PRODUCTS

Explore our extensive selection of innovative food processing equipment tailored to meet the diverse demands of the industry. Our equipment spans various segments, improving productivity, enhancing production efficiency and ensuring high product quality. Invest in innovative solutions that advance your food processing operations.

The fat melter refers to periodic equipment designed for the preliminary melting and mixing of both crystallized honey and frozen blocks of fat or oil. This installation combines thermal and mechanical effects on the product and can also function as a feeding device for loading and feeding dense products for further processing.

- Highly Efficient Combined Processing of Products: Thermal and Mechanical Effects

- Universal heat carrier source (steam/water).

- No pump required; the mixing device functions as a screw pump.

- Large area for laying out the product blocks ‚Äď ensuring high productivity.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 400l/ 1000l

- Total power, kW: 1,1/ 2,2

- Voltage: 380-400V

The cost is specified for the basic modification without a heating system

Fat block melters are designed for melting frozen, solid blocks of animal or vegetable fat, as well as maintaining them in a molten state at a specified temperature. We produce models with the option to connect steam as a coolant to the melting grid, separate electric heating systems, or configurations with built-in electric heating for supply into the jacket and melting grid.

- Large area of the melting grid where the coolant circulates

- Special shape of the melting grid, cutting blocks during melting

- Greater versatility in terms of the coolant and its source

- Mirror surface of the melting grid, ensuring high hygiene

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 200l/ 300l/ 500l/ 1000l

A vacuum evaporator is a device used to evaporate liquids at lower temperatures by creating a vacuum environment, which reduces the boiling point of the liquid and enables efficient evaporation without thermal degradation of sensitive materials. Working volume up to, l: 1900 l.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: up to 1900 l

A rotating drum unit designed for continuous coating and seasoning operations as well as product saturation with spices and flavor additives, utilized in production lines for chips, snacks, and various semi-finished products.

- Adjustment of the Drum Tilt Angle

- Hygienic design and execution: mirror-polished inner surface of the drum

- Various blade options for gently turning the product (optional)

- Dispensers for dry and wet flavorings (optional)

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 0,25

- Voltage: 380-400V

A twin-screw mixer with a homogenizer is an ideal solution for the production of creamy cheese, such as feta cheese, including with various flavors and seasonings. Thanks to mechanical homogenization, the cheese acquires a delicate structure without changing the individual taste properties of the product. It is used for plasticizing, creaming and softening butter, margarine and other fats.

- Capacity of the receiving hopper 50L

- Compact tabletop design for convenient operator maintenance

- A powerful independent drive for each screw with a reverser

- Easy maintenance and cleaning of the equipment

- Productivity: 250 kg/h/ 1500 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 3,5

- Voltage: 380-400V

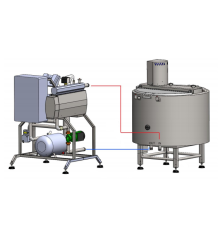

The inline homogenizer is designed for mixing, emulsifying, dispersing, and homogenizing thick and viscous products in the production of mayonnaise, soy milk, toothpaste, yogurt, and much more. It can be installed in an external circulation circuit of reactors, production lines, or used independently with a loading hopper for processing small volumes of products.

- Creates stable emulsions and suspensions

- Reduces particle size

- Quickly dissolves solids

- Accelerates chemical reactions

- Does not require an additional pump

- Material: Stainless steel

- Engine power, kW: 5,5/ 7,5/ 9/ 11/ 15

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

The price is indicated with a semi-automatic control panel

The vacuum cooking kettle is designed for use in public catering establishments (restaurants, hotels, catering companies) and small manufacturing businesses. This equipment enables boiling, blanching, frying, evaporation, pasteurization, mixing or stirring.

