PRODUCTS

Explore our extensive selection of innovative food processing equipment tailored to meet the diverse demands of the industry. Our equipment spans various segments, improving productivity, enhancing production efficiency and ensuring high product quality. Invest in innovative solutions that advance your food processing operations.

The combination of the compact 400/1100/12 fryer with the secondary upper pressure conveyor, allows you to expand the variety of products that can be fried on it. It ensures uniform, high-quality frying of fresh and semi-finished products in small to medium scale, making it suitable for small-scale production, professional kitchens and street food businesses. The fryer fully submerges the product in oil throughout the whole frying process with the help of the second pressure conveyor that forces the product beneath the oil's surface.

- The maximum height of the fried product is - up to 50 mm

- Immersion thermometer for visual monitoring of the oil temperature

- Frying time can be set from a few seconds up to an hour!

- High temperature ŌĆō up to 200┬░C

- The conveyor belt is made out of a food-grade stainless steel thin mesh

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Total power, kW: 12

- Oil volume: 60l

- Voltage: 380-400V

The price is set for the basic fryer version without additional modules. If purchasing the fryer together with both of the additional conveyor modules ŌĆō the double conveyor fryer and the paddle conveyor fryer ŌĆō we offer a discount of 300 EUR.

The versatile modular conveyor fryer with a single conveyor belt is used for the continuous frying of a variety of products with a low moisture content, that do not require forced immersion beneath the surface of the oil for even frying.

- Adjustable frying time from a few seconds up to an hour!

- Ability to use the unit as a continuous blancher or boiler for cooking products with a delicate structure

- Modular system, expanding functions with each new module

- Compact, desktop version

- Possibility of periodic frying of products with automatic unloading

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Oil volume: 60l

- Voltage: 380-400V

We offer equipment for processes such as: honey dissolution, honey drying, honey homogenization, honey pasteurization, honey creaming and honey packaging. The necessary equipment is selected by the customer based on the required processing technology for their manufacturing process.

- Material: Stainless steel

- Type of the equipment: Part of a production line

- Country of origin: Slovakia

The price is indicated without gastro containers

Use this all-stainless steel water bath for gradual heating or cooking. The device is equipped with a practical drain tap for easy emptying of the container and is suitable for use with gastronorm containers.

- Compact installation

- Simple controls

- Safe operation

- Wide range of applications

- Material: Stainless steel

- Principle of operation: Batch mode

- Voltage: 220-230V

The price is set based on the basic built-in heating option of 24 kW.

The vacuum fryer is designed for frying foods in oil at low temperatures, allowing for the production of healthy snacks such as vegetable and fruit chips. The vacuum feature enables you to reduce the frying temperature of oil down to 110-120 degrees!

- «Cold roast» is a tasty and healthy method of processing the product

- Drying and frying without caramelizing the sugars contained in the product

- Large frying tank - for processing foods with a higher water content

- Modular heating system which allows you to increase the heating power up to 108 kW (optional)

- Circulating heating of oil through a heat exchanger minimizes oil spoilage and prevents localized overheating

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 24

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 30l

- Oil volume: 200l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

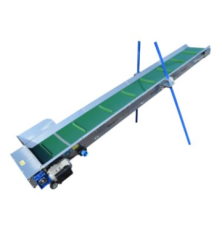

Optional module for the 400/1100/12 universal tabletop Modular Fryer - Pressure Conveyor for frying foods that require forced immersion in oil.

- Material: Stainless steel

For frying foods in oil, deep-frying, suitable for frying onions, seeds, nuts, vegetable snacks and chips, and other products, including breaded or covered in liaison. Can also be used as an oil separating centrifuge for deep fryer.

- Two in one: a deep fryer and a centrifuge to remove excess oil

- Possibility of frying small and fragile products

- Obtaining a ŌĆ£dry productŌĆØ after frying

- Low carbonization of oil due to the cleaning feature after frying

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 30l/ 90l

- Total power, kW: 11

- Voltage: 380-400V

Universal cooking kettle with a built-in mixer, used for cooking and stirring a variety of food products, cosmetic emulsions, creams and much more.

- Easily removable self-adjusting scrapers

- Lid opening sensor for safe stirrer maintenance

- Hygienic temperature sensor for the product

- Large diameter outlet valve

- Safe steam outlet on top of the boiler lid

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

The industrial meat grinder is made out of food-grade stainless steel. The kit includes various accessories such as a sausage attachment and an attachment with two cross blades. The productivity of the meat grinder is around 120 kg of minced meat per hour.

