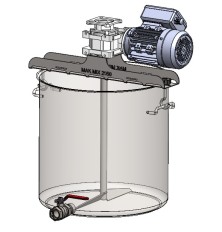

Universal cooking kettle with a built-in mixer, used for cooking and stirring a variety of food products, cosmetic emulsions, creams and much more.

- Easily removable self-adjusting scrapers

- Lid opening sensor for safe stirrer maintenance

- Hygienic temperature sensor for the product

- Large diameter outlet valve

- Safe steam outlet on top of the boiler lid

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

Professional cooking boiler with a stirrer for particularly thick and viscous products. An excellent technical solution for the production of caramel, syrups and sugar paste for sugaring. The heating source is selected separately.

- The kettle can be used on all types of cooking surfaces, including induction

- The basic version has easily removable, self-aligning stainless steel scrapers

- High torque of the stirrer with 14-18 revolutions per minute

- Professional 3-phase industrial motor

- The stirrer is turned on independently using a remote control with IP66 protection, connected to the boiler using quick-release connectors

- The unit can be connected to a 220-230 volt network even with a 3-phase motor!

- Material: Stainless steel

- Engine power, kW: 0,25/ 0,37

- Volume: 20l/ 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

A compact electric pasteurizer with a heating power of 5 kW is used for long-term batch pasteurization of milk, which includes heating milk to a temperature up to 100 degrees C and maintaining it for a selected period of time. The milk pasteurizer can also be used in the form of a Milk pot to heat milk for feeding calves.

- High heating power (5â¯kW) on a 220â¯V single-phase connection

- Stirrer with bottom scrapers that prevents milk from burning when directly heated

- Direct electric heating with a multi-stage power switch

- Hygienic design for simple and easy cleaning

- Simple system for removing and lifting the top hatch with an agitator

- Absence of blind spots where bacteria can grow

- Heating: Electricity

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Heating power, kW: 5

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 150l

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

The price is set for the basic fryer version without additional modules. If purchasing the fryer together with both of the additional conveyor modules â the double conveyor fryer and the paddle conveyor fryer â we offer a discount of 300 EUR.

The versatile modular conveyor fryer with a single conveyor belt is used for the continuous frying of a variety of products with a low moisture content, that do not require forced immersion beneath the surface of the oil for even frying.

- Adjustable frying time from a few seconds up to an hour!

- Ability to use the unit as a continuous blancher or boiler for cooking products with a delicate structure

- Modular system, expanding functions with each new module

- Compact, desktop version

- Possibility of periodic frying of products with automatic unloading

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Oil volume: 60l

- Voltage: 380-400V

The Economy series of the cooking kettles comprise a thick-walled stainless steel container with an electric mixer mounted on the quick-release upper housing. The installation allows you to mix and stir products during processing. The thick bottom of the pot allows it to be installed on all types of heating surfaces (gas, induction or electric stove).

The Economy version is recommended for use with low-viscosity liquid products; If processing more thick and viscous products is necessary, we offer the Premium version of the cooking kettle or the caramel & syrup cooking kettle for extra thick substances.

- Sandwich bottom (multilayer) for use on all types of hobs, including induction

- Quick release lid with an electric stirrer

- Safety grid under the upper hull hatch - safe handling when stirring

- Possibility of visual inspection through the safety grid during processing

- Safe loading of components even during mixing

- Material: Stainless steel

- Engine power, kW: 0,12

- Volume: 30l/ 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

This compact nuts and seeds roaster is ideal for efficiently and evenly processing nuts and seeds to perfection.

- Productivity: 5-15 kg

- Material: Stainless steel

- Principle of operation: Batch mode

The colloid mill is used for continuous grinding of nuts, to obtain a finished nut paste of various viscosities with one pass through, without requiring additional processing or preparation!

- Simple and easy operation

- Three-point grinding adjustment

- Possibility of producing both creamy and crunch-type nut butters

- Compact design

- High performance

- Productivity: 180-240 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

The cost is specified for the basic modification without a heating system

Fat block melters are designed for melting frozen, solid blocks of animal or vegetable fat, as well as maintaining them in a molten state at a specified temperature. We produce models with the option to connect steam as a coolant to the melting grid, separate electric heating systems, or configurations with built-in electric heating for supply into the jacket and melting grid.

- Large area of the melting grid where the coolant circulates

- Special shape of the melting grid, cutting blocks during melting

- Greater versatility in terms of the coolant and its source

- Mirror surface of the melting grid, ensuring high hygiene

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 200l/ 300l/ 500l/ 1000l

This ground-breaking device allows for constant fine tuning of the roundness of the boilies thanks to its PLC control device. It is sold in two versions. The price depends on the options you choose.

We also offer a extruding machine suitable for this boilie machine.