- A unique multifunctional device

- Possibility to cook/fry under atmospheric or vacuum conditions

- Laboratory version of a Vacuum Fryer

- Built-in condensation and secondary steam removal system

- Intense electric heating

- Sectional basket with a lid

- Built-in system for separating and removing excess liquid from the product

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Volume: 20l

- Oil volume: 8l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The cost is indicated without the control panel, which can be selected and offered separately

A versatile cooking system, featuring an inclined reactor, a duplicator for heating and a frame mixing device, it is designed for processing a diverse range of products through methods such as cooking, boiling, and concentrating at atmospheric pressure. This system is commonly used for the production of syrups, jams, confiture, and honey processing.

- Slanted design with gravity mixing - 25% more efficient!

- External decorative casing made out of polished stainless steel with insulation

- Jacket for the bottom and the walls of the working container along the entire height

- Lid opening sensor for safe operation

- Scrapers are already included in the basic version of the installation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 300l/ 430l/ 600l/ 1000l

- Voltage: 220-230V 380-400V

The colloid mill is used for continuous grinding of nuts, to obtain a finished nut paste of various viscosities with one pass through, without requiring additional processing or preparation!

- Simple and easy operation

- Three-point grinding adjustment

- Possibility of producing both creamy and crunch-type nut butters

- Compact design

- High performance

- Productivity: 180-240 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

Compact food filtration equipment with 12 filtering units. Unique filtration purifies products to very high standard- all materials used are perfectly compatible with liquids for human consumption.

- Engine power, kW: 0,34

- Principle of operation: Continuous mode

- Weight: 16

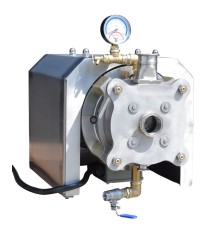

The pump provides a delicate straight-streaming pumping of a wide range of liquids with or without solid fragments with viscosity up to 150 Pa.s.

- Material: Stainless steel

- Engine power, kW: 1,1

- Principle of operation: Continuous mode

The conveyor for transferring empty as well as filled bottles and jars. Widely used within packaging lines for various liquids.

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Country of origin: EU

Electric continuous flow heaters in different designs and performance parameters.

- Heating: Electricity

- Material: Stainless steel

- Country of origin: Slovakia

- Type of pump: sealless pump

The drum washer is designed for washing potatoes and other roots as well as for seeds, nuts and grains.

- Material: Stainless steel

- Engine power, kW: 1,1

- Principle of operation: Continuous mode

- Country of origin: Slovakia

MP cooker is a reliable and extremely functional solution for cooking, pasteurizing in the same tank thus saving equipment cost, space. All material are most reliable in European market so guarantee a long and trouble free operation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

Strainer filter protect product or production machines from mechanical damage, keep undesirable particles away from your product to help to prevent production downtimes.

- Material: Stainless steel

- Country of origin: EU

Electric heating panel with three different power possibilities: 12, 24 and 48 KW ‚Äď excellent product manufactured by people who perfectly know the secret of product storage, maintenance and processing.

- Heating power, kW: 12/ 24/ 48

- Country of origin: EU

The cooling tank is designed for storing milk and other beverages.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

This compact nuts and seeds roaster is ideal for efficiently and evenly processing nuts and seeds to perfection.

- Productivity: 5-15 kg

- Material: Stainless steel

- Principle of operation: Batch mode

The plate heat exchanger is designed for cooling/heating and transfer liquid products such as milk, water, juices, syrups etc.

- Type of the equipment: Individual machine

- Country of origin: EU

Vertical shell and tube heat exchanger is designed to heat and cool such viscous/pasty products as sauces, mayonnaise, creams yogurts, jams, caramel, baby food, honey etc.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Shell-and-tube or tabular heat exchanger is designed to heat and cool viscous/pasty products such as sauces, mayonnaise, creams yogurts, jams, caramel, baby food, honey etc. Shell-and-tube heat exchangers are one of the most widely used units due to their robust design and a variety of options to suit different operating conditions.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The incline screw conveyor is used for transporting a wide range of bulk, powdery, fine-grained, and dusty products in food, chemical, construction, or agro-industries.

- Material: Stainless steel

- Engine power, kW: 0,75 1,1/ 1,5 / 2,2

The box tipper VK is designed for semi-automatic emptying of boxes/containers/crates with all kinds of root, tuber vegetables, and fruits.

