We offer different types of honey dryers with a capacity for this model ranging from 50 kg up to 1000 kg.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: EU

This multi layer belt dryer with integrated cooling system works as a dryer and cooler in one installation.

- Material: Stainless steel

- Principle of operation: Continuous mode

Homogenizer for the production of whipped cream, ice cream, and much more. It allows you to obtain stable liquid emulsions of food mixtures.

- The homogenizer can be installed directly into the container with the product

- High productivity - in just 8 minutes, it is possible to whip up to 60 liters of milk mixture

- The peripheral speed of the knives is 16 m/s

- Material: Stainless steel

- Engine power, kW: 0,37/ 2,2

- Country of origin: EU

- Voltage: 380-400V

The mixers are made up of a double-walled cylindrical stainless steel vessel with cavity, with drain hole and 50 cm diameter butterfly valve. The cavity is filled with water which is heated by an electric resistance thermostat. The honey is mixed by blades with a marine propeller profile, adjustable in height along an oblique shaft.┬Ā

- Material: Stainless steel

- Engine power, kW: 0,37/ 0,55/ 1,1

- Principle of operation: Batch mode

- Volume: 100 kg / 250 kg/ 600 kg/ 1000 kg/ 2000 kg

Stainless steel jam cooking pot with agitator 50l and electric stove 5kW, ideal and affordable cooking solution.

- Heating: Electricity

- Material: Stainless steel

- Engine power, kW: 0,18/

- Heating power, kW: 5

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

Chocolate fountain attracts the attention of customers thanks to its stylish design, and can be used to top ice cream cones, to fill cups with hot chocolate drinks etc. Price is for the machine only. You can purchase additional mobile counter, covering rings or various nozzles.

- Material: Stainless steel

- Voltage: 220-230V

This machine is suitable for washing fresh fruits and vegetables. We offer 2 different capacities.

- Productivity: 1000 kg/h/ 3000 kg/h

- Material: Stainless steel

- Engine power, kW: 0,55/ 0,75

- Principle of operation: Continuous mode

- Voltage: 380-400V

It is possible to order tubs with four perforated walls and bottom, with or without outlet drain or with a tap.

- Material: Stainless steel

- Volume: 120l 200l/ 300l

A sturdy extruder machine, with a tank made from AISI 304 stainless steel, ideal for extruding and mixing, and the production of protein bars. For a mini line for making boilie, you can purchase our boilie rolling machine.

- Material: Stainless steel

- Engine power, kW: 0,55/ 0,75

- Principle of operation: Continuous mode

Table-top compact chicken breast slicing machine. It can produce up to 300 kg of sliced chicken breasts per hour.┬Ā

- Material: Stainless steel

- Voltage: 220-230V

The vacuum homogenizer is designed for whipping mayonnaise, ketchup, various sauces, confectionery pastes and fillings, condensed milk, jams and marmalades, canned goods, as well as similar liquid or pasty products with a homogeneous structure.

- Homogenizer in an external circulation loop

- Built-in vacuum generation and retention system

- Modular design with numerous options

- Possibility of automatic dosing of ingredients (optional)

- No additional pump required for loading/unloading

- Automatic top cover lifting system

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 13,5

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The manual bottle filler is designed to fill liquids in glass bottles.┬Ā

- Productivity: 650 psc/h

- Material: Stainless steel

- Operation mode: Manual

Keg washing and filling machine used for washing and filling kegs and barrels for beer, cider, wine and other beverages.

- Material: Stainless steel

- Engine power, kW: 0,75

- Operation mode: Manual

- Voltage: 220-230V 380-400V

A large stainless steel pot with a drain valve and a temperature sensor can be used on any cooking surface: electric, gas, induction.

- Large 6/4'' drain valve

- Multi-layer sandwich bottom

- Cooking pot wall thickness 1 mm

- Professional, high-temperature temperature sensor

- Material: Stainless steel

- Volume: 50l/ 100l/ 150l

- Diameter, mm: 400/ 500/ 600

Installations for the production of non-alcoholic wine are manufactured in various models and configurations starting from volumes of 100 liters. The systems operate on the principle of vacuum distillation, which allows for alcohol removal at low temperatures, resulting in a healthy product with minimal alcohol content.