- Material: Stainless steel

- Principle of operation: Continuous mode

A detachable lid with an automatic food stirrer for stainless steel 40 cm pots, suitable for volumes of 50 and 100 liters. An automatic stirrer allows you to mix and stir various products, including during thermal processing. The type of mixing device can be additionally selected depending on the required process.

- Professional industrial single-phase motor for 220-230 Volts

- The control is located directly on the motor housing or on the drive cable

- Easy and simple installation and fixation of the lid on the pan

- Suitable for standard 40 cm pots with a capacity of 50 or 100 liters

- The lid and stirrer are made entirely out of stainless steel

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Principle of operation: Batch mode

- Voltage: 220-230V

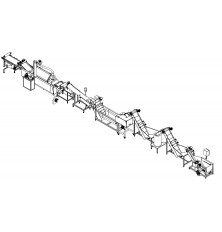

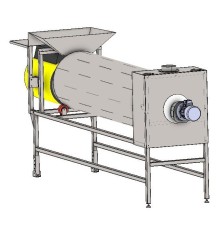

A production line for making puree from seeded fruits such as apples or pears with a processing capacity of up to 2000 kg/hour of raw materials.

- Productivity: 1000 kg/h/ 2000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The combination of the compact 400/1100/12 fryer with the secondary upper pressure conveyor, allows you to expand the variety of products that can be fried on it. It ensures uniform, high-quality frying of fresh and semi-finished products in small to medium scale, making it suitable for small-scale production, professional kitchens and street food businesses. The fryer fully submerges the product in oil throughout the whole frying process with the help of the second pressure conveyor that forces the product beneath the oil's surface.

- The maximum height of the fried product is - up to 50 mm

- Immersion thermometer for visual monitoring of the oil temperature

- Frying time can be set from a few seconds up to an hour!

- High temperature â up to 200°C

- The conveyor belt is made out of a food-grade stainless steel thin mesh

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Total power, kW: 12

- Oil volume: 60l

- Voltage: 380-400V

The cherry seeds separation machine has a high processing capacity ranging - from 200 to 300 kg of raw materials that can be loaded per hour (depending on the size of the cherries). It roughly equals to 720 processed berries per minute. This machine is perfect for small and medium-sized food enterprises and farms.

- Productivity: 300 kg/h

- Voltage: 220-230V

Pasteurization dipping tub is suitable for the heat treatment of packaged fruit preparations, (jams, fillings, hams) or fermented preparations (vinegar, beer) and pickles to preserve them, and to eliminate harmful microorganisms.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 200l/ 300l

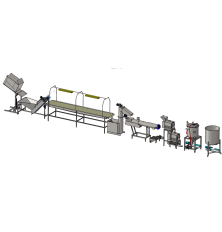

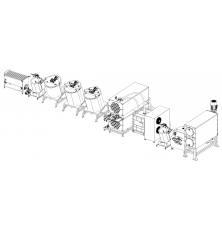

The set of individual equipment for the production of French fries may differ depending on the initial raw materials. We offer various modifications from washing to frying with subsequent dehumidification starting from 50 kg/h for the final product.

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The Z-Sigma Arm paddle mixer is designed for intensive mixing, stirring, kneading and plasticizing products with high and very high viscosity, such as chewing gum base, stiff dough with low water content, toffee mass, soap base, adhesives.

- Double Z-shaped blade

- Very high shear force

- Minimum gap between z blades and the working container

- Independent electric drive for each blade

- Electric tilting for automatic unloading up to 180 degrees

- The mixer is made entirely out of food grade stainless steel AISI304

- Possibility to choose the side of tilting and unloading

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 70l/ 140/ 300l/ 460/ 700l/

- Voltage: 380-400V

The vacuum cooking and concentration unit is designed for concentrating products at low temperatures (about 60 degrees) in a reactor with a discharged environment to preserve the color, nutritional value and useful natural substances in present in food products. Evaporation and concentration units are often used when cooking jams, sauces, as well as fruit or vegetable concentrates. The vacuum concentrator allows you to boil and concentrate heat-sensitive products without damaging or destroying their structure or proteins, such as milk.

- Inclined design - allows for gravity mixing, which is 40% more efficient than usual

- Quick and 100% emptying of the tank thanks to the inclined design with the mixer on

- Heating/cooling jacket (duplicator) for the working tank and bottom

- High hygiene standard - the output valve is located at the lowest hydraulic point of the reactor

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l/ 500l/ 875l

The vacuum evaporation unit is specially designed for thickening dense food products in industrial quantities. The evaporator can be used for the production of thick syrups, caramel masses, dense fruit masses, as well as for the production of pectin, or heat-stable fillings with a high productivity.

- High performance

- Rotary spraying system with a powerful electric drive

- Evaporation in a thin layer with a large heat transfer area

- Low investment installation costs

- Tangential entry for product swirling

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

The price is stated for the basic version of the installation without balls.

The mill is designed for mechanical grinding of raw materials for the production of chocolate, nut butters and obtaining a creamy, homogeneous product structure with a fraction size of up to 20 microns.