- Compact

- Professional

- With anti-slip rubber feet

- Stainless steel housing

- Productivity: 120 kg/h

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Continuous mode

- Total power, kW: 0,75

- Voltage: 220-230V

The automatic donut forming and frying machine is a high-quality device that is suitable for high productivity and daily usage.

- Tabletop system

- Includes a depositing attachment

- Compact design

- Completely out of stainless steel

- Material: Stainless steel

- Principle of operation: Continuous mode

- Weight: 40

- Total power, kW: 3

- Voltage: 220-230V

- Dimensions, mm: 965 x 330 x 650

The price is stated for the basic version of the installation without balls.

The mill is designed for mechanical grinding of raw materials for the production of chocolate, nut butters and obtaining a creamy, homogeneous product structure with a fraction size of up to 20 microns.

- Compact installation on a self-supporting structure

- Simple and convenient maintenance

- Plexiglas cover for visual inspection

- Removable stirring device

- Jacket for the heat transfer medium

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 5l

- Total power, kW: 1,5

- Voltage: 380-400V

The price is set for the combination of a basic fryer model and an additional module with rotating paddles.

The universal modular SnackPro fryer equipped with an additional paddle module is designed for frying thin slices of products that require immersion beneath the oil level.

- Adjustable frying time from a few seconds up to an hour

- Compact, tabletop version

- The paddle conveyor is installed on top of the basic fryer

- Safety thermostats on each heating element

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Total power, kW: 12

- Oil volume: 60l

- Voltage: 380-400V

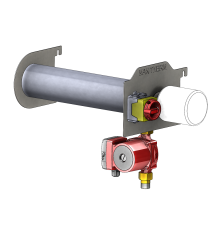

A flow-through water heater is a device for flow-through electric heating of water in heating systems for cooking boilers, evaporators and other units where it is necessary to supply a hot heat transfer medium - superheated water - to the heating jacket (duplicator). When choosing a flow-through heater, it is necessary to select a circulation pump based on the volume of the jacket or heat transfer vessel.

- The heater allows you to heat water up to 110 degrees

- Easily integrated into heating systems

- Has heating temperature regulation

- 2 stages of heating power adjustment

- Independent control panel with protection against overheating and "dry" running

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 2/ 3/ 6/ 9/ 10/ 12

- Principle of operation: Continuous mode

The price is set for the basic version, without additional options.

The industrial infrared dryer is suitable for drying a wide range of products: nuts, apples, plums, strawberries, raspberries, blueberries, mushrooms, carrots, onions, garlic, herbs, meat, figs, bananas, marshmallows. If additional options are selected, it can also be used for curing and drying whole meat and fish.

- Compact installation

- Fast and efficient drying

- Possibility of selecting individual settings for drying

- Made entirely out of stainless steel

- The interior surface of the cabinet has a mirror coating

- Quiet operation of the installation

- Low energy consumption per drying cycle

- Heating: Electricity

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 7l/ 10l/ 14l

- Total power, kW: 10/ 15/ 20

- Area, m┬▓: 3,5/ 5,2/ 6,9

- Number of shelves: 10/ 15/ 20

The vacuum bread cooler is well-suited for application in small bakeries or as a laboratory unit in industrial enterprises. This enables the post-baking of bread under vacuum conditions, influencing both its shape and structure.

- Built-in deep vacuum system

- Built-in vapor removal and condensation system

- Built-in refrigeration system

- The chamber is designed for 3 gastro containers size GN 1/1, or pallets: 400x600/530x325 mm

- Compact and mobile installation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 130l

- Voltage: 380-400V

The price is indicated without a source of compressed air - compressor (optional).

This is periodic type of equipment designed for removing moisture and excess water from honey under vacuum conditions. This pilot vacuum dryer can be used for processing small volumes of honey directly at apiaries.

- Drying rate up to 1% per hour! (with a gradual decrease as the concentration increases)

- Large heat transfer area

- Low drying temperature thanks to the vacuum

- Easy operation and maintenance

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100 - 140 kg

- Total power, kW: 6,5

- Voltage: 220-230V 380-400V

- Max vacuum: -0,8 Bar

Universal cooking kettle for thick mixtures: it works on the principle of a water bath and can be used in confectionery shops, bakeries and other catering establishments. Offers a wide variety of models.