- Principle of operation: Batch mode

The big bag discharge station is designed for the efficient handling of bulk products stored in big bags up to 1500 kg. The machine is a perfect solution for the food, chemical, pharmaceutical, and construction industries. This type of equipment is suitable for a wide range of bulk products from seeds, cocoa, beans up to construction materials such as dry gypsum, cement, etc.

The new line of TCAEY compact cooling units is suitable as a cooling source for industrial applications. It's a reliable chilling device for cooling different kinds of liquids.

- Principle of operation: Continuous mode

- Country of origin: EU

The AS series chillers belong to the top professional cooling devices for quick beverages' chilling in restaurants, cafes, catering industry facilities, and pubs. The chiller is suitable for cooling water, spark or soft drinks, beer, wine, strong alcohol drinks, and others.

- Principle of operation: Continuous mode

- Country of origin: EU

- Cooling performance l/h: 160 l/h / 200 l/h

The new line of NDJ refrigeration units is suitable as a cooling source for industrial applications operating with a closed coolant circuit. Efficient and reliable flow cooling of liquids

- Principle of operation: Continuous mode

- Country of origin: EU

A chiller is a cooling machine that removes heat from a liquid through vapor compression and absorption in a cyclic manner.

- Principle of operation: Continuous mode

- Cooling performance l/h: 100 / 200 l/ 300

The tilting cooker is produced in 2 versions: with gas or electric heating. The pan is designed for use in the food, hospital, catering industry and in large kitchens for making pasta, stewing and frying meat, fish, vegetables, mushrooms, frozen or semi-prepared, ready-to-cook meals, etc.

- Principle of operation: Batch mode

- Volume: 50l/ 80l/ 120l

- Voltage: 380-400V

The kettle is designed for cooking qualitative jam, marmalade, confiture from different fruits, vegetables and berries. It's an ideal and affordable solution for cooking various products.

- Material: Stainless steel

- Heating power, kW: 9/ 12/ 18/ 24

- Principle of operation: Batch mode

- Volume: 80l/ 120 l/ 200l/ 300l

Filling machine is designed for pumping and filling high viscosity liquids, such as jams, confiture, sauces, dressings, syrups, and like products.

- Productivity: 200‚Äď600 bottles per hour

- Material: Stainless steel

- Principle of operation: Continuous mode

The professional yogurt making machine is designed to produce a wide range of yogurt production, e.g. creamy, liquid drinking, greek, white, organic, fruit yogurts. The machine can be used by farms and small dairy factories.

- Material: Stainless steel

- Principle of operation: Batch mode

We sell many different types of cooking equipment, with a mixer or without, tilting, electric/steam/gas heating system, and many different modifications.

- Heating: Steam

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 250l/ 300l/ 350 l

The professional cooking vat is designed for dairy products processing. The machine can be used by farms and small dairy factories.

- Material: Stainless steel

- Heating power, kW: 24

- Volume: 150l/ 300l/ 500l

A versatile atmospheric kettle suitable for cooking various products, including jams, syrups, sauces, fruit and vegetable juices, and many others.

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 250l/ 300l

The bucket elevator is designed for transporting loose bulk materials, such as grain and seeds in a vertical position. It's an ideal solution for transporting various products for the baking industry as well as animal feed and other granular productions.

- Principle of operation: Continuous mode

Batter breading machines are designed for batter breading products such as meatball, hamburgers, soya, vegetarian burgers, croquettes, vegetables and other products. The machine is suitable for catering companies as well as big productions.

- Material: Stainless steel

- Country of origin: EU

- Working Area Width: 240 mm/ 350 mm

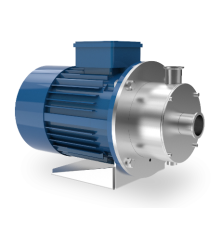

The homogenizer is designed to homogenize, mix and disintegrate / grind different fluids and components into small particles.

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

Multifunctional barrel dumper is designed for efficient and simple handling of plastic and steel barrels.