- A wide range of models ŌĆö suitable both for small-scale production and large-scale industrial operations

- Capability to produce a "healthy product" while preserving all organoleptic properties of the beverage

- Depending on production capacity, the systems can be designed for batch or continuous operation

- Deep vacuum conditions allow for low evaporation temperatures, enabling especially gentle evaporation without thermal degradation of the flavor profiles of different types of wine

- Material: Stainless steel

- Country of origin: Slovakia

Vacuum evaporator with remote circulation using a heat exchanger is one of the most efficient evaporation methods. This evaporation system is suitable for boiling and concentrating heat-sensitive products such as milk, cream, etc.

- No mixing device required, the product has forced circulation!

- Modular system: possibility to choose the vacuum generator, power and heat exchanger type

- Inclined design and bottom valve for 100% product discharge without losses and blind spots

- Insulated upper hatch of the unit for heat retention and safety

- Tangential product inlet into the vacuum vessel for guaranteed evaporation in a thin layer

- Material: Stainless steel

- Volume: 50l/ 100l/ 300l

An automatic forming machine shapes food mixtures such as ground meat or plant-based alternatives into uniform portions. It automates portioning and shaping, and can also add a separation paper for easier handling before transferring the products with a conveyor. These machines reduce manual labor and increase output capacity for food processing facilities, butcher shops, and commercial kitchens.

- Material: Stainless steel

- Principle of operation: Continuous mode

The continuous production line for deep-frying and the subsequent cooling of semi-finished products includes:

- modular deep fryer┬Āwith the option of choosing the conveyor type: a┬Āsecondary conveyor for forced immersion┬Āof the product in oil or a┬Āconveyor with paddles┬Āfor frying light floating products, such as chips;

- stainless steel table┬Āunder the deep fryer with the option of installing an oil container and an┬Āoil filtration system┬Āinside it;

- cooling conveyor for removing excess oil and surface cooling of the product after frying it in the deep fryer.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 400 mm

- Voltage: 380-400V

The electric industrial WOK frying pan with a stirrer and automatic tilting system is suitable for intensive thermal processing, allowing you to stew, fry, boil, and concentrate large quantities of both solid and liquid products.

- Special eccentric working bowl tilting system, up to 90 degrees

- Low working height for loading and operation

- Hydraulic system for tilting and unloading the product

- Direct powerful electric heating of the bottom of the working bowl up to 220 degrees

- Heated walls of the working bowl (optional)

- Unloading of the product into standard 200 L trolleys (optional)

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 70+12

- Principle of operation: Batch mode

- Volume: 450

- Voltage: 380-400V

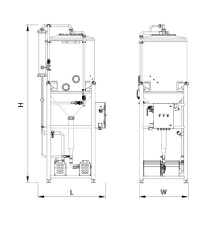

The peculiarity of this unit is the combination of several functions: homogenization and drying of honey. The vertical vacuum dryer allows you to dry honey weighing up to 3300 kg in a short time while preserving its useful properties, color, taste, and organoleptic qualities. The vacuum honey dryer has a number of significant advantages over classic atmospheric honey dryers due to the reduction of processing time and the preservation of its beneficial properties, which is achieved by drying at a lower temperature.

- The drying process occurs much faster due to the evaporation of moisture under vacuum.

- High degree of homogenization of honey due to the operation of a special mixing device.

- The narrow vertical design does not require large production areas while boasting high productivity.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Designed for a load of up to 200 kg!

The 5 kW induction cooker is the best alternative to traditional electric and gas stoves. It reduces energy costs, improves safety, and minimizes air pollution, making it suitable for both stationary kitchens and mobile catering setups. Its compact design also makes it a practical choice for small kitchens where space and efficiency matter.

- 10-step power (500ŌĆō5000 W) or 10-step temperature (60ŌĆō280 ┬░C) control

- Connection - 230 Volt

- Compact dimensions: 410x500x200 mm

- Temperature range from 60 to 280 degrees

- Heating power, kW: 5

- Voltage: 220-230V

A circulation-type vacuum evaporator refers to a combined version of an evaporator that also takes advantage of other types to improve evaporation efficiency particularly by reducing concentration time and when processing heat-sensitive products such as milk.