- Mechanical tilting system for unloading

- Safety grill for the mixer drive

- Built-in electric heating up to 150 degrees

- Mobile support structure on wheels

- Heating: Electricity

- Principle of operation: Batch mode

- Volume: 30l/ 60l/ 80l/ 120l

The Price is specified for the version with a hydraulic lift.

The industrial electric frying pan using thermal oil is an optimal and economical solution for small-scale industrial food production. It allows for low energy and operating costs while ensuring uniform and intense heating for the entire working bowl. The system's thermal inertia helps maintain the required temperature for an extended time, making it effective for frying onions, carrots, saut├®ing flour and vegetables, and preparing sauces, soups, side dishes, stews, and more.

- Low energy consumption

- Uniform heating

- Heated conical sides

- Adjustable heating intensity

- Controller with a hygienic housing directly on the supporting structure

- Lid opening handles located in the cold zone

- Automatic lifting/tilting system

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 26

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

- Total power, kW: 28

- Voltage: 380-400V

- Duplicator volume: 106l

This premium cooking kettle is gas-fired and has a volume of 160 liters. Ideal for preparing a wide variety of dishes in professional kitchens.

- Heating: Gas

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 150l

The portable vertical pump is designed for pumping fluent or viscous liquids in the range from 1-2300 m2/s at a temperature of around 25┬░C. The pump cannot be used in potentially explosive atmospheres.

- Material: Stainless steel

- Engine power, kW: 0,25

- Voltage: 380-400V

An ideal solution that greatly facilitates and speeds up the work of the attendants, without having to lift and turn the bowl in order to transfer the dough to another dosing or portioning machine, for example, to another batcher or portioner.

- Material: Stainless steel

A modern cooking and mixing device with a wide range of applications in confectionery, bakeries, catering establishments.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 200l/ 300l/ 500l

Fat block melter Fastmelter refers to the equipment of periodic action for melting butter and other frozen fats within the food industry.

- Material: Stainless steel

- Principle of operation: Batch mode

This 60 liter cooking kettle is indispensable for cooking large amounts of food. Runs on gas and handles all basic cooking tasks with ease.

- Material: Stainless steel

- Principle of operation: Batch mode

- Working volume: 50

This electric cooking pot has a volume of 60 liters and is used to prepare a large number of dishes. It is comfortable to use and easy to clean.

- Material: Stainless steel

- Volume: 60l/

- Voltage: 380-400V

This premium cooking kettle is gas-fired and has a capacity of 120 liters. Ideal for preparing a wide variety of dishes.

- Heating: Gas

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 120l

- Working volume: 100

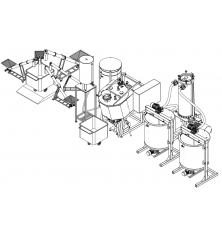

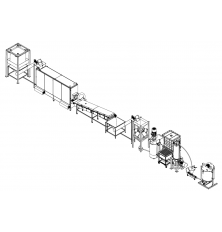

This equipment complex enables the production of Nutella-type chocolate pastes with a capacity of up to 250 kg/h.

- Material: Stainless steel

- Country of origin: Slovakia

Thanks to the indirect heating system, this kettle is ideal for cooking liquid dishes. It is completely made of stainless steel and equipped with a convenient drain valve.

- Material: Stainless steel

- Heating power, kW: 18

- Voltage: 380-400V

This 265 liter stainless steel cooker is great for boiling or roasting a variety of ingredients. It is made of stainless steel and equipped with a convenient drain valve.

- Heating: Gas

- Material: Stainless steel

- Principle of operation: Batch mode

This stainless steel cooking pot will always ensure cooking, baking or boiling different foods.

- Material: Stainless steel

- Voltage: 380-400V

- Working volume: 100

Thanks to the indirect heating system, this electric kettle is ideal for cooking liquid foods. It is completely made of stainless steel and equipped with a convenient drain valve.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

This gas powered professional cooker is indispensable in professional kitchens. It allows you to easily prepare the most delicious soups, broths, sauces and creams.

- Heating: Gas

- Material: Stainless steel

- Working volume: 100l/ 150 l

This 550 l professional tilting kettle is gas-fired and is indispensable in the professional kitchen. It allows you to easily prepare the most delicious soups, broths, sauces and creams. With this tilting version, you can make your life even easier.