- Principle of operation: Batch mode

- Voltage: 220-230V

Bin tipper/dumper with pneumatic lift VBB is a device suitable for lifting and emptying big bags, plastic bags and boxes with food and other materials.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

Designed for cooking or blanching vegetables, fruits, legumes, pasta, seafood and other products in a continuous manner.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

We offer different types of washing equipment for various different fruits and vegetables.

- Productivity: 1500 kg/h

- Material: Stainless steel

- Engine power, kW: 3

- Weight: 200

- Productivity: 800 psc/h

- Material: Stainless steel

- Operation mode: Semi-automatic

The tempering machine ensures a shiny, smooth finish and stable structure for chocolate, significantly reducing the possibility of fat bloom. This equipment is essential in the production of various sweets, confections, chocolate-coated dragees, and other applications requiring chocolate coatings.

- 4-zone tempering system

- Automatic control system

- Temperature measurement in each zone at the inlet and outlet

- High productivity from 150-300 kg/hour

- Heating: Electricity

- Productivity: 150-300 kg/h

- Heating power, kW: 10-18

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

The container washer for canned food is a specialized washing system designed to thoroughly clean containers used for canning food products, ensuring hygiene and sanitation standards are met within your food processing facility.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The washer with external loading conveyor UNI M is specifically designed for the efficient and high-performance washing of vegetables, potatoes, and fruits, using gentle exposure to water to ensure thorough cleaning without harming the product.

- Material: Stainless steel

The CEP washing machine is a mobile cleaning station designed to efficiently clean various containers, including mixers and boilers, suitable for use in the food, chemical, and pharmaceutical industries.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 85

A rotary defroster is a device used to thaw or defrost frozen food products by rotating them gently in a heated chamber, allowing for even and efficient thawing without damaging the food's texture or integrity.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The screw conveyor with heating is a device designed for the transportation of material using a screw mechanism, while heat is applied to the product to facilitate easier transfer. This type of conveyor is often used to simplify the transfer of various bulk materials.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product and size of the conveyor.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: EU

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product and size of the conveyor.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

A universal conveyor with a PVC belt with horizontal sections, a volumetric storage, adjustable in height and angle of inclination, which can easily be adapted to existing installations for lifting the product to a certain height. The conveyor has its own independent drive, the speed of which can be adjusted using an inverter (optional).

- Lightweight: the supporting structure of the conveyor is made out of aluminum profiles

- Hopper made out of food grade stainless steel

- Bearing frame on wheeled supports with position locks

- High sidewalls made out of stainless steel

- White PVC tape for transporting products with temperatures of up to 80 degrees

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 500 mm

- Volume: 50l/

A vat or cooking kettle for milk is a large container or vessel used for heating and processing milk, typically in dairy production, to pasteurize, cook, or produce various dairy products such as cheese or yogurt.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 500l/ 1000l

The price depends on the required capacity.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 18

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 350 l

- Total power, kW: 1,5

We offer different types of dryers for different products.

- Material: Stainless steel

- Engine power, kW: 2,2

- Type of the equipment: Individual machine

- Country of origin: Slovakia

The tank is designed for heating and mixing chocolate, butter, margarine, honey and similar products.

- Material: Stainless steel

Shaker mixer SMU6 is designed for mixing the contents of packaged products that are in foil or other protective packaging. The device is used in the food, pharmaceutical, chemical, construction and cosmetic industries, where it is necessary to thoroughly mix the contents without damaging the packaging.

- No need to remove the product from the packaging - mixing takes place in the original packaging

- Hygienic and safe mixing without contamination

- Robust and durable construction made of stainless steel AISI 304

- Material: Stainless steel

- Country of origin: Slovakia

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. The price depends on the product as well as the size of the conveyor.

- Material: Stainless steel

- Engine power, kW: 0,25

- Working Area Width: 300 mm

- Voltage: 380-400V

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 220l/ 500 l

A vacuum cooker is used in the food processing industry to cook ingredients under reduced pressure, typically in a vacuum environment. This method allows for precise temperature control and faster cooking times while preserving the quality and flavor of the ingredients.