- The external circulation circuit with heating intensifies the cyclic evaporation process.

- The forced circulation system ensures a decrease in the risk of localized product overheating.

- The condenser enables a deep vacuum and maintains a low evaporation temperature.

- Utilizing a mixing device with a spray system facilitates product evaporation in a thin layer, mimicking a film-type evaporator.

- Heating: Steam

- Material: Stainless steel

- Operation mode: Semi-automatic

- Country of origin: Slovakia

- Total power, kW: 2,4

- Voltage: 380-400V

Equipment for mixing multi-component mixtures of products, such as vegetable salads with various dressings, including thick and viscous ones like mayonnaise, thick sour cream and other similar sauces.

- Hydraulic tilting system is included in the basic version

- The controls are located directly on the frame supporting structure

- Eccentrically offset working shaft for rotating/tilting the working tank

- Low loading height

- The installation is made entirely out of food grade stainless steel

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 600l/ 1000l

Multifunctional vacuum unit MINI5 - is ideal for cooking, drying, concentrating, mixing and much more. Suitable for laboratories and small-scale production.

- Processing heat-sensitive products at lower temperatures

- Ideal for making creamed honey

- Possibility of vacuum drying honey

- Material: Stainless steel

- Engine power, kW: 0,12

- Country of origin: Slovakia

- Volume: 5l

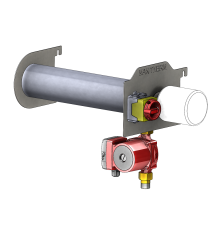

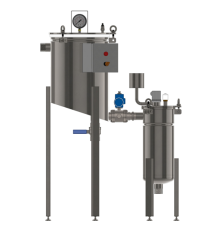

A flow-through water heater is a device for flow-through electric heating of water in heating systems for cooking boilers, evaporators and other units where it is necessary to supply a hot heat transfer medium - superheated water - to the heating jacket (duplicator). When choosing a flow-through heater, it is necessary to select a circulation pump based on the volume of the jacket or heat transfer vessel.

- The heater allows you to heat water up to 110 degrees

- Easily integrated into heating systems

- Has heating temperature regulation

- 2 stages of heating power adjustment

- Independent control panel with protection against overheating and "dry" running

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 2/ 3/ 6/ 9/ 10/ 12

- Principle of operation: Continuous mode

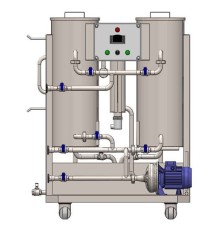

Improve the cleaning process with the CIP-53, a mobile station designed for thorough sterilization and sanitation of vessels and pipelines. Ideal for breweries and the food industry, this comprehensive system with three 50 or 100 liter tanks ensures efficient cleaning of fermentation and storage tanks, offers digital temperature control and neutralization.

- Material: Stainless steel

- Voltage: 380-400V

The automatic donut forming and frying machine is a high-quality device that is suitable for high productivity and daily usage.

- Tabletop system

- Includes a depositing attachment

- Compact design

- Completely out of stainless steel

- Material: Stainless steel

- Principle of operation: Continuous mode

- Weight: 40

- Total power, kW: 3

- Voltage: 220-230V

- Dimensions, mm: 965 x 330 x 650

For frying foods in oil, deep-frying, suitable for frying onions, seeds, nuts, vegetable snacks and chips, and other products, including breaded or covered in liaison. Can also be used as an oil separating centrifuge for deep fryer.

- Two in one: a deep fryer and a centrifuge to remove excess oil

- Possibility of frying small and fragile products

- Obtaining a ŌĆ£dry productŌĆØ after frying

- Low carbonization of oil due to the cleaning feature after frying

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 30l/ 90l

- Total power, kW: 11

- Voltage: 380-400V

The portable vertical pump is designed for pumping fluent or viscous liquids in the range from 1-2300 m2/s at a temperature of around 25┬░C. The pump cannot be used in potentially explosive atmospheres.