- Compact installation on a self-supporting structure

- Simple and convenient maintenance

- Plexiglas cover for visual inspection

- Removable stirring device

- Jacket for the heat transfer medium

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 5l

- Total power, kW: 1,5

- Voltage: 380-400V

For a price quote or for a free consultation, send us a request.

- Productivity: 90l

- Material: Stainless steel

- Heating power, kW: 6/

- Principle of operation: Continuous mode

- Voltage: 380-400V

The concentration and thickening line line has been especially designed for industrial dairy production facilities with a small surplus of milk or smaller milk processing businesses that want to expand their product range. It has an estimated productivity of up to 50-120 kg/hour during continuous operation.

- Professional industrial technology with compact dimensions

- A large number of additional equipment and options to choose from

- Material: Stainless steel

- Principle of operation: Continuous mode

We offer equipment for processes such as: honey dissolution, honey drying, honey homogenization, honey pasteurization, honey creaming and honey packaging. The necessary equipment is selected by the customer based on the required processing technology for their manufacturing process.

- Material: Stainless steel

- Type of the equipment: Part of a production line

- Country of origin: Slovakia

The kettle is designed for cooking qualitative jam, marmalade, confiture from different fruits, vegetables and berries. It's an ideal and affordable solution for cooking various products.

- Material: Stainless steel

- Heating power, kW: 9/ 12/ 18/ 24

- Principle of operation: Batch mode

- Volume: 80l/ 120 l/ 200l/ 300l

Manual cutter for cutting potions of fresh cured meats with interchangeable eccentrics to obtain different sausage lengths up to a maximum of 280 mm. Works with any type of casing.

- Productivity: 100-400 psc/h

- Material: Stainless steel

- Principle of operation: Continuous mode

Convective rotary drum dryers are used for drying granular, loose and bulk materials. They can be used for drying salt, coffee, various granules, powders, grain, nuts, seeds, fruit/vegetable bagasse, and many other products. When used in other industries, the dryer allows for the drying of salt, sand, expanded clay granules, and other similar non-flammable substances. For more information, send us a request.

The drum dryer can be configured to operate with either electric heating or gas heating (which can offer a lot more power), depending on your specific requirements and preferences.

Warning: It is not recommended to use the gas heating option for drying substances that are highly flammable, as doing so could pose a significant fire risk.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The fruit pitting machine is intended for removing cores or pits from plums and apricots. Besides the fruits mentioned above, this device can be used for nectarines, peaches, etc. It can simultaneously cut fruits into several parts (two, four). The machine is perfect for use by small and medium-sized enterprises, and in farms.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 220-230V

The price is set for the basic version of the vacuum evaporation unit with basic controls (mixer motor switch) and without additional options. The control unit is customized based on individual customer requirements. The pump is also selected separately depending on the product.

A compact vacuum evaporation unit that allows you to concentrate solutions, mixtures, and various products by evaporating the solvent. A modular version based on the basic version of the 110/100 vacuum reactor.

- Gravity mixing - 25% more efficient

- Reinforced agitator design with no blind spots

- Bottom ball valve with no dead zones

- Condensation and secondary vapor removal system

- Easy to disassemble mixing device

- Large heat exchange area

- Ability to measure and monitor condensate volume (optional)

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

- Working volume: 50-80l

- Condensing capacity, l/h: 45-55

- Steam consumption, kg/h: up to 150

The CSM conveyor is designed for closing the lids on buckets filled with food products (HORECA packaging and wholesale packaging) as well as non-food products such as paints and other products in the chemical and other industries.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The cylindrical drum rotary machine is designed for drying and crystallizing liquid and paste food products into solid crystals.

- Compact tabletop design

- Automatic knives for cutting the product film

- Adjustable product layer thickness when applied to the drum

- Adjustable drum rotation speed to control drying time

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Rotary molding machine for confectionery products: candies from paste-like masses, crushed fruit masses, protein candies and bars. Specially designed for molding candies from food masses.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 1,5

- Voltage: 380-400V

The honey creaming machine is produced in various capacities with the possibility of loading from 30 to 225 kg of honey, so every beekeeper can choose the model that suits him. After processing, honey acquires a creamy structure. The creaming process is a method of crystallizing honey using a sample â seed (creamed honey), carried out through stirring.

- Compact design

- Easy to operate and maintain

- Connection - 220-230 Volts

- Container and mixing device made out of stainless steel

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Voltage: 220-230V

- Loading, kg: 30/ 75/ 150/ 225

- Diameter, mm: 400/ 500/ 600

Condensation dryer for vegetables, fruits, berries, mushrooms, herbs and other products. The condensation drying method is the most energy efficient way to dry food. The installation is intended for use in the food industry.