We offer different vacuum cookers.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 2500 l

An air cooling conveyor is used to rapidly cool products in food processing industries by circulating cool air over them as they move along a conveyor belt. This efficient cooling process helps preserve product quality and reduce the time between processing stages, facilitating smoother production workflows.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

A Vacuum cooker is a versatile device used in culinary settings to cook food under vacuum conditions, enhancing flavors and textures while also reducing cooking times.

We offer various different cookers.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 380-400V

Twin-screw extruder is designed for effective extruding, homogenization, pumping over of plastic masses (butter, margarine, honey, curd products, confectionery mixtures), and forming it into bars and rolls.

- Productivity: 400 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Weight: 115 kg

Grinding mill for continuous grinding of meat and ingredients such as seeds, small bones and cartilages that are unwanted in the final product.

- Engine power, kW: 3

- Principle of operation: Continuous mode

- Voltage: 380-400V

EcoFry is designed for frying onion rings, seafood, dumplings, spring rolls, pies, vegetables, nuggets and hamburgers with the help of pouring hot oil. A smaller capacity, efficient frying equipment intended for small to medium sized production facilities.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 36

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The series of Continuous Fryers Pour Oil is the boom in the market of frying and roasting equipment. The new construction designed by our engineers, based on existing practical experience in the production and use of conveyor fryers, provides the best example of environmental friendliness.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

The continuous pouring fryer is designed to fry meat, fish, vegetables and pasta products as well as chicken drumsticks, cutlets, nuggets, croutons, sliced zucchini or eggplant, and etc. using immersion frying and hot oil pouring methods.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

Intense fat melting machines MixMelters are designed for melting frozen, solid blocks of animal and vegetable fat such as butter and margarine as well as to maintain them in a melted state at a given temperature. Working volume up to, l: 200 l.

- Material: Stainless steel

- Heating power, kW: 12/ 24/ 48

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 200 l

It's compact cooking equipment for catering and gastronomic sphere: cafes, bars, canteens. The cooking equipment is designed for boiling, stewing, frying and mixing products of different viscosity.

Our continuous fryer is designed for frying cutlets, potatoes, meatballs, croquettes, fish, vegetables and many other products. Working volume up to l: 300 l.

- Material: Stainless steel

- Heating power, kW: 40

- Principle of operation: Continuous mode

- Oil volume: 300 l

- Voltage: 380-400V

A pouring fryer is a specialized equipment used in commercial kitchens for frying foods using a continuous pouring method which helps to close down the pores of the product to prevent excessive oil absorption. It offers precise control over the frying process by continuously pouring oil over the food, ensuring even cooking and consistent results.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

The industrial mixing and homogenizing equipment is well-suited for small and medium-sized production enterprises engaged in the processing of food, cosmetics, and various chemicals.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 300 l

The conical bottom mixer with a 400-liter capacity is designed for efficient mixing and smooth product discharge. Its conical shape directs contents toward the lower outlet, making it ideal for processing thicker or denser materials in an atmospheric-pressure environment.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 400l

- Voltage: 380-400V

This versatile 300 liter planetary mixer is a professional food processing equipment used for mixing, kneading, and blending ingredients in various culinary applications. It features a unique mixing action where the beater rotates on its axis while also revolving around the bowl, ensuring thorough and consistent mixing of ingredients.

Used in chemical, construction, cosmetic or food industries.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 85

- Volume: 50l

- Voltage: 380-400V

A cheese kettle is a specialized cooking vat used in cheese making processes to heat and curdle milk, allowing the separation of curds and whey. It provides controlled heating and agitation to facilitate the cheese production process. Working volume up to, l: 300 l.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 300 l

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

Running of various production processes such as cutting, mixing, crushing, refining and emulsifying different types of product in a single unit.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 359 kg

- Volume: 150l

Vacuum diffusion - the process in which the air inside the product is removed by vacuum and the released pores are filled with flavor, vitamins or other ingredients.

- Material: Stainless steel

- Country of origin: Slovakia

- Geometric volume: 350 l/ 700 l

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product and size of the conveyor.