- Heating: Gas

- Productivity: 500 l

- Material: Stainless steel

The paddle module for the 400/1100/12 Universal Tabletop Modular Fryer is a conveyor with specially curved paddles for gentle frying of fragile and light foods.

- Material: Stainless steel

- Type of the equipment: Optional equipment

Cooking kettle for making syrups, caramel, sugaring paste as well as processing and producing various thick and viscous products. Often used for dissolving sugar and producing various saturated and supersaturated solutions.

- Built-in heating with thermal oil up to 150 degrees Celsius

- Anchor frame stirrer for rapid dissolution

- Conical bottom design of the working container without dead zones

- Heating: Electricity

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 200l/ 300l

- Total power, kW: 19

Designed for "cold" vacuum drying of products sensitive to high temperatures, also suitable for liquid and viscous products.

This 160L or 220L professional cooking pot is indispensable in the professional kitchen. It allows you to easily prepare the most delicious soups, broths, sauces and creams.

- Material: Stainless steel

- Heating power, kW: 18/ 27

- Voltage: 380-400V

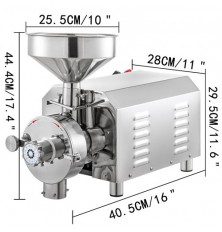

This powder making machine is made out of stainless steel. All parts that are in contact with food are made out of food grade 304 stainless steel for health and safety reasons.

- Material: Stainless steel

- Engine power, kW: 2,2

The single-stage vacuum pumps are versatile, offering a wide range of applications when it comes to transporting liquids due to their simplicity, reliability, and robustness. The device operates with minimal vibrations, and its noise levels do not exceed the prescribed standards. Additionally, it ensures oil-free operation.

Compact, reliable, and easy to use. The frequency converter ensures smooth starting and stopping of the device's motor, reducing inrush currents, and adjusting the motor speed. It can also be connected to your smartphone via Bluetooth for convenient configuration and parameter adjustment.

Key benefits:

- Precise digital control at the touch of a button.

- Application macros.

- Switch between Industrial, Pump, and Fan modes for optimized operation.

- It is used and mounted directly on the equipment, eliminating the need for electrical cabinets. It can also be wall-mounted.

We also offer programming and installation of the frequency converter to ensure seamless integration and optimal functionality for your equipment.

- Type of the equipment: Optional equipment

Additional option to VMG laboratory vacuum homogenizer 20/50.

- Type of the equipment: Optional equipment

The price is set for the basic version of the reactor without additional options and the control panel

The vacuum vessel with a coolant duplicator and a mixing device is a universal solution for processing various products at sub-atmospheric pressure. Based on this simple device, you can select and modulate it into complex installations such as a┬Āvacuum evaporator, a┬Āvacuum cooking kettle, and a┬Āunit for the production of cream honey.

- Sloped Design - Gravity Mixing

- Bottom valve DN40 included in the basic version

- Small-volume duplicator - low costs for coolant heating/cooling

- Modular system: customization of the equipment and its functionalities by ordering additional options

- An easy to disassemble mixing device

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

A production line for thermostable fruit-based fillings, widely used in the production of pastries, baked goods, and various semi-finished products, as well as curd cheeses, creams, and even ice cream.

- Obtaining top-notch thermostable fillings while preserving essential nutrients and vitamins.

- Compact system featuring a unified control panel, ensuring easy and straightforward operation.

- Swift and efficient recycling included as a standard feature.

- Modular design with numerous additional options for customization.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

The complex of equipment for the production of mayonnaise consists of several installations for automatic dosing, mixing, and obtaining a stable emulsion.

- Compact design, offering convenient and straightforward operation in a limited space.

- Cost-effective solution for automatic dosing without incurring high automation costs.

- A wide range of additional modular options.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 13,5

- Voltage: 380-400V

Equipment for mixing multi-component mixtures of products, such as vegetable salads with various dressings, including thick and viscous ones like mayonnaise, thick sour cream and other similar sauces.

- Hydraulic tilting system is included in the basic version

- The controls are located directly on the frame supporting structure

- Eccentrically offset working shaft for rotating/tilting the working tank

- Low loading height

- The installation is made entirely out of food grade stainless steel

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 600l/ 1000l

The price is indicated for the basic version of the set of equipment with a homogenizer

The equipment for the production of ice cream mixtures is based on a universal vacuum reactor with a coolant jacket and a multi-stage dispersant/homogenizer in an external circulation loop.