- entirely made out of food grade stainless steel AISI304

- polished external coating

- fully automatic control system

- 100% insulation without freon (70 mm)

- Volume: 250l/ 550l/ 1225l

- Voltage: 220-230V

- Number of shelves: 6/ 11/ 22

Price depends on the capacity and product.Â

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

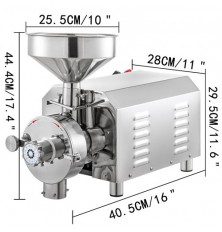

This is a highly efficient equipment designed for fine grinding and homogenization of solid products. Thanks to its unique design and high speed, the mill provides fine mixing and crushing of particles, which makes it indispensable in a variety of industries.

- Compact design - tabletop installation

- Possibility of using different feeder models

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Voltage: 220-230V

Compact vacuum evaporation machine with an external circulation heat exchanger for the production of test batches of products, development of new recipes and technological maps.

- Compact installation

- Capable of replicating all processing techniques used in industrial vacuum evaporation units with circulation

- Preserves the natural taste, aroma and color of the product

- Can be used to produce small batches of products

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Volume: 20l

Complete set of equipment for processing shelled beans, and the production of a soy base with a capacity of 800-1000 liters per hour.

- Productivity: 800 l/h

- Material: Stainless steel

- Country of origin: Slovakia

Designed for "cold" vacuum drying of products sensitive to high temperatures, also suitable for liquid and viscous products.

An air cooling conveyor is used to rapidly cool products in food processing industries by circulating cool air over them as they move along a conveyor belt. This efficient cooling process helps preserve product quality and reduce the time between processing stages, facilitating smoother production workflows.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

A vacuum honey dryer is used to dehydrate (remove moisture from) honey at sub-atmospheric pressure.

- This highly efficient and innovative vacuum drying process guarantees honey drying rates exceeding 1% per hour!

- The vacuum dryer allows for quick and gentle drying of honey at temperatures up to 39°C without increasing hydroxymethylfurfural (HMF) levels.

- Any heat source (hot water, steam) can be used to supply thermal energy to the dryer's jacket.

- The specially designed mixing device enhances heat transfer within the product, improving its thermal efficiency and significantly reducing drying energy costs.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Max vacuum: -0,8 Bar

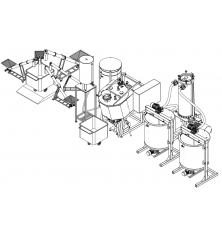

This equipment complex enables the production of Nutella-type chocolate pastes with a capacity of up to 250 kg/h.

- Material: Stainless steel

- Country of origin: Slovakia

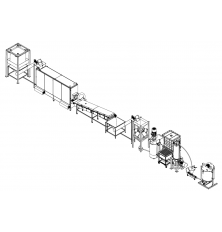

This jam production line allows you to get ready-made jam at the exit from whole fruits at the entrance! Equipment options may vary depending on the customer's technology.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: EU

The screw pump is used for transferring "un-pumpable" products. A great choice for those who work with hard to move liquids and need to move them as quickly as possible.

- Material: Stainless steel

- Voltage: 380-400V

The cost is indicated without the control panel, which can be selected and offered separately

A versatile cooking system, featuring an inclined reactor, a duplicator for heating and a frame mixing device, it is designed for processing a diverse range of products through methods such as cooking, boiling, and concentrating at atmospheric pressure. This system is commonly used for the production of syrups, jams, confiture, and honey processing.

- Slanted design with gravity mixing - 25% more efficient!

- External decorative casing made out of polished stainless steel with insulation

- Jacket for the bottom and the walls of the working container along the entire height

- Lid opening sensor for safe operation

- Scrapers are already included in the basic version of the installation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 300l/ 430l/ 600l/ 1000l

- Voltage: 220-230V 380-400V

Equipment for the production of creamed honey, soufflé honey, whipped creamy honey. The machine is produced both in atmospheric and vacuum versions, the loading capacity ranges from 70 to 3500 kg of honey.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

100 and 120 liter cutter mixers have been designed for the food industry, pharmaceutical industry and test labs.

- Productivity: 120 kg/h

- Material: Stainless steel

- Engine power, kW: 15/ 18

- Principle of operation: Batch mode

- Volume: 100l/ 120l

Unbeatable price, universal application, high quality material, optional accessories available to suit many different products. Various sieves / screens available for different products.

- Productivity: 500 kg/h/

- Material: Stainless steel

- Engine power, kW: 1,1

- Principle of operation: Continuous mode

Compact, practical machine for your fruit processing needs. Capable of destoning cherries, apricots or plums. The price is for the destoner for cherries.

If you wish to purchase an additional sieve drum for apricots and plums, please include it in the request.

- Productivity: 500 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

Fruit washer is designed for washing and cleaning products such as fruit or vegetables before processing, especially apples.