- Material: Stainless steel

- Engine power, kW: 0,25

- Voltage: 380-400V

The price is indicated without the frequency converter

A twin-screw mixer for fast and intensive mixing, stirring of bulk solid products, such as granules, muesli with various powder additives.

- The mixing blades carefully move while thoroughly mixing the product

- The mixing mode allows you to move the product cyclically in a circle

- High mixing efficiency due to the counter-movement of the 2 shafts

- Compact design

- Possibility to install scrapers on each blade (optional)

- Reinforced drive, can be used for products saturated with moisture as well

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 500l

- Total power, kW: 3

The cutter is designed for cutting into cubes, stripes or slices.

- Material: Stainless steel

- Engine power, kW: 2,2

- Principle of operation: Continuous mode

- Voltage: 380-400V

The universal bath pasteurizer is used for processing a wide range of different food products, such as ready meals, sausages, hams or liquid products. Effective temperature regulation and a hygienic stainless steel design.

The vacuum homogenizer with an inclined design is designed for processing and manufacturing a wide range of liquid, pasty and viscous products with different requirements for their production conditions and other products including those with a high viscosity.

- Material: Stainless steel

- Engine power, kW: 1,5 KW

- Principle of operation: Batch mode

- Country of origin: Slovakia

Normelt C is a compact machine for efficient industrial melting of solid fats of vegetable and animal origin.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Geometric volume: 100 l

We offer professional infrared dryers from 8 to 56 trays with a capacity of 200 to 3000 kg/day for vegetables, fruits, tea, herbs, mushrooms, medicinal herbs and other products. The dryers of this type is a turnkey solution based on two technologies - direct infrared and air convection drying.

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

A twin-screw mixer with a homogenizer is an ideal solution for the production of creamy cheese, such as feta cheese, including with various flavors and seasonings. Thanks to mechanical homogenization, the cheese acquires a delicate structure without changing the individual taste properties of the product. It is used for plasticizing, creaming and softening butter, margarine and other fats.

- A capacious volumetric mixer with a capacity of 50 l

- Compact tabletop design for convenient operator maintenance

- A powerful independent drive for each screw with a reverser

- Easy maintenance and cleaning of the equipment

- Productivity: 250 kg/h/ 1500 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 3,5

- Voltage: 380-400V

The equipment is designed for centrifuging and separating different types of products and raw materials.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

We can help you choose the right continuous fryer suited for your needs.

- Productivity: nuts 400 kg/h

- Material: Stainless steel

- Heating power, kW: 30/ 60

- Operation mode: Automatic

- Principle of operation: Continuous mode

- Country of origin: EU

- Weight: 245 kg

- Working Area Width: 250 mm

- Oil volume: 100 l

Washing tank with wheels with conveyor belt for fruits and vegetables.

- Material: Stainless steel

- Engine power, kW: 2,4/

- Principle of operation: Continuous mode

- Country of origin: EU

- Working Area Width: 330 mm

- Voltage: 380-400V

This cookie making machine is designed to produce an unlimited variety of cookies, cakes, and other pastry snacks. We offer five different types of cookie depositing machines, each tailored to various cookie types

- Engine power, kW: 2,4/ 2,5/ 3,3 3/

- Principle of operation: Continuous mode

- Voltage: 220-230V

Monoblock pumps with an integrated frequency converter. We offer many different types of pumps, if you need any advice on which pump to choose, feel free to send us the request.┬Ā

- Principle of operation: Continuous mode

We offer different types of vacuum evaporation machines, this type is an affordable option for efficient evaporation in a stainless steel unit.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l

This cutter┬Ā as an essential instrument in kitchens, prepares hummus, dressings, herb oils, aromatic butter, thickenings, mayonnaise, sauces, soups, desserts, pure├®s, pates and etc.

- Material: Stainless steel

- Engine power, kW: 2,2/ 3/ 7,5/ 11

- Principle of operation: Batch mode

- Weight: 50 / 85 / 175 / 200

- Volume: 20l/ 30l/ 50l/

- Voltage: 230 V/ 380-400V

- Dimensions, mm: 700 x 480x 1070 / 740 x 480x 1070 / 850 x 580x 1140 / 850x580x1190

This head capping machine has a magnetic clutch, ribbed spindle. It is semi-automatic and closes bottles or jars with PFP aluminum caps, twist off caps or plastic screws. The price depends on the cap, product you are filling, and capacity.