- Special type of a stirring device for easy disassembly and cleaning

- Processing with minimal product loss

- The bottom outlet valve is included in the basic version of the installation

- Multi-stage disperser for intensive wetting and homogenization of the flowing mixture

- External circulation circuit with a three-way valve for operation/washing of the equipment

- Reinforced agitator drive for thick and viscous mixtures

- Built-in vacuum pump

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Total power, kW: 3

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The FRP hydraulic press is the easiest and fastest solution for pressing various types of crushed fruits. The device is used for pressing crushed fruits with water.

- simple and fast extraction,

- no physical effort required,

- high percentage of juice yield (up to 80%),

- easy cleaning,

- long service life.

- Material: Stainless steel

- Principle of operation: Batch mode

The Bag in Box Filler is designed for filling hot and cold liquids into Bags in Boxes and for Stand Up Pouch packaging.

- The machine fills the bags up automatically.

- Material: Stainless steel

- Principle of operation: Continuous mode

The electric pasteurizer is ideal for the heat treatment of various fruits, including apples, pears, blackberries, strawberries, blueberries, elderberries, currants, carrots, greens, quince, beets, sea buckthorn, rowan berries, and onions.

- Material: Stainless steel

- Principle of operation: Continuous mode

The VMG S 650P vacuum homogenizing unit can be used for making toothpaste as well as a variety of similar products with complex production requirements.

- The vacuum ensures effective air removal, eliminating the conditions for the development of bacteria and other pathogenic organisms.

- The special shape of the mixing device is tailored for the thickest and most viscous products.┬Ā

- The Ultra Shear submersible homogenizer creates a stable emulsion.

- The cavitation processes aid in activating hydrodynamic mixing.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 29

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 52

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Multifunctional vacuum unit MINI5 - is ideal for cooking, drying, concentrating, mixing and much more. Suitable for laboratories and small-scale production.

- Processing heat-sensitive products at lower temperatures

- Ideal for making creamed honey

- Possibility of vacuum drying honey

- Material: Stainless steel

- Engine power, kW: 0,12

- Country of origin: Slovakia

- Volume: 5l

Used for blanching products in water, it is suitable for processing various vegetables, legumes, grains, mushrooms and other products. This versatile machine also functions as a water separator centrifuge which is activated after the blanching processes.

- Productivity: 30l/ 90l

- Material: Stainless steel

Multifunctional vacuum mixer/homogenizer for grinding, mixing, and homogenizing products to obtain homogeneous masses.

- Built-in jacket for the bottom and walls of the unit.

- Cutter knives with a powerful electric drive

- Slanted design for efficient mixing and chopping

- Forced circulation circuit (optional)

- Wide range of options

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 350l/ 650l

- Total power, kW: 13/ 17

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The tubular pasteurizer is typically designed for pasteurizing cream in butter production lines. These pasteurizers are commonly used in dairy processing industrial facilities, especially in butter production and other related sectors.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The working surface is made out of food-grade stainless steel, on top of which the deep fryer can be installed. It is quipped with wheels for ease of movement.

- Material: Stainless steel

A complete set of equipment for the production of margarine with a capacity of up to 500 kg/hour.

- Type of the equipment: Part of a production line

- Country of origin: Slovakia

Cooking tank with a bottom out of stainless steel AISI 316. Capacity of 150 liters.

- Heating: Steam

- Material: Stainless steel

- Volume: 150l

Chocolate heating pump is the perfect solution to upgrade your production line. You can easily connect the pump to any device (such as a chocolate enrobing machine).

- Principle of operation: Batch mode

- Voltage: 380-400V

This kettle with a radiator cooling system ranging from 30 to 500 liters is ready to cook according to the principle of a water bath.

- Material: Stainless steel

- Volume: 30l/ 60l/ 80l/ 120 l/ 200l/ 300l

- Voltage: 380-400V

Modern equipment with a wide range of applications in pastries, bakeries, catering facilities.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 200l/ 300l/ 500l

Electric steam generator with capacity of 2*24.5 liters - meets PED standards - with double or single resistance.

- Type of the equipment: Individual machine

Electric steam generator equipped with two boilers.