If you're looking for any other fruit and vegetable washers, send us a request.Â

- Material: Stainless steel

- Principle of operation: Continuous mode

Batter breading machines are designed for batter breading products such as meatball, hamburgers, soya, vegetarian burgers, croquettes, vegetables and other products. Whether you are a small kitchen or have bigger production capacity, we are able to offer complete solution.

The price depends on your production capacity.Â

- Productivity: do 2000 ks

- Material: Stainless steel

- Weight: 55

- Working Area Width: 150 mm

- Voltage: 220-230V

- Dimensions, mm: 1770x899x997

Electric fat melter (butter melter) â is a batch-type machine used for melting solid, frozen blocks of fat, animal fats and vegetable oils, frozen juices, chocolate and glaze, as well as maintaining them in a molten state in the container. It is possible to use it for melting refractory fats due to the high heating temperature of up to 200 degrees!

- Built-in powerful 2.6 / 5 / 6.5 kW electric heating

- Multi-stage switch with 7 heating intensity levels

- Professional, stainless steel thermometer for measuring the temperature in the product

- Compact support structure on height-adjustable legs / optional wheel support

- Three tilt positions of the working container for convenient unloading of the product

- Principle of operation: Batch mode

- Volume: 50l/ 100l

- Total power, kW: 3,5/ 6,5

- Voltage: 380-400V

The home cheese making unit is a simple and compact solution for producing homemade cheeses right in your kitchen or for small-scale food production, it can also be used as a laboratory unit for testing new cheese recipes in industrial factories. The unit is designed for processing milk and producing various cheeses and cheese-based products.

- Options to choose electric or gas heating (additional options)

- Special stirrer for automatic mixing, which prevents possible burning of milk

- Visual control during operation thanks to a special safety grid on the upper sectional opening hatch

- Quick-release lid with a stirrer for easy unloading of the product or cleaning of the unit

You can also choose a version of the cooking kettle with a thermometer and an outlet valve, making it suitable for milk pasteurization as well.

- Material: Stainless steel

- Engine power, kW: 0,12 0,18/ 0,25

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

A complete set of equipment for the production of margarine with a capacity of up to 500 kg/hour.

- Type of the equipment: Part of a production line

- Country of origin: Slovakia

Designed for pumping hot thermal oil in frying circulation and filtration systems, for oil loading and unloading, in "hot" continuous oil filtration systems with a maximum temperature of up to 200 degrees.

- Material: Stainless steel

- Engine power, kW: 0,55

- Country of origin: Slovakia

The price is set for the model with an area of 7 m²

Compact condensate dryer, heat pump powered dehydrator for drying vegetables, fruits, berries, mushrooms, legumes and grains.

- Energy saving, low consumption model (consumption up to 0.9 kW/h)

- Possibility of increasing the drying area in this model up to 14 m² (optional)

- Intensive drying, each section is equipped with a heat pump

- Automatic drying system control

- Delicate drying at low temperatures

- Preservation of most nutrients and the products natural color

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 0,9

- Voltage: 220-230V

- Area, m²: 7

- Number of shelves: 22

We offer different types of dryers for different products.

- Material: Stainless steel

- Engine power, kW: 2,2

- Country of origin: Slovakia

- Weight: 255 kg

- Volume: 500l

- Voltage: 380-400V

- Geometric volume: 170 l

- Dimensions, mm: 2350 x1500 x2000

Electric cooking boilers are cooking devices powered by electricity, designed for heating and cooking products intended for consumption. They are intended for use in catering kitchens, school kitchens, professional kitchens and other food processing plants.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 250l/ 300l/ 350l/

A universal vessel for mixing, whipping and stirring any products using a blade mixing device operating at high speeds.

- Crescent shaped mixing device with three sharpened blades (cutter knives)

- Special high speed drive

- Sandwich bottom for all types of heating surfaces (electricity, gas, induction).

- Productivity: 50l/ 100l

- Material: Stainless steel

- Engine power, kW: 0,18/

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Diameter, mm: 400/ 500/ 600

The FRP hydraulic press is the easiest and fastest solution for pressing various types of crushed fruits. The device is used for pressing crushed fruits with water.

- simple and fast extraction,

- no physical effort required,

- high percentage of juice yield (up to 80%),

- easy cleaning,

- long service life.

- Material: Stainless steel

- Principle of operation: Batch mode

Universal cooking kettle for thick mixtures: it works on the principle of a water bath and can be used in confectionery shops, bakeries and other catering establishments. Offers a wide variety of models.

- Mechanical tilting system for unloading

- Safety grill for the mixer drive

- Built-in electric heating up to 150 degrees

- Mobile support structure on wheels

- Heating: Electricity

- Principle of operation: Batch mode

- Volume: 30l/ 60l/ 80l/ 120l

Equipment for the production of condensed milk from pre-pasteurized milk. This equipment can be manufactured with a capacity of 50 to 500 kg/hour, or on request. We also manufacture condensed milk lines according to TU from dry milk or normalized milk concentration lines.