Price depends on the lid, the product you are filling, and the container.

- Productivity: 400-700 psc/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 220-230V

Vacuum mixer processing plant for viscous products is an ideal solution for the production of pilot batches and the industrial manufacturing of a wide range of products from small to medium capacity.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l

The universal cooking boiler with an integrated homogenizer and a capacity of 1200 liters is designed for efficient mixing, heating, cooking and homogenizing of products for food, pharmaceutical and cosmetic industries such as jams, marmalades, syrups, fruit juices, nectars, beers, creams, ointments, soaps and many others.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

A cooking kettle and a vacuum mixer for periodic deaeration of products such as mayonnaise, ketchup, various sauces, creams, gels and pastes. It is one of the modifications of a vacuum reactor and a vacuum evaporator. The presence of a vacuum system allows you to create a vacuum after the cooking process and perform vacuuming (deaeration) to remove air bubbles with potential contaminants and obtain a product with a denser structure. Thanks to vacuuming, the product has an extended shelf life, since pathogens and microbes contained within are removed together with the air.

- Inclined design with gravity mixing, which is 30% more efficient than usual

- 100% emptying of the product after processing due to the bottom valve

- Easy to disassemble removable mixing device

- Possibility of connecting it to a CIP station for cleaning and washing

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l

- Total power, kW: 0,12

- Max vacuum: -0,8 Bar

Pneumatic fruit presses are intended for smaller winemakers who want to produce high quality wine. Price depends on your production parameters.

- Material: Stainless steel

- Principle of operation: Continuous mode

The fruit destemming machine eliminates seeds and kernels from the fruit's core, preparing it for subsequent processing.

- Productivity: 500 kg/h/ 1000 kg/h/ 2000 kg/h

- Material: Stainless steel

- Engine power, kW: 2,2/ 5,5

- Principle of operation: Continuous mode

The Milk Cooler has a simple design, which allows for easy and safe operation. it meets the requirements of all dairy production facilities.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 200l/ 300l

- Voltage: 380-400V

Ball mills are used for the production of a chocolate mass, various types of chocolate glazes, nut and chocolate pastes (such as Nutella) and similar products.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

A vacuum frying unit designed for frying vegetables and other snacks at low temperatures, thus making them healthier and less saturated with oil.

- Productivity: 160 kg/15 min

- Material: Stainless steel

- Heating power, kW: 90/ 110/ 180

- Country of origin: Slovakia

Pasteurizer, cheese boiler is designed for processing milk, yogurt, fruit juice or other liquids.┬Ā

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Volume: 200l/ 300l/ 500l

The vacuum cutter is intended for large processing enterprises dealing in the confectionery, fruit and vegetable processing industries. They are intended for processing food down to a homogenous mixture with minimal air content.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

Filling and capping machine designed for the filling and capping of liquid or semi-liquid products into flexible doypack bags with a spout.

- Material: Stainless steel

- Voltage: 220-230V

The piston-operated pneumatic liquid dispenser is a semi-automatic filler used for dispensing various low viscosity liquids ranging from 10 to 100 ml in volume.

- Compact tabletop installation

- Simple control with two operating modes: manual and semi-automatic

- Suitable for liquid products with low viscosity (from water to oil)

- Optional compressed air compressor available

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Continuous mode

- Voltage: 220-230V

The NORMIT drum mixers are designed for thorough mixing for products such as combined feed for animals, infant formulas, baby food, food concentrates and additives, sports supplements and nutrients, coffee, tea, pharmaceuticals and chemical products.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 150l/ 200l/ 500l

4 Heads vacuum bottle filling machine serves as a professional semi-automatic filling and dosing machine for filling glass bottles with various fluids.

- Material: Stainless steel

- Operation mode: Manual

- Type of the equipment: Individual machine

This convective honey dryer is used for drying and mixing honey, it is a high-performance solution for thoroughly mixing honey while simultaneously removing excess moisture.

