЎkГЎla aplikacГӯ

- Material: Stainless steel

- Principle of operation: Batch mode

- Voltage: 220-230V

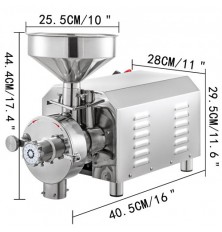

MlГҪnek na obilГӯ vyrobenГҪ z nerezovГ© oceli je robustnГӯ a odolnГҪ mlГҪnek se zvГҪЕЎenou odolnostГӯ proti opotЕҷebenГӯ.

Pro vГӯce informacГӯ kontaktujte naЕЎe obchodnГӯ oddДӣlenГӯ na adrese sales@foodtechprocess.com

Tento stroj na vГҪrobu prГЎЕЎku je vyroben z nerezovГ© oceli. VЕЎechny ДҚГЎsti, kterГ© pЕҷichГЎzejГӯ do styku s potravinami, jsou ze zdravotnГӯch a bezpeДҚnostnГӯch dЕҜvodЕҜ vyrobeny z potravinГЎЕҷskГ© nerezovГ© oceli 304.

DalЕЎГӯ informace zГӯskГЎte na adrese sales@foodtechprocess.com

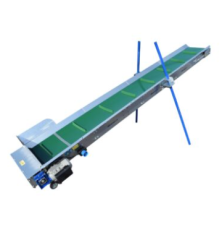

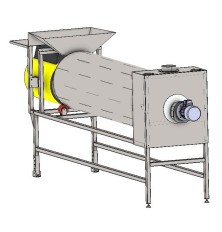

DopravnГӯk je vyroben z pevnГ© a vysoce odolnГ© nerezovГ© oceli. Pro spolehlivost pЕҷi provozu je navГӯc zesГӯlen.

Pro dalЕЎГӯ informace nГЎs prosГӯm kontaktujte na adrese sales@foodtechprocess.com

Tento kutr o objemu 9 l je robustnГӯ a spolehlivГ© zaЕҷГӯzenГӯ, kterГ© se pouЕҫГӯvГЎ ke zpracovГЎnГӯ rЕҜznГҪch potravin.

Е krabka na koЕҷeny zeleniny MPP 8 je prЕҜmyslovГҪ loupaДҚ s tДӣlem z nerezovГ© oceli.

UrДҚeno k ДҚerpГЎnГӯ horkГ©ho termickГ©ho oleje ve fritovacГӯch cirkulaДҚnГӯch a filtraДҚnГӯch systГ©mech, k naklГЎdГЎnГӯ a vyklГЎdГЎnГӯ oleje, v "horkГҪch" systГ©mech kontinuГЎlnГӯ filtrace oleje s maximГЎlnГӯ teplotou aЕҫ 200 stupЕҲЕҜ.

DalЕЎГӯ informace: sales@foodtechprocess.com

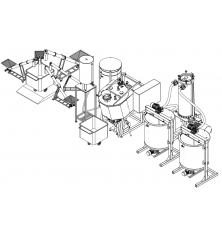

NabГӯzГӯme zaЕҷГӯzenГӯ pro procesy, jako je rozpouЕЎtДӣnГӯ medu, suЕЎenГӯ medu, homogenizace medu, pasterizace medu, krГ©movГЎnГӯ medu a balenГӯ medu. PotЕҷebnГ© zaЕҷГӯzenГӯ si zГЎkaznГӯk vybГӯrГЎ na zГЎkladДӣ poЕҫadovanГ© technologie zpracovГЎnГӯ pro svЕҜj vГҪrobnГӯ proces.

DalЕЎГӯ informace: sales@foodtechprocess.com

Tuto sadu zaЕҷГӯzenГӯ lze pouЕҫГӯt k vГҪrobДӣ nejrЕҜznДӣjЕЎГӯch omГЎДҚek a takГ© rЕҜznГҪch vegetariГЎnskГҪch vГҪrobkЕҜ na bГЎzi oЕҷechЕҜ, sГіji a rГҪЕҫe. Je schopna zpracovat pЕҷibliЕҫnДӣ 300/600 litrЕҜ vГҪrobku na dГЎvku.

Pro dalЕЎГӯ informace nГЎs kontaktujte na adrese sales@foodtechprocess.com

Filtr urДҚenГҪ pro prЕҜbДӣЕҫnou jemnou filtraci dopravnГӯkovГҪch fritГ©z na rostlinnГҪ olej a jinГ© fritovacГӯ tuky.

DalЕЎГӯ informace: sales@foodtechprocess.com

Pro smaЕҫenГӯ potravin v oleji, fritovГЎnГӯ, vhodnГ© pro smaЕҫenГӯ cibule, semГӯnek, oЕҷechЕҜ, zeleninovГҪch snackЕҜ a chipsЕҜ a dalЕЎГӯch vГҪrobkЕҜ, vДҚetnДӣ obalovanГҪch nebo obalovanГҪch v liaisonu. Lze pouЕҫГӯt takГ© jako odstЕҷedivku na oddДӣlovГЎnГӯ oleje pro fritГ©zu.

- Dva v jednom: fritГ©za a odstЕҷedivka na odstranДӣnГӯ pЕҷebyteДҚnГ©ho oleje.

- MoЕҫnost smaЕҫenГӯ malГҪch a kЕҷehkГҪch vГҪrobkЕҜ

- ZГӯskГЎnГӯ "suchГ©ho vГҪrobku" po smaЕҫenГӯ

- NГӯzkГЎ karbonizace oleje dГӯky funkci ДҚiЕЎtДӣnГӯ po smaЕҫenГӯ

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 30l/ 90l

- Total power, kW: 11

- Voltage: 380-400V

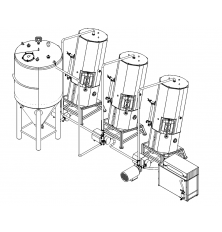

Komplex zaЕҷГӯzenГӯ urДҚenГҪ ke zpracovГЎnГӯ syrovГҪch, loupanГҪch a blanЕЎГӯrovanГҪch araЕЎГӯdЕҜ s vГҪrobnГӯ kapacitou aЕҫ 500 kg/hod.

Tento komplex zaЕҷГӯzenГӯ umoЕҫЕҲuje vГҪrobu ДҚokolГЎdovГҪch past typu Nutella s kapacitou aЕҫ 250 kg/h.

Pro dalЕЎГӯ informace nГЎs prosГӯm kontaktujte na adrese sales@foodtechprocess.com

KompletnГӯ sada zaЕҷГӯzenГӯ pro zpracovГЎnГӯ loupanГҪch fazolГӯ a vГҪrobu sГіjovГ©ho zГЎkladu o kapacitДӣ 800-1000 litrЕҜ za hodinu.

DalЕЎГӯ informace zГӯskГЎte na adrese sales@foodtechprocess.com

Tato sada zaЕҷГӯzenГӯ pro vГҪrobu kondenzovanГ©ho mlГ©ka ze suchГҪch sloЕҫek obnovenГӯm mlГ©ka. Tuto vГҪrobnГӯ linku lze vyrobit s kapacitou aЕҫ 500 kg/h nebo ji lze pЕҷizpЕҜsobit na zГЎkladДӣ specifickГҪch poЕҫadavkЕҜ.

Pro vГӯce informacГӯ a podrobnГ© dotazy nГЎs prosГӯm kontaktujte na adrese sales@foodtechprocess.com

UrДҚeno pro vakuovГ© suЕЎenГӯ vГҪrobkЕҜ citlivГҪch na vysokГ© teploty za studena, vhodnГ© takГ© pro tekutГ© a viskГіznГӯ vГҪrobky.

Pro vГӯce informacГӯ nГЎs kontaktujte na: sales@foodtechprocess.com

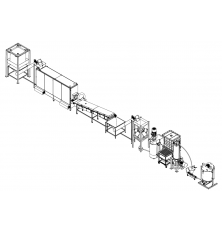

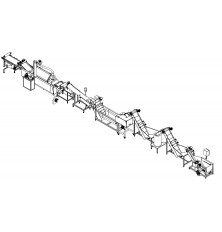

Soubor jednotlivГҪch zaЕҷГӯzenГӯ pro vГҪrobu hranolkЕҜ se mЕҜЕҫe liЕЎit v zГЎvislosti na vГҪchozГӯch surovinГЎch. NabГӯzГӯme rЕҜznГ© modifikace od mytГӯ po smaЕҫenГӯ s nГЎslednГҪm odvlhДҚovГЎnГӯm od 50 kg/h pro finГЎlnГӯ vГҪrobek.

DalЕЎГӯ informace zГӯskГЎte na adrese: sales@foodtechprocess.com

Tato linka na vГҪrobu dЕҫemЕҜ vГЎm umoЕҫnГӯ zГӯskat hotovГҪ dЕҫem na vГҪstupu z celГ©ho ovoce na vstupu! MoЕҫnosti vybavenГӯ se mohou liЕЎit v zГЎvislosti na technologii zГЎkaznГӯka.

Pro dalЕЎГӯ informace nГЎs prosГӯm kontaktujte na adrese sales@foodtechprocess.com

ZaЕҷГӯzenГӯ na vГҪrobu kondenzovanГ©ho mlГ©ka z pЕҷedpaЕҷenГ©ho mlГ©ka. Toto zaЕҷГӯzenГӯ lze vyrobit s kapacitou 50 aЕҫ 500 kg/hod. nebo na pЕҷГЎnГӯ. VyrГЎbГӯme takГ© linky na kondenzovanГ© mlГ©ko podle TU ze suЕЎenГ©ho mlГ©ka nebo normovanГ© linie koncentrace mlГ©ka.

Cena je uvedena bez zdroje stlaДҚenГ©ho vzduchu - kompresoru (volitelnДӣ).

JednГЎ se o periodickГ© zaЕҷГӯzenГӯ urДҚenГ© k odstraЕҲovГЎnГӯ vlhkosti a pЕҷebyteДҚnГ© vody z medu ve vakuu. Tuto pilotnГӯ vakuovou suЕЎiДҚku lze pouЕҫГӯt pro zpracovГЎnГӯ malГҪch objemЕҜ medu pЕҷГӯmo na vДҚelnicГӯch.

- Rychlost suЕЎenГӯ aЕҫ 1 % za hodinu! (s postupnГҪm sniЕҫovГЎnГӯm koncentrace)

- VelkГЎ plocha pro pЕҷenos tepla

- NГӯzkГЎ teplota suЕЎenГӯ dГӯky vakuu

- SnadnГЎ obsluha a ГәdrЕҫba

- ExternГӯ okruh nucenГ©ho obДӣhu pro intenzivnГӯ odpaЕҷovГЎnГӯ

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100 - 140 kg

- Total power, kW: 6,5

- Voltage: 220-230V 380-400V

- Max vacuum: -0,8 Bar

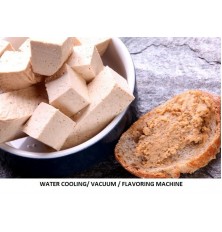

VakuovГЎ chladniДҚka chleba je vhodnГЎ pro pouЕҫitГӯ v malГҪch pekГЎrnГЎch nebo jako laboratornГӯ jednotka v prЕҜmyslovГҪch podnicГӯch. UmoЕҫЕҲuje dopeДҚenГӯ chleba ve vakuu, coЕҫ ovlivЕҲuje jeho tvar i strukturu.

- VestavДӣnГҪ systГ©m hloubkovГ©ho vysГЎvГЎnГӯ

- VestavДӣnГҪ systГ©m odvodu par a kondenzace

- VestavДӣnГҪ chladicГӯ systГ©m

- Komora je urДҚena pro 3 gastronГЎdoby velikosti GN 1/1 nebo palety: 400x600/530x325 mm

- KompaktnГӯ a mobilnГӯ instalace

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 130l

- Voltage: 380-400V

SuЕЎiДҚka zeleniny byla navrЕҫena pro rychlГ© a ГәДҚinnГ© suЕЎenГӯ listovГ© zeleniny, syrovГ© i vaЕҷenГ©, pЕҷipravovanГ© ve stЕҷednДӣ velkГҪch profesionГЎlnГӯch kuchynГӯch a v potravinГЎЕҷskГ©m prЕҜmyslu.

DalЕЎГӯ informace: sales@foodtechprocess.com

Sada 4 vГҪЕЎkovДӣ nastavitelnГҪch nohou +/- 100 mm.

Pro vГӯce informacГӯ kontaktujte: sales@foodtechprocess.com

NosnГЎ konstrukce na kolech s aretacГӯ (brzdou), 2 otoДҚnГЎ kola, 2 otoДҚnГЎ kola s brzdou.

Pro vГӯce informacГӯ kontaktujte: sales@foodtechprocess.com

Cena je stanovena pro zГЎkladnГӯ verzi bez dalЕЎГӯch moЕҫnostГӯ.

PrЕҜmyslovГЎ infraДҚervenГЎ suЕЎiДҚka je vhodnГЎ pro suЕЎenГӯ ЕЎirokГ© ЕЎkГЎly produktЕҜ: oЕҷechЕҜ, jablek, ЕЎvestek, jahod, malin, borЕҜvek, hub, mrkve, cibule, ДҚesneku, bylinek, masa, fГӯkЕҜ, banГЎnЕҜ, marshmallows. Pokud zvolГӯte dalЕЎГӯ moЕҫnosti, lze suЕЎiДҚku pouЕҫГӯt takГ© k suЕЎenГӯ a konzervaci celГ©ho masa a ryb.

- KompaktnГӯ instalace

- RychlГ© a ГәДҚinnГ© suЕЎenГӯ

- MoЕҫnost volby individuГЎlnГӯho nastavenГӯ suЕЎenГӯ

- Vyrobeno vГҪhradnДӣ z nerezovГ© oceli

- VnitЕҷnГӯ povrch skЕҷГӯnДӣ je opatЕҷen zrcadlovou vrstvou.

- TichГҪ provoz zaЕҷГӯzenГӯ

- NГӯzkГЎ spotЕҷeba energie na suЕЎicГӯ cyklus

- Heating: Electricity

- Material: Stainless steel

- Operation mode: Mixed

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 7l/ 10l/ 14l

- Total power, kW: 10/ 15/ 20

- Area, m2: 3,5/ 5,2/ 6,9

- Number of shelves: 10/ 15/ 20

Cena je uvedena pro verzi s hydraulickГҪm zvedГЎkem.