- Type of the equipment: Individual machine

Electric steam generator with capacity of 57 liters - meets PED standards - with double or single resistance.

- Material: Stainless steel

- Type of the equipment: Individual machine

Electric steam generator with capacity of 24.5 liters - meets PED standards - with double or single resistance.

- Type of the equipment: Individual machine

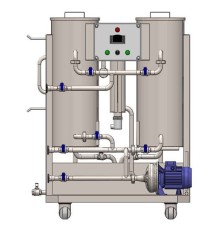

Cleaning-In-Place - Machine for cleaning and disinfection of vessels and pipelines in breweries and other food processing plants with four tanks.

- Heating: Electricity Steam

- Material: Stainless steel

- Voltage: 380-400V

Improve the cleaning process with the CIP-53, a mobile station designed for thorough sterilization and sanitation of vessels and pipelines. Ideal for breweries and the food industry, this comprehensive system with three 50 or 100 liter tanks ensures efficient cleaning of fermentation and storage tanks, offers digital temperature control and neutralization.

- Material: Stainless steel

- Voltage: 380-400V

CIP-302: Cleaning-In-Place - Machine for cleaning and disinfection of vessels and pipelines in breweries and other food processing plants with two tanks of 300 liters.

- Material: Stainless steel

- Country of origin: EU

CIP-202: Cleaning-In-Place - Machine for cleaning and disinfecting vessels and pipelines in breweries and other food processing plants with two 200 liter tanks.

- Material: Stainless steel

- Country of origin: EU

- Volume: 200l

CIP-102 consists of two main tanks for alkaline and acid solution and one vessel used for neutralization of solutions.

- Material: Stainless steel

- Engine power, kW: 0,75

- Volume: 100l

- Voltage: 380-400V

CIP-52: Clean-In-Place - Machine for cleaning and the disinfection vessels and pipelines in breweries and other food processing plants with two 50 liter tanks.

- Material: Stainless steel

- Country of origin: EU

CIP-201 - installation for cleaning and disinfection of vessels and pipelines in breweries and other food industries with one tank of 200 liters.

- Material: Stainless steel

- Engine power, kW: 0,75

- Voltage: 380-400V

CIP station CIP-101 With a usable capacity of 1├Ś100 liters, it is used for cleaning, sanitizing and sterilizing vessels and pipes in a brewery. This type of CIP station is recommended for cleaning and sanitizing tanks from 0 to 4000 liters.

- Material: Stainless steel

- Country of origin: EU

CIP-51: Equipment for cleaning and disinfection of vessels and pipelines in breweries and other food industries with one tank of 50 liters

- Material: Stainless steel

- Country of origin: EU

Additional option to VMG laboratory vacuum homogenizer 20/50.

- Material: Stainless steel

- Type of the equipment: Optional equipment

Additional option for the VMG laboratory vacuum homogenizer 20/50.

- Type of the equipment: Optional equipment

Fast, sleek, quiet, user-friendly, safe, smooth-running commercial salad dryer, designed to efficiently dry up to 6 Kg.

- Engine power, kW: 0,55

- Principle of operation: Batch mode

A grain mill made out of stainless steel, it is sturdy and durable grinder, with increased wear resistance.

- Material: Stainless steel

- Engine power, kW: 3

The conveyor is made out of strong and highly-resistant stainless steel. It is also additionally reinforced for reliability during operation.

- Material: Stainless steel

- Principle of operation: Continuous mode

This 9L cutter is a robust and reliable device used for processing various foods.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 9

- Voltage: 220-230V

The MPP 8 vegetable root peeler is an industrial peeling machine with a stainless steel body.

- Productivity: up to 160 kg/h

- Material: Stainless steel

- Engine power, kW: 0,37

- Voltage: 220-230V

Designed for pumping hot thermal oil in frying circulation and filtration systems, for oil loading and unloading, in "hot" continuous oil filtration systems with a maximum temperature of up to 200 degrees.

- Material: Stainless steel

- Engine power, kW: 0,55

- Country of origin: Slovakia

This equipment set can be used for the production of a diverse array of sauces, as well as various vegetarian products based on nuts, soy and rice. It is capable of processing around 300/600 liters of product per batch.

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 300l/ 600l/

- Voltage: 380-400V

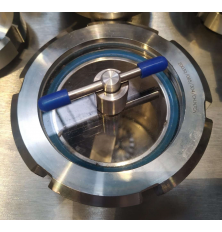

A filter designed for continuous fine filtration of conveyor fryers using vegetable oil, and other frying fats.