- Material: Stainless steel

- Type of the equipment: Part of a production line

- Country of origin: Slovakia

A vacuum deaerator is extensively used in the food industry to remove gases from products that may retain some bubbles post-processing. Additionally, a flow deaerator is utilized to minimize foaming in products, ensuring a denser structure, especially prior to packaging. Vacuum deaerators play a crucial role in eliminating specific odors from the products, such as in the production of juices, purees, and herbal drinks. This process significantly contributes to enhancing the overall quality and taste of the final product.

- Enhances product quality, structure, and shape

- Prevents oxidation by removing gases

- Preserves organoleptic properties and extends the shelf life

- Suitable for thick and viscous products

- The flow principle allows for the installation of this equipment in existing production lines

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Lowering the temperature and humidity protects the product even without chemical treatment. The device is also used for continuous air cooling after heat treatment.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

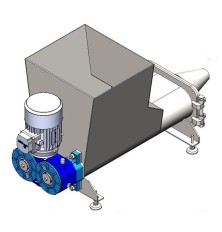

The compact model of the screw press is designed for quickly and efficiently squeezing honey from wax.Â

- Reinforced design

- The press allows you to separate 100% of honey from the wax at a speed of 100 kg/h

- Simple and easy maintenance

- Compact installation on a supporting structure

- Made from food grade stainless steel

- Productivity: 100kg/h

- Principle of operation: Continuous mode

- Country of origin: EU

- Total power, kW: 0,55

- Voltage: 220-230V

- Outlet valve, inches: 5/4

We offer different capacity infrared dryers.

- Productivity: 250 kg/h/ 1000 kg/h/ 1500 kg/h/ 2000 kg/h / 3000 kg/h / 6000 kg/h

Double-jacket stainless steel cooker for marmalade and jam production.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Principle of operation: Batch mode

- Volume: 100l/ 200l/ 300l

- Voltage: 380-400V

The high quality atmospheric 1500 kg condensate honey dryer is designed specifically for professional honey dehumidification.

Price depends on the chosen option.

- Material: Stainless steel

- Working volume: 1000

- Dimensions, mm: 3600x1400x2000

We produce atmospheric honey homogenizers with a batch load ranging from 7500 up to 22 000 kg of honey. The homogenizers HPL are designed for thoroughly mixing, blending, and homogenizing various kinds of honey to improve its qualities.

The price depends on the options you choose.

- Productivity: do 12000 kg

- Material: Stainless steel

- Volume: 8000 l

The price is set for the basic version of the installation without additional equipment.

The vacuum homogenizer is designed for a wide range of processes such as for the production of mayonnaise, ketchup, various sauces, confectionery pastes and fillings, liquid or paste like products with a homogeneous structure. It is also suitable for the production of various creams, gels, shampoos and other products in the cosmetic industry.

- Built-in Ultra Shear bottom homogenizer

- Mixing device with movable scrapers

- Tilting version for easy unloading

- Wide range of applications

- Entirely made of food grade stainless steel AISI304/ AISI316 - option

- Compact design

- Lots of additional options to choose from

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 20l/ 50l

- Total power, kW: 2,3/ 2,4

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

Semi automatic packaging machine for filling and capping jars.

- Material: Stainless steel

The high-performance slicing and dicing machine can function as a standalone unit or be integrated into a production line.

- Can process large products - sweet potato, lettuce, root vegetables

- Large selection of replaceable knives - different sizes of the final product

- Material: Stainless steel

The unique feature of this vacuum honey evaporator model, distinguishing it from a honey dryer, is its ability to create a deep vacuum with a residual pressure of up to 0.08 Bar during processing, and thus lowering the processing temperature! This innovative unit not only allows for quick and efficient drying of honey but also enables the immediate evaporation of water, producing a semi-finished product suitable for the subsequent production of «dry honey» or powdered honey.

- There is no need to have a large drying surface â an evaporation mirror.

- There is no need to install a mixing device for thick and viscous products.

- Low evaporation temperature of moisture â water from honey, at which its quality and medicinal properties are not compromised, and the risk of HMF growth is reduced to almost zero.

- Fast and efficient dehydration of honey at a low processing temperature.

- Material: Stainless steel

- Principle of operation: Batch mode

- Max vacuum: -1 Bar

Steel balls for grinding chocolate are essential components used in ball/bead mills. These 6 mm diameter balls are made out of hardened steel and are considered as consumables required for operating the BALL MILL 5.

- Spherical shape with a diameter of 6 mm

- High hardness steel

- Supplied in 10 kg boxes

- The mill requires 2 boxes (20 kg in total).

- Type of the equipment: Spare parts

An equipment complex designed for processing raw, peeled, and blanched peanuts, offering a production capacity of up to 500 kg/hour.

- Productivity: 500 kg/h/

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The price is set based on the basic built-in heating option of 24 kW.