- Material: Stainless steel

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Voltage: 230 V/ 380-400V

The destoner lift machine is designed for pre-washing and transporting root vegetables such as potatoes, carrots, beets, and other similar vegetables. After rinsing, the auger destoner separates floating particles like leaves and stems in the receiving hopper, while the product is conveyed up to the discharge height using a screw lift.

- Allows you to separate stones, leaves from root vegetables

- Pre-washing of root vegetable crops

- Two functions in one unit: washing and transporting

- Spacious hopper/tub for loading the product

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The block cutter is designed for chopping frozen blocks of meat, fish, poultry, meat by-products, juice, butter or margarine without prior defrosting. This is a convenient and quick method of preparing the products for further processing, which saves time and reduces the likelihood of product contamination.

- Efficiently slices the product into thin layers while preserving its texture

- Safe pneumatic feeding of the product into the grinding section

- Special fixation system for the product container during unloading

- Low product losses during processing

- A powerful blade drive

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 600 mm

- Total power, kW: 11

- Voltage: 380-400V

The multifunctional cooking and pasteurization kettle with manual tilting is a simple device designed for the entire jam production process: from cooking the fruit mixture to the subsequent pasteurization of finished products directly in jars. It allows you to prepare the product in a container and then, using an additional basket, pasteurize the filled jars without the need for any additional equipment.

- 6-stage regulation of the built-in heating allows you to set the optimal conditions for cooking the fruits and subsequent pasteurization without the risk of burning or loss of quality.

- The manual tilting mechanism with a three-stage adjustment and a maximum tilt angle of 110┬░ ensures convenient emptying of the container and dosing of the finished product with virtually no losses.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 2,6 / 6,5

- Volume: 50l/ 100l

This industrial hybrid drying cabinet combines two drying principles: heat pump (condensation) and convection (forced circulation of heated air). This dryer is designed for fast, efficient, energy-saving, and "cold" drying of vegetables, fruits, berries, mushrooms, legumes, herbs, meat, fish, and even liquid or semi-liquid products by replacing the shelves with standard GN 2/1 containers. The size of one shelf is 530 x 650 mm.

- Dual technology: condensation drying + hot air convection

- Energy-efficient with optimized consumption (approx. 0.9ŌĆō1.3 kWh depending on mode)

- Drying area expandable up to 14 m┬▓ (optional)

- Uniform drying thanks to forced air flow and controlled moisture removal

- Gentle operation at low temperatures for maximum preservation of nutrients and color

Small 3L vacuum unit with a stirring device for the production of non-alcoholic wine.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Volume: 5l

A 15-liter pasteurizer with a water bath that has a flat bottom and two canning racks, featuring a large capacity and made out of food grade 304 stainless steel.

- Material: Stainless steel

- Principle of operation: Batch mode

The long-term pasteurization tank is a compact solution for the heat treatment of milk in order to disinfect the microflora and eliminate harmful microorganisms. This unit belongs to the category of long-term pasteurization systems, heating milk between 63 and 95 degrees Celsius, and maintaining it at a specific temperature for a set period of time. The special design allows not only for pasteurization of milk in the flow, but also for sequential cooling, by feeding cold water into the heat exchanger after heating.

- External forced circulation with a heat exchanger

- Highly efficient steam heating via the heat exchanger

- Can also be used as both a pasteurization and cooling unit

- High-performance milk pump

- Compact vertical design

- Heating: Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 1000l

You don't need professional equipment or special skills to brew beer at home; all you need is to buy a spacious kettle with an automatic stirring device!

- Special mixing device prevents malt from sticking to the bottom.

- The cooking kettle has two side handles for easy manipulation.

- The kettle, lid, and outlet valve are made entirely of stainless steel.

- The beer kettle can be used on any stove or you can purchase an electric base along with the kettle (optional).

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

Production line for vegetarian vegetable-based formed or molded products such as falafel. The line is based on the classical method of producing semi-finished products for their subsequent freezing and packaging.

- Compact line suitable for both professional kitchens and industrial production.

- Fully automatic operation with minimal manual labor.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 380-400V

The price is set for the combination of a basic fryer model and an additional module with rotating paddles.