- Material: Stainless steel

- Operation mode: Automatic

- Type of the equipment: Optional equipment

- Working Area Width: 400 mm

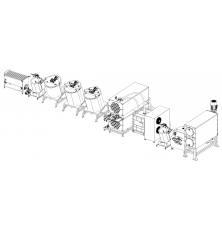

An equipment complex designed for processing raw, peeled, and blanched peanuts, offering a production capacity of up to 500 kg/hour.

- Productivity: 500 kg/h/

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Complete set of equipment for processing shelled beans, and the production of a soy base with a capacity of 800-1000 liters per hour.

- Productivity: 800 l/h

- Material: Stainless steel

- Country of origin: Slovakia

This set of equipment for the production of condensed milk from dry components by restoring the milk. This production line can be manufactured with a capacity of up to 500 kg/h or can be customized based on specific requirements.

- Material: Stainless steel

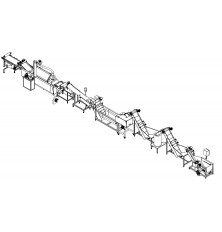

The set of individual equipment for the production of French fries may differ depending on the initial raw materials. We offer various modifications from washing to frying with subsequent dehumidification starting from 50 kg/h for the final product.

- Principle of operation: Continuous mode

- Country of origin: Slovakia

This jam production line allows you to get ready-made jam at the exit from whole fruits at the entrance! Equipment options may vary depending on the customer's technology.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: EU

Equipment for the production of condensed milk from pre-pasteurized milk. This equipment can be manufactured with a capacity of 50 to 500 kg/hour, or on request. We also manufacture condensed milk lines according to TU from dry milk┬Āor┬Ānormalized milk concentration lines.

- Material: Stainless steel

- Type of the equipment: Part of a production line

- Country of origin: Slovakia

The vegetable spin dryer has been designed for drying leafy vegetables rapidly and efficiently, both raw and boiled, prepared in medium-large sized professional kitchens and in food industries.

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Batch mode

- Voltage: 220-230V

Set of 4 height adjustable legs+/- 100 mm.

- Material: Stainless steel

- Type of the equipment: Optional equipment

Supporting structure on wheels with locks (brakes), 2 swivel wheels, 2 swivel wheels with a brake.

- Type of the equipment: Optional equipment

Variable belt conveyor with wide use not only in the food industry. The length of the conveyor can be selected from 2 to 6 m. The width of the belt is 200 and 400 mm.

- Engine power, kW: 0,75

- Principle of operation: Continuous mode

Protective decorative cover for colloid mill 132 (additional option)

- Material: Stainless steel

- Country of origin: Slovakia

Stand (support structure) for colloid mill machine - additional option for the colloid mill 132

- Type of the equipment: Optional equipment

Potato and root vegetable peelers are manufactured in all-stainless steel casing. The device is directly ready for use (no installation required), it is supplied for a 3x400 V power supply.

- Engine power, kW: 0,35/ 0,55/ 0,75/ 1,1

- Country of origin: EU

- Voltage: 380-400V

Thermal insulation of the drying cabinet body to reduce heat loss during product drying. Additional option for the MAK DRYER 7-14.

- Type of the equipment: Optional equipment

The price is indicated without the frequency converter

A twin-screw mixer for fast and intensive mixing, stirring of bulk solid products, such as granules, muesli with various powder additives.

- The mixing blades carefully move while thoroughly mixing the product

- The mixing mode allows you to move the product cyclically in a circle

- High mixing efficiency due to the counter-movement of the 2 shafts

- Compact design

- Possibility to install scrapers on each blade (optional)

- Reinforced drive, can be used for products saturated with moisture as well

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 500l

- Total power, kW: 3

The generator is mounted on a stainless steel platform support, covered with stainless steel AISI 304 properly shaped with electrical and water connections already made. Stainless steel cocks AISI 316, malleable iron pipe fittings, feed water pump (mod. TP78A CALPEDA) with 1 stainless steel non-return valve, with VITON seal.

- Heating power, kW: 24/ 32/ 48

The 5 kw stool-type electric heating stove with a diameter of 40 cm is designed to heat large pots and pans with a volume of up to 100 liters.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Type of the equipment: Optional equipment