- Material: Stainless steel

- Engine power, kW: 0,25

- Weight: 100

The Atmospheric Evaporating Pan efficiently concentrates liquids by evaporating them on a large surface area, while also being suitable for various cooking methods including braising, cooking, and roasting.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

An evaporator concentrator-crystallizer is a multifunctional unit that concentrates liquids by evaporating water and inducing crystallization for the production of concentrated solutions or crystalline products.

- Material: Stainless steel

- Working volume: up to 6000 L

- Geometric volume: 6500 l

Plant for evaporating, concentrating and crystallizing solutions. Vacuum evaporator ensures a complete separation of the solution into a solid fraction and pure water.

An evaporating unit is utilized to remove moisture from sweet substances through heating, transforming them into concentrated syrups or solutions.

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

- Geometric volume: 200 l

Blanchers are used to quickly heat or steam vegetables or fruits, often for the purpose of softening, preserving color, or removing skins before further processing. Geometrical volume 400 l.

- Material: Stainless steel

- Heating power, kW: 18

- Type of the equipment: Individual machine

- Country of origin: EU

- Weight: 300 kg

- Voltage: 380-400V

- Geometric volume: 400 l

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The KWS mixing vessel is engineered for versatile operations, including heating, cooling, and mixing of liquid products, with a maximum heating temperature of 60 ¬įC.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Geometric volume: 100 l

Atmospheric cookers ASC are designed for efficient mixing, heating and cooking products for food and cosmetic industries. Volume, l: 100 l.

- Heating: Electricity

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 100l

Atmospheric cookers AC are designed for efficient mixing, heating and cooking products for the food, pharmaceutical and cosmetic industries. Working volume up to, l: 300 l.

- Material: Stainless steel

- Engine power, kW: 1,5 KW

- Heating power, kW: 13,5

- Principle of operation: Batch mode

- Working volume: 300 l

- Geometric volume: 350 l

Universal dissolver AT is used to mix medium-hard products in liquid media. Working volume up to, l: 500 l

- Engine power, kW: 1,5 KW

- Working volume: up to 500 l

Our company offers equipment for whisking honey with a new updated design with gravity mixing! A characteristic feature of the new series, which is 20-25% more efficient than conventional mixing! The inclined design also makes it easier to unload the product after processing, due to the centrifugal force and gravity!

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

Our company offers equipment for whipping honey with a new design which includes gravity mixing. The main advantage of the technique is the ability to produce creamy honey in 4 hours! The device is designed for 450 kg of honey per batch.

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 300l

The twinscrew mixer with two horizontal shafts is designed for intensive mixing and kneading dough as well as chocolate, pralines and other similar products with medium or high viscosity.

- Material: Stainless steel

- Engine power, kW: 2,2

- Country of origin: Slovakia

- Weight: 281 kg

- Volume: 500l

The coating machine is designed for uniform application, impregnation of oil and fat mixture, dyes and flavors, enzymes, vitamins and other additives, various products with a high level of hygiene.

- Material: Stainless steel

- Engine power, kW: 2,2

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 281 kg

- Volume: 500l

Pneumatic capper PTC applies crown caps to beer bottles, cork caps on wine bottles, snap-on caps on other containers in just a matter of seconds.

- Productivity: 400 bottles/ h

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

- Country of origin: EU

- Weight: 25 kg

The CSM conveyor is designed for closing the lids on buckets filled with food products (HORECA packaging and wholesale packaging) as well as non-food products such as paints and other products in the chemical and other industries.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The equipment is designed for centrifuging and separating different types of products and raw materials.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

This compact batch blancher is designed for efficient and simple blanching in smaller-scale food processing. Price depends on the chosen option.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 450l/

Blancher pouring AQ is designed for heat treatment of a wide range of products whose fine structure requires to minimize mechanical influence in the blanching or cooking process. Unlike a drum blancher, in which the product is blanched in a process of single directional mixing and rolling and a screw blancher, in which the product passes through a working chamber by means of a screw, in the belt type blancher the product lies motionless on the conveyor belt and is processed without damaging its surface.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V