The universal modular SnackPro fryer equipped with an additional paddle module is designed for frying thin slices of products that require immersion beneath the oil level.

- Adjustable frying time from a few seconds up to an hour

- Compact, tabletop version

- The paddle conveyor is installed on top of the basic fryer

- Safety thermostats on each heating element

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Total power, kW: 12

- Oil volume: 60l

- Voltage: 380-400V

The tubular pasteurizer is typically designed for pasteurizing cream in butter production lines. These pasteurizers are commonly used in dairy processing industrial facilities, especially in butter production and other related sectors.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Cooking kettle for making syrups, caramel, sugaring paste as well as processing and producing various thick and viscous products. Often used for dissolving sugar and producing various saturated and supersaturated solutions.

- Built-in heating with thermal oil up to 150 degrees Celsius

- Anchor frame stirrer for rapid dissolution

- Conical bottom design of the working container without dead zones

- Heating: Electricity

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 200l/ 300l

- Total power, kW: 19

Fat block melter Fastmelter refers to the equipment of periodic action for melting butter and other frozen fats within the food industry.

- Material: Stainless steel

- Principle of operation: Batch mode

CIP-52: Clean-In-Place - Machine for cleaning and the disinfection vessels and pipelines in breweries and other food processing plants with two 50 liter tanks.

- Material: Stainless steel

- Country of origin: EU

The price is indicated without gastro containers

Use this all-stainless steel water bath for gradual heating or cooking. The device is equipped with a practical drain tap for easy emptying of the container and is suitable for use with gastronorm containers.

- Compact installation

- Simple controls

- Safe operation

- Wide range of applications

- Material: Stainless steel

- Principle of operation: Batch mode

- Voltage: 220-230V

This equipment set can be used for the production of a diverse array of sauces, as well as various vegetarian products based on nuts, soy and rice. It is capable of processing around 300/600 liters of product per batch.

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 300l/ 600l/

- Voltage: 380-400V

This set of equipment for the production of condensed milk from dry components by restoring the milk. This production line can be manufactured with a capacity of up to 500 kg/h or can be customized based on specific requirements.

- Material: Stainless steel

The price is indicated without a source of compressed air - compressor (optional).

This is periodic type of equipment designed for removing moisture and excess water from honey under vacuum conditions. This pilot vacuum dryer can be used for processing small volumes of honey directly at apiaries.

- Drying rate up to 1% per hour! (with a gradual decrease as the concentration increases)

- Large heat transfer area

- Low drying temperature thanks to the vacuum

- Easy operation and maintenance

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100 - 140 kg

- Total power, kW: 6,5

- Voltage: 220-230V 380-400V

- Max vacuum: -0,8 Bar

The vacuum bread cooler is well-suited for application in small bakeries or as a laboratory unit in industrial enterprises. This enables the post-baking of bread under vacuum conditions, influencing both its shape and structure.

- Built-in deep vacuum system

- Built-in vapor removal and condensation system

- Built-in refrigeration system

- The chamber is designed for 3 gastro containers size GN 1/1, or pallets: 400x600/530x325 mm

- Compact and mobile installation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 130l

- Voltage: 380-400V

The Price is specified for the version with a hydraulic lift.

The industrial electric frying pan using thermal oil is an optimal and economical solution for small-scale industrial food production. It allows for low energy and operating costs while ensuring uniform and intense heating for the entire working bowl. The system's thermal inertia helps maintain the required temperature for an extended time, making it effective for frying onions, carrots, saut├®ing flour and vegetables, and preparing sauces, soups, side dishes, stews, and more.

- Low energy consumption

- Uniform heating

- Heated conical sides

- Adjustable heating intensity

- Controller with a hygienic housing directly on the supporting structure

- Lid opening handles located in the cold zone

- Automatic lifting/tilting system

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 26

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

- Total power, kW: 28

- Voltage: 380-400V

- Duplicator volume: 106l

The 5 kw stool-type electric heating stove with a diameter of 40 cm is designed to heat large pots and pans with a volume of up to 100 liters.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Type of the equipment: Optional equipment

Progressive cavity pumps are used to transfer low and high viscosity products as well as products containing soft particles. They are available in three sizes.