PrЕҜmyslovГЎ elektrickГЎ pГЎnev na termГЎlnГӯ olej je optimГЎlnГӯm a ekonomickГҪm ЕҷeЕЎenГӯm pro malou prЕҜmyslovou vГҪrobu potravin. UmoЕҫЕҲuje nГӯzkГ© energetickГ© a provoznГӯ nГЎklady a zГЎroveЕҲ zajiЕЎЕҘuje rovnomДӣrnГҪ a intenzivnГӯ ohЕҷev celГ© pracovnГӯ mГӯsy. TepelnГЎ setrvaДҚnost systГ©mu pomГЎhГЎ udrЕҫet poЕҫadovanou teplotu po delЕЎГӯ dobu, takЕҫe je efektivnГӯ pro smaЕҫenГӯ cibule, mrkve, osmahnutГӯ mouky a zeleniny a pЕҷГӯpravu omГЎДҚek, polГ©vek, pЕҷГӯloh, duЕЎenГҪch pokrmЕҜ a dalЕЎГӯch.

- NГӯzkГЎ spotЕҷeba energie

- RovnomДӣrnГ© vytГЎpДӣnГӯ

- VyhЕҷГӯvanГ© kuЕҫelovГ© strany

- NastavitelnГЎ intenzita ohЕҷevu

- OvladaДҚ s hygienickГҪm krytem pЕҷГӯmo na nosnГ© konstrukci

- Гҡchyty pro otevГӯrГЎnГӯ vГӯka umГӯstДӣnГ© v chladicГӯ zГіnДӣ

- AutomatickГҪ systГ©m zvedГЎnГӯ/naklГЎpДӣnГӯ

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 26

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

- Total power, kW: 28

- Voltage: 380-400V

- Duplicator volume: 106l

VariabilnГӯ pГЎsovГҪ dopravnГӯk s ЕЎirokГҪm vyuЕҫitГӯm nejen v potravinГЎЕҷskГ©m prЕҜmyslu. DГ©lku dopravnГӯku lze zvolit. od 2 do 6 m. Е ГӯЕҷka pГЎsu je 200 a 400 mm.

DalЕЎГӯ informace o zaЕҷГӯzenГӯ zГӯskГЎte na adrese naЕЎeho obchodnГӯho oddДӣlenГӯ. sales@foodtechprocess.com

Cena je stanovena pro zГЎkladnГӯ verzi reaktoru bez dalЕЎГӯch moЕҫnostГӯ a ovlГЎdacГӯho panelu.

VakuovГЎ konvice s duplikГЎtorem chladicГӯ kapaliny a mГӯchacГӯm zaЕҷГӯzenГӯm je univerzГЎlnГӯm ЕҷeЕЎenГӯm pro zpracovГЎnГӯ rЕҜznГҪch produktЕҜ pЕҷi subatmosfГ©rickГ©m tlaku. Na zГЎkladДӣ tohoto jednoduchГ©ho zaЕҷГӯzenГӯ lze zvolit a modulovat do komplexnГӯch zaЕҷГӯzenГӯ, jako je napЕҷ. vakuovГЎ vГҪparnГӯk, vakuovГЎ konvicea zaЕҷГӯzenГӯ na vГҪrobu smetanovГ©ho medu.

- Е ikmГЎ konstrukce - gravitaДҚnГӯ mГӯsenГӯ

- SpodnГӯ ventil DN40 v zГЎkladnГӯ verzi

- DuplikГЎtor s malГҪm objemem - nГӯzkГ© nГЎklady na ohЕҷev/chlazenГӯ chladicГӯ kapaliny

- ModulГЎrnГӯ systГ©m: pЕҷizpЕҜsobenГӯ zaЕҷГӯzenГӯ a jeho funkcГӯ objednГЎnГӯm dalЕЎГӯch moЕҫnostГӯ.

- Snadno rozebГӯratelnГ© mГӯchacГӯ zaЕҷГӯzenГӯ

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

- Duplicator volume: 3l

JednostupЕҲovГ© vГҪvДӣvy jsou vЕЎestrannГ© a dГӯky svГ© jednoduchosti, spolehlivosti a robustnosti nabГӯzejГӯ ЕЎirokou ЕЎkГЎlu aplikacГӯ pЕҷi pЕҷepravДӣ kapalin. ZaЕҷГӯzenГӯ pracuje s minimГЎlnГӯmi vibracemi a jeho hluДҚnost nepЕҷekraДҚuje pЕҷedepsanГ© normy. NavГӯc zajiЕЎЕҘuje bezolejovГҪ provoz.

Pro vГӯce informacГӯ a cenovou nabГӯdku kontaktujte obchodnГӯ oddДӣlenГӯ na adrese sales@foodtechprocess.com

PЕҷenosnГ© vertikГЎlnГӯ ДҚerpadlo je urДҚeno k ДҚerpГЎnГӯ tekutГҪch nebo viskГіznГӯch kapalin v rozsahu 1-2300 m2/s pЕҷi teplotДӣ kolem 25 В°C. ДҢerpadlo nelze pouЕҫГӯvat v prostЕҷedГӯ s nebezpeДҚГӯm vГҪbuchu.

Pro vГӯce informacГӯ nebo cenovou nabГӯdku kontaktujte naЕЎe obchodnГӯ oddДӣlenГӯ na adrese sales@foodtechprocess.com

OchrannГҪ dekorativnГӯ kryt pro koloidnГӯ mlГҪn 132 (volitelnДӣ)

Pro vГӯce informacГӯ nebo ЕҫГЎdost o dalЕЎГӯ podrobnosti kontaktujte: sales@foodtechprocess.com

Stojan (podpЕҜrnГЎ konstrukce) pro koloidnГӯ mlГҪn - doplЕҲkovГЎ moЕҫnost pro mlГҪn koloidnГӯ mlГҪn 132

DalЕЎГӯ informace zГӯskГЎte u: sales@foodtechprocess.com

Е krabky na brambory a koЕҷenovou zeleninu jsou vyrobeny v celonerezovГ©m pouzdЕҷe. ZaЕҷГӯzenГӯ je pЕҷГӯmo pЕҷipraveno k pouЕҫitГӯ (nenГӯ nutnГЎ instalace), dodГЎvГЎ se pro napГЎjenГӯ 3x400 V.

Pro vГӯce informacГӯ o zaЕҷГӯzenГӯ a cenovou nabГӯdku kontaktujte obchodnГӯ oddДӣlenГӯ spoleДҚnosti sales@foodtechprocess.com

FrekvenДҚnГӯ mДӣniДҚ se pouЕҫГӯvГЎ a instaluje pЕҷГӯmo na zaЕҷГӯzenГӯ bez nutnosti instalace elektrickГҪch rozvГЎdДӣДҚЕҜ.

Pro vГӯce informacГӯ nebo ЕҫГЎdost o dalЕЎГӯ podrobnosti kontaktujte: sales@foodtechprocess.com

Sada hГЎДҚkЕҜ na zavДӣЕЎenГӯ a suЕЎenГӯ masa a ryb. DoplЕҲkovГ© pЕҷГӯsluЕЎenstvГӯ pro suЕЎiДҚku MAK DRYER 7-14.