The vacuum fryer is designed for frying foods in oil at low temperatures, allowing for the production of healthy snacks such as vegetable and fruit chips. The vacuum feature enables you to reduce the frying temperature of oil down to 110-120 degrees!

- «Cold roast» is a tasty and healthy method of processing the product

- Drying and frying without caramelizing the sugars contained in the product

- Large frying tank - for processing foods with a higher water content

- Modular heating system which allows you to increase the heating power up to 108 kW (optional)

- Circulating heating of oil through a heat exchanger minimizes oil spoilage and prevents localized overheating

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 24

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 30l

- Oil volume: 200l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Multifunctional pans function as a frying, cooking, and mixing device in one installation.

- Material: Stainless steel

- Principle of operation: Batch mode

We sell many different filling machines for different products.

- Material: Stainless steel

- Country of origin: EU

Mechanical vacuum filler, regulated by an electronic system, with a frequency converter.

We offer different hopper capacities.

- Material: Stainless steel

- Operation mode: Automatic

- Country of origin: EU

- Volume: 40/ 90/ 125 / 200l

We sell different types of deep fryers, for a price quote or for a free consultation, please contact us by sending a request.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: EU

- Voltage: 380-400V

Fruit crushing mill, entirely made of AISI 304 stainless steel is suitable for fruit, vegetables and for many other products such as apples, pears, carrots, lemons and others; easy to use, high productivity. It can be supplied with one or more sieves (screens or riddles).

- Productivity: 800 kg/h/ 1500 kg/h/ 3000 kg/h

- Engine power, kW: 1,35/ 2,1/ 2,6

- Hopper volume, l: 30/ 60/ 100

The knife mill is used for grinding products such as sugar, pepper, dry leaves and other products that are used during the production of spices and sauces.

- Adjustable grinding size

- Easy maintenance

- Support structure

- Large capacity hopper

- Material: Stainless steel

- Engine power, kW: 5,5

- Principle of operation: Continuous mode

- Voltage: 380-400V

- Hopper volume, l: 30

The piston filler is designed for dosing different types of liquid products in the food, chemical, pharmaceutical and cosmetic industries.

- Material: Stainless steel

- Operation mode: Manual

- Type of the equipment: Individual machine

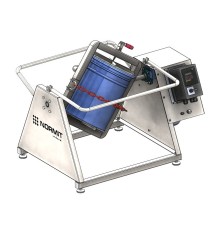

Barrel mixers are used to mix a wide range of loose and granular products in a shipping/barrel container. The available mixer models are suitable for the following volumes:

ConMix 20 - 20-30 liter standard drums with a diameter of 316 mm, adjustable frame structure height

ConMix 75 - 48-65 liter standard barrels with a diameter of 400 mm, adjustable frame structure height

- It is possible to use standard food containers ranging from 20-65 liters

- Easy control via a frequency converter as a stand-alone control panel

- Safe operation thanks to a roll bar with a position sensor

- Engine power, kW: 0,37/ 0,55/ 1,1

- Volume: 20l/ 75/ 100l

The electric kettle with a stirring device and manual tilting is suitable for a wide range of applications in food production or professional kitchens. It has an independent frame and built-in intensive electric heating with a wok-shaped, multi-layer âsandwichâ base, allowing the heating temperature to reach up to 200 °C.

- High processing temperatures of up to 200 °C

- Built-in, powerful 2,6 kW / 5 kW / 6,5 kW electric heating

- Manual tilting and unloading system with three working positions, allowing a maximum tilt angle of 110°

- Professional high-temperature thermometer with a probe in the product

- Air insulation of the outer casing

- Stirring device with stainless steel scrapers for high-temperatures

- Material: Stainless steel

- Engine power, kW: 0,25/ 0,37

- Heating power, kW: 2,6 / 6,5

- Volume: 50l/ 100l

- Stirrer speed, rpm: 18

Milk pasteurizer for small and medium-sized enterprises, designed to carry out the pasteurization process of milk and other liquid products.

- Precision and stability of temperature control

- Maintaining the set temperature

- Uniform heating

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 3/

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Volume: 100l/ 300l

A drying chamber for vegetables and fruits is a specialized enclosure designed to gently remove moisture from produce, preserving its natural flavors and nutrients while extending its shelf life.

- Type of the equipment: Individual machine

- Weight: 215

- Area, m²: 14

- Number of shelves: 40

The vacuum crystallizer-cooler is specifically designed for sweetened condensed milk. Crystallization with cooling is one of the most important stages in the production of condensed milk according to GOST and is necessary before dosing and packing the finished product.

- After crystallization, condensed milk has a delicate structure with small crystals

- Condensed milk has a homogeneous shape and attractive consumer properties

- The shelf life of condensed milk is extended without changing the quality of the product

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 300l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The complex of equipment for the production of mayonnaise consists of several installations for automatic dosing, mixing, and obtaining a stable emulsion.

- Compact design, offering convenient and straightforward operation in a limited space.