- Material: Stainless steel

- Engine power, kW: 3/ 4

Create natural shapes of nuggets, pieces that have the appearance of a "hand-formed" product.

- Material: Stainless steel

The nut grinding machine is used for processing sesame seeds to produce a tahini or a sesame paste.

- Material: Stainless steel

- Country of origin: Slovakia

The brush washer/scraper is an industrial device for washing and scraping root vegetables depending on the degree of contamination.

- Productivity: 300 kg/h

- Material: Stainless steel

- Engine power, kW: 1

- Voltage: 230 V/ 380-400V

A honey processing machine with preheating and filtering, suitable for industrial honey processing facilities.

- Material: Stainless steel

- Voltage: 220-230V

Industrial churning machine available in two capacities. Simple production of butter.

- Geometric volume: 30 l/ 70 l

Semi-automatic labeler for the application of self-adhesive labels for round bottles.

- Operation mode: Automatic

- Voltage: 220-230V

Pneumatic capping machine suitable for closing twist off, snap on or plastic screw caps.

- Productivity: 500-600 psc/h

- Country of origin: EU

Planetary mixers are primarily used in the confectionary industry. Offered in three different capacities.

- Material: Stainless steel

- Engine power, kW: 1,5 / 2,2

- Principle of operation: Batch mode

ACM mixing tank is intended for efficient cooling, heating, tempering and storing of mayonnaise, sour cream, chocolate, oil and similar products after their production.

- Material: Stainless steel

- Principle of operation: Batch mode

The appropriate mixing equipment for drum processing depends upon the properties of the products and with the available drum opening.

- Type of the equipment: Individual machine

- Voltage: 230 V/ 380-400V

The salting machine is designed for the continuous feeding and dispensing of salt or seasoning onto food products, it is recommended to install it above a conveyor belt.

- Simple controls

- Spacious hopper - up to 25 kg

- Simple and easy installation

- Height-adjustable salting machine supports

- Built-in control panel for adjusting the speed and volume of salt supplied

- Material: Stainless steel

- Engine power, kW: 0,55

- Working Area Width: 500 mm

- Voltage: 220-230V

Mixers are carefully designed, constructed and tested to handle a variety of industrial applications that require mixing, dispersive mixing, distributive mixing and more.

- Material: Stainless steel

- Country of origin: Slovakia

- Voltage: 380-400V

- Geometric volume: 500 l

We offer new compact continuous infrared oven that is designed for backing different variants of products such as falafel, meat and vegetable balls, chicken wings, nuts, pizza, baguettes, toasts, croutons and many other snacks.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Length: 340 mm

- Working Area Width: 300 mm

- Voltage: 380-400V

Pasteurizers are used for the heat treatment (pasteurization) of juice before it is filled into bottles, containers or other types of packaging. Its compact, space-saving design and simple operation make it suitable for various production facilities.

- Productivity: 400 l

- Material: Stainless steel

- Heating power, kW: 36

- Country of origin: EU

- Voltage: 380-400V

The forming device guarantees precise shaping of a wide range of food mixtures.

- Material: Stainless steel

- Principle of operation: Continuous mode

The incline screw conveyor is used for transporting a wide range of bulk, powdery, fine-grained, and dusty products in food, chemical, construction, or agro-industries.

- Material: Stainless steel

- Engine power, kW: 0,75 1,1/ 1,5 / 2,2

Filling machine is designed for pumping and filling high viscosity liquids, such as jams, confiture, sauces, dressings, syrups, and like products.

- Productivity: 200ŌĆō600 bottles per hour

- Material: Stainless steel

- Principle of operation: Continuous mode

The professional yogurt making machine is designed to produce a wide range of yogurt production, e.g. creamy, liquid drinking, greek, white, organic, fruit yogurts. The machine can be used by farms and small dairy factories.

- Material: Stainless steel

- Principle of operation: Batch mode

The pump provides a delicate straight-streaming┬Āpumping of a wide range of liquids with or without solid fragments with viscosity up to 150 Pa.s.┬Ā

- Material: Stainless steel

- Engine power, kW: 1,1

- Principle of operation: Continuous mode