DalЕЎГӯ informace zГӯskГЎte u: sales@foodtechprocess.com

TepelnГЎ izolace tДӣlesa suЕЎicГӯ komory pro snГӯЕҫenГӯ tepelnГҪch ztrГЎt bДӣhem suЕЎenГӯ vГҪrobkЕҜ. DalЕЎГӯ moЕҫnost pro SUЕ IДҢKA MAK 7-14.

Pro vГӯce informacГӯ kontaktujte: sales@foodtechprocess.com

Cena je uvedena bez frekvenДҚnГӯho mДӣniДҚe

DvouЕЎnekovГ© mГӯchadlo pro rychlГ© a intenzivnГӯ mГӯchГЎnГӯ, mГӯchГЎnГӯ sypkГҪch produktЕҜ, jako jsou granule, mГјsli s rЕҜznГҪmi prГЎЕЎkovГҪmi pЕҷГӯsadami.

- MГӯchacГӯ noЕҫe se pЕҷi dЕҜkladnГ©m promГӯchГЎnГӯ vГҪrobku opatrnДӣ pohybujГӯ.

- ReЕҫim mГӯchГЎnГӯ umoЕҫЕҲuje cyklickГҪ pohyb vГҪrobku v kruhu.

- VysokГЎ ГәДҚinnost mГӯchГЎnГӯ dГӯky protibДӣЕҫnГ©mu pohybu 2 hЕҷГӯdelЕҜ.

- KompaktnГӯ design

- MoЕҫnost instalace ЕЎkrabek na kaЕҫdГҪ nЕҜЕҫ (volitelnДӣ)

- ZesГӯlenГҪ pohon, lze pouЕҫГӯt i pro vГҪrobky nasycenГ© vlhkostГӯ.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 500l

- Total power, kW: 3

GenerГЎtor je namontovГЎn na podpДӣЕҷe z nerezovГ© oceli, pokrytГ© nerezovou ocelГӯ AISI 304, ЕҷГЎdnДӣ tvarovanou s jiЕҫ provedenГҪmi elektrickГҪmi a vodovodnГӯmi pЕҷГӯpojkami. Kohouty z nerezovГ© oceli AISI 316, tvarovky z kujnГ© litiny, ДҚerpadlo napГЎjecГӯ vody (mod. TP78A CALPEDA) s 1 zpДӣtnГҪm ventilem z nerezovГ© oceli, s tДӣsnДӣnГӯm VITON.

DalЕЎГӯ informace zГӯskГЎte na e-mailovГ© adrese sales@foodtechprocess.com

Cena je uvedena za zГЎkladnГӯ verzi instalace bez koulГӯ.

MlГҪnek je urДҚen k mechanickГ©mu mletГӯ surovin pro vГҪrobu ДҚokolГЎdy, oЕҷechovГҪch mГЎsel a zГӯskГЎnГӯ krГ©movГ©ho, homogennГӯho vГҪrobku o velikosti frakce aЕҫ 20 mikronЕҜ.

- KompaktnГӯ instalace na samonosnou konstrukci

- JednoduchГЎ a pohodlnГЎ ГәdrЕҫba

- Kryt z plexiskla pro vizuГЎlnГӯ kontrolu

- OdnГӯmatelnГ© mГӯchacГӯ zaЕҷГӯzenГӯ

- PlГЎЕЎЕҘ pro tepelnГҪ nosiДҚ

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 5l

- Total power, kW: 1,5

- Voltage: 380-400V

Cena je stanovena na zГЎkladДӣ zГЎkladnГӯ moЕҫnosti vestavДӣnГ©ho vytГЎpДӣnГӯ o vГҪkonu 24 kW.

VakuovГЎ fritГ©za je urДҚena ke smaЕҫenГӯ potravin v oleji pЕҷi nГӯzkГҪch teplotГЎch, coЕҫ umoЕҫЕҲuje vГҪrobu zdravГҪch pochutin, jako jsou zeleninovГ© a ovocnГ© chipsy. VakuovГЎ funkce umoЕҫЕҲuje snГӯЕҫit teplotu fritovГЎnГӯ v oleji aЕҫ na 110-120 stupЕҲЕҜ!

- "PraЕҫenГӯ za studena" je chutnГҪ a zdravГҪ zpЕҜsob zpracovГЎnГӯ produktu.

- SuЕЎenГӯ a smaЕҫenГӯ bez karamelizace cukrЕҜ obsaЕҫenГҪch v produktu

- VelkГЎ fritovacГӯ nГЎdoba - pro zpracovГЎnГӯ potravin s vyЕЎЕЎГӯm obsahem vody

- ModulГЎrnГӯ topnГҪ systГ©m, kterГҪ umoЕҫЕҲuje zvГҪЕЎit topnГҪ vГҪkon aЕҫ na 108 kW (volitelnДӣ).

- CirkulaДҚnГӯ ohЕҷev oleje pЕҷes vГҪmДӣnГӯk tepla minimalizuje jeho znehodnocenГӯ a zabraЕҲuje lokГЎlnГӯmu pЕҷehЕҷГЎtГӯ.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 24

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 30l

- Oil volume: 200l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

ElektrickГЎ topnГЎ kamna stoliДҚkovГ©ho typu o vГҪkonu 5 kw a prЕҜmДӣru 40 cm jsou urДҚena k ohЕҷevu velkГҪch hrncЕҜ a pГЎnvГӯ o objemu aЕҫ 100 litrЕҜ.

DalЕЎГӯ informace zГӯskГЎte na e-mailovГ© adrese sales@foodtechprocess.com

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

Sada se sklГЎdГЎ z 20 polic z nerezovГ© oceli AISI304. DalЕЎГӯ moЕҫnost pro suЕЎiДҚku MAK DRYER 7-14.

Cena je stanovena pro model s plochou 7 mВІ.

KompaktnГӯ kondenzaДҚnГӯ suЕЎiДҚka, suЕЎiДҚka pohГЎnДӣnГЎ tepelnГҪm ДҚerpadlem pro suЕЎenГӯ zeleniny, ovoce, bobulovin, hub, luЕЎtДӣnin a obilovin.

- Energeticky ГәspornГҪ model s nГӯzkou spotЕҷebou (spotЕҷeba do 0,9 kW/h)

- MoЕҫnost zvДӣtЕЎenГӯ suЕЎГӯcГӯ plochy u tohoto modelu aЕҫ na 14 mВІ (volitelnДӣ)

- IntenzivnГӯ suЕЎenГӯ, kaЕҫdГЎ sekce je vybavena tepelnГҪm ДҚerpadlem.

- AutomatickГ© ЕҷГӯzenГӯ suЕЎГӯcГӯho systГ©mu

- JemnГ© suЕЎenГӯ pЕҷi nГӯzkГҪch teplotГЎch

- ZachovГЎnГӯ vДӣtЕЎiny Еҫivin a pЕҷirozenГ© barvy vГҪrobkЕҜ

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 0,9

- Voltage: 220-230V

- Area, m2: 7

- Number of shelves: 22

Kotel GHE lze pouЕҫГӯt v ЕҷeznictvГӯ, uzenГЎЕҷstvГӯ, pЕҷi zavaЕҷovГЎnГӯ ovoce atd. PouЕҫГӯvГЎ se k vaЕҷenГӯ polГ©vek, omГЎДҚek, masa, tДӣstovin, mlГ©ДҚnГҪch jГӯdel bez rizika pЕҷipГЎlenГӯ, k duЕЎenГӯ ryb, zeleniny, hub, k ohЕҷevu mraЕҫenГҪch jГӯdel nebo polotovarЕҜ.

Pro vГӯce informacГӯ kontaktujte naЕЎe obchodnГӯ oddДӣlenГӯ na adrese sales@foodtechprocess.com

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24/ 30/ 36/ 42

- Principle of operation: Batch mode

- Volume: 85l/ 100l/ 150l/ 200l/ 300l/ 400l/ 500l

MlГҪnek na maso se pouЕҫГӯvГЎ ke zpracovГЎnГӯ hroznЕҜ. DodГЎvГЎ se v provedenГӯ z nerezovГ© oceli.

DalЕЎГӯ informace o zaЕҷГӯzenГӯ a moЕҫnostech zpracovГЎnГӯ zГӯskГЎte na adrese obchodnГӯho oddДӣlenГӯ naЕЎГӯ spoleДҚnosti. sales@foodtechprocess.com

MultifunkДҚnГӯ pГЎnve fungujГӯ jako zaЕҷГӯzenГӯ na smaЕҫenГӯ, vaЕҷenГӯ a mГӯchГЎnГӯ v jednom zaЕҷГӯzenГӯ.

DalЕЎГӯ informace o naЕЎГӯ automatickГ© pГЎnvi typu Wok s vestavДӣnГҪm mixГ©rem zГӯskГЎte na adrese naЕЎeho obchodnГӯho oddДӣlenГӯ. sales@foodtechprocess.com

Inline homogenizГЎtory Yumix Basic majГӯ nejniЕҫЕЎГӯ cenu v ЕҷadДӣ homogenizГЎtorЕҜ YUMIX a jejich modely se pohybujГӯ od 1,1 do 3 kW.

DalЕЎГӯ informace o zaЕҷГӯzenГӯ zГӯskГЎte od obchodnГӯho oddДӣlenГӯ spoleДҚnosti na adrese sales@foodtechprocess.com

KrГЎjeДҚ je urДҚen ke krГЎjenГӯ na kostky, prouЕҫky nebo plГЎtky.

Pro vГӯce informacГӯ kontaktujte naЕЎe obchodnГӯ oddДӣlenГӯ na adrese sales@foodtechprocess.com

ProgresivnГӯ dutinovГЎ ДҚerpadla se pouЕҫГӯvajГӯ k pЕҷeДҚerpГЎvГЎnГӯ produktЕҜ s nГӯzkou a vysokou viskozitou i produktЕҜ obsahujГӯcГӯch mДӣkkГ© ДҚГЎstice. Jsou k dispozici ve tЕҷech velikostech.

Pro vГӯce informacГӯ o ДҚerpadlech nebo pro cenovou nabГӯdku kontaktujte naЕЎe obchodnГӯ oddДӣlenГӯ na adrese sales@foodtechprocess.com

ДҢerpadlo s eliptickГҪm rotorem (k dispozici jsou tЕҷi vГҪkonovГ© Еҷady).

DalЕЎГӯ informace o ДҚerpadlech nebo nabГӯdku na konkrГ©tnГӯ model zГӯskГЎte na adrese naЕЎeho obchodnГӯho oddДӣlenГӯ. sales@foodtechprocess.com

PevnГЎ chladicГӯ jednotka s rЕҜznГҪmi vГҪkony od 67 kW do 226 kW. Jednotky jsou pevnГ© a zajiЕЎЕҘujГӯ dlouhodobГҪ zГЎkladnГӯ provoz.

DalЕЎГӯ informace o chladicГӯm zaЕҷГӯzenГӯ zГӯskГЎte na adrese naЕЎeho obchodnГӯho oddДӣlenГӯ. sales@foodtechprocess.com

PoloautomatickГЎ vГҪrobnГӯ linka na mytГӯ a vykosЕҘovГЎnГӯ jablek. PЕҷibliЕҫnГЎ kapacita 1000 kg/h.

Pro vГӯce informacГӯ nebo cenovou nabГӯdku kontaktujte naЕЎe obchodnГӯ oddДӣlenГӯ na adrese sales@foodtechprocess.com

VГҪbornГЎ pomoc v kuchyni, kterГЎ vГЎm umoЕҫnГӯ spojit vaЕЎe zkuЕЎenosti a kreativitu s poЕҫadavky na vynikajГӯcГӯ vГҪrobek. VaЕҷiДҚ karamelu je nabГӯzen ve dvou objemech, 50 a 100 litrЕҜ.

Pro vГӯce informacГӯ o produktu kontaktujte sales@foodtechprocess.com

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Volume: 50l/ 100l

VakuovГЎ difuznГӯ chladicГӯ jednotka je multifunkДҚnГӯ zaЕҷГӯzenГӯ nejen pro veganskГ© procesory.

Pro vГӯce informacГӯ kontaktujte naЕЎe obchodnГӯ oddДӣlenГӯ na adrese sales@foodtechprocess.com

JednГЎ se o cenovДӣ vГҪhodnГ© ЕҷeЕЎenГӯ, kterГ© splЕҲuje speciГЎlnГӯ poЕҫadavky na vaЕҷenГӯ v segmentu Horeca. Je vybaveno vestavДӣnГҪm mixГ©rem, kterГҪ sniЕҫuje nГЎroky na ruДҚnГӯ prГЎci a zabraЕҲuje pЕҷichycenГӯ vГҪrobku.

DalЕЎГӯ informace o pГЎnvi zГӯskГЎte na adrese naЕЎeho prodejnГӯho oddДӣlenГӯ. sales@foodtechprocess.com

AtmosfГ©rickГЎ jednotka pro ЕЎlehГЎnГӯ a krГ©movГЎnГӯ medu s novou konstrukcГӯ s gravitaДҚnГӯm mГӯchГЎnГӯm pЕҷedstavuje druhou generaci ГәspДӣЕЎnГ©ho modelu krГ©movacГӯ jednotky CH Light. GravitaДҚnГӯ mГӯchГЎnГӯ medu je o 40 % ГәДҚinnДӣjЕЎГӯ neЕҫ tradiДҚnГӯ metody, zejmГ©na pЕҷi vГҪrobДӣ smetanovГ©ho medu, kde hrajГӯ rozhodujГӯcГӯ roli zpЕҜsob mГӯchГЎnГӯ a cyklogram. Е ikmГЎ konstrukce napomГЎhГЎ rychlГ©mu vyprГЎzdnДӣnГӯ pracovnГӯ nГЎdrЕҫe s minimГЎlnГӯmi ztrГЎtami produktu.

- Е ikmГЎ konstrukce - o 40 % ГәДҚinnДӣjЕЎГӯ mГӯchГЎnГӯ

- VГҪkonnГҪ pohon mГӯchadla

- SklГЎdacГӯ rГЎmovГЎ mГӯchaДҚka s pohyblivГҪmi ЕЎkrabkami z fluoroplastu

- Senzor otevЕҷenГӯ vГӯka - zГЎruka vysokГ© bezpeДҚnosti obsluhy

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 400l/600 kg

- Total power, kW: 1,5

- Voltage: 380-400V

VytvГЎЕҷejte pЕҷГӯrodnГӯ tvary nugetЕҜ, kusy, kterГ© majГӯ vzhled "ruДҚnДӣ tvarovanГ©ho" vГҪrobku.

Pro vГӯce informacГӯ kontaktujte obchodnГӯ oddДӣlenГӯ spoleДҚnosti na adrese sales@foodtechprocess.com

VakuovГҪ odvzduЕЎЕҲovaДҚ se v potravinГЎЕҷskГ©m prЕҜmyslu hojnДӣ pouЕҫГӯvГЎ k odstraЕҲovГЎnГӯ plynЕҜ z vГҪrobkЕҜ, kterГ© si mohou po zpracovГЎnГӯ zachovat bublinky. KromДӣ toho se prЕҜtokovГҪ odvzduЕЎЕҲovaДҚ pouЕҫГӯvГЎ k minimalizaci pДӣnДӣnГӯ vГҪrobkЕҜ, coЕҫ zajiЕЎЕҘuje jejich hustЕЎГӯ strukturu, zejmГ©na pЕҷed balenГӯm. VakuovГ© deaerГЎtory hrajГӯ zГЎsadnГӯ roli pЕҷi odstraЕҲovГЎnГӯ specifickГҪch pachЕҜ z vГҪrobkЕҜ, napЕҷГӯklad pЕҷi vГҪrobДӣ ЕЎЕҘГЎv, pyrГ© a bylinnГҪch nГЎpojЕҜ. Tento proces vГҪznamnДӣ pЕҷispГӯvГЎ ke zvГҪЕЎenГӯ celkovГ© kvality a chuti koneДҚnГ©ho vГҪrobku.

- ZlepЕЎuje kvalitu, strukturu a tvar vГҪrobku

- ZabraЕҲuje oxidaci odstraЕҲovГЎnГӯm plynЕҜ.

- ZachovГЎvГЎ organoleptickГ© vlastnosti a prodluЕҫuje trvanlivost.

- VhodnГ© pro hustГ© a viskГіznГӯ produkty

- PrЕҜtokovГҪ princip umoЕҫЕҲuje instalaci tohoto zaЕҷГӯzenГӯ do stГЎvajГӯcГӯch vГҪrobnГӯch linek.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

VibraДҚnГӯ dopravnГӯky vhodnГ© k uspoЕҷГЎdГЎnГӯ produktu pЕҷed dalЕЎГӯm zpracovГЎnГӯm.

Pro vГӯce informacГӯ kontaktujte naЕЎe obchodnГӯ oddДӣlenГӯ na adrese sales@foodtechprocess.com

Е roubovГ© ДҚerpadlo se pouЕҫГӯvГЎ pro pЕҷeДҚerpГЎvГЎnГӯ "neДҚerpatelnГҪch" produktЕҜ. SkvДӣlГЎ volba pro ty, kteЕҷГӯ pracujГӯ s tДӣЕҫko pohyblivГҪmi kapalinami a potЕҷebujГӯ je co nejrychleji pЕҷemГӯstit.

Pro vГӯce informacГӯ o produktu kontaktujte prosГӯm obchodnГӯ oddДӣlenГӯ na adrese sales@foodtechprocess.com

MlГҪnek na oЕҷechy se pouЕҫГӯvГЎ ke zpracovГЎnГӯ sezamovГҪch semen na tahini nebo sezamovou pastu.

Pro vГӯce informacГӯ kontaktujte naЕЎe obchodnГӯ oddДӣlenГӯ na adrese sales@foodtechprocess.com

SnГӯЕҫenГӯ teploty a vlhkosti chrГЎnГӯ vГҪrobek i bez chemickГ©ho oЕЎetЕҷenГӯ. ZaЕҷГӯzenГӯ se takГ© pouЕҫГӯvГЎ k prЕҜbДӣЕҫnГ©mu chlazenГӯ vzduchem po tepelnГ©m zpracovГЎnГӯ.

Pro vГӯce informacГӯ o chladiДҚi kontaktujte naЕЎe prodejnГӯ oddДӣlenГӯ na adrese sales@foodtechprocess.com

Е krabka na brambory KPM-400 pro komerДҚnГӯ pouЕҫitГӯ: EfektivnГӯ zaЕҷГӯzenГӯ pro loupГЎnГӯ brambor a podobnГ© koЕҷenovГ© zeleniny, kterГ© poskytuje vysoce kvalitnГӯ vГҪsledky.

KartГЎДҚovГЎ myДҚka/ЕЎkrГЎbaДҚka je prЕҜmyslovГ© zaЕҷГӯzenГӯ pro mytГӯ a ЕЎkrГЎbГЎnГӯ koЕҷenovГ© zeleniny v zГЎvislosti na stupni zneДҚiЕЎtДӣnГӯ.

Pro vГӯce informacГӯ kontaktujte sales@foodtechprocess.com

ZaЕҷГӯzenГӯ je urДҚeno k plnДӣnГӯ sГЎДҚkЕҜ v krabicГӯch. VhodnГ© pro plnДӣnГӯ horkГҪch neviskГіznГӯch vГҪrobkЕҜ. ZaЕҷГӯzenГӯ lze zakoupit samostatnДӣ nebo s dalЕЎГӯmi moЕҫnostmi - vozГӯkem a zГЎsobnГӯkem.

Pro vГӯce informacГӯ nebo cenovou nabГӯdku kontaktujte sales@foodtechprocess.com

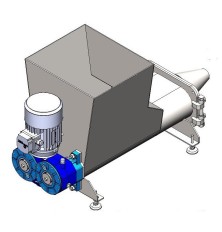

NastavitelnГ© dopravnГӯky vyrobenГ© z nerezovГ© oceli s velkou naklГЎdacГӯ nГЎsypkou o objemu 100 l vhodnГ© pro potravinГЎЕҷskГҪ prЕҜmysl.

Pro vГӯce informacГӯ o transportГ©ru kontaktujte naЕЎe prodejnГӯ oddДӣlenГӯ na adrese sales@foodtechprocess.com

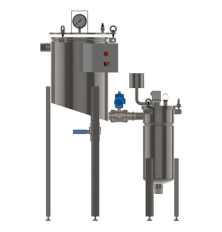

Stroj na zpracovГЎnГӯ medu s pЕҷedehЕҷГӯvГЎnГӯm a filtracГӯ, vhodnГҪ pro prЕҜmyslovГ© provozy na zpracovГЎnГӯ medu.

KrouhaДҚ zelГӯ CAF 65 je urДҚen pro velkГ© zpracovatelskГ© provozy s dennГӯ produkcГӯ pЕҷibliЕҫnДӣ 60 tun.

DalЕЎГӯ informace o zaЕҷГӯzenГӯ zГӯskГЎte na adrese naЕЎeho obchodnГӯho oddДӣlenГӯ. sales@foodtechprocess.com

NГЎkladovДӣ efektivnГӯ systГ©m pro plnДӣnГӯ sudЕҜ na zГЎkladДӣ vГЎhy pro plnДӣnГӯ vГҪrobku pomocГӯ ДҚerpadla.

Pro vГӯce informacГӯ kontaktujte naЕЎe obchodnГӯ oddДӣlenГӯ na adrese sales@foodtechprocess.com

MГЎselnice o objemu 50 l a uЕҫitnГ©m objemu 25 l pro tradiДҚnГӯ vГҪrobu mГЎsla ze smetany.

Pro vГӯce informacГӯ kontaktujte naЕЎe obchodnГӯ oddДӣlenГӯ na adrese sales@foodtechprocess.com

PrЕҜmyslovГ© ЕЎrotovnГӯky jsou k dispozici ve dvou vГҪkonnostnГӯch variantГЎch. JednoduchГЎ vГҪroba mГЎsla.

Pro vГӯce informacГӯ kontaktujte naЕЎe obchodnГӯ oddДӣlenГӯ na adrese sales@foodtechprocess.com

DigitГЎlnДӣ ЕҷГӯzenГҪ kontinuГЎlnГӯ dopravnГӯ systГ©m zajiЕЎЕҘuje smaЕҫenГӯ ЕЎirokГ© ЕЎkГЎly produktЕҜ na konstantnГӯ Гәrovni. DГӯky moЕҫnostem fritovГЎnГӯ je tento model vhodnГҪ pro ЕЎirokou ЕЎkГЎlu vГҪrobkЕҜ od jarnГӯch zГЎvitkЕҜ, cibulovГҪch bhajЕҜ a falafelЕҜ aЕҫ po rybГӯ prsty, hamburgery a kuЕҷecГӯ nugety. FritГ©za je k dispozici v ЕЎГӯЕҷkГЎch 200, 300, 400 a 600 mm.

Pro dalЕЎГӯ informace nГЎs prosГӯm kontaktujte na adrese sales@foodtechprocess.com

ZaЕҷГӯzenГӯ bylo primГЎrnДӣ navrЕҫeno pro zvГҪЕЎenГӯ pЕҷilnavosti (adheze) tДӣsta pomocГӯ tenkГ© vrstvy prachu - mouky. ZaЕҷГӯzenГӯ je k dispozici ve ДҚtyЕҷech ЕЎГӯЕҷkГЎch 200, 300, 400 a 600 mm.

DalЕЎГӯ informace o stroji na vГҪrobu chleba zГӯskГЎte na adrese naЕЎeho prodejnГӯho oddДӣlenГӯ. sales@foodtechprocess.com

DrobenГӯ chleba nebylo nikdy jednoduЕЎЕЎГӯ. Toto zaЕҷГӯzenГӯ je k dispozici v rЕҜznГҪch konfiguracГӯch ЕЎГӯЕҷky pГЎsu 200, 300, 400 a 600 mm.

Pro vГӯce informacГӯ kontaktujte naЕЎe obchodnГӯ oddДӣlenГӯ na adrese sales@foodtechprocess.com

Stroj je k dispozici ve ДҚtyЕҷech ЕЎГӯЕҷkГЎch pГЎsu 200, 300, 400 a 600 mm. Pro vГӯce informacГӯ nebo cenovou nabГӯdku kontaktujte naЕЎe obchodnГӯ oddДӣlenГӯ na adrese sales@foodtechprocess.com

JednoduchГЎ mobilnГӯ plniДҚka je ekonomicky vГҪhodnГҪm ЕҷeЕЎenГӯm pro plnДӣnГӯ sudЕҜ. NabГӯzГӯme takГ© vrchnГӯ plniДҚ sudЕҜ.

Pro vГӯce informacГӯ kontaktujte naЕЎe obchodnГӯ oddДӣlenГӯ na adrese sales@foodtechprocess.com

PasterizГЎtor nГЎpojЕҜ SB 750 se tГҪkГЎ komorovГҪch typЕҜ pasterizГЎtorЕҜ pouЕҫГӯvanГҪch k pasterizaci lahvovГҪch nГЎpojЕҜ.

PlniДҚka je zaЕҷГӯzenГӯ urДҚenГ© k dГЎvkovГЎnГӯ a ДҚerpГЎnГӯ medu. ZaruДҚuje pohodlnГ© a profesionГЎlnГӯ zpracovГЎnГӯ medu.

Pro vГӯce informacГӯ kontaktujte naЕЎe obchodnГӯ oddДӣlenГӯ na adrese sales@foodtechprocess.com

KompaktnГӯ a snadno pouЕҫitelnГҪ filtraДҚnГӯ systГ©m pro olej slouЕҫГӯ k ДҚiЕЎtДӣnГӯ oleje, coЕҫ umoЕҫЕҲuje prodlouЕҫit jeho pouЕҫitГӯ.

Tento chladiДҚ a ohЕҷГӯvaДҚ vzduchu je multifunkДҚnГӯ. Lze jej pouЕҫГӯt jako chladiДҚ vzduchu, ohЕҷГӯvaДҚ. KompaktnГӯ a lehkГҪ chladiДҚ vzduchu / ohЕҷГӯvaДҚ obsahuje. PЕҷemГӯsЕҘovГЎnГӯ pЕҷГӯstroje usnadЕҲujГӯ 4 koleДҚka.

Pro vГӯce informacГӯ o stroji kontaktujte prodejnГӯ oddДӣlenГӯ sales@foodtechprocess.com

CyklГіnovГҪ filtr ГәДҚinnДӣ oddДӣluje ДҚГЎstice a neДҚistoty z proudЕҜ vzduchu nebo plynu, ДҚГӯmЕҫ zajiЕЎЕҘuje kvalitu vГҪrobkЕҜ a udrЕҫuje ГәДҚinnost zaЕҷГӯzenГӯ, coЕҫ je dЕҜleЕҫitГ© zejmГ©na v potravinГЎЕҷskГ©m prЕҜmyslu.

Pro vГӯce informacГӯ o tomto produktu nebo pro cenovou nabГӯdku nГЎm napiЕЎte na adresu sales@foodtechprocess.com

PrЕҜtokovГҪ filtr fritovacГӯho oleje CFC nabГӯzГӯ moЕҫnost kombinovanГ©ho vyuЕҫitГӯ pevnГҪch lГЎtek a dalЕЎГӯ podporu filtrace.

Chcete-li zГӯskat cenovou nabГӯdku, kontaktujte nГЎs na adrese sales@foodtechprocess.com

SorpДҚnГӯ filtr 3000l je beztlakovГ© zaЕҷГӯzenГӯ s periodickou ДҚinnostГӯ pro filtraci kapalin pomocГӯ sypkГҪch filtraДҚnГӯch ДҚinidel a rЕҜznГҪch sorbentЕҜ.

Chcete-li zГӯskat cenovou nabГӯdku, kontaktujte nГЎs na adrese sales@foodtechprocess.com

VBF je rychlГЎ, robustnГӯ a vЕЎestrannГЎ vakuovГЎ plniДҚka lahvГӯ. Tento plnicГӯ stroj hledГЎte, pokud chcete zvГҪЕЎit objem vГҪroby svГҪch domГЎcГӯch produktЕҜ a profesionalizovat stГЎДҚenГӯ vГӯna, oleje, piva, ovocnГҪch ЕЎЕҘГЎv nebo jinГҪch produktЕҜ.

Chcete-li zГӯskat cenovou nabГӯdku, kontaktujte nГЎs na adrese sales@foodtechprocess.com

DГЎvkovacГӯ nГЎdrЕҫ na plnДӣnГӯ a mДӣЕҷenГӯ oleje navrЕҫenГЎ jako zГЎsobnГӯk oleje s moЕҫnostГӯ nastavenГӯ poЕҫadovanГ©ho objemu.

Chcete-li si vyЕҫГЎdat cenovou nabГӯdku, kontaktujte nГЎs na adrese sales@foodtechprocess.com

NavrЕҫeno pro pЕҷesnГ© podГЎvГЎnГӯ a balenГӯ kapalin pod tlakem.

Pro cenovou nabГӯdku nГЎm zaЕЎlete e-mail na adresu sales@foodtechprocess.com

PlnicГӯ a filtraДҚnГӯ stroj slouЕҫГӯ jako spolehlivГҪ zdroj pro zГЎsobovГЎnГӯ tekutГҪm produktem a zГЎroveЕҲ jej udrЕҫuje v tekutГ©m stavu.

Pro cenovou nabГӯdku nГЎm zaЕЎlete e-mail na adresu sales@foodtechprocess.com

VynikajГӯcГӯ blanЕЎГӯrovaДҚ a vaЕҷiДҚ pro efektivnГӯ zpracovГЎnГӯ zeleniny a dalЕЎГӯch potravin.

Pro cenovou nabГӯdku nebo dalЕЎГӯ informace nГЎm napiЕЎte na adresu sales@foodtechprocess.com

- Principle of operation: Continuous mode

KompaktnГӯ stolnГӯ lopatkovou fritГ©zu lze pouЕҫГӯt k vГҪrobДӣ rЕҜznГҪch druhЕҜ obДҚerstvenГӯ, vДҚetnДӣ zeleninovГҪch a ovocnГҪch hranolkЕҜ smaЕҫenГҪch v oleji. Je takГ© vhodnГЎ pro smaЕҫenГӯ extrudovanГҪch chipsЕҜ a snackЕҜ.

- InovativnГӯ design: kompaktnГӯ prЕҜbДӣЕҫnГЎ lopatkovГЎ fritГ©za pro profesionГЎlnГӯ kuchynДӣ

- IntenzivnГӯ tЕҷГӯzГіnovГ© vytГЎpДӣnГӯ pomocГӯ tepelnГҪch regulГЎtorЕҜ pro kaЕҫdГ© topnГ© tДӣleso

- SpeciГЎlnДӣ navrЕҫenГ© lopatky po celГ© dГ©lce fritГ©zy pro ponoЕҷenГӯ vГҪrobku do oleje.

- Dobu smaЕҫenГӯ lze nastavit od nДӣkolika sekund aЕҫ po hodinu.

- SystГ©m mГӯchГЎnГӯ produktu bДӣhem naklГЎdky pro separaci produktu

- TepelnГЎ izolace pracovnГӯho tДӣlesa pro snГӯЕҫenГӯ tepelnГҪch ztrГЎt a bezpeДҚnДӣjЕЎГӯ provoz.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Voltage: 380-400V

FritГ©za na koblihy je speciГЎlnДӣ navrЕҫena pro malГ© cukrГЎrny, prЕҜmyslovГ© podniky a stravovacГӯ zaЕҷГӯzenГӯ. Je schopna smaЕҫit rЕҜznГ© vГҪrobky podobnГ© koblihГЎm.

DalЕЎГӯ informace zГӯskГЎte na adrese sales@foodtechprocess.com

ZaЕҷГӯzenГӯ je urДҚeno k pasterizaci ЕЎirokГ© ЕЎkГЎly vГҪrobkЕҜ v rЕҜznГҪch typech obalovГҪch materiГЎlЕҜ, jako jsou plechovky a sklenice.

Pro vГӯce informacГӯ kontaktujte naЕЎe obchodnГӯ oddДӣlenГӯ na adrese sales@foodtechprocess.com

- Heating: Mixed

- Capacity: 300 l 400 l 500 l

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Single machine

Filtr na med - ГәДҚinnГ© ЕҷeЕЎenГӯ pro filtrovГЎnГӯ medu od rЕҜznГҪch vmДӣstkЕҜ a neДҚistot v prЕҜmyslovГ©m mДӣЕҷГӯtku.

Pro vГӯce informacГӯ kontaktujte naЕЎe obchodnГӯ oddДӣlenГӯ na adrese sales@foodtechprocess.com

PoloautomatickГЎ etiketovaДҚka pro aplikaci samolepicГӯch etiket na kulatГ© lahve.

Pro dalЕЎГӯ informace nebo cenovou nabГӯdku kontaktujte naЕЎe obchodnГӯ oddДӣlenГӯ na adrese sales@foodtechprocess.com

BlanЕЎГӯrovaДҚ SnackPro pЕҷipravГӯ rЕҜznГ© typy produktЕҜ, takЕҫe je skvДӣlГҪm ЕҷeЕЎenГӯm pro blanЕЎГӯrovГЎnГӯ velkГ©ho mnoЕҫstvГӯ ovoce a zeleniny v krГЎtkГ©m ДҚase.

Pro vГӯce informacГӯ a cenovou nabГӯdku nГЎm napiЕЎte na sales@foodtechprocess.com

PneumatickГҪ uzavГӯracГӯ stroj vhodnГҪ pro uzavГӯrГЎnГӯ twist off, snap on nebo plastovГҪch ЕЎroubovacГӯch uzГЎvДӣrЕҜ.

Pro vГӯce informacГӯ kontaktujte naЕЎe obchodnГӯ oddДӣlenГӯ na adrese sales@foodtechprocess.com

UniverzГЎlnГӯ vanovГҪ pasterizГЎtor se pouЕҫГӯvГЎ ke zpracovГЎnГӯ ЕЎirokГ© ЕЎkГЎly rЕҜznГҪch potravinГЎЕҷskГҪch vГҪrobkЕҜ, jako jsou hotovГЎ jГӯdla, uzeniny, ЕЎunky nebo tekutГ© vГҪrobky. ГҡДҚinnГЎ regulace teploty a hygienickГ© provedenГӯ z nerezovГ© oceli.

DalЕЎГӯ informace: sales@foodtechprocess.com

SpirГЎlovГҪ mixГ©r s pevnou mГӯsou a elektronickГҪm ovlГЎdacГӯm panelem. K dispozici v rЕҜznГҪch vГҪkonnostnГӯch variantГЎch.

Pro vГӯce informacГӯ kontaktujte naЕЎe obchodnГӯ oddДӣlenГӯ na adrese sales@foodtechprocess.com

PrЕҜmyslovГҪ planetovГҪ mixГ©r se pouЕҫГӯvГЎ pЕҷedevЕЎГӯm v cukrГЎЕҷskГ©m prЕҜmyslu. K dispozici ve tЕҷech rЕҜznГҪch velikostech: 120, 140 a 170 l.

Pro vГӯce informacГӯ kontaktujte naЕЎe obchodnГӯ oddДӣlenГӯ na adrese sales@foodtechprocess.com

Tento multifunkДҚnГӯ varnГҪ stroj se dvДӣma koЕЎi je navrЕҫen pro rЕҜznГ© zpЕҜsoby pouЕҫitГӯ a je vhodnГҪ pro nejrЕҜznДӣjЕЎГӯ podniky - pro vЕЎechny podniky nebo ГәДҚastnГӯky trhu HoReCa. PomocГӯ tohoto zaЕҷГӯzenГӯ mЕҜЕҫete vaЕҷit, pasterizovat nebo blanЕЎГӯrovat.

Pro cenovou nabГӯdku nГЎm zaЕЎlete e-mail na adresu sales@foodtechprocess.com