- Cost-effective solution for automatic dosing without incurring high automation costs.

- A wide range of additional modular options.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 13,5

- Voltage: 380-400V

The Bag in Box Filler is designed for filling hot and cold liquids into Bags in Boxes and for Stand Up Pouch packaging.

- The machine fills the bags up automatically.

- Material: Stainless steel

- Principle of operation: Continuous mode

Multifunctional vacuum mixer/homogenizer for grinding, mixing, and homogenizing products to obtain homogeneous masses.

- Built-in jacket for the bottom and walls of the unit.

- Cutter knives with a powerful electric drive

- Slanted design for efficient mixing and chopping

- Forced circulation circuit (optional)

- Wide range of options

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 350l/ 650l

- Total power, kW: 13/ 17

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

This powder making machine is made out of stainless steel. All parts that are in contact with food are made out of food grade 304 stainless steel for health and safety reasons.

- Material: Stainless steel

- Engine power, kW: 2,2

The price is set for the basic version, without additional options.

The industrial infrared dryer is suitable for drying a wide range of products: nuts, apples, plums, strawberries, raspberries, blueberries, mushrooms, carrots, onions, garlic, herbs, meat, figs, bananas, marshmallows. If additional options are selected, it can also be used for curing and drying whole meat and fish.

- Compact installation

- Fast and efficient drying

- Possibility of selecting individual settings for drying

- Made entirely out of stainless steel

- The interior surface of the cabinet has a mirror coating

- Quiet operation of the installation

- Low energy consumption per drying cycle

- Heating: Electricity

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 7l/ 10l/ 14l

- Total power, kW: 10/ 15/ 20

- Area, m²: 3,5/ 5,2/ 6,9

- Number of shelves: 10/ 15/ 20

Beverage Pasteurizer SB 750 refers to chamber types of pasteurizers used to pasteurize bottled beverages.

- Material: Stainless steel

- Principle of operation: Batch mode

The cost is indicated without the price of the baskets

A batch blancher with indirect electric or steam heating is used for blanching vegetables, mushrooms, meat, fish, and seafood. This type of blancher is ideal for use in catering kitchens and hospitals.

- Simple controls

- Built-in electric heating

- Large outlet valve

- Safe operation

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 18/ 24/ 30/ 36

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 200l/ 300l

The atmospheric tank with an inclined design is used for mixing, stirring, and dissolving various products. By supplying a thermal carrier to the unitâs jacket (duplicator) from an external source, thermal processing such as heating or cooling can occur (i.e. heating or cooling from an external coolant source with an inlet pressure of up to 0.5 bar). These units are widely utilized in the food and cosmetic industries.

- Inclined design: 50% more efficient mixing

- Due to the inclination angle of the working tank, rapid and complete (100%) emptying is achieved.

- Efficient heat transfer through the heating/cooling jacket

- No dead zones during mixing!

- Modular system with a wide range of additional options

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Working volume: 100l/ 200l/ 300l/ 450l/ 600l/ 900l

The new design of the universal cutter with gravity mixing is used for the production of thick and pasty products. The cutter is designed to carry out production processes such as cutting, mixing, crushing and emulsifying of various types of products to a liquid state. Thanks to the built-in duplicator, it can also be used as a device for the production of cream honey or cream honey soufflé.

- Cutting knives with a powerful 11 kW electric drive

- Frame mixing device with fluoroplastic scrapers

- Hatch opening sensor for safe maintenance

- Plexiglass hatch for visual inspection

- Duplicator for the thermal liquid around the bottom as well as the walls of the installation

- Inclined design for efficient grinding, homogenization and discharge of thick and viscous products

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

- Total power, kW: 12

- Voltage: 380-400V

Compact food filtration equipment with 12 filtering units. Unique filtration purifies products to very high standard- all materials used are perfectly compatible with liquids for human consumption.

- Engine power, kW: 0,34

- Principle of operation: Continuous mode

- Weight: 16

The tempering machine ensures a shiny, smooth finish and stable structure for chocolate, significantly reducing the possibility of fat bloom. This equipment is essential in the production of various sweets, confections, chocolate-coated dragees, and other applications requiring chocolate coatings.

- 4-zone tempering system

- Automatic control system

- Temperature measurement in each zone at the inlet and outlet

- High productivity from 150-300 kg/hour

- Heating: Electricity

- Productivity: 150-300 kg/h

- Heating power, kW: 10-18

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

The industrial mixing and homogenizing equipment is well-suited for small and medium-sized production enterprises engaged in the processing of food, cosmetics, and various chemicals.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 300 l

An evaporating unit is utilized to remove moisture from sweet substances through heating, transforming them into concentrated syrups or solutions.

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

- Geometric volume: 200 l

We offer many different types of blanchers including continuous models as well as batch blanchers.

- Material: Stainless steel

- Heating power, kW: 72

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

- Working Area Width: 